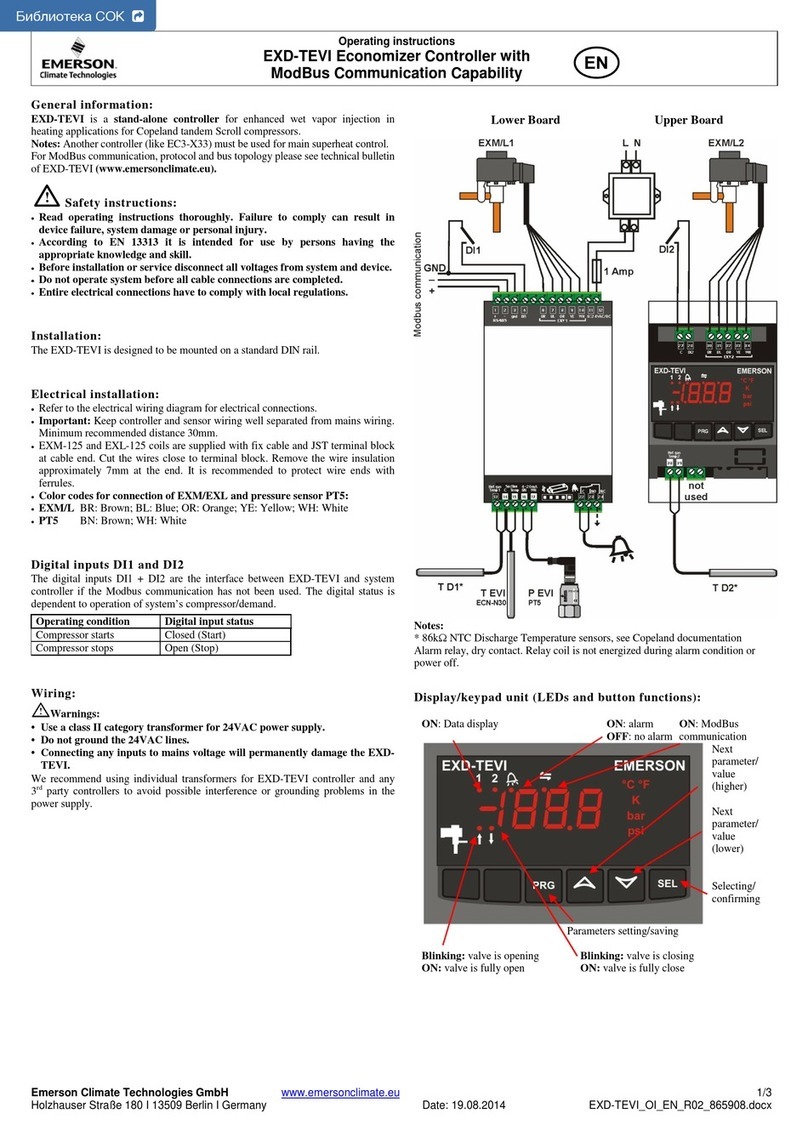

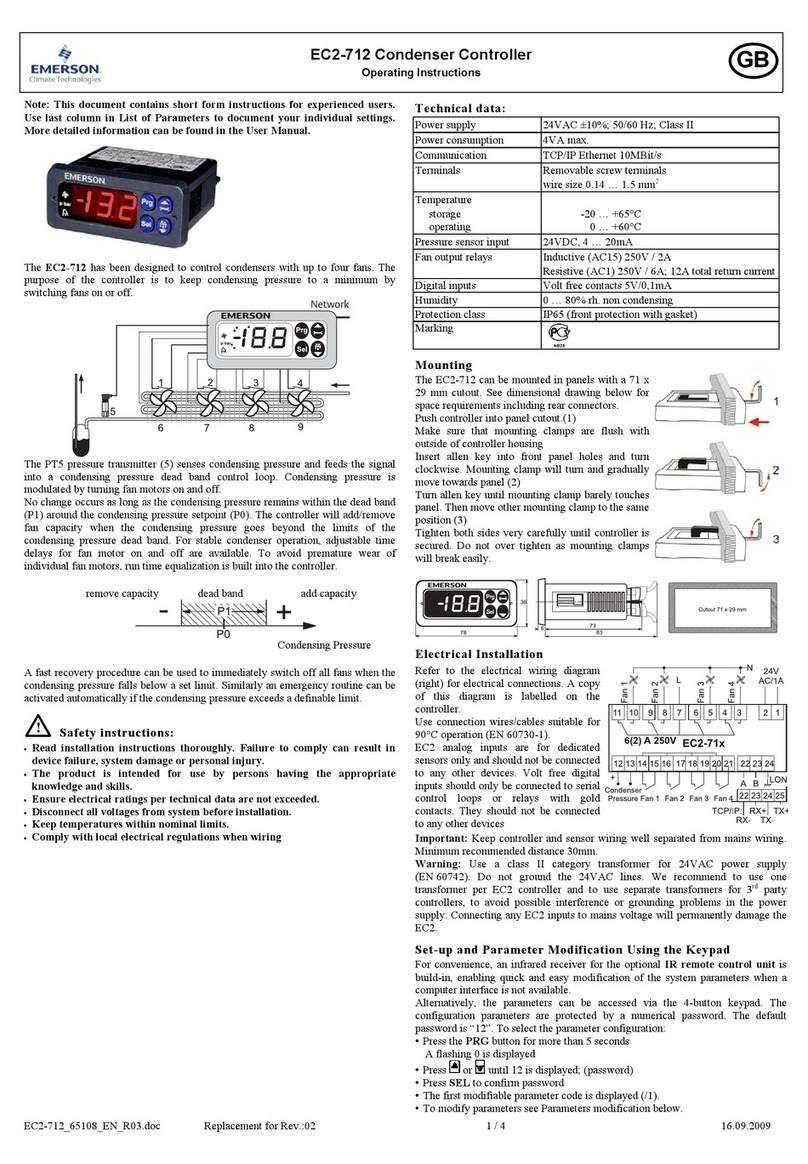

Pilot

1. Remove the protecting cover from the top flange

of the valve and flange of the pilot. Mount the pilot

to the valve as shown in Figure 3.

2. Screw No. 4A bleedport fitting into the 1/8 in. /

3.18 mm pipe tap on the outlet side of the main

valve body. Note that the bleed orifice in this fitting

is vital to the operation of the regulator.

3. Screw No. 4B coupling into 1/8 in. / 3.18 mm pipe

tap in pilot.

4. Screw No. 5A elbow containing the restriction

orifice into the 1/8 in. / 3.18 mm pipe tap on the

underside of the main valve diaphragm chamber.

Type E2 main valves use a No. 5B elbow

without orifice.

5. Connect the tubing bends as illustrated in Figure 3

for Type E and E2 main valves.

Control Pipe

1. Use 1/4 in. / 6.35 mm pipe for this line which

connects the pilot pressure diaphragm chamber to

the desired point of pressure control. See Figure 3.

2. On instantaneous heaters with steam in shell, tap

the control pipe into the shell. Otherwise, enter

the delivery steam pipe at point of entrance to the

heater. (See Figure 2)

3. Pitch the control pipe away from the pilot and

avoid water pockets.

Insulation

Insulation may be applied to the upper portion (globe

and flanges) of the main valve. Do not insulate the

diaphragm chamber or any part of the pilot. See

Figure 3.

Starting Up and Setting

Controlled Temperature

Best temperature control will result when the delivery

pressure setting is the lowest steam pressure capable

of sustaining the desired temperature at maximum

load. The following adjustments should be made under

full load conditions or as near such as possible:

1. Close by-pass. Open 1/4 in. / 6.35 mm control

pipe valve and turn up temperature adjusting

wheel, until 1/2 in. / 12.7 mm of thread is exposed.

Back off pressure adjusting screw to remove all

compression from pressure limit spring. (See

Figure 3)

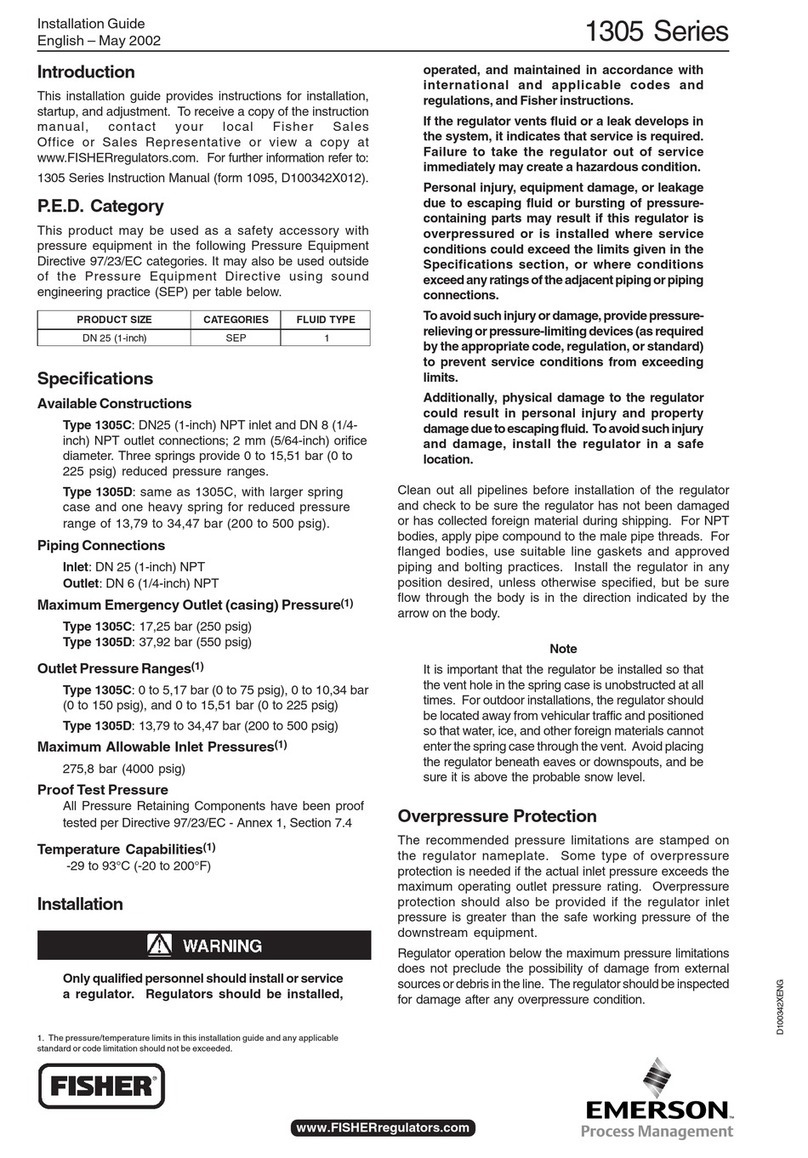

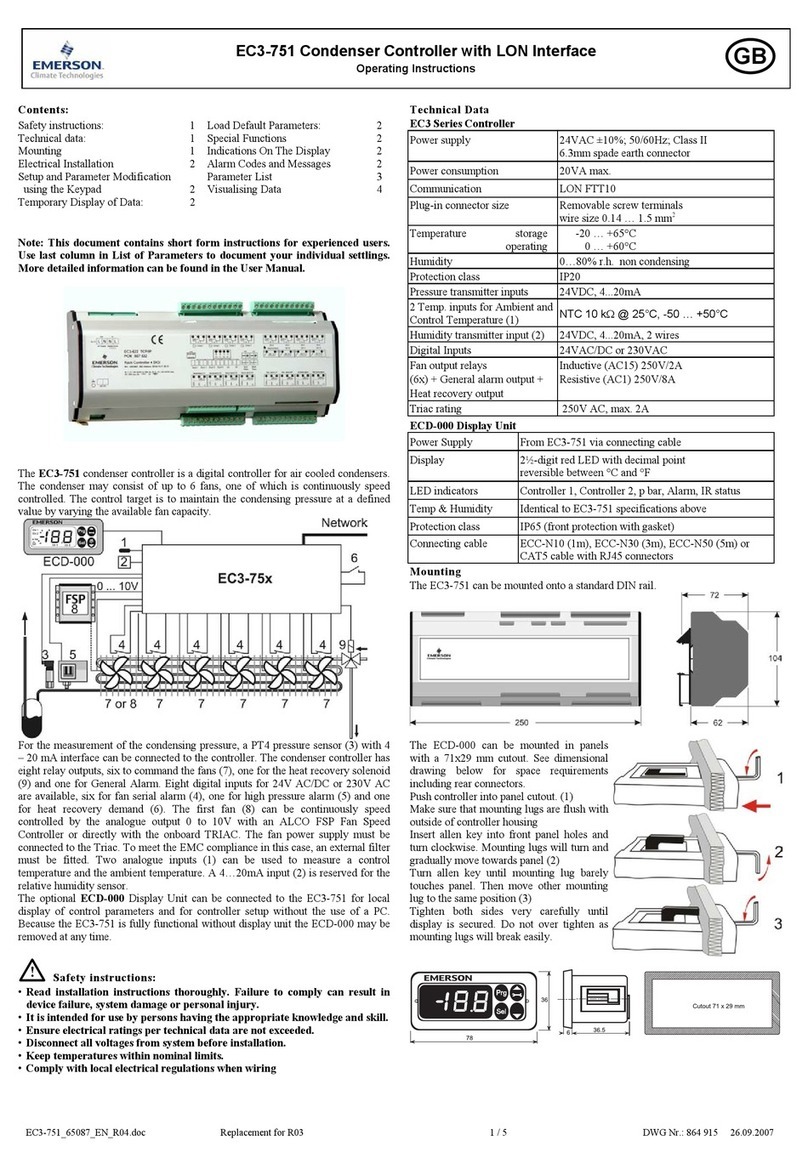

Planning the Installation

1. Locate the regulator in a horizontal pipe.

2. Prevent water hammer and erratic operation by

providing a trap ahead of the regulator.

3. Avoid damaging the effects of scale and dirt

in pipe lines by using a strainer to protect

the regulator.

4. Provide a three-valve by-pass to facilitate inspection

of the regulator without interrupting service.

5. Thermostat position:

a. The preferred thermostat position is horizontal.

b. When vertical or slanting, the tip of the bulb

must point downward.

c. Locate the thermostat as close to the heater

outlet as practical.

d. Expose the entire length of the bulb to the

active flow leaving the heater.

6. If the pressure rating of the heater or the

connected equipment is less than the initial stream

pressure, provide a safety valve.

7. Hot water and similar liquid systems require a

relief valve to prevent dangerous overpressure

due to expansion.

8. Instantaneous Heaters - When operated on

intermittent demand, as in domestic water

heating, require the following conditions for best

temperature regulation.

a. Constant forced recirculation of fluid through

the heater.

b. Omission of thermostat well to reduce

temperature lag. Use of a thermostat

compatible with the heated medium is preferred

over the use of a standard thermostat installed

in a well, which is compatible with the heated

medium. When the use of a well is unavoidable,

an appropriate heat transfer medium should be

installed between the well and the thermostat.

Main Valve

1. Flush the piping system thoroughly to clear it of

welding beads, scale, sand, etc.

2. Mount the main valve with the diaphragm chamber

down and arrow on body pointing in the direction

of the flow.

4

ET124 and ET134 Series