Instruction Manual

D200138X012

3582, 582i, and 3583

February 2015

2

Contents (cont'd)

Valve Positioner Bypass Operation 26.............

Input Signal Ranges 27.........................

Valve Positioner Split‐Range Operation 27.........

Changing Valve Positioner Action 28.............

Changing Valve Stem Position Transmitter

Action 28..................................

Calibration Of Valve Positioner Or

Valve Stem Position Transmitter 29................

Beam Alignment 29...........................

Calibration 31................................

Principle of Operation 32........................

3582 Valve Positioners 32......................

3582i Valve Positioner 33.......................

3583 Valve Stem Position Transmitters 34.........

Maintenance 35................................

Changing the Range Spring 36..................

Replacing Gaskets 36..........................

Replacing the Nozzle O‐Ring 37..................

Replacing the Relay 37.........................

Adjusting the Flapper Pivot 38...................

Replacing the 582i Converter

Primary O‐Ring and Filter 38..................

Replacing the 582i Converter Housing

Cap O‐Ring 38..............................

Removing the 582i Converter 38.................

Reassembling the 582i Converter 39.............

Parts Ordering 40...............................

Parts Kits 40...................................

Parts List 41...................................

Loop Schematics 54.............................

Introduction

Scope of Manual

This instruction manual includes installation, operation, calibration, maintenance, and parts ordering information for

Fisher 3582 pneumatic valve positioners, the 3582i electro‐pneumatic valve positioner, and 3583 pneumatic valve

stem position transmitters. Refer to separate instruction manuals for information on the control valve, actuator, and

accessories.

Do not install, operate or maintain a 3582 pneumatic valve positioner, a 3582i electro‐pneumatic valve positioner, or a

3583 pneumatic valve stem position transmitter without being fully trained and qualified in valve, actuator and

accessory installation, operation and maintenance. To avoid personal injury or property damage it is important to

carefully read, understand, and follow all of the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

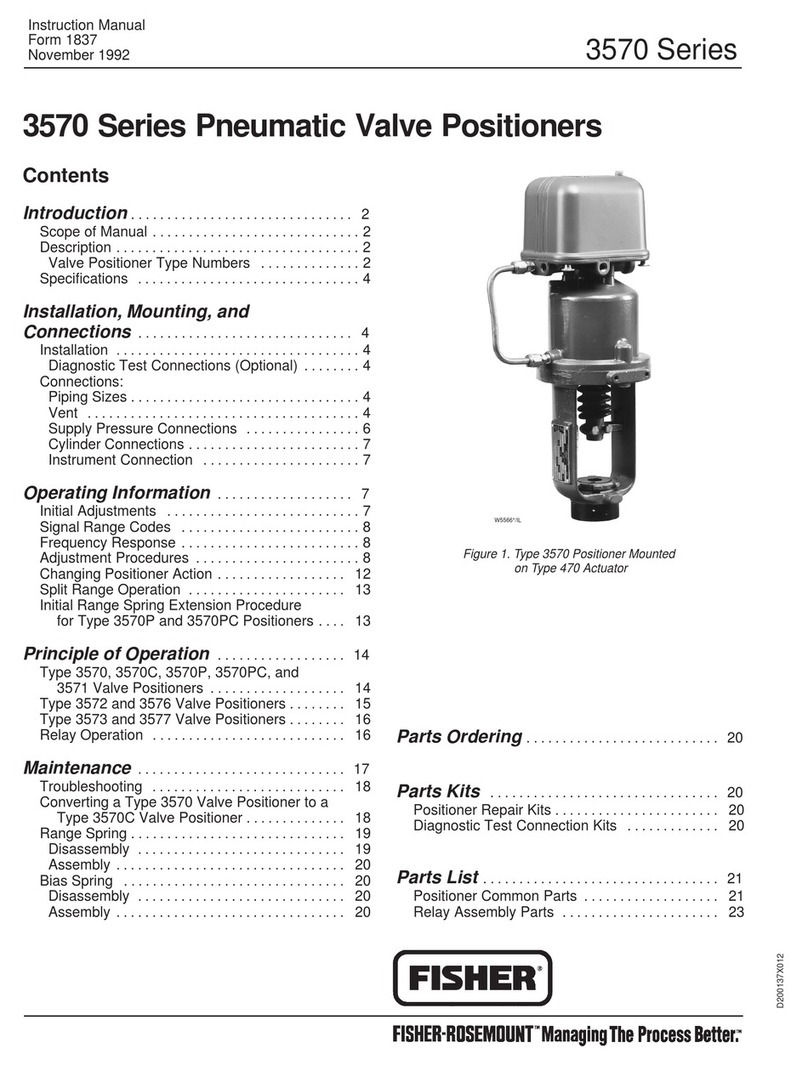

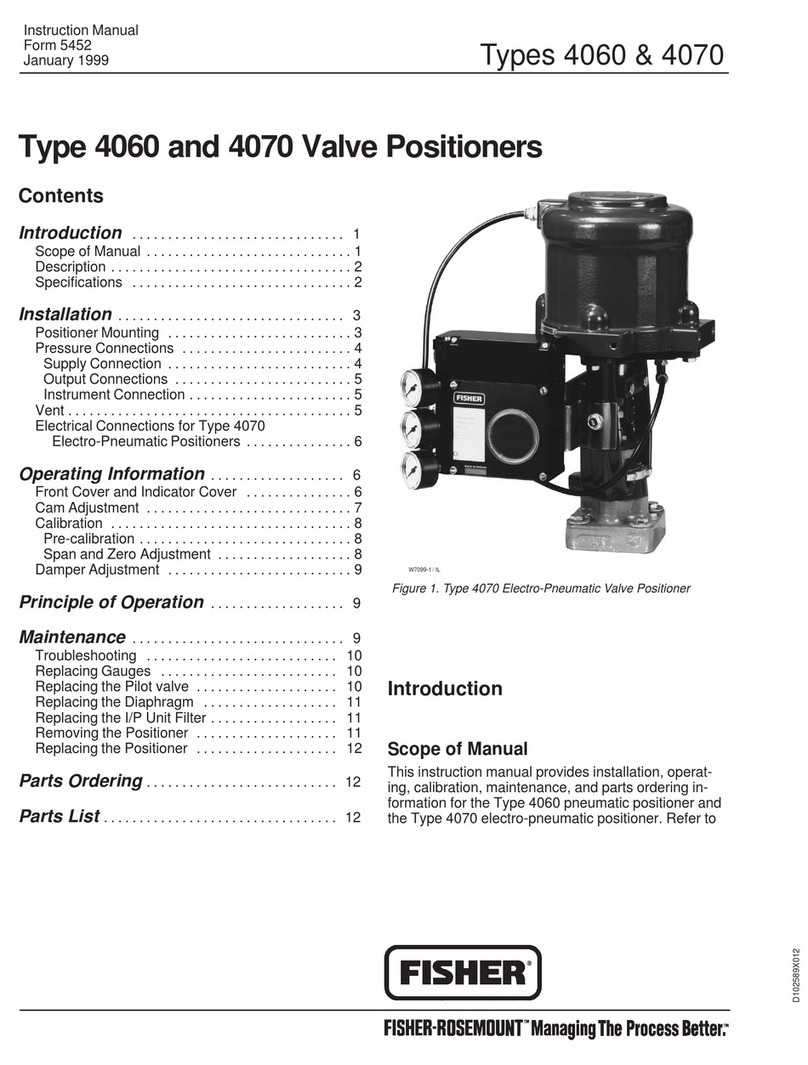

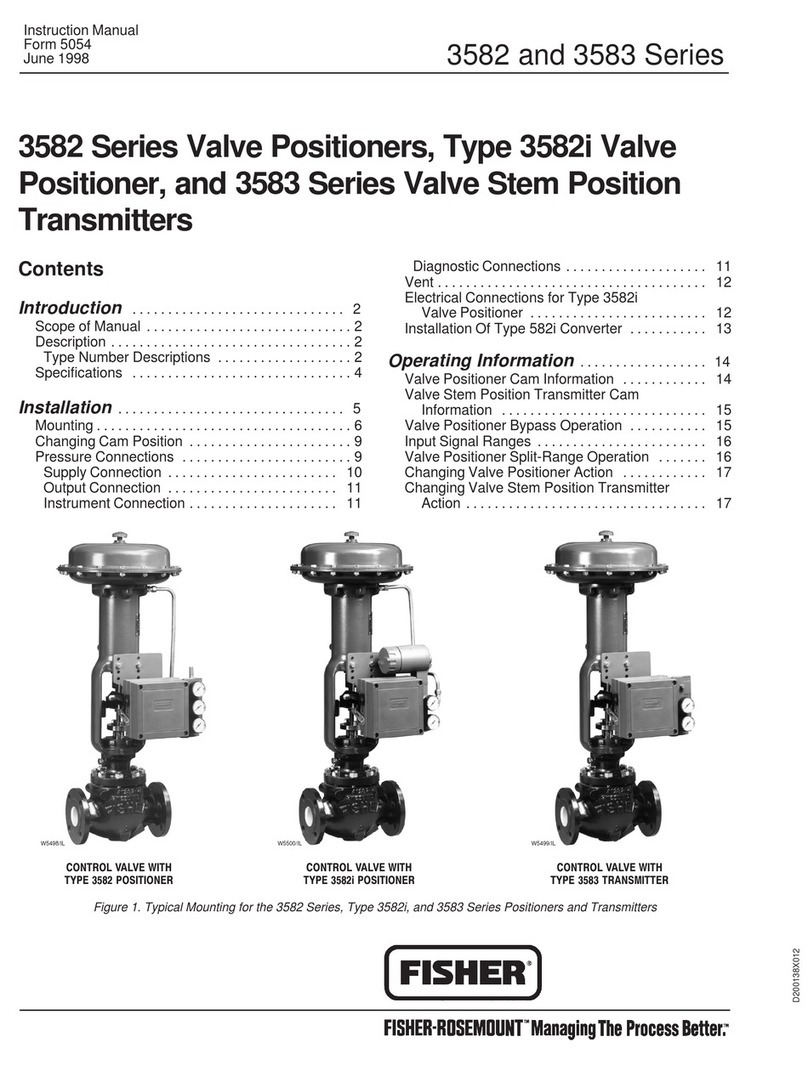

3582 pneumatic valve positioners and the 3582i electro‐pneumatic valve positioner shown in figure 1 are used with

diaphragm‐actuated, sliding‐stem control valve assemblies. The pneumatic valve positioners receive a pneumatic

input signal from a control device and modulate the supply pressure to the control valve actuator. The positioner

adjusts the actuator supply pressure to maintain a valve stem position proportional to the pneumatic input signal.

3582NS positioners are designed for nuclear power applications. The 3582NS construction includes materials that

provide superior performance at elevated temperature and radiation levels. The O‐rings are EPDM (ethylene

propylene) and the diaphragms are EPDM/meta‐aramid fabric. EPDM demonstrates superior temperature capability

and shelf life over nitrile. The meta‐aramid diaphragm fabric demonstrates improved strength retention at elevated

temperature and radiation conditions.

CAUTION

Use a clean, dry, oil‐free air supply with instruments containing EPDM components. EPDM is subject to degradation when

exposed to petroleum‐based lubricants.