CG Drives & Automation, 01-6142-01r0 3

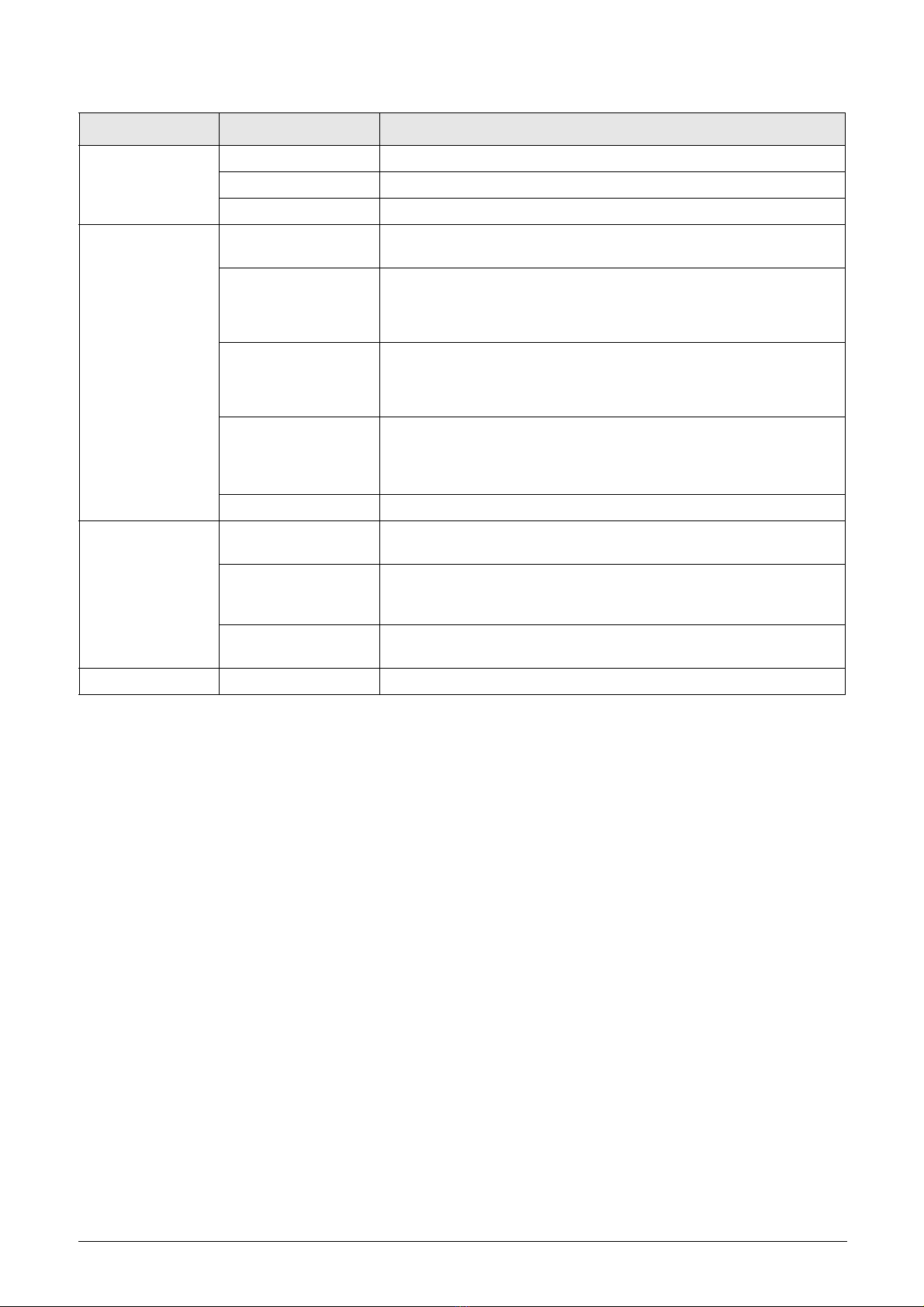

Contents

Safety Instructions ......................................... 1

Contents.......................................................... 3

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Warranty .................................................................... 6

1.4 Type code number..................................................... 7

1.5 Standards .................................................................. 8

1.6 Dismantling and scrapping..................................... 10

1.7 Glossary ................................................................... 10

2. Mounting ...................................................... 11

2.1 Lifting instructions................................................... 11

2.2 Stand-alone units .................................................... 11

3. Installation ................................................... 17

3.1 Before installation................................................... 17

3.2 Cable connections................................................... 18

3.3 Connection of motor and mains cables for larger

frame sizes .............................................................. 23

3.4 Cable specifications ................................................ 24

3.5 Thermal protection on the motor ........................... 28

3.6 Motors in parallel .................................................... 28

4. Control Connections.................................... 29

4.1 Control board........................................................... 29

4.2 Terminal connections ............................................. 30

4.3 Inputs configuration

with the switches..................................................... 31

4.4 Connect control cables ........................................... 31

4.5 Connecting options ................................................. 37

5. Getting Started ............................................ 39

5.1 Function keys .......................................................... 39

5.2 Generic configuration (all drives) ........................... 40

5.3 Additional configuration for Standalone / Master

drives........................................................................ 41

5.4 Test run.................................................................... 42

5.5 Engage “auto tune” program to optimize energy

consumption............................................................ 43

5.6 Configuration of additional features...................... 44

6. EMC and standards ..................................... 45

6.1 EMC standards ........................................................ 45

6.2 Stop categories and emergency stop .................... 45

7. Options ......................................................... 47

7.1 Options for the control panel.................................. 47

7.2 Handheld Control Panel 2.0 ................................... 47

7.3 Gland kits................................................................. 48

7.4 EmoSoftCom............................................................ 48

7.5 I/O Board ................................................................. 48

7.6 PTC/PT100 .............................................................. 48

7.7 RTC- Real time clock board .................................... 48

7.8 Serial communication and fieldbus ....................... 48

7.9 Standby supply board option.................................. 49

7.10 Safe Stop option...................................................... 49

7.11 EMC filter class C1/C2 ........................................... 52

7.12 Output chokes ......................................................... 52

7.13 Liquid cooling .......................................................... 52

7.14 Top cover for IP20/21 version ............................... 52

7.15 Other options........................................................... 52

8. Technical Data ............................................. 53

8.1 Electrical specifications related to model ............. 53

8.2 General electrical specifications............................ 55

8.3 Operation at higher temperatures ......................... 56

8.4 Operation at higher switching frequency............... 56

8.5 Dimensions and Weights........................................ 57

8.6 Environmental conditions....................................... 58

8.7 Fuses and glands .................................................... 59

8.8 Control signals......................................................... 62

Index ............................................................. 63