Emicon EMIBYTE DXi.H User guide

Instructions:

Referring to the specify

Read and understand all

the present Manual before

any intervention.

PRESERVE THE PRESENT FOR FUTURE

The instructions unit manuali s composed by the following:

• Conformity declaration

• Technical Manual

USE AND MAINTENANCE TECHNICAL MANUAL

Original Instruction

DXi.H

WITH INVERTER COMPRESSORS

DXi.HF

WITH INVERTER COMPRESSORS

AND ADDITIONAL FREE-COOLING COIL

'XDOÁXLGLQGLUHFWIUHHFRROLQJ

DIRECT EXPANSION WATER CONDENSED CLOSE CONTROL UNITS

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF series English Rev. 3 02-2021

Rev. 3 02-2021

2

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

The copy, transmission or memorization of the present Manual is forbidden in any form without the written authorisation from the Manufac-

turer.

The Manufacturer could be contacted to receive any information about his products.

7KH0DQXIDFWXUHUZRUNVLQDFRQVWDQWSROLF\RISURGXFWVGHYHORSPHQWDQGUHVHUYHVWKHULJKWWRPRGLI\KLVSURGXFWVWKHVSHFL¿FVDQGWKH

instructions about use and maintenance without any prior notice.

&RQIRUPLW\GHFODUDWLRQ

We declare under our responsability that the supplied units comply in every part with the directives of the CE marking and the current EN

VWDQGDUGV7KH&RQIRUPLW\GHFODUDWLRQLVDWWDFKHGWRWKHRQERDUGGRFXPHQWDWLRQ%HLQIRUPHGWKDWWKHXQLWFRQWDLQVÀXRULQDWHGJUHHQKRX-

ses gases.

Rev. 3 02-2021

3

5

5

5

5

5

5

6

7

8

8

9

10

10

10

11

11

12

12

14

15

17

20

24

25

26

28

29

29

29

29

30

30

30

31

31

32

34

35

36

40

44

44

45

46

46

48

49

50

50

51

51

52

52

53

53

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

INDICE

1. INTRODUCTION.....................................................................................................................................................................................

1.1 Preliminary information......................................................................................................................................................

1.2 Instructions content and pourpose.....................................................................................................................................

1.3 Instruction conservation.....................................................................................................................................................

1.4 Instruction updating ...........................................................................................................................................................

1.5 Instruction use ...................................................................................................................................................................

1.6 Residual risks ....................................................................................................................................................................

1.7 Safety symbols generality..................................................................................................................................................

1.8 Safety symbols ..................................................................................................................................................................

1.9 Unit limit and not allowed usesi .........................................................................................................................................

8QLWLGHQWL¿FDWLRQ .............................................................................................................................................................

2. SAFETY .................................................................................................................................................................................................

2.1 Advise about toxic substances potentially dangerous .......................................................................................................

2.2 First AID and injuries prevention........................................................................................................................................

7R[LFLQIRUPDWLRQDERXWWKHUH¿UJHUDQWÀXLGXVHG..............................................................................................................

2.4 First AID measures ............................................................................................................................................................

3. TECHNICAL CHARACTERISTICS .........................................................................................................................................................

3.1 Unit description..................................................................................................................................................................

&RQ¿JXUDWLRQV...................................................................................................................................................................

3.3 Accessories description .....................................................................................................................................................

3.4 DXi.H series technical data................................................................................................................................................

3.5 DXi.HF series technical data .............................................................................................................................................

3.6 Refrigerant charge.............................................................................................................................................................

3.7 Operation limits..................................................................................................................................................................

3.8 DXi.H Sound data..............................................................................................................................................................

3.9 DXi.HF Sound data............................................................................................................................................................

4. INSTALLATION .......................................................................................................................................................................................

4.1 General advices and symbols use.....................................................................................................................................

4.2 Workers health and safety.................................................................................................................................................

4.3 Individual protection devices..............................................................................................................................................

4.4 Receipt and inspection ......................................................................................................................................................

4.5 Storage and transport........................................................................................................................................................

4.6 Unpacking..........................................................................................................................................................................

4.7 Lifting and handling............................................................................................................................................................

4.8 Location and minimum technical clearances.....................................................................................................................

4.9 Hydraulic connections........................................................................................................................................................

4.10 Pipeline diameters ...........................................................................................................................................................

4.11 Plate condenser hydraulic connections ...........................................................................................................................

4.12 DXi.H Refrigerant circuit layout........................................................................................................................................

4.13 DXi.HF Refrigerant circuit layout .....................................................................................................................................

4.14 Condensing water connection .........................................................................................................................................

4.15 Renewal air intake connection (Optional) (PR)................................................................................................................

+XPLGL¿HURSWLRQDO+...................................................................................................................................................

4.17 Electric connections: safety preliminary advices .............................................................................................................

4.18 Electrical data ..................................................................................................................................................................

4.19 Power supply connection.................................................................................................................................................

4.20 RS485 Serial interface

5. START UP ...............................................................................................................................................................................................

5.1 Preliminary checks.............................................................................................................................................................

5.2 First start up.......................................................................................................................................................................

5.3 Operation checks...............................................................................................................................................................

5.4 Safety valves .....................................................................................................................................................................

5.5 Safety devices calibration..................................................................................................................................................

6. USE .................................................................................................................................................................................................

6.1 Electronic microprocessor control description and use .....................................................................................................

Rev. 3 02-2021

4

53

55

55

56

56

62

71

71

71

71

74

75

76

76

76

77

77

77

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

6.2 Remote control description................................................................................................................................................

6.3 Keys function .....................................................................................................................................................................

6.4 User interface ....................................................................................................................................................................

6.5 Password settings..............................................................................................................................................................

6.6 Quick access Menu ...........................................................................................................................................................

6.7 Main Menu.........................................................................................................................................................................

7. UNIT MAINTENANCE .............................................................................................................................................................................

7.1 General advices.................................................................................................................................................................

7.2 Unit access ........................................................................................................................................................................

7.3 Scheduled maintenance ....................................................................................................................................................

7.4 Periodical checks...............................................................................................................................................................

7.5 Straordinary maintenance..................................................................................................................................................

8. DECOMMISSIONING.............................................................................................................................................................................

8.1 Disconnect the unit ............................................................................................................................................................

8.2 Disposal, recovery and recycling.......................................................................................................................................

8.2 RAEE Directive (UE members only)..................................................................................................................................

9.DIAGNOSIS AND TROUBLESHOOTING ................................................................................................................................................

)DXOW¿QGLQJ .......................................................................................................................................................................

Rev. 3 02-2021

5

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

1. INTRODUCTION

3UHOLPLQDU\LQIRUPDWLRQ

,QVWUXFWLRQVFRQWHQWDQGSRXUSRVH

,QVWUXFWLRQFRQVHUYDWLRQ

,QVWUXFWLRQXSGDWLQJ

,QVWUXFWLRQXVH

The copy, transmission or memorisation of the present Manual is forbidden in any form without the written authorisation from the Manufac-

turer.

The unit which the present Manual refers is designed only for the uses presented in the following pages, comply with their performances

and characteristics. Any contractual or extra-contractual liability of the Manufacturer for damages caused to people, animals, thigs or envi-

ronment made by installation, regulation, maintainence errors or improper uses are excluded

All the uses not mentioned in the present Manual are not allowed.

The present documentation is an informative support and has not to be considered as a contract with third parts.

7KH0DQXIDFWXUHUZRUNVLQDFRQVWDQWSROLF\RISURGXFWVGHYHORSPHQWDQGUHVHUYHVWKHULJKWWRPRGLI\KLVSURGXFWVWKHVSHFL¿FVWKH

instructions and also the documentation in any moment without any prior notice

The present instructions porpose to give all information concerning the selection, installation, use and maintenance of the units.

The instructions are written in conformity with legislative disposition of UE and to the technical available norms.

The instructions including the indication to avoid reasonably foreseeable improper uses of the units.

The instruction must be posed in a proper place, away from dust, humidity and where every person in charge to use and operate with the

XQLWFRXOG¿QGWKHPHDVLO\

The instruction has to be always on board and during all the life cycle of the unit, therefore has to be transferred to every subsequent user

Is suggested to verify that all the instructions are updated to the last release available.

Any updates sended to the user must be kept attached to the present Manual.

The Manufacturer is available to provide any information about use of his products.

The present instructions are integral part of the unit which are referred.

The users and operators have to consults mandatory the instructions before any intervention on the unis and in every

occasion of doubt about the transport, the handling, the installation, the maintenance, the use and the disposal of the unit.

In the following are mentioned all the graphic symbols which indicate all the operation has to be safety done

Rev. 3 02-2021

6

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

5HVLGXDOULVNV

The units are deigned to reduce at minimum the risk for the people who will use them.

Anyway is impossible to eliminate completely the risk, so is strictly necessary refers to the following prescription in order to avoid them at

the maximum.

ELEMENTS

CONSIDERED

LISUHVHQWV

RESIDUAL RISK MODE PRECAUTIONS

Exchanger coils Small cutting wounds Contact Avoid the contact, use protective gloves.

Fans and grid fans. Injury

Insertion of tools through

the fans grid during the

fans operation

Do not insert any tools throught the fans grid during

their operation

Inside unit: compres-

sors and discharge gas

pipes

Burns Contact Avoid the contact, use protective gloves

Inside unit: metallic

components and

electrical cables.

Electrocution, several

burns

Power supply cables in-

sulation defect, electrical

tension on metallic com-

ponents.

Adequate supply line electrical protection; utmost

care making the metallic parts ground connection.

Outside unit: Area

around the unit

Intoxicaions, several

burns

Fire due to short-circuit or

overheating of the power

supply line upstream of the

unit’s electrical panel

Section of the cables and protection system of the po-

wer supply line complying with the standard in force

High pressure safety

valve (if present)

Intoxications, several

burns, hearing loss

High pressure valve inter-

vention with the cooling

circuit panel open

Avoid opening the refrigeration circuit compartment

as much as possible; carefully check the value of

intervention of the condensation pressure valve;

use all the high pressure personal protection sa-

fety devices required by law. Use all the personal

protection devices required by law. PPE must also

protect against gas leakage from the safety valve.

The discharge of these valve is director to prevent

damage to people or things.

Unit

Burst, injuries, burns,

poisoning due to exter-

nal incense.

Fire due to natural disaster

or combustion of elemets

adjacent to the unit.

3UHSDUHWKHQHFHVVDU\¿UH¿JKWLQJHTXLSPHQWDQG

or adequate signals indicating that the uniti s under

pressure

Unit

Burst, injuries, poiso-

ning, electrocution due

to natural disasters,

earthquake

Breaks, sagging for natu-

ral disasters or earthquake

Prepare the necessary precautions, both electrical

(adequate thermal magnetic circuit breaker and

electrical protection of the power supply lines; tre-

atment for maximum calamity when connecting the

metal parts to earth, and mechanical (for example

special antisismic anchors or anti-vibration dampers

to avoid cause accidentals breakages or falls).

Rev. 3 02-2021

7

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

PROHIBITION

Black symbol inside a red circle with red diagonal indicates a forbidden action.

ADVISE

A black graphic symbol inside a yellow triangle with black edges indicates a danger.

MANDATORY ACTION

A white symbol inside ina blue circle indicates a mandatory action to avoid a risk.

The advise graphic symbol is completed with additional safety information (text or many symbols).

ISO 3864-2 complied Combined safety symbols:

6DIHW\V\PEROVJHQHUDOLW\

ISO 3864-2 complied safety symbols :

Rev. 3 02-2021

8

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

GENERIC DANGER

Follow strictly all the advises near the symbol.

Failure to follow the indications could generate user health risks.

ELECTRICAL DANGER

Follow strictly all the advises near the symbol.

The symbol indicates unit components or, in the present Manual actions could generate electrical risks.

MOVING COMPONENTS

The symbols indicates unit’s moving components could generate risk situations.

HOT SURFACES

The symbols indicates unit’s components could be very hot and that could cause several burns.

SHARP SURFACES

The symbol indicates unit components could cause cutting wounds by contact.

GROUND CONNECTION

The symbol indicates the unit’s ground connection point.

READ AND UNDERSTAND TEH INSTRUCTIONS

Read and understand the instruction before any intervention on the unit

RECOVERABLE OR RECYCLABLE MATERIAL

1.8 SDIHW\V\PEROV

The unit is not suitable to operate in environments:

• Excessively dusty or potentially explosive;

• Where are present vibrations;

:KHUHDUHSUHVHQWHOHFWURPDJQHWLF¿HOGV

• Where are present aggressive ambients.

Units are designed and produced exclusively for the uses described in the paragraph “Use limits” of technical Manual. Any other use is

forbidden because could generate user health risks.

1.9 UQLWOLPLWDQGQRWDOORZHGXVHV

Rev. 3 02-2021

9

TEL.+39 0543495611 FAX+39 0543 495612

Via A.Volta 49 Meldola FC ITALY

NB 0948

MODELLO

MODEL

MODèLE

MODEL

R 410A / 2088

MATRICOLA

SERIAL NR

N°DE SèRIE

STAMM NR

ALIMENTAZIONE ELET.

SUPPLY VOLTAGE

ALIMENTATION ELECT.

SPANNUNG

CORRENTE MAX.

MAX CURRENT INPUT

MAXIMALEN STROM

AMPèRES MAXIMALE

ANNO DI COSTRUZIONE / PED CATEGORIA

MANIFACTURE YEA R/ PED CATEGORY

JAHR VON KONSTRUCT

/ PED KATEGORIE

ANNè DE FABBRICA / CATèGORIE PED

CARICA REFRIGERANTE

REFRIGERANT CHARGE

KALTEMITTEL

CHARGE FRIGORIGèNE

PESO OPERATIVO

OPERATING WEIGHT

POIDS OPERATION.

ARBEITSGEWICHT

GAS REFRIGERAN

REFRIGERANT

RèFRIGèRANT

KALTEMITTEL

Bar

° C

° C

° C

° C

Bar

PRESSIONE DI PROGETTO

DESING PRESSURE

PRESSION DE PROJET

DRUCK DES PROJEKTES

PRESSIONE DI PROGETTO PS

DESING PRESSURE PS

PRESSION DE PROJET PS

DRUCK DES PROJEKTES PS

TEMP.MIN PROGETTO

MINI DESING TEMPERATURE

KLEINSTE TEMP.DES PRDJEKTES

TEMP.MOINORE DE PROJET

TEMP.MIN PROGETTO

MINI DESING TEMPERATURE

KLEINSTE TEMP.DES PRDJEKTES

TEMP.MOINORE DE PROJET

MAX TEMPERATURA PROGETTO

MAX DESING TEMPERATURE

MAXIMALE TEMP.DES PRDJEKTES

MAXIMUN TEMP DE PROJET

MAX TEMPERATURAPROGETTO

MAX DESING TEMPERATURE

MAXIMALE TEMP.DES PRDJEKTES

MAXIMUN TEMP DE PROJET

+ 50

- 30

29,5

- 10

+120 GAS

+ 65 LIQU

A

Kg.

kW

2018

CO2

Ton

Kg.

C1

C1

C2

C2

ASSORBIMENTO ELETTRICO

NOMINALE

PUISSANCE èLECTRIQUE3

NOMINALE

NOMINAL ABSORBED POWER

NOMINALE LEISTUNGSAUFNAHME

- "apparecchiatura che contiene gas uorurati ad eetto serra

disciplinati dal protocollo di Kyoto"

- "equipment that contains uorinated greenhouse gases

covered by the Kyoto protocol"

- "équipement qui contient des gaz uorés à eet de serre

couverts per le protocole de Kyoto"

- "Maschine die enthait uorierte Treibhausgase en thalt

durch das Kyoto-protokoll fallen"

CORRENTE CORTO CIRCUITO

SHORT CIRCUIT CURRENT

COURANT COURT-CIRCUIT

STROM KURZSCHLUSS

10 kA

LATO BASSA PRESSIONE / LOW PRESSURE SIDE

CIRCUIT BASSE PRESSION / NIEDERDRUCKSEITE

LATO ALTA PRESSIONE / HIGH PRESSURE SIDE

CIRCUIT HAUTE PRESSION / HOCHDRUCKSEITE

TARATURA

ORGANO SICUREZZA

SETTING OF SAFETY

DEVISE

MISE AU POINT DISPOSITIF

DE SECURITè

EINSTELLWERT

SICHERHEITSELEMENT

Bar

P

R

E

DRUCK

D

E

T

T

E

M

P

R

OG

E

TT

O

M

I

N

I

D

S

I

N

G

T

E

M

PE

R

A

T

A

A

UR

E

K

L

E

I

N

S

T

E

T

E

M

P

.

D

K

T

K

K

E

S

T

E

M

P

.

M

O

I

N

O

R

M

P

E

R

A

T

AA

N

G

R

OG

E

TT

O

29

,

5

P

R

ES

S

I

O

SE

P

R

ES

L

C

S

T

R

O

T

O

E

L

E

TT

R

I

C

L

E

C

T

R

I

Q

U

E

3

N

O

M

B

E

D

P

O

W

E

R

N

O

M

I

N

A

L

E

G

S

A

U

F

N

H

M

E

O

RR

E

N

T

E

C

O

R

T

O

C

I

RC

U

I

T

O

R

T

C

I

R

C

U

I

T

CURR

E

N

T

T

C

O

U

R

T

-

T

T

C

I

T

Z

S

C

H

L

U

S

S

W

1

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

THE PLATE HAS NOT TO BE MOVED FROM THE ORIGINALLY POSITION

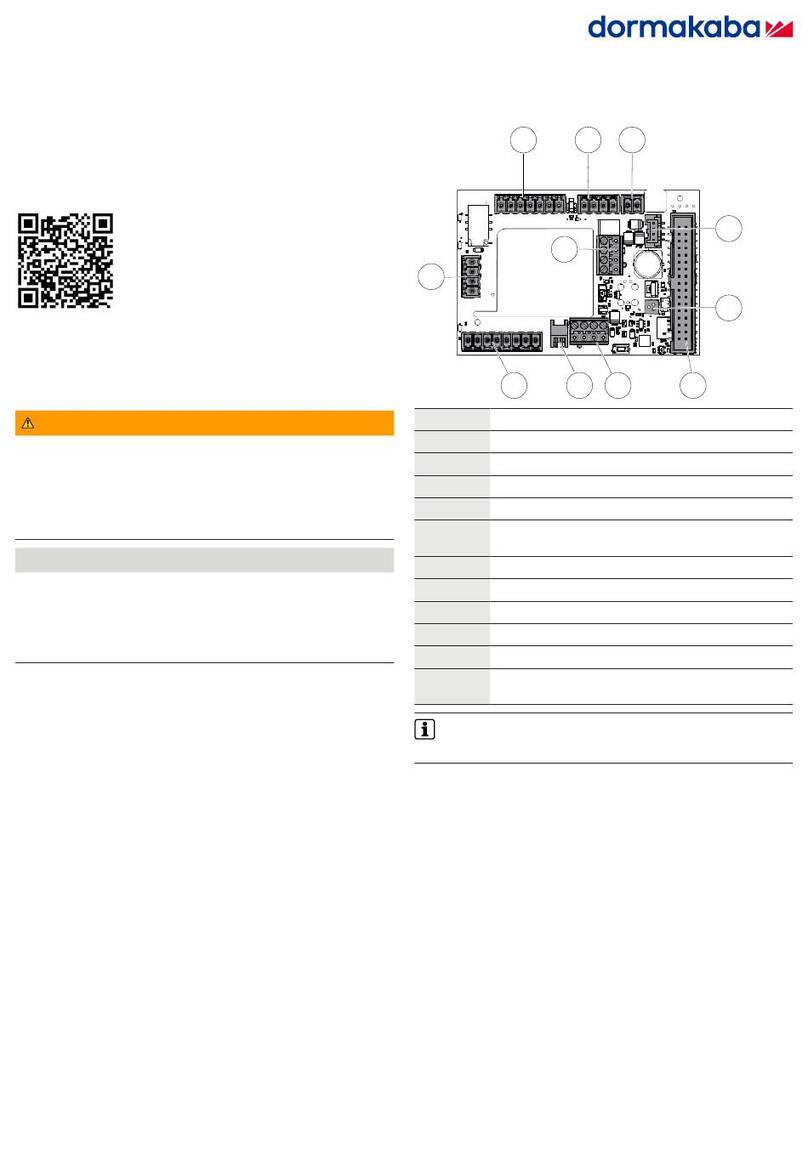

Every unit has a plate which contains it’s main information. The plate data could be different from the technical Manual because in the

Manual are mentioned the standard unit data without any accessory.

On the Serial number plate is also mentioned the refrigerant charge.

For the non mentioned electrical information refers to the Wiring diagram attached to the present Manual.

Following a FAC-SIMILE of the plate.

8QLWLGHQWLÀFDWLRQ

Rev. 3 02-2021

10

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

)RUDQ\LQIRUPDWLRQDERXWUHIULJHUDQWRURLOFKDUDFWHULVWLFVSOHDVHUHIHUVWR6DIHW\6FKHGHZKLFKLVSRVVLEOHWR¿QG

to their Producers.

$GYLVHDERXWWR[LFVXEVWDQFHVSRWHQWLDOO\GDQJHURXV

8VHGRLOLGHQWLÀFDWLRQ

2. SAFETY

The oil used into the unit cooling circuit is polyester type. Anyway refers always to the compressor’s plate.

(19,5210(17'()(1&(Read carefully the following ecological information and instructions.

3HUVLVWHQFHDQGGHJUDGDWLRQ

(IIHFWVRQHIÁXHQWVWUHDWPHQW

,QGLYLGXDOH[SRVLQJDQGSURWHFWLRQFRQWURO

3URIHVVLRQDOOLPLWHVSRVLQJ

)LUVW$,'DQGLQMXULHVSUHYHQWLRQ

7KHFRROLQJÀXLGVXVHGGHFRPSRVHDWWKHLQIHULRUDWPRVSKHUHWURSRVSKHUHUHODWLYHO\TXLFNO\GHFRPSRVHGWKH\DUHKLJKO\GLVSHUVLEOHVR

WKHFRQFHQWUDWLRQZLOOEHUHDOO\ORZ7KH\GRQ¶WLQÀXHQFHWKHSKRWRFKHPLFDOVPRJDQGDUHQRWLQFOXGHGLQYRODWLOHRUJDQLFFRPSRXQGV92&

(UNECE agreement).

Used refrigerants don’t damage the ozone layer, there are regulated by the Montreal protocol (1992 release) and the CE 2037/200 of

29/06/2000 regulation.

The release into the atmosphere of these products do not cause lon-term water contamination

Is suggested to use clothes and protective gloves; is reccomended to always protect face and eyes.

0DLQHFRORJLFDOLQIRUPDWLRQDERXWFRROLQJÀXLGVXVHG

7KHXVHUVDQGPDLQWHQDQFHWHFKQLFLDQVKDVWREHZHOOLQIRUPHGDERXWULVNVRIWR[LFSRWHQWLDOO\ÀXLGV)DLOXUHWR

observe the mentioned indications could cause damages to people or to unit.

8VHGÁXLGLGHQWLÀFDWLRQ5$

• 'LÀXRURPHWKDQ+)&ZHLJKW&$61R

• 3HQWDÀXRURHWKDQ+)&ZHLJKW&$61R

R410A

HFC-32 TWA 1000 ppm

HFC-125 TWA 1000 ppm

Rev. 3 02-2021

11

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

+LJKTXDQWLW\VWHDPLQKDODWLRQ

$FFLGHQWDOUHIULJHUDQWOHDNSURFHGXUHV

7R[LFLQIRUPDWLRQDERXWWKHUHÀUJHUDQWÁXLGXVHG

,QKDODWLRQ

A great atmospheric concentration can cause anesthetic effects combined with loss of consciousness. Long expositions can cause abnor-

mal heart rhytm and even sudden death.

More elevate concentrations can cause asphyxia for reduced oxygen content in the air.

6NLQFRQWDFW

Splashes of sprayed refrigerant can cause frost burns. It is unlikely tobe dangerous due to skin absorption; Prolonged and repeated contact

may cause removal of skin fat, dryness and dermatitis.

(\HVFRQWDFW

Splashes of sprayed refrgerant can cause frost burns.

,QJHVWLRQ

Highly unlikely but can cause frost burns.

The atmospheric refrigerant concentration has to be minimum reduced (lower then overmentioned professional exposition limit). Be infor-

med that the steam is havier then air so high concentrations can stay near the ground, where the general ventilation is low, is suggested to

ensure an adequate ventilation in order to avoid it.

$YRLGFRQWDFWZLWKIUHHÀDPHVDQGKRWVXUIDFHVEHFDXVHWR[LFDQGLUULWDWLQJGHFRPSRVLWLRQSURGXFWVFDQEHIRUPHG

Avoid contact between the liquid and the skin or the eyes.

During the cleaning operation be sure to have the adequate safety protection (using respiratory breatheways protections)

,IWKHFRQGLWLRQVDUHVXI¿FLHQWO\VDIHLVRODWHWKHOHDNVRXUFHLIWKHOHDNLVOLPLWHGOHDYHWKHHYDSRUDWLRQUHIULJHUDQWIUHHHQVXULQJDJRRG

ventilation.

Otherwise if the leak is large ensure a good ventilation, contain spilled material with sand, earth or other suitable absorbent material; prevent

that the refrigerant enter into drains, sewers, basements or work holes in order to avoid suffocating vapors formation.

)LUVW$,'PHDVXUHV

,QKDODWLRQ

6NLQFRQWDFW

5HPRYHLQMXULHGSHUVRQIURPWKHVRXUFHRIH[SRVXUHNHHSKLPZDUPDQGDWUHVW,IQHFHVVDU\DGPLQLVWHUVRPHR[\JHQSUDFWLFHDUWL¿FLDO

respiration if breathing has stopped or any signs of stopping occurs.

If there is cardiac arrest perform cardiac massage; request medical assistance

In case of skin contact wash immediately with warm water; if necessary thaw the epidermal tissue with water. Remove contaminated

clothing which can stick to skin in case of frost burns. If there is irritation or blistering, request medical assistance.

)ROORZVWULFWO\WKHIROORZLQJDGYLVHVDQGWKH¿UVW$,'SURFHGXUHV

(\HVFRQWDFW

Wash immediately with eye washing solution or with clean water, keep eyelids open for at least two minutes; request medical assistance.

,QJHVWLRQ

Do not induce vomiting, if the injured person is conscious rinse mouth with water and allow 200-300 ml of water to be drunk; request medical

assistance.

)XUWKHUPHGLFDOWUHDWPHQW

Symptomatic treatment and supportive therapy as indicated; do not administer adrenaline and sympathomimetic drugs as a result of expo-

sure, due to the risk of cardiac arrhythmia.

Rev. 3 02-2021

12

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

3. TECHNICAL CHARACTERISTICS

8QLWGHVFULSWLRQ

Close control unit are designed and produced in compliance with 9001:2015 ISO norms for technological plants of conditioning, data center,

for UPS and all the ambients where are needed special conditions and a strictly control.

The units are suitable for internal installation. The units are built with the most advanced industry technology, including variable speed

compressors equipped with brushless permanent magnets (BLDC) and fans with electronic commutated motor (EC).

BLDC compressors are driven by an inverter with 0-10V signal sent by the controller; they are able to vary the load continuously and the

FRROLQJFLUFXLWUHJXODWLRQHDVLO\¿WVWRRSHUDWLQJFRQGLWLRQVUHTXLUHG(&FHQWULIXJDOIDQVDOORZWKHFRQWLQXHVSHHGUHJXODWLRQXVLQDDQDQDOR-

gic 0-10V signal sent from the controller; thanks to technology used the fans ensure reduced absorption compared to traditional centrifugal

IDQVDOORZWRDGMXVWWKHDLUÀRZWRWKHV\VWHPUHTXLUHGSUHYDOHQFH

(PLE\WHSUHVHQWVWKHIROORZLQJGLUHFWH[SDQVLRQFRQ¿JXUDWLRQV

8SFRQ¿JXUDWLRQ8VXFWLRQDLUIURPWKHIURQWDQGGLVFKDUJHWRWKHWRSRIWKHXQLW

9HUWLFDOFRQ¿JXUDWLRQ9VXFWLRQDLUIURPWKHERWWRPDQGGLVFKDUJHWRWKHWRSRIWKHXQLW

'RZQFRQ¿JXUDWLRQ'VXFWLRQDLUIURPWKHWRSDQGGLVFKDUJHWRWKHERWWRPRIWKHXQLW

%RWWRPFRQ¿JXUDWLRQ%VXFWLRQDLUIURPWKHEDFNDQGGLVFKDUJHWRWKHWRSRIWKHXQLW

7KLVGLYHUVL¿FDWLRQFDQVDWLVI\DOPRVWHYHU\FXVWRPHU¶VUHTXHVWIURPPDQDJHPHQWSRLQWRIYLHZDQGWKHDLUÀRZUDWH

%/'&VFUROORUURWDU\KHUPHWLFFRPSUHVVRUW\SH

All the models are provided with a BLDC hermetic compressor (with brushless permanents magnets motor) rotary or scroll type, suitable

for functioning with R410a refrigerant.

Each compressor is installed on a rubber-type vibration dampers and are equipped with:

• Oil carter, where the crankcase heater is installed (only Scroll);

• Thermistor included protection for the overloads;

• Polyester oil charge.

The compressor’s terminal board has IP54 protection. Starts and stops of compressors are directly managed by the unit controller which in

this way modulates the cooling capacity. For rotary type compressors an equalization pressure valve is provided.

)UDPH

The modular structure of this equipment is made up of press-formed section in galvanized sheet elements painted with a RAL 9004 epoxy

powder cycle. The elements are assembled together to make up a sturdy frame, capable of supporting units parts and to sustain strain

which may derive from unit handling and operation. The devices are arranged inside the frame in a way that they are easy to reach from

the front, to make necessary handling during unit operation and easier and more safety maintenance.

(&5DGLDOIDQV

7KHXQLWVDUHVXSSOLHGZLWKEDFNZDUGFXUYHGEODGHVUDGLDOIDQVLQFRPSRVLWHPDWHULDOHTXLSSHGZLWKKLJKHI¿FLHQF\EUXVKOHVV(&PRWRU

The electric motor is suitable to be used at a variable rotation speed managed usign the controller with 0-10V signal. The blades, with a

EDFNZDUGSUR¿OHVSHFL¿FDOO\GHVLJQHGWRPD[LPL]HWKHHI¿FLHQF\DQGUHGXFHVRXQGHPLVVLRQDUHGLUHFWO\FRXSOHGZLWKWKHHOHFWURQLFDOO\

commutated motor equipped with internal thermal protection.

For further details on controlling the EC fans (rate calibration and static counter-pressure) please refer to the Microprocessor’s Manual.

'LUHFWH[SDQVLRQFRLOZLWKK\GURÀOLFWUHDWPHQW

7KHFRROLQJFRLOKDVEHHQGHVLJQHGZLWKDJUHDWIURQWVXUIDFHLQRUGHUWRKDYHDQKLJK6+56HQVLEOH+HDW5DWLRDQGDORZDLUÀRZVSHHG

LQRUGHUWRDYRLGWKHFRQGHQVDWHWRGHWDFKWRUHGXFHDLUSUHVVXUHGURSDQGWRJXDUDQWHHDQKLJKHUHI¿FLHQF\RIWKHKHDWH[FKDQJHERWK

GXULQJWKHFRROLQJDQGWKHGHKXPLGL¿FDWLRQSURFHVV7KHFRLOLVPDGHXSRIFRSSHUWXEHVPHFKDQLFDOO\H[SDQGHGRQK\GURSKLOLFWUHDWHG

DOXPLQLXP¿QVWUHDWPHQWWKDWDOORZVWRUHGXFHWKHVXUIDFHWHQVLRQEHWZHHQZDWHUDQGPHWDOVXUIDFHSURYLGLQJD¿OPFRQGHQVDWLRQDQG

avoiding the drain of condensate outside the drip tray. The drip tray is made up of painted and galvanized sheet or in peraluman (aluminium

and magnesium alloy). All the coils are factory tested and cleaned before their installation by the Manufacturer.

3.1.5 'LUHFWH[SDQVLRQFRLOZLWKK\GURÀOLFWUHDWPHQW2QO\';L+)

7KHFRROLQJFRLOKDVEHHQGHVLJQHGZLWKDJUHDWIURQWVXUIDFHLQRUGHUWRKDYHDQKLJK6+56HQVLEOH+HDW5DWLRDQGDORZDLUÀRZVSHHG

LQRUGHUWRDYRLGWKHFRQGHQVDWHWRGHWDFKWRUHGXFHDLUSUHVVXUHGURSDQGWRJXDUDQWHHDQKLJKHUHI¿FLHQF\RIWKHKHDWH[FKDQJHERWK

GXULQJWKHFRROLQJDQGWKHGHKXPLGL¿FDWLRQSURFHVV

7KHFRLOLVPDGHXSRIFRSSHUWXEHVPHFKDQLFDOO\H[SDQGHGRQK\GURSKLOLFWUHDWHGDOXPLQLXP¿QVWUHDWPHQWWKDWDOORZVWRUHGXFHWKH

VXUIDFHWHQVLRQEHWZHHQZDWHUDQGPHWDOVXUIDFHSURYLGLQJD¿OPFRQGHQVDWLRQDQGDYRLGLQJWKHGUDLQRIFRQGHQVDWHRXWVLGHWKHGULSWUD\

The drip tray is made up of painted and galvanized sheet or in peraluman (aluminium and magnesium alloy).

All the coils are factory tested and cleaned before their installation by the Manufacturer.

Rev. 3 02-2021

13

DXi.H/DXi.HF - 39 - 0 - U

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

,QGLUHFW:DWHUEDVHG)UHHFRROLQJ

Thanks to the double coil (Freecooling water and Direct Expansion) the unit provides the highest saving match with full availability of the

DX solution.

The usage of Free cooling coil and the BLDC Inverter compressor allows maximizing the saving in mixed mode operation, so whenever the

freecooling is not able to fully take the load the compressors can work just to complete the missing cooling needs.

Therefore Emicon DXI-HF can provide extremely high energy saving granting the highest availability of the application.

(OHFWULFDOERDUG

The unit electrical board is in compliance with the European regulations in force and has been realised inside a metal compartment:

The main characteristics are the following:

• Three phase power supply 400/3/50+N+PE on all units, unless different special requests are demanded;

• Auxiliary circuit in low voltage 24Vac with isolation transformer;

• Main switch (mechanical interlock is an optional);

• Terminal board for signal and control free contacts;

In this compartment, which axcess is allowed by a main switch, contains moreover the following main devices:

• Contactors;

• Transformers;

• Numbered conducers;

• Low tension auxiliary circuits;

• Terminal boards;

• Electronic cards to manage and control.

All units undergo a safety cycle with continuity test on protection conductors, insulation resistance and wihtstanding test. The unit control is

managed by controller program installed on the Microprocessor onboard.

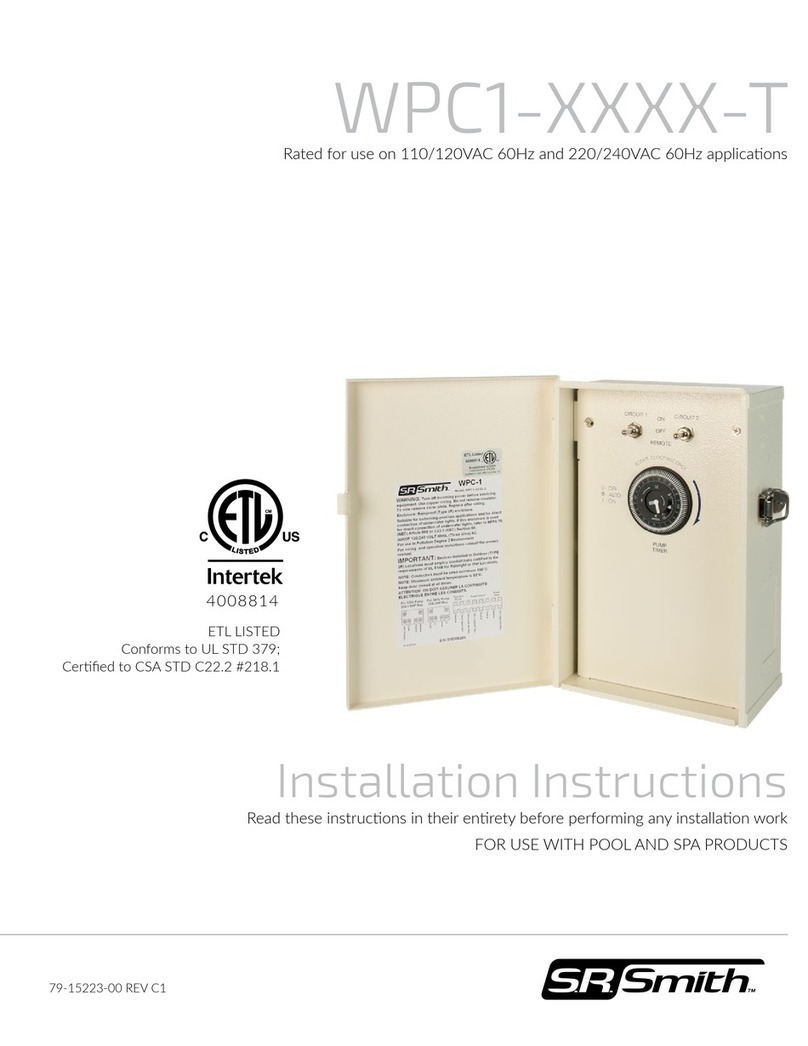

3.1.7 3ODWH+HDW([FKDQJHU

The plate heat exchangers are brazed plate type, asymmetrical channels, and made of AISI 316 stainless steel.

The use of this type of exchangers reduces the refrigerant gas charge of the unit in comparison with standard models, allowing a reduced

SUHVVXUHGURSDWZDWHUVLGHDQGKLJKFRHI¿FLHQWRIKHDWH[FKDQJH$OO(PLE\WHKHDWH[FKDQJHUVDUHIDFWRU\LQVXODWHGXVLQJFORVHGFHOO

material.

&RQWUROOHU

The unit manage electronic controller is installed in the electrical board and it has the cooling capacity regulation control through the air

temperature measure (evaporator inlet-outlet double check), operation parameters check, equalizer and hour counte (options), troublesho-

oting autodiagnosys, alarm log memorization, switch on time and set point value programming, remote control of the unit using the standard

communication protocols installed in the Microprocessor.

)UHTXHQFHFRQYHUWHULQYHUWHU

All the models are provided with an inverter able to manage the compressors with permanent brushless magnets BLDC.

7KHLQYHUWHUZROORZVWKH&(QRUPDQGLVHTXLSSHGZLWKLQWHJUDWHG(0&¿OWHU&FRQWUROSDQHODQGFRROLQJIDQ

7HVWV

Once the uniti s complete, the cooling circuiti s completely tested (following the Manufacturer Warraty procedures) to a pressure and leak

WHVWWR¿QGDQ\ORVVHV

Before the delivery the unit is subjects to a complete functional test.

';L+DQG';L+)QRPHQFODWXUH

Following is shown the unit name meanings:

Air direction:

89% 7RSDLUÀRZ

' 'RZQDLUÀRZ

Unit size

N° cooling circuits

DXi.H= inverter compressor

DXi.HF= inverter compressor

free-cooling coil

Rev. 3 02-2021

14

DXi.H/DXi.HF - V

DXi.H/DXi.HF - D

DXi.H/DXi.HF - U

DXi.H/DXi.HF - B

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

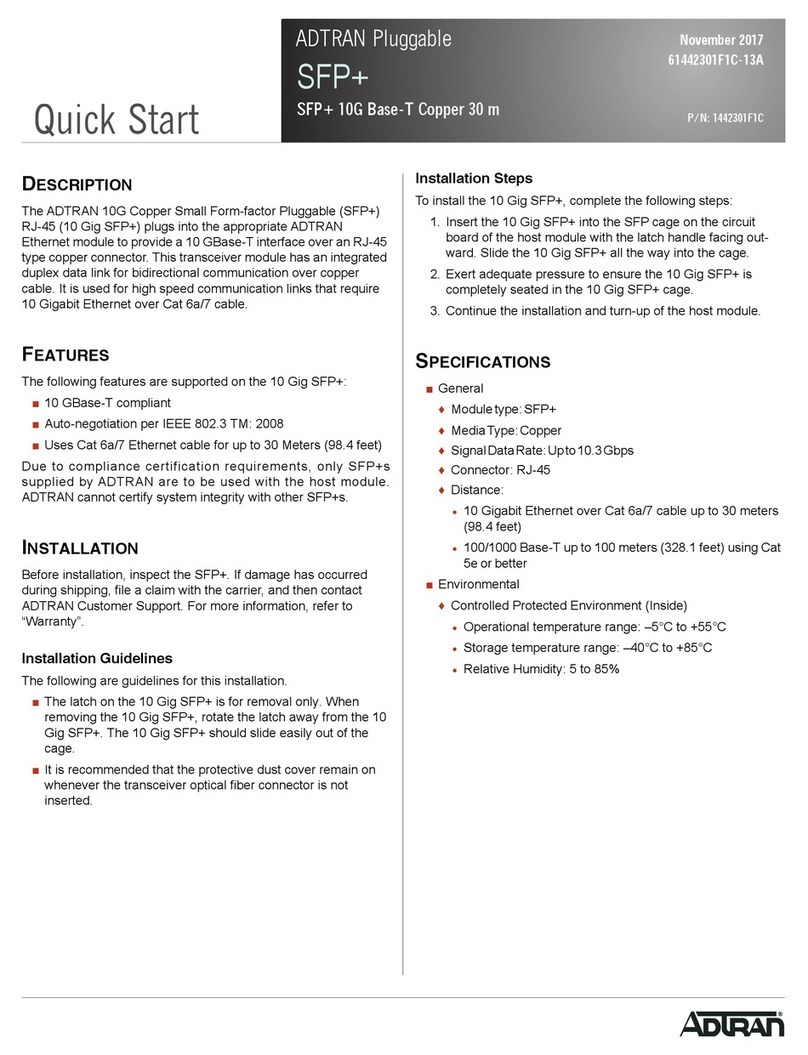

&RQÀJXUDWLRQV

Front suction

Up discharge

Down suction

Up discharge

Up suction

Down discharge

Discharge

Suction

Suction

Suction

Discharge

Discharge

Behind suction

Up discharge

Discharge

Suction

Rev. 3 02-2021

15

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

$FFHVVRULHVGHVFULSWLRQ

AA )ORRGLQJDODUP Water sensible probe, is already wired by Manufacturer. This option has to be installed under the unit by the

unit installation technicians.

AE (OHFWULFDOSRZHUVXSSO\GLIIHUHQWIURPVWDQGDUGManily, 230V three phase, 460V three phase, with 50/60Hz of frequency.

AL 6PRNHDODUPSmoke sensible probe installed inside of the unit which activate an alarm in case of smoke presence which stops

the fans and compressors.

B%DVHPHQWSuitable for installation on raised floors, it can be regulate from 170mm to 600mm. It is provided with adjustable

feets.

BAS

%DVHIUDPHIRUODWHUDOFRQQHFWLRQV

BC +RWZDWHUFRLOOne or two-row water coil, placed after the cooling coil to re-heating and/or the heating of treated air; provided

with modulating actuator and with three-way valve and controlled by the on board microprocessor. This option has the priority

when requested with the electric heaters (RE option).

BG

+RWJDVFRLOOne pr two-row water coil, placed after the cooling coil to re-heating of treated air; provided with three-way valve

(ON/OFF type) and controlled by the onboard microprocessor.

DH 'HKXPLGLILFDWLRQFRQWUROV\VWHPComposed by a humidity probe.

DP 'RXEOHSDQHOVInternal panels for closing the compartments affected by the air flow made with profiles in galvanized pre-

painted sheet steel, which allow the reduction of the noise transmitted through the paneling and a better air tightness even

without external panels; it allows the unit operation also during maintenance operations with the panels removed, such as filter

replacement.

(30

EPM7

$LUILOWHURSWLRQV)ODWHIILFHQF\ILOWHUVH30DQGH30VXSSOLHGDVDQRSWLRQDVDQDOWHUQDWLYHWRVWDQGDUGVRQHV

FR

6SDUHILOWHUVNLW&2$56(in alternative to to standard ones.

FRM6

6SDUHÀOWHUVNLWH30

FRM7

6SDUH¿OWHUVNLWH30

H

+XPLGLILHU: Immerse-electrode type for the modulating production of steam; it is made of a steam cylinder, a steam distributor, water

inlet and outlet valves and a maximum water level probe. The onboard microprocessor indicates when the steam cylinder needs to

be replaced in order to be able to make a maintenance during the unit operation.

IE

)XPLJDWHGZRRGHQFUDWHSDFNLQJAvailable on request for critical transports in order to assure a protection to the unit.

IH 563URWRFROVHULDOLQWHUIDFHAllows the communication between the unit and an external supervision system (the external

supervision system and the communication software are not provided with the unit; please contact the Manufacturer in order to

have more info about the available communication protocols).

IH-BAC

%$&1(73URWRFRO6HULDO,QWHUIDFHGateway to be connected to the microprocessor to allow the connection between the unit

and an external supervision system with BACNET protocol, for a remote control and monitoring of the unit. (Alternative to IH,

IH LON and IWG).

IH-LON

/213URWRFROVHULDOLQWHUIDFHGateway to be connected to the microprocessor to allow the connection between the unit and

an external supervision system with LON protocol, for a remote control and monitoring of the unit. (Alternative to IH, IH BAC

and IWG).

IM 6HDZRRGSDFNLQJFumigated seawood case and protection bag with hygroscopic salts, suitable for long sea transports.

IP 0DJQHWRWKHUPLFVZLWFKHVIRUDX[LOLDU\FLUFXLWVInstalled instead of fuses for auxiliary circuits protection.

IS1 &ODVVLQVXODWLRQPDWHULDOIn conformity to the main European regulations in force.

IWG

6103R7&3,33URWRFROVHULDOLQWHUIDFHElectronic card to be connected to the microprocessor to allow the connection

between the unit and an external supervision system with SNMP or TCP/IP protocol, for a remote control and monitoring of the

unit. (Alternative to IH, IH BAC and IH LON).

MF 3KDVHPRQLWRUElectronic device controlling the correct sequence and/or the eventual lack of one ot the three phases switching

off the unit if necessary.

MN

1HXWUDOZLUHODFNIRUSRZHUVXSSO\Unit general power supply without neutral wire; for IT power supplies the

Manufacturer has to release, after a check, the connection authorization.

Rev. 3 02-2021

16

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

MP $GYDQFHGPLFURSURFHVVRUFDUG Contained the Ethernet gateway and Master&Slave

PB

&RQGHQVDWLRQZDWHUSXPSVMicro pump discharging the condensing water produced by the unit provided totally installed.

PBH

+XPLGLÀHUDQGFRQGHQDWVLRQZDWHUSXPSMicro pump discharging the condensing water produced by the unit coupled with a

KXPLGL¿HUSURYLGHGLQDNLWIRURXWGRRULQVWDOODWLRQ

PL 'LVWULEXWLRQSOHQXP3URYLGHGZLWKDIURQWDOJULGDQGDGRXEOHUDZRIDGMXVWDEOH¿QVIRUDEHWWHUDLUGLVWULEXWLRQ2QO\IRU:8

series, U and V version).

PQ 5HPRWHGLVSOD\Remote terminal which allows to display the temperature and humidity values detected by probes, the alarm

digital inputs, the outputs and the remote ON/OFF of the unit, to change the program of the parameters, the sound signals and the

display of the present alarms.

PR )UHVKDLULQOHW([WHUQDOIUHVKDLULQOHWZLWKDÀDW¿OWHUSODFHGRQXQLWVLGHZLWKFLUFXODUFRQQHFWLRQ

RE (OHFWULFDOKHDWHUVMade of aluminium and installed after the cooling coil, suitable for re-heating and/or heating of the treated

DLULQRUGHUWRFRPSHQVDWHIRUWKHVHQVLWLYHFRROLQJRIWKHV\VWHPGXULQJWKHGHKXPLGL¿FDWLRQF\FOH7KHKHDWLQJFDSDFLW\LVVSOLW

on 3 steps max, so to reduce the energy consumptions. The heaters are managed by the onboard microprocessor meanwhile the

electric protections managed by a magnetothermic switch.

REM 2YHUVL]HGHOHFWULFDOKHDWHUV

RV 3HUVRQDOL]HGIUDPHSDLQWLQJLQ5$/FRORU

SEP 6HWSRLQWFRPSHQVDWLRQFDUGPD[PWComposed by probes allows the set-point set according to the external air temperature

STP $LUÁRZVWDELOLVDWLRQ

TS 7RXFKVFUHHQJUDSKLFGLVSOD\The new settable EMIBYTE electronic display allows to develope simples and appeal interfaces

IRUWKH¿QDOXVHUVWKHWRXFKVFUHHQGLVSDO\UDQJHFDQFRPELQHGLIIHUHQWFRORUVDQGOHYHOVRIWUDQVSDUHQF\XVLQJ$OSKD%OHQGLQJ

technology.

VCP 9&3ZD\FRQGHQVLQJSUHVVXUHFRQWUROJDVYDOYHDVDQDOWHUQDWLYHWRWKH93LWLV¿WWHGDWWKHRXWOHWRISODWHKHDWH[FKDQJHU

on gas line.

VP 93ZD\FRQGHQVLQJSUHVVXUHFRQWUROZDWHUYDOYHDVDQDOWHUQDWLYHWRWKH9&3LWLV¿WWHGDWWKHRXWOHWRISODWHKHDWH[FKDQJHU

DQGUHJXODWHVWKHZDWHUÀRZLQDFFRUGDQFHZLWKXQLWFRQGHQVLQJSUHVVXUHWKHYDOYHLVVXSSOLHGDVVSDUHNLWDORQJZLWKXQLW

Rev. 3 02-2021

17

DXi.H 61 111 121 151 181 201 251 321

kW 7,7 10,5 12,1 17,7 20,2 21,7 25,9 35,1

kW 7,7 9,5 11,8 15,4 18,5 21,7 24,8 31,6

kW 2,1 3,0 3,2 4,5 4,7 4,8 6,4 7,6

1,00 0,91 0,97 0,88 0,91 1,00 0,96 0,90

m3/h 1,7 2,3 2,6 3,8 4,3 4,6 5,6 7,3

kPa 46 35 45 45 33 37 29 27

m3/h 3900 3900 3900 3900 5700 5700 8150 8150

n11111111

Pa 535 536 512 439 622 575 399 358

W/W 4,0 3,8 4,1 4,2 4,7 4,9 4,4 5,0

kW 4 6 6 9 11 11 12 15

A14 18 18 16 21 21 21 24

A44447766

V/ph/Hz

400/3/50+N+PE

kg/h 33335588

kg/h 33338888

kW 2,25 2,25 2,25 2,25 3,75 3,75 6,0 6,0

A10,0 10,0 10,0 10,0 5,5 5,5 8,7 8,7

ȝ6FP 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250

mg/l CaCO3100/400 100/400 100/400 100/400 100/400 100/400 100/400 100/400

n° 33332233

kW 4,5 4,5 4,5 4,5 6,0 6,0 9,0 9,0

A6,5 6,5 6,5 6,5 8,7 8,7 13,0 13,0

n° 22223333

kW 6,0 6,0 6,0 6,0 9,0 9,0 12,0 12,0

A8,7 8,7 8,7 8,7 13,0 13,0 17,3 17,3

kW 7,3 7,3 7,3 7,3 10,6 10,6 16,7 16,7

m3/h 1,3 1,3 1,3 1,3 1,8 1,8 2,9 2,91

kPa 31 31 31 31 48 48 56 56

dm31,4 1,4 1,4 1,4 2,1 2,1 3,3 3,3

l/h 390,0 390,0 390,0 390,0 390,0 390,0 390,0 390,0

l/h 500 500 500 500 500 500 500 500

m5,4 5,4 5,4 5,4 5,4 5,4 5,4 5,4

l/h ------600600

l/h ------900900

m------6,06,0

n° 22223344

mm 750 750 750 750 980 980 1160 1160

mm 550 550 550 550 750 750 850 850

mm 1980 1980 1980 1980 1980 1980 1980 1980

Kg 201 209 212 223 289 297 339 372

Kg 204 212 215 226 293 301 343 376

Kg 205 213 217 228 295 303 345 379

Kg 204 212 215 226 293 301 343 376

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

';L+VHULHVWHFKQLFDOGDWD

Cooling capacity (Total) (1) ESP 20 Pa

Cooling cpacity (Sensible) (1) ESP 20 Pa

Tot. absorbed power (2) ESP 20 Pa

SHR

:DWHUÀRZ

Pressure drop

$LUÀRZ

Fan

Max. ESP

EER

Maximum absorbed power

Maximum absorbed current

starting current

Power supply

+XPLGLÀHU

Steam production (nominal)

Steam production (max.)

Max. absorbed power

Max. absorbed current

6SHFL¿FFRQGXFLELOLW\DW&PLQPD[

Total hardness (min/max)

(OHFWULFDOKHDWHUV

Steps

Power

Absorbed current

2YHUVL]HGHOHFWULFDOKHDWHUV

Steps

Power

Absorbed current

+RWZDWHUFRLO

Heating capacity (3)

:DWHUÀRZ

Pressure drop (coil + 3 way valve)

Coil internal volume

&RQGHQVLQJZDWHUSXPS

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

&RQGHQVLQJZDWHUSXPSKXPLGLÀHU

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

'LPHQVLRQVDQGZHLJKW

Frame

Width

Depth

Height

:HLJKW&RQ¿JXUDWLRQ8

:HLJKW&RQ¿JXUDWLRQ9

:HLJKW&RQ¿JXUDWLRQ'

:HLJKW&RQ¿JXUDWLRQ%

Performances are referred to the following conditions:

$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\:DWHUWHPSHUDWXUH&

(2) The fans electrical power has to be added to the ambient load.

:DWHUWHPSHUDWXUH&$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\

Rev. 3 02-2021

18

DXi.H 381 392 472 491 531 532 631 652

kW 36,4 39,4 48,0 50,9 55,0 53,7 68,1 70,6

kW 37,5 35,0 40,7 45,4 53,4 52,8 65,3 66,2

kW 8,0 8,0 11,0 11,8 12,2 13,0 14,6 15,5

1,00 0,89 0,85 0,89 0,97 0,98 0,96 0,94

m3/h 7,6 8,2 10,1 10,8 11,6 11,5 14,2 14,8

kPa 21 7 103337122810

m3/h 11500 11500 11500 11500 14500 14500 17600 17600

n11112222

Pa 344 399 370 323 389 360 390 361

W/W 4,9 5,4 4,7 4,7 4,9 4,5 5,0 4,9

kW 16 19 21 23 24 23 28 31

A26 38 40 34 37 42 47 48

A8 24 25 8 10 27 156 30

V/ph/Hz

400/3/50+N+PE

kg/h 88888888

kg/h 88888888

kW 6,0 6,0 6,0 6,0 6,0 6,0 6,0 6,0

A8,7 8,7 8,7 8,7 8,7 8,7 8,7 8,7

ȝ6FP 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250

mg/l CaCO3100/400 100/400 100/400 100/400 100/400 100/400 100/400 100/400

n° 33333333

kW 9,0 9,0 9,0 9,0 15,0 15,0 18,0 18,0

A13,0 13,0 13,0 13,0 21,7 21,7 26,0 26,0

n° 33333333

kW 12,0 12,0 12,0 12,0 18,0 18,0 24,0 24,0

A17,3 17,3 17,3 17,3 26,0 26,0 34,6 34,6

kW 24,5 24,5 24,5 24,5 31,1 31,1 37,4 37,4

m3/h 4,3 4,3 4,3 4,3 5,43 5,43 6,5 6,5

kPa 46 46 46 46 53 53 34 34

dm34,7 4,7 4,7 4,7 5,8 5,8 7,1 7,1

l/h 390,0 390,0 390,0 390,0 390,0 390,0 390,0 390,0

l/h 500 500 500 500 500 500 500 500

m5,4 5,4 5,4 5,4 5,4 5,4 5,4 5,4

l/h 600 600 600 600 600 600 600 600

l/h 900 900 900 900 900 900 900 900

m6,0 6,0 6,0 6,0 6,0 6,0 6,0 6,0

n° 4,5 4,5 4,5 4,5 5 5 6 6

mm 1505 1505 1505 1505 1860 1860 2210 2210

mm 850 850 850 850 850 850 850 850

mm 1980 1980 1980 1980 1980 1980 1980 1980

Kg 428 456 458 435 525 548 627 652

Kg 433 462 464 440 531 554 634 660

Kg 436 465 466 443 535 558 638 663

Kg 433 462 464 440 531 554 634 660

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

Performances are referred to the following conditions:

$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\:DWHUWHPSHUDWXUH&

(2) The fans electrical power has to be added to the ambient load.

:DWHUWHPSHUDWXUH&$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\

Cooling capacity (Total) (1) ESP 20 Pa

Cooling cpacity (Sensible) (1) ESP 20 Pa

Tot. absorbed power (2) ESP 20 Pa

SHR

:DWHUÀRZ

Pressure drop

$LUÀRZ

Fan

Max. ESP

EER

Maximum absorbed power

Maximum absorbed current

starting current

Power supply

+XPLGLÀHU

Steam production (nominal)

Steam production (max.)

Max. absorbed power

Max. absorbed current

6SHFL¿FFRQGXFLELOLW\DW&PLQPD[

Total hardness (min/max)

(OHFWULFDOKHDWHUV

Steps

Power

Absorbed current

2YHUVL]HGHOHFWULFDOKHDWHUV

Steps

Power

Absorbed current

+RWZDWHUFRLO

Heating capacity (3)

:DWHUÀRZ

Pressure drop (coil + 3 way valve)

Coil internal volume

&RQGHQVLQJZDWHUSXPS

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

&RQGHQVLQJZDWHUSXPSKXPLGLÀHU

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

'LPHQVLRQVDQGZHLJKW

Frame

Width

Depth

Height

:HLJKW&RQ¿JXUDWLRQ8

:HLJKW&RQ¿JXUDWLRQ9

:HLJKW&RQ¿JXUDWLRQ'

:HLJKW&RQ¿JXUDWLRQ%

Rev. 3 02-2021

19

DXi.H 691 742 761 861 931 952 1021 1142

kW 72,2 76,4 85,9 87,3 100,3 104,6 107,4 118,9

kW 67,0 75,8 80,1 80,7 96,5 98,0 99,4 104,5

kW 15,7 16,9 18,7 19,9 21,9 23,5 22,9 26,8

0,93 0,99 0,93 0,92 0,96 0,94 0,93 0,88

m3/h 15,1 16,0 18,0 18,4 21,0 22,0 22,4 25,1

kPa 31 11 29 21 26 12 22 15

m3/h 17600 20900 20900 20900 25700 25700 25700 25700

n22223333

Pa 390 365 394 394 414 385 414 386

W/W 5,0 4,9 5,0 4,7 4,9 4,8 5,1 4,8

kW 30 33 36 38 45 49 47 56

A50 51 58 61 76 74 79 93

A167 33 168 179 185 47 219 203

V/ph/Hz

400/3/50+N+PE

kg/h 88888888

kg/h 88888888

kW 6,0 6,0 6,0 6,0 6,0 6,0 6,0 6,0

A8,7 8,7 8,7 8,7 8,7 8,7 8,7 8,7

ȝ6FP 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250

mg/l CaCO3100/400 100/400 100/400 100/400 100/400 100/400 100/400 100/400

n° 33333333

kW 18,0 24,0 24,0 24,0 27,0 27,0 27,0 27,0

A26,0 34,6 34,6 34,6 39,0 39,0 39,0 39,0

n° 33333333

kW 24,0 27,0 27,0 27,0 36,0 36,0 36,0 36,0

A34,6 39,0 39,0 39,0 52,0 52,0 52,0 52,0

kW 37,4 48,9 48,9 48,9 60,8 60,8 60,8 60,8

m3/h 6,5 8,5 8,5 8,5 10,6 10,6 10,6 10,6

kPa 34 48 48 48 42 42 42 42

dm37,1 10,45 10,45 10,45 12,6 12,6 12,6 12,6

l/h 390,0 390,0 390,0 390,0 390,0 390,0 390,0 390,0

l/h 500 500 500 500 500 500 500 500

m5,4 5,4 5,4 5,4 5,4 5,4 5,4 5,4

l/h 600 600 600 600 600 600 600 600

l/h 900 900 900 900 900 900 900 900

m6,0 6,0 6,0 6,0 6,0 6,0 6,0 6,0

n° 67778888

mm 2210 2565 2565 2565 3100 3100 3100 3100

mm 850 850 850 850 850 850 850 850

mm 1980 1980 1980 1980 1980 1980 1980 1980

Kg 627 749 735 739 900 919 904 995

Kg 634 757 743 748 910 929 915 1006

Kg 638 761 747 752 915 934 920 1011

Kg 634 757 743 748 910 929 915 1006

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

Performances are referred to the following conditions:

$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\:DWHUWHPSHUDWXUH&

(2) The fans electrical power has to be added to the ambient load.

:DWHUWHPSHUDWXUH&$PELHQWWHPSHUDWXUH&5HODWLYHKXPLGLW\

Cooling capacity (Total) (1) ESP 20 Pa

Cooling cpacity (Sensible) (1) ESP 20 Pa

Tot. absorbed power (2) ESP 20 Pa

SHR

:DWHUÀRZ

Pressure drop

$LUÀRZ

Fan

Max. ESP

EER

Maximum absorbed power

Maximum absorbed current

starting current

Power supply

+XPLGLÀHU

Steam production (nominal)

Steam production (max.)

Max. absorbed power

Max. absorbed current

6SHFL¿FFRQGXFLELOLW\DW&PLQPD[

Total hardness (min/max)

(OHFWULFDOKHDWHUV

Steps

Power

Absorbed current

2YHUVL]HGHOHFWULFDOKHDWHUV

Steps

Power

Absorbed current

+RWZDWHUFRLO

Heating capacity (3)

:DWHUÀRZ

Pressure drop (coil + 3 way valve)

Coil internal volume

&RQGHQVLQJZDWHUSXPS

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

&RQGHQVLQJZDWHUSXPSKXPLGLÀHU

1RPLQDOÀRZ

0D[ÀRZSUHYDOHQFH P

0D[GLVFKDUJHKHLJKWÀRZ P3h )

'LPHQVLRQVDQGZHLJKW

Frame

Width

Depth

Height

:HLJKW&RQ¿JXUDWLRQ8

:HLJKW&RQ¿JXUDWLRQ9

:HLJKW&RQ¿JXUDWLRQ'

:HLJKW&RQ¿JXUDWLRQ%

Rev. 3 02-2021

20

DXi.HF 181 251 381 392 531 532

kW 19,2 23,6 35,1 38,4 48,1 45,9

kW 17,1 23,9 33,8 34,4 43,5 43,1

kW 4,3 5,6 7,7 8,4 10,8 10,8

0,89 1,00 0,96 0,90 0,90 0,94

m3/h 4,0 5,0 7,4 8,1 10,1 9,8

m3/h 5700 8150 11500 11500 14500 14500

n111122

Pa 622 399 344 399 389 360

W/W 4,7 4,4 4,9 5,4 4,9 4,5

kW 11 12 16 19 24 23

A21 21 26 38 37 42

A7 6 8 24 10 27

V/ph/Hz

400/3/50+N+PE

kW 18,1 25,4 36,5 37,2 47,5 47,2

kW 0,8 1,1 1,6 1,6 1,9 1,8

1,00 1,00 1,00 1,00 1,00 1,00

m3/h 4,0 5,0 7,4 8,1 10,1 9,8

kPa 55 42 41 32 65 43

m3/h 4,0 5,0 7,4 8,1 10,1 9,8

kPa 55 42 41 32 65 43

kg/h 588888

kg/h 888888

kW 3,75 6,0 6,0 6,0 6,0 6,0

A5,5 8,7 8,7 8,7 8,7 8,7

ȝ6FP 300/1250 300/1250 300/1250 300/1250 300/1250 300/1250

mg/l CaCO3100/400 100/400 100/400 100/400 100/400 100/400

n° 233333

kW 6,0 9,0 9,0 9,0 15,0 15,0

A8,7 13,0 13,0 13,0 21,7 21,7

n° 333333

kW 9,0 12,0 12,0 12,0 18,0 18,0

A13,0 17,3 17,3 17,3 26,0 26,0

MTEC.DXi.H/DXi.HF.GB-3 Use and Maintenance technical manual DXi.H/DXi.HF English

Emibyte DXi.H/DXi.HF Direct expansion close control

3.5 DXi.HF VHULHVWHFKQLFDOGDWD

Cooling capacity (Total) (1) ESP 20 Pa

Cooling cpacity (Sensible) (1) ESP 20 Pa

Tot. absorbed power (2) ESP 20 Pa

SHR

:DWHUÀRZ

$LUÀRZ

Fan

Max. ESP

EER

Maximum absorbed power

Maximum absorbed current

Starting current

Power supply

)UHHFRROLQJGDWD

Cooling capacity (Total) (3) ESP 20 Pa

Tot. absorbed power (2) ESP 20 Pa

SHR

:DWHUÀRZ

Pressure drop (water coil+condenser+valve)

:DWHUÀRZ

Total pressure drops

+XPLGLÀHU

Steam production (nominal)

Steam production (max.)

Max. absorbed power

Max. absorbed current

6SHFL¿FFRQGXFLELOLW\DW&PLQPD[

Total hardness (min/max)

(OHFWULFDOKHDWHUV

Steps

Power

Absorbed current

2YHUVL]HGHOHFWULFDOKHDWHUV

Steps

Power

Absorbed current

This manual suits for next models

1

Other Emicon Control Unit manuals