EC3-932_65149_EN_R02.doc Replacement for R01 3 / 4 PCN: 865 874 22.09.2009

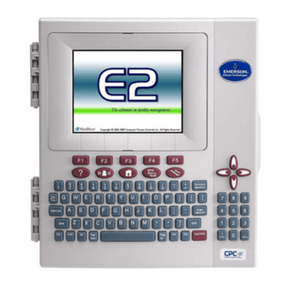

EC3-932 Rack and Condenser Controller and ECD-000 Display Unit

Operating Instructions GB

List Of Parameters

/ DISPLAY PARAMETERS Min Max Unit Def. Custom

/1 Value to show 0 4 - 0

0 = Compressors and fans states (controller 1 and controller 2)

1 = Suction pressure (bar)

2 = Saturation temperature (°C) calculated from suction pressure

3 = Condensing pressure (bar)

4 = Saturation temperature (°C) calculated from discharge pressure

5 = Digital Scroll capacity (%); 6 = Variable fan speed capacity %

Controller C1 (Rack Controller)

P SET-POINT PARAMETERS (C1)

P0 Suction pressure set point -1 50 bar 3.0

P1 Suction band 0 50 bar 2.0

P3 Fast recovery from low pressure -9.9 50 bar -9.9

P4 Suction shift (0=disabled, 1=enabled) 0 1 - 0

P5 Suction shift max 0 3.0 bar 3.0

P8 High discharge pressure recovery -9.9 50 bar 50.0

P9 Discharge recovery step 0 5.0 bar 1.0

t TIME PARAMETERS (C1)

t0 Integration time 30 99 10 sec* 60

t1 Time delay before adding capacity 0 99 10 sec* 6

t2 Time delay before removing capacity 0 99 10 sec* 0.2

t3 Compressor min on time 0 99 10 sec* 6

t4 Compressor min off time 0 99 10 sec* 6

t5 Maximum compressor switching

(0=number of switching unrestricted)

0 199 1/hr 0

A ALARM-PARAMETERS (C1)

A0 Alarm delay LP 0 99 10 sec* 0

A1 Alarm delay HP 0 99 10 sec* 0

A2 Suction alarm min. limit -1.0 50 bar 1.0

A3 Suction alarm max. limit -1.0 50 bar 6.0

A4 Alarm delay suction min. limit 0 99 10 sec* 0

A5 Alarm delay suction max. limit 0 99 10 sec* 0

A6 Maximum discharge temperature 50 150 °C 130

A7 Maximum discharge temperaturedelay 0 99 10 sec* 3

A8 Alarm delay serial alarm comp. 0 99 10 sec* 0

A9 Compressor service interval 0 99 10,000hr** 0

u STEP ENABLE PARAMETERS (C1)

u0 Compressor service interval reset 0 5 - 0

0 = do nothing

1 = reset operating time compr. 1

2 = reset operating time compr. 2

3 = reset operating time compr. 3

4 = reset operating time compr. 4

5 = reset op. time all compressors

u1 Compressor 1: 0=disable, 1=enable 0 1 flag 1

u2 Compressor 2 enable ( - " - ) 0 1 flag 1

u3 Compressor 3 enable ( - " - ) 0 1 flag 1

u4 Compressor 4 enable ( - " - ) 0 1 flag 1

c APPLICATION PARAMETERS (C1)

c1 Number of compressors 1 4 - 4

c3 Compr. control mode (0 = P mode, 0 3 - 2

1 = PI mode, 2 = dead band mode 3 = binary mode)

c4 Compressor 1 control mode 0 2 - 2

0 = in standard control loop 1 = act as base load compressor

2 = act as modulating capacity; function defined by parameter F5

c5 Compressor rotation 0 1 flag 1

0 = FILO logic (First In, Last Out) 1 = FIFO logic (First In, First Out)

c6 Sensor fail 0 4 - 0

(number of compressors in case of sensor failure)

h0 Discharge pressure sensor

0 = not available; 1 = available

0 1 flag 1

r SENSOR PARAMETERS (C1)

r0 Suction sensor 0% -1.0 50 bar -0.8

r1 Suction sensor 100% -1.0 50 bar 7

r2 Suction sensor offset -1.0 1.0 bar 0.0

r3 Refrigerant 0 7 - 3

0 = R 22

1 = R 134a

2 = R 507

3 = R 404A

4 = R 407C

5 = R 410A

6 = R 124

7 = R 744

* Resolution = 10 sec, on the local display. Example a value 2 means 20 sec.

** Resolution = 10,000 hrs. on the local display. Example a value 2 means 2.000 hours.

F MODULATING PARAMETERS (C1)

Min Max Unit Def. Custom

F2 Minimum output value (F5 = 0 or 1) 10 100 % 10

F3 Maximum output value (F5 = 0 or 1) 10 100 % 100

F3 PWM rate if F5 = 2 (Digital Scroll) 10 20 sec 10

F5 Analogue output mode for Comp. 1

0 or 1 = 0 … 10V; 2 = PWM (digital)

0 2 - 2

Controller C2 (Condenser Controller)

P SET-POINT PARAMETERS (C2)

P0 Condensing pressure set point -1 50 bar 14.0

P1 Cond. pressure band 0 50 bar 4.0

P2 Condensing pressure set point 2 -1 50 bar 14.0

P3 Condensing recovery min -9.9 50.0 bar -9.9

P4 Condensing shift (0 = off, 1 = on) 0 1 - 0

P5 Condensing shift max 0.0 3.0 bar 3.0

P6 Condensing shift temp min -50 50 °C 30°C

P7 Condensing shift temp max -50 50 °C 15°C

P8 Condensing recovery max -9.9 50 bar 50

t TIME PARAMETERS (C2)

t0 Integration time 30 99 10 sec* 60

t1 Time delay before adding capacity 0 99 10 sec* 3

t2 Time delay before removing capacity 0 99 10 sec* 3

A ALARM-PARAMETERS (C2)

A1 Alarm delay HP 0 99 10 sec* 0

A2 Condensing alarm limit min -1.0 50 bar 10

A3 Condensing alarm limit max -1.0 50 bar 27

A4 Alarm delay condensing limit min 0 99 10 sec* 0

A5 Alarm delay condensing limit max 0 99 10 sec* 0

A8 Alarm delay serial alarm fan 0 99 10 sec* 0

A9 Service interval 0 99

1,000 hr** 0

u STEP ENABLE PARAMETERS (C2)

u0 Fan service interval reset 0 4 - 0

0 = do nothing

1 = reset operating time fan 1

2 = reset operating time fan 2

3 = reset operating time fan 3

4 = reset op. time all fans

u1 Fan 1 enable (0=disable, 1=enable) 0 1 flag 1

u2 Fan 2 enable (0=disable, 1=enable) 0 1 flag 1

u3 Fan 3 enable (0=disable, 1=enable) 0 1 flag 1

c APPLICATION PARAMETERS (C2)

c1 Number of fans 1 3 - 3

c3 Control mode (0 = P mode,

1 = PI mode, 2 = dead band mode)

0 2 - 2

c4 First fan control mode 0 2 - 0

0 = in standard control loop,

1 = act as base load fan,

2 = act as modulating capacity (0…10V

for inverter command or TRIAC output)

c5 Fan rotation 0 1 flag 0

0 = FILO logic (First In, Last Out) 1 = FIFO logic (First In, First Out)

c6 Sensor fail (nr. of fans in case of sens fail) 0 3 - 0

r SENSOR PARAMETERS (C2)

r0 Condensing sensor 0% -1.0 50 bar 0.0

r1 Condensing sensor 100% -1.0 50 bar 30

r2 Condensing sensor offset -1.0 1.0 bar 0.0

F MODULATING PARAMETERS (C2)

F2 Fan 1 min speed (if controlled) 0 100 % 0

F3 Fan 1 max speed (if controlled) 0 100 % 100

F4 Fan 1 at min: (0=off; 1 =min speed) 0 1 flag 0

F7 Output mode for modulating fan 1: 0 1 flag 0

0 = 0 – 10V analogue output; 1 = Phase cutting with Triac

H OTHER PARAMETERS

H2 ECD Display access 0 3 - 3

0 = all disabled (Caution, access

to controller only via TCP/IP

network possible)

1 = Keyboard enabled

2 = IR remote control enabled

3 = Keyboard and IR remote

control enabled

H3 IR access code 0 199 - 0

H5 Password 0 199 - 12