Instruction Manual

D101728X012

3710 and 3720 Positioners

September 2017

4

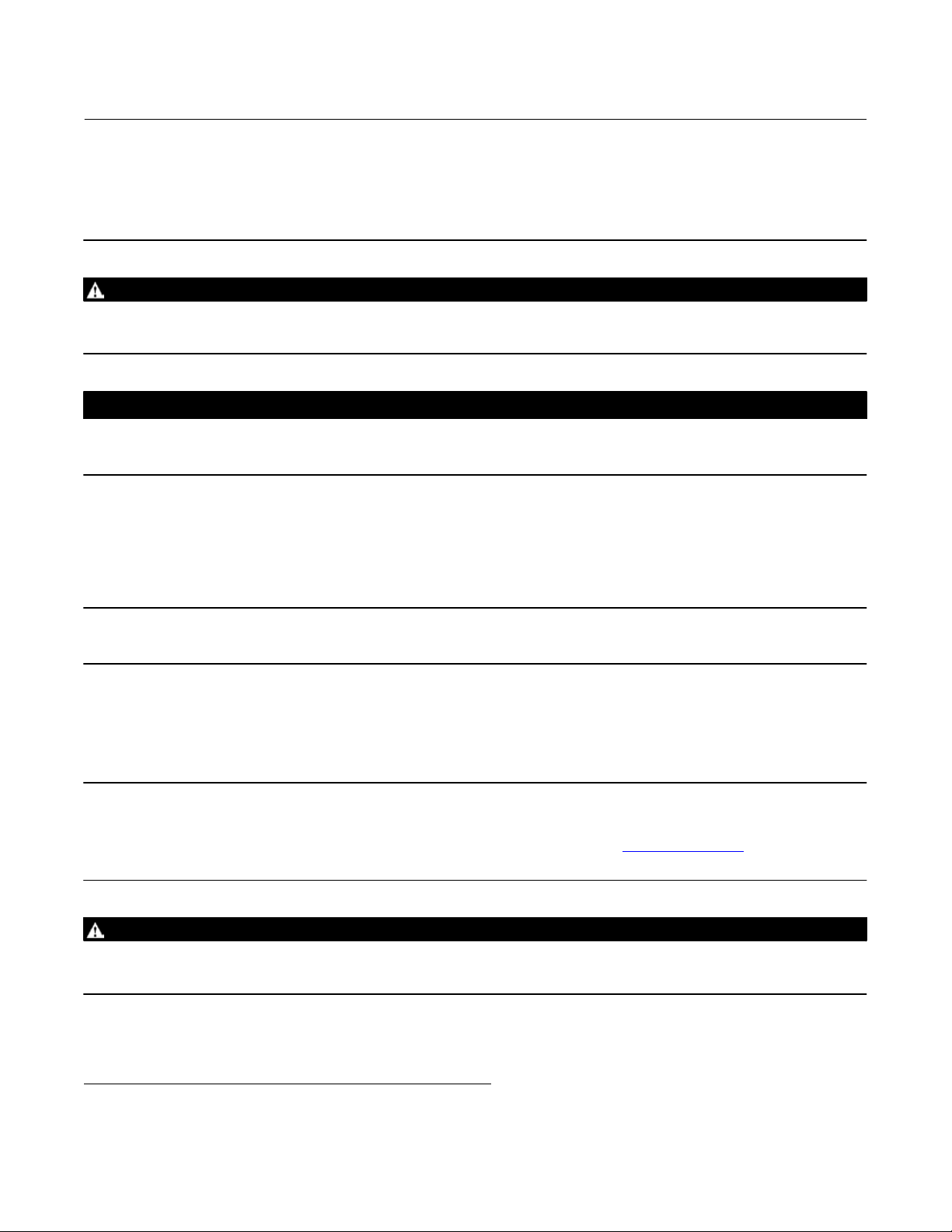

Table 1. Specifications (Continued)

Hazardous Area Classification for 3710 Positioner

3710 pneumatic positioners comply with the

requirements of ATEX Group II Category 2 Gas and

Dust

Electrical Classifications for 3722 Converter

CSA— Intrinsically Safe, Explosion-proof, Type n,

Dust Ignition-proof

FM— Intrinsically Safe, Explosion-proof, Type n,

Dust Ignition-proof, Non‐incendive

ATEX— Intrinsically Safe, Flameproof, Type n

IECEx— Intrinsically Safe, Flameproof, Type n

Note: These classifications also apply to the 3720

positioner

Refer to Hazardous Area Classifications and Special

Instructions for “Safe Use” and Installation in

Hazardous Locations, starting on page 7, for

additional information.

Housing Classification for 3722 Converter

CSA— Type 3 Encl. ATEX— IP64

FM— NEMA 3, IP54 IECEx— IP54

Mount instrument with vent on side or bottom if

weatherproofing is a concern.

Note: These classifications also apply to the 3720

positioner

Other Classifications/Certifications for 3722

Converter

CUTR—Customs Union Technical Regulations (Russia,

Kazakhstan, Belarus, and Armenia)

INMETRO— National Institute of Metrology, Quality

and Technology (Brazil)

KGS— Korea Gas Safety Corporation (South Korea)

Contact your Emerson sales office or Local Business

Partner for classification/certification specific

information

Pressure Connections

1/4 NPT internal

Electrical Connection for 3720 Positioner

1/2‐14 NPT conduit connection

Rotary Valve Rotation

J90 degrees (standard) J60 degrees (optional)

Approximate Weight

3710: 2.04 kg (4.5 pounds)

3720: 2.72 kg (6.0 pounds)

Declaration of SEP

Fisher Controls International LLC declares this

product to be in compliance with Article 4

paragraph 3 of the PED Directive 2014/68/EU. It was

designed and manufactured in accordance with

Sound Engineering Practice (SEP) and cannot bear

the CE marking related to PED compliance.

However, the product may bear the CE marking to

indicate compliance with other applicable European

Community Directives.

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 ‐ Process Instrument Terminology.

1. For direct action, an increasing input signal extends actuator rod. For reverse action, an increasing input signal retracts actuator rod.

2. The pressure and temperature limits in this document, and any applicable code or standard limitation should not be exceeded.

3. Normal cubic meters per hour (0°C and 1.01325 bar absolute). Scfh — standard cubic feet per hour (60°F and 14.7 psia).

4. Typical values tested using a 1061 size 30 actuator at 4.1 bar (60 psig) supply pressure. Performance may vary with other actuator types and supply pressures.

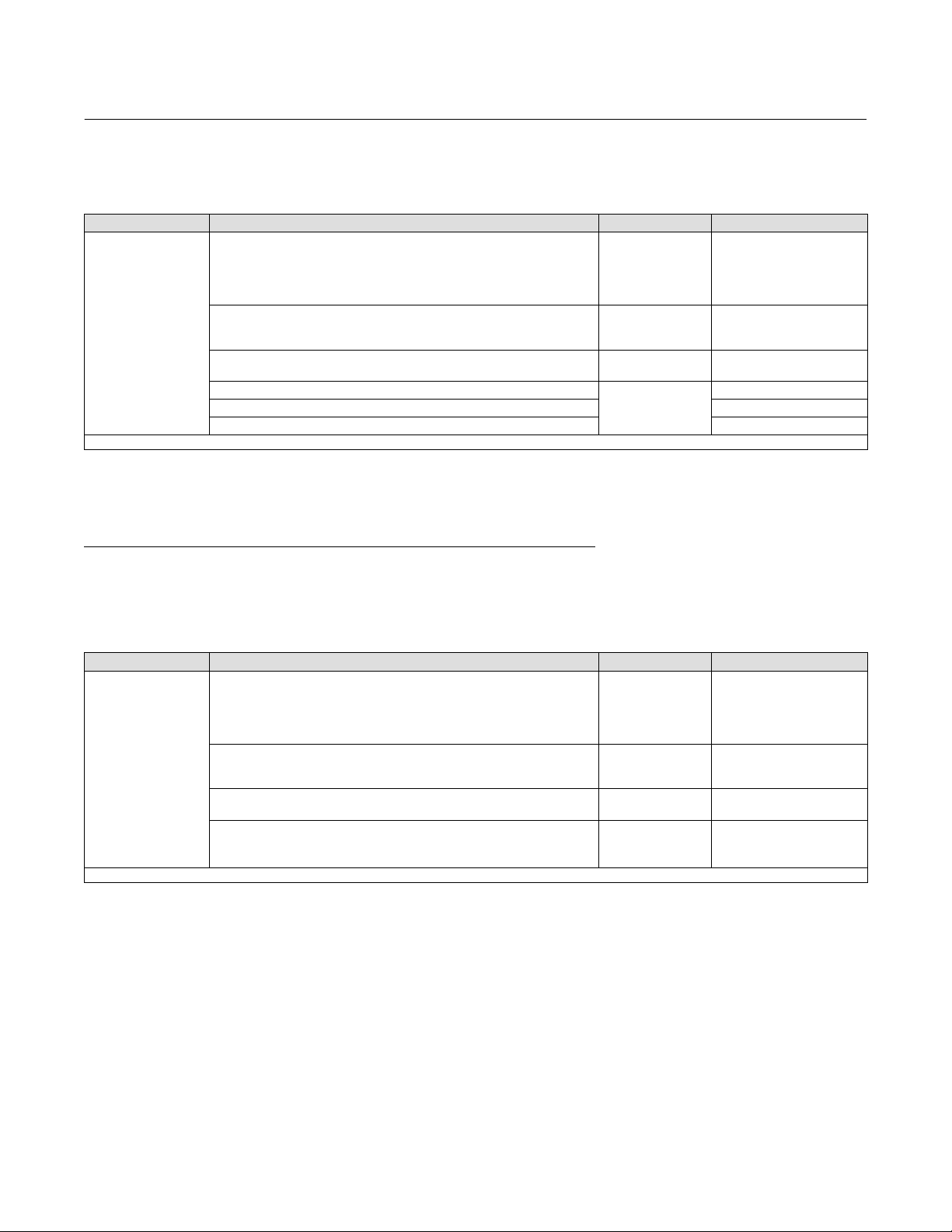

Table 2. Fisher 3722 Electro‐Converter(1) EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level Performance

Criteria(2)

Enclosure

Electrostatic Discharge (ESD) IEC 61000‐4‐2 4 kV contact

8 kV air A

Radiated EM field IEC 61000‐4‐3

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

14000 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

A

Rated power frequency magnetic

field IEC 61000‐4‐8 60 A/m at 50 Hz A

I/O signal/control

Burst (fast transients) IEC 61000‐4‐4 1 kV A

Surge IEC 61000‐4‐5 1 kV (line to ground only, each) B

Conducted RF IEC 61000‐4‐6 150 kHz to 80 MHz at 3 Vrms A

Specification limit = ±1% of span

1. The information contained in this table also applies to the 3720 positioner.

2. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.