Safety

Information

Product

Information

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor Optimization SMARTCARD

operation PC tools Advanced

parameters

Technical

Data Diagnostics UL Listing

Information

Affinity User Guide 7

Issue Number: 5 www.controltechniques.com

1 Safety information

1.1 Warnings, cautions and notes

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this User Guide.

1.3 System design and safety of

personnel

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

design to avoid hazards either in normal operation or in the event of

equipment malfunction. System design, installation, commissioning/

start-up and maintenance must be carried out by personnel who have

the necessary training and experience. They must read this safety

information and this User Guide carefully.

The STOP function of the drive do not isolate dangerous voltages from

the output of the drive or from any external option unit. The supply must

be disconnected by an approved electrical isolation device before

gaining access to the electrical connections.

None of the drive functions must be used to ensure safety of

personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended behavior or

through incorrect operation due to a fault. In any application where a

malfunction of the drive or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

1.4 Environmental limits

Instructions in this User Guide regarding transport, storage, installation

and use of the drive must be complied with, including the specified

environmental limits. Drives must not be subjected to excessive physical

force.

1.5 Access

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided. See section 3.2.6 Fire protection on

page 20 for more information.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective earth (ground) connections.

This User Guide contains instruction for achieving compliance with

specific EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations. Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed

operation. If it is intended to use the capability of the drive to run a motor

at speeds above its designed maximum, it is strongly recommended that

the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective. The motor should be installed with a protection

thermistor. If necessary, an electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive should not be relied upon.

It is essential that the correct value is entered in parameter 0.46 motor

rated current. This affects the thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

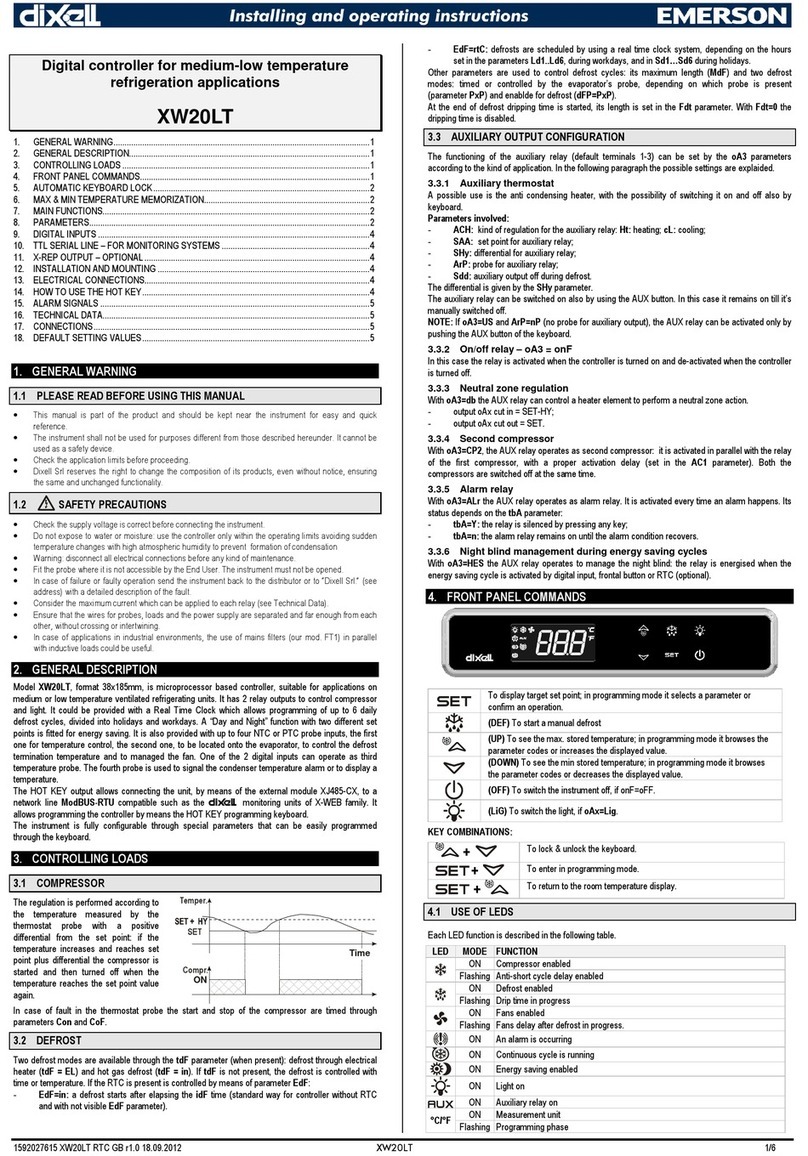

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.