Emist EPIX360 User manual

OPS MANUAL

Version 052721

ENGLISH

For video explanation,

scan code and watch

the video

Thank you for choosing the EMist®EPIX360TM TruElectrostaticTM Sprayer.

We’ve created an easy-to-use system that combines advanced liquid application technologies

with improved mobility. The result is superior application and enhanced disinfection, as well as

a convenient convertible design for users.

We recommend you read through this entire instruction manual before beginning.

Included are assembly, operating, and safety instructions. Following these manufacturer

guidelines will help the system perform at peak eectiveness, extend the life of the product,

and ensure operator safety.

Questions?

Each component has been inspected prior to your purchase. However, in the event that

there is a problem, please contact our technical support center at Emist.com.

In the event of a conflict between different translations

of this document, the English translation shall prevail.

In addition, certain services and documents provided

by EMist may only be available in English.

SERVICES IN ENGLISH

- Original Version -

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 3

Warnings

Please read the manual carefully and pay special attention to the

symbols and warning labels. Warning labels indicate a potentially

hazardous situation which, if not avoided, could result in serious injury

or death.

SAFETY NOTICES

• Read and fully understand the EMist Electrostatic Sprayer Operators

Manual prior to using the electrostatic sprayer.

• EMist TruElectrostatic Sprayers should never be used in a hazardous

environment.

• EMist Electrostatic Sprayers should never be used in an area

containing volatile chemicals. Nor should it be used in any area

containing volatile or explosive levels of gas, vapor or particulates.

• EMist Electrostatic Sprayers should never be used by untrained

personnel.

WARNINGS

• Check equipment daily. Replace worn or

damaged parts immediately.

PRESSURIZED EQUIPMENT HAZARD

Liquid from equipment that leaks or ruptures from a

component can splash in the eyes or on skin, causing serious

injury. In order help prevent a leak or rupture:

WARNINGS

This manual contains information that is important for you to know

and understand before operating the EMist Electrostatic Sprayer. This

information relates to protecting your safety and ensures product

reliability and performance. It is the owner’s responsibility to ensure

that all who operate this equipment read this manual.

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

4

• Use only water-based solvents to clean

equipment or parts.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Many solvents can degrade plastic parts and cause them to fail,

which can lead to serious injury or property damage. In order to help

prevent against degradation:

WARNINGS

• Electrostatic equipment must be used only

by trained, qualied personnel who understand

the requirements of this manual.

• Stop operation immediately if static sparking

occurs or you feel a shock. Do not use

equipment until you identify and correct the

problem.

• Use and clean equipment only in well

ventilated area.

• Never spray a ammable chemical

(with a ashpoint less than 60˚C).

• Do not turn lights on or o when ammable

fumes are present.

• Keep spray area free of debris, including

solvents, rags, gasoline or any ammable

chemicals.

• CAUTION, DO NOT INSERT ANY

FOREIGN OBJECT IN THE NOZZLE OF

THE SPRAYER TO AVOID DAMAGING THE

EQUIPMENT OR STATIC DISCHARGE.

• Disconnect electrostatic equipment from

its power source when servicing or replacing

parts.

FIRE, EXPLOSION AND ELECTRIC SHOCK

HAZARD

Flammable fumes, such as solvent and paint fumes, in a work area

can ignite or explode. To help prevent fire, explosion and electric

shock:

WARNINGS

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 5

• Follow the chemical manufacturer’s

recommended directions of use found on

product label including but not limited to

wearing appropriate protective equipment

to help prevent serious injury.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment to help prevent

serious injury.

WARNINGS

• Do not operate the unit when fatigued

or under the inuence of drugs or alcohol.

• Use only water soluble uids that are

compatible with equipment wetted parts.

• Check equipment daily. Repair

or replace worn or damaged parts

immediately with genuine replacement

parts from trusted EMist partners only.

• Do not alter or modify equipment.

Alterations or modications void your

EMist warranty, and create safety

hazards.

EQUIPMENT MISUSE HAZARD

Misuse can cause serious injury or death.

WARNINGS

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

6

• Be aware of rst aid procedures related to the product in

use.

• It is a violation of Federal law to use a chemical in a manner

inconsistent with its label.

• For use with water-soluble, non-ammable, non-combustible

and non-volatile liquids only. Never spray a ammable

chemical (ash point less than 60˚C).

• Ensure the area being sprayed has proper ventilation.

• Store all chemicals in original containers in a cool, dry place,

away from heat and open ames.

• Do not reuse or rell a chemical container.

• Follow the chemical manufacturer’s recommended directions

of use found on product label.

CHEMICAL USE HAZARD

Each chemical, such as a disinfectant, has a unique set of

hazards and needs to be handled properly to ensure worker

safety.

WARNINGS

SAFETY WARNING!

DO NOT USE THE ELECTROSTATIC

APPLICATION SYSTEM IF YOU HAVE

A PACEMAKER OR AN IMPLANTABLE

CARDIOVERTER DEFIBRILLATOR

(ICD).

WARNINGS

STATE OF CALIFORNIA -

PROPOSITION 65 WARNING

• This product may contain chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm.

WARNINGS

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 7

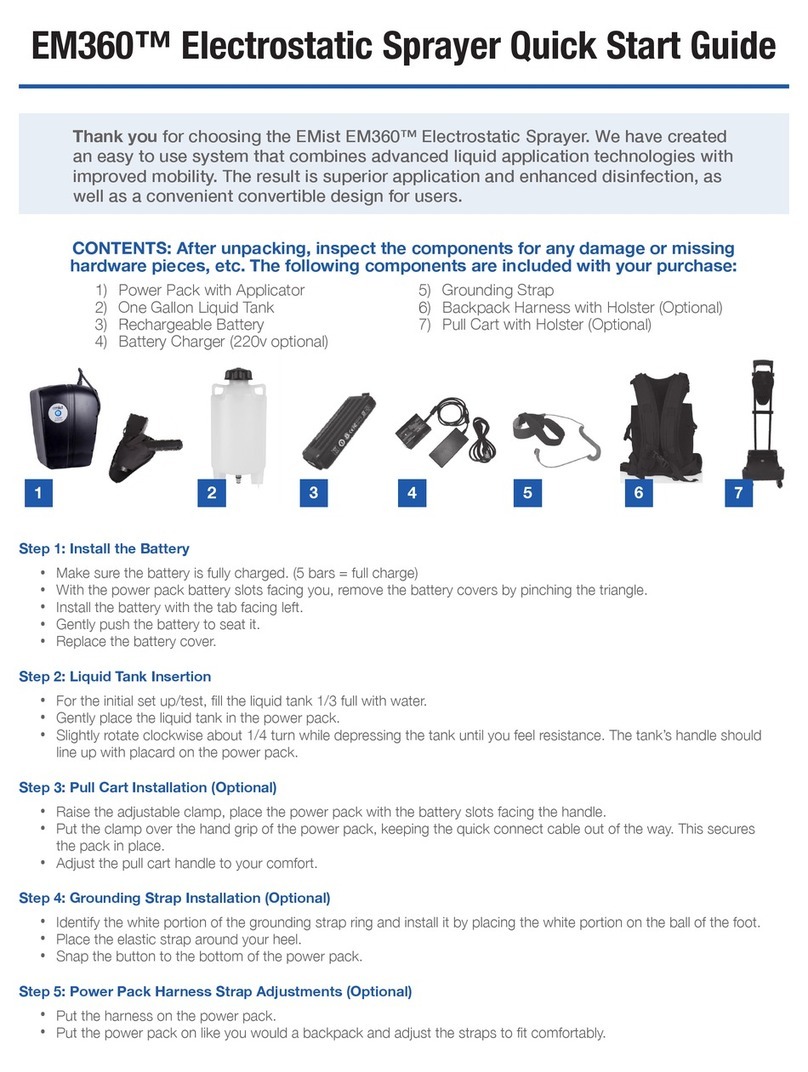

Storage Case

6

5

7

1 42 3

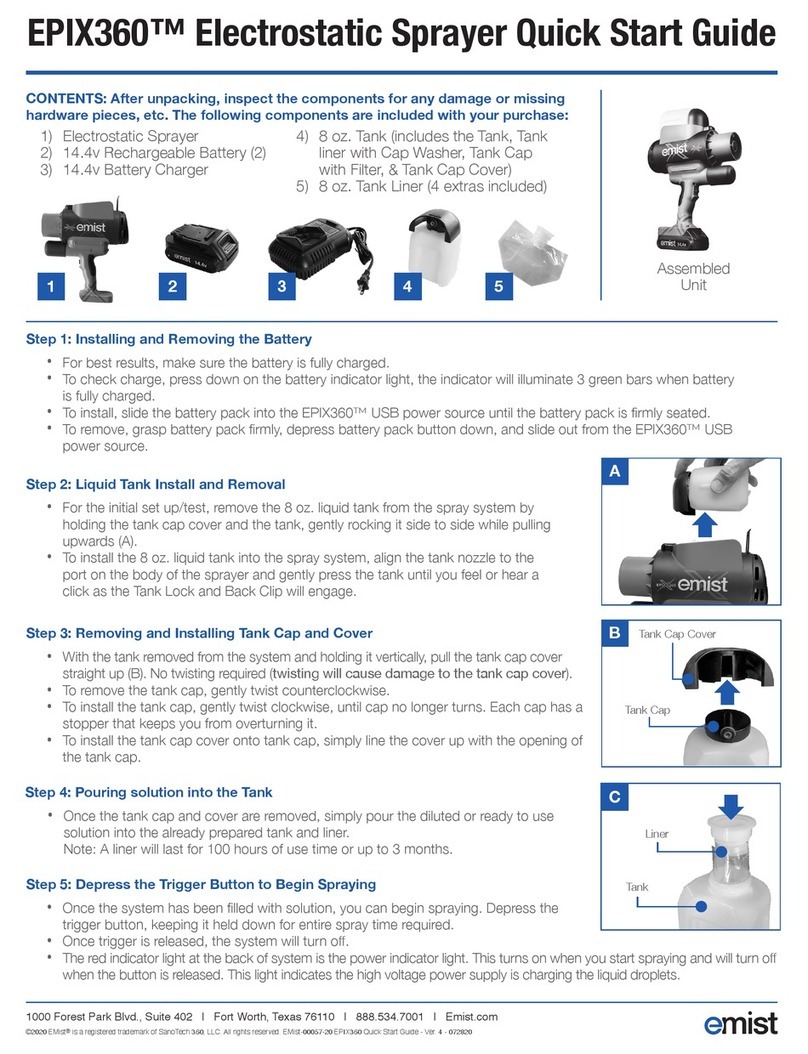

1. Electrostatic Sprayer: a cordless, handheld electrostatic sprayer that is

powerful, durable and provides breakthrough disinfectant application performance.

2. Tank: Interchangeable liquid tank includes liner with cap washer, cap with strain

lter and tank cap cover. The tank was specically designed to t securely onto the

sprayer and is easy to use. The tank has a tab along the threads to keep a user

from over rotating the tank cap. Please Note: a small amount of water may reside

in the tank when rst used as a result of quality control testing. When switching

tank liners, also move the removable rubber liner ring to the new liner to be used.

This ring ensures proper t and seal of tank cap assembly to the tank.

3. Liquid Tank Liners: The purpose of our disposable tank liners is to provide all

directional spraying and the ability to use all the disinfectant within the tank. Our

tank liners are manufactured to be used up to 100 hours or 3 months before an

actual liner must be replaced.

4. Tank Cap Assembly: The tank cap assembly comes with the cap, a check

valve, O-ring and strain lter. This cap is designed to t securely onto the tank. The

cap has a tab in order to stop over rotation onto the tank.

5. Tank Cap Cover: The cap cover is the main piece that locks the tank in place

on the sprayer along with the clip on the back of the unit. This allows for all

directional spraying, including upside down, when needed.

6. Rechargeable Battery: The system comes with 2 14.4v lithium ion batteries.

Each has a 3-bar green indicator light to determine charge. If the battery shows no

bars, place on the charger for recharging.

7. Battery Charger: The battery charger comes with 110-120v standard plug. It

takes approximately 45 minutes to recharge a battery. International charger cables

are available for purchase upon request.

INITIAL INSPECTION & SET UP - INVENTORY

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

8

ASSEMBLY & OPERATING INSTRUCTIONS

Tip: Charge battery rst

1. Plug charger cord into wall outlet.

2. Install battery into charger.

3. Reference power indicator (3 bars = full charge)

Step 1: Install Battery into Charger.

yTo install, slide battery pack into the charger until the battery pack is

rmly seated. It will click into the slot.- Note: Some chargers might

require more force on rst seat.

yOnce battery is on the charger, a ashing red light indicates the battery

is charging.

yOnce the battery is fully charged, a solid red light will indicate the batter

is fully charged.

- Tip: A fast blinking light on the charger indicates battery pack is not

seated correctly.

yTo remove battery from charger, grasp battery pack rmly, depress

battery pack button down, and slide out from the charger.

yTo check charge, press down on the battery indicator light, the light will

illuminate 3 green bars when battery is fully charged.

Step 2: Liquid Tank Removal:

yTo remove the 8oz tank from the spray system hold the tank cap cover

and the tank while gently pulling up the front of the tank from the spray

system to remove it from the tank lock. Then pull up on the back to

remove it from the tank back clip.

yThis removes the whole tank assembly from the sprayer.

Step 3: Removing the Tank Cap Cover & Cap.

yWith the tank removed from the sprayer and holding it vertically, pull the

tank cap cover straight up. No twisting is required.

yTo remove the tank cap, gently turn the cap counterclockwise until it is

fully removed from the tank.

Step 4: Installing the Tank Liner:

Tip: When you rst receive your sprayer bundle, a tank liner is already

installed in the tank for you. It includes the cap washer which is

required for the liner to sit correctly into the tank itself. The liner is

manufactured to last 100 spray hours or up to 3 months.

yWhen replacing your tank liner, rst remove the used liner from the tank

with the black cap washer by rmly holding the tank.

yOnce removed from the tank, remove the liner from the black cap

washer by holding the liner rmly in one hand, and pushing upwards on

the washer to remove it from the liner threads.

yGet new liner, push the black cap washer on by pushing it down around

the spout of the liner. Push the cap washer until the top of the liner spout

and washer are ush with each other.

yOnce the liner is installed with cap washer, fold the liner in an accordion

style and slide it into the tank until the cap washer is ush with the tank

opening.

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 9

ASSEMBLY & OPERATING INSTRUCTIONS

Tip: When a new liner is rst installed it requires air to be blown into

it for the liner to fully expand. By doing this the liner becomes fully

inated for all of uid to ll the tank.

CAUTION: If a tank liner is not used, liquid will leak from the small

holes in the bottom of the tank.

These holes allow for air to escape through the tank itself to collapse

the liner. Collapsing the liner is what makes the system capable of

using all liquid solutions and provide all directional spraying.

Warning: Do not plug the hole in the bottom of the tank to keep from

using the tank liner. This is considered a modication to the product and

will void the warranty if done. There is high potential for burning up the

pump if this is done.

yOnce this is completed, pour the diluted or ready to use solution into the

tank.

Step 5: Installing the Tank Cap and Cover:

yTo install the tank cap, gently turn clockwise against the threads until the

cap no longer turns.

yEach tank cap has a stopper along the tank that prevents overturning.

yTo install the tank cap cover, simply line the opening of the cover with

the nose of the tank cap.

Step 6: Installing the Liquid Tank:

yTo install the tank onto the sprayer, align the tank nozzle to the port on

the body of the sprayer and gently press in until you hear a click. This

is the tank lock locking into place along with the tank back clip. This is

what holds the overall tank in place.

Step 7: Depress the Trigger Button to Begin Spraying:

yOnce the system has been lled with liquid solution, you can begin

spraying.

yDepress the trigger button located on the front of the sprayer handle.

Hold it down for the entire spray time required for surface treatment.

yThe red indicator light at the back of the system indicates power on

and the high voltage power supply is charging the liquid droplets and

recognizes power to the system.

Tip: When rst starting to spray, the system needs to be primed with liquid,

hold down the trigger button for 10 to 15 seconds or until the sprayer

produces the mist. This needs to be done every time a tank is relled or the

liner has been replaced.

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

10

1. EMist recommends the use of disinfecting products on EPA’s

Disinfection List N that are approved for electrostatic application.

2. Begin at the farthest point from the doorway and work back toward

the doorway so you can step out when application is complete.

3. Aim applicator 24”-36” (optimal distance) from the surface target

area and begin with a smooth figure “S” movement aiming below,

at, and above the surface target area while walking at an average

pace (continuously moving).

4. Make sure you are working in a methodical “S” pattern and let your

passes overlap when moving to the next surface target area.

5. Allow treated area to sit for contact time as recommended by the

chemical manufacturer’s label before re-entry into the area.

B. SPRAY APPLICATION PROCESS:

1. Make sure food and drinks are removed or covered before

application.

2. Spotless, clean interiors require no prep work prior to application.

3. Loose debris should be swept from floors and other surfaces prior

to application.

4. Inspect the area for mechanical barriers such as: magazines

on table tops, chairs touching each other, a table or a wall.

The intended target surface area for application will need to be

accessible.

5. Please cover and remove valuables. Electronics, furniture, paper

or other common necessities do not need to be removed from the

area.

6. Once the area has been cleaned, application can begin.

7. This system is NOT a mechanical cleaner.

A. PREPARING THE SPRAY AREA:

TIP: IF THE APPLICATOR BECOMES WET OR BEGINS

TO DRIP, YOU ARE MOVING TOO SLOWLY OVER THE

SURFACE TARGET AREA AND NEED TO SPEED UP THE

APPLICATION PROCESS. DO NOT OVER-SATURATE THE

SURFACE. IF YOU SEE RUNS OR PUDDLES YOU ARE

APPLYING TOO MUCH CHEMICAL. THE GOAL IS TO

ACHIEVE EVEN COVERAGE OVER THE TARGET SURFACE

AREA.

SPRAY APPLICATION

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 11

The system is designed for single or multiple application

environments. Please use the multiple tank applications carefully

by marking tanks with your chemical identiers when necessary.

Application Tips:

1. While depressing the trigger button, move the applicator in an

“S” pattern from bottom to the top of the surface target area in a

continuous motion.

2. Stay in motion, electrostatically charged droplets will accumulate in

higher levels at the tip of the applicator if you move too slowly while

the device is in use.

3. Do not over apply.

4. In between chemical changes, press the trigger while pointing

to the floor or other safe target area 1-2 minutes to clear the

remaining chemical in the system.

C. FLUID MANAGEMENT:

Tips:

1. Fully charge each battery before use.

2. Keep battery, charger and all connectors clean and dry at all times.

3. Insert with the battery release button facing upwards into the

battery port.

4. Do not expose batteries, chargers or connectors to liquid.

D. BATTERY MANAGEMENT:

SPRAY APPLICATION

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

12

IT IS IMPORTANT TO FLUSH THE APPLICATION SYSTEM

AT LEAST ONCE EVERY 24 HOURS WITH CLEAN WATER

AND BETWEEN EACH USE. DO NOT STORE CHEMICALS

IN THE RESERVOIR WHILE THE SYSTEM IS NOT IN USE

FOR GREATER THAN A 24 HOUR PERIOD.

IT’S IMPORTANT TO FLUSH THE SYSTEM IN BETWEEN

USES OR WHEN SWITCHING CHEMICALS TO PREVENT

RESIDUAL BUILD UP OR CORROSION AND TO AVOID

MIXING CHEMICALS.

CHANGING CHEMICALS:

The sprayer is designed to require minimal maintenance and

cleaning.

• Fill the tank and liner with 4oz (1/2 of a tank) of water.

• Spray for at least 1-2 minutes to flush the previous chemistry

from the system.

• Pour the new solution into the recently flushed tank to begin next

surface treatment.

• Make sure the system is primed with the new solution by

depressing the trigger button continuously for about 10 - 15

seconds.

FLUSHING THE ELECTROSTATIC SPRAYER

MAINTENANCE & CLEANING

• Flush the system at least once a day by spraying at least 4oz (1/2 of a

tank) of clean water through the sprayer for at least 1-2 minutes.

• Do this by filling the tank and liner with 4oz (1/2 of a tank) of water and

continuously depressing the trigger button as this will flush the entire

system.

• Some chemicals are harsher or more volatile than others. Because

corrosion caused by chemicals is not covered under Manufacturer’s

limited warranty, it is imperative that you properly flush the system

as directed herein. Note that the use of some chemicals may require

more frequent flushing of the system based on the chemicals corrosive

nature. Signs of failing to properly flush the system include clogged

nozzle, hardened or calcified hoses or lines, deterioration of the plastics

such as the manifold, and/or clogged filters.

• After flushing the system, inspect for any debris or damage from the

days use.

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 13

STORAGE

• Insert at least 4 oz of water into the liquid tank.

• Run the sprayer for at least 1-2 minutes to flush active chemicals from

the system.

• Remove batteries and re-charge by placing on the charger.

• Wipe down exterior with water or alcohol to remove dirt and soil.

• Use the battery power indicator to determine the `battery’s state of

charge (3 bars = full charge).

• Remove the tank and battery from the system when not in use.

This keeps the unit from leaking or getting any fluid into the battery

compartment or the contacts.

BATTERY REMOVAL

• Make sure the system is off.

• Remove the battery from the sprayer by grasping the battery pack

firmly, depress the battery pack button down and slide out from the

bottom of the unit.

• Place battery into charger to fully charge for next usage. Each battery

takes approximately 45 minutes to fully charge.

• Store batteries and chargers in a cool, dry place.

MAINTENANCE & CLEANING

Empty uid or run until empty

CAUTION: DO NOT STORE THE SPRAYER IN AN AREA

THAT MAY FREEZE (TO AVOID DAMAGE FROM LIQUID

REMAINING IN THE SYSTEM AND LINES). THIS WILL

VOID THE WARRANTY. DO NOT STORE THE UNIT IN

EXTREME HEAT, AS IT DOES HAVE CIRCUIT BOARDS

AND ELECTRICAL COMPONENTS. THIS WILL VOID THE

WARRANTY.

TO PREVENT CROSS CONTAMINATION OF CHEMICALS,

YOU MUST PERFORM A FLUSH ANY TIME YOU CHANGE

THE TYPE OF CHEMICALS BEING USED.

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721

14

INDICATIONS & REMEDIES

PLEASE SEE BELOW FOR EASY INSTRUCTIONS FOR ADDRESSING

ISSUES THAT MAY ARISE WHILE USING THE EPIX360™

TROUBLESHOOTING, SUPPORT, & REPAIR

Issue Reason Troubleshooting

No Power to

the System

(Battery)

• Battery Not Installed

Correctly

• Battery Not Charged

• Battery Does Not

Slide Easily into the

slot (Do not try to

slam the battery to

seat)

Verify battery connector

issue by trying the 2nd

battery to determine if it will

not seat correctly. if not,

Battery is mechanically

obstructed

System

operates, but

red indicator

light not

illuminating

• High Voltage power

supply LED is

broken

• High voltage power

supply is not

working

Call Customer Care

No Mist or

Inadequate

Mist

• Tank Empty

• Tank Not Seated

Correctly

• System Lines not

primed

• Battery Not fully

charged

• Nozzle Clogged

• Release check valve

missing from port of

system

• Internal Component

Leak

• Pump Failure

• Fill Tank

• Remove Tank and

Re-apply

• Prime System for 5

to 10 seconds after

replacing tank

• Charge to Full battery

• Remove Nozzle Tip to

check if any residual

or contaminant is

blocking

• Replace check valve if

missing

• Call Customer Care

Nozzle Tip

leaking or

dribbling

• Remove tank when

system not in use.

• Nozzle Extension &

Tip are not lined up

or check valve is not

seated correctly

Verify the nozzle tip is

hand tighened in place

System turns

on and o

automatically

• Trigger button failure

• Main electrical

componets have

been exposed to

liquid/moisture

Call Customer Care

EN

Copyright ©2021 SanoTech 360, LLC. All rights reserved. All product names, logos, and brands are property of their

respective owners. Prices are in U.S. Dollars. Prices are subject to change. All use of the website and resources is

subject to the Terms of Use. EMI-018-21 Multilingual Manuals - 052721 15

The EPIX360™ is designed and manufactured to function without

defects. The system will operate normally with properly maintained

batteries and without abuse to any parts of the system.

If your system fails to return to normal use, excluding obvious user

damage, please contact EMist or your authorized EMist distributor.

If an issue occurs that is not addressed in the troubleshooting

methods, please contact an EMist Customer Care representative

at: 888.534.7001 or visit Emist.com to ll out a request for a

warranty or repair form.

SUPPORT OR REPAIR

TROUBLESHOOTING, SUPPORT, & REPAIR

ESPAÑOL

ES

17

Copyright © 2021 SanoTech 360, LLC. Reservados todos los derechos. Todos los nombres de productos, logotipos

y marcas son propiedad de sus respectivos dueños. Los precios están en dólares estadounidenses. Los precios

están sujetos a cambios. Todo uso del sitio web y los recursos está sujeto a los Términos de uso. Manuales

multilingües EMI-018-21 - 052721

Advertencias

Lea atentamente el manual y preste especial atención a los símbolos

y etiquetas de advertencia. Las etiquetas de advertencia indican una

situación potencialmente peligrosa que, si no se evita, podría provocar

lesiones graves o la muerte.

AVISOS DE SEGURIDAD

• Lea y comprenda completamente el Manual del operador del

pulverizador electrostático EMist antes de usar el pulverizador

electrostático.

• Los pulverizadores EMist TruElectrostatic nunca deben utilizarse en

un entorno peligroso.

• Los pulverizadores electrostáticos EMist nunca deben utilizarse en

un área que contenga productos químicos volátiles. Tampoco debe

usarse en áreas que contengan niveles volátiles o explosivos de gas,

vapor o partículas.

• Los pulverizadores electrostáticos EMist nunca deben ser utilizados

por personal no capacitado.

ADVERTENCIAS

• Revise el equipo a diario. Reemplace las

piezas gastadas o dañadas inmediatamente.

PELIGRO DE EQUIPO A PRESIÓN

El líquido del equipo que tiene fugas o rupturas de un

componente puede salpicar los ojos o la piel y causar lesiones

graves. Para ayudar a prevenir una fuga o ruptura:

ADVERTENCIAS

Este manual contiene información que es importante que usted

conozca y comprenda antes de utilizar el pulverizador electrostático

EMist. Esta información se relaciona con la protección de su

seguridad y garantiza la conabilidad y el rendimiento del producto. Es

responsabilidad del propietario asegurarse de que todos los que

operan este equipo lean este manual.

ES

18

Copyright © 2021 SanoTech 360, LLC. Reservados todos los derechos. Todos los nombres de productos, logotipos

y marcas son propiedad de sus respectivos dueños. Los precios están en dólares estadounidenses. Los precios

están sujetos a cambios. Todo uso del sitio web y los recursos está sujeto a los Términos de uso. Manuales

multilingües EMI-018-21 - 052721

• Utilice solo disolventes a base de agua para

limpiar equipos o piezas.

PELIGRO DEL DISOLVENTELA LIMPIEZA DE

PIEZAS DE PLÁSTICO

Muchos disolventes pueden degradar las piezas de plástico y hacer

que fallen, lo que puede provocar lesiones graves o daños a la

propiedad. Para ayudar a prevenir la degradación:

ADVERTENCIAS

• El equipo electrostático debe ser utilizado

únicamente por personal capacitado y calificado

que comprenda los requisitos de este manual.

• Detenga el funcionamiento inmediatamente si

se producen chispas estáticas o si siente una

descarga. No utilice el equipo hasta que identifique

y corrija el problema.

• Use y limpie el equipo solo en áreas bien

ventiladas.

• Nunca rocíe un químico inflamable

(con un punto de inflamación inferior a 60˚C).

• No encienda ni apague las luces en presencia de

vapores inflamables.

• Mantenga el área de rociado libre de escombros,

incluidos solventes, trapos, gasolina o cualquier

químico inflamable.

• PRECAUCIÓN, NO INSERTE NINGÚN OBJETO

EXTRAÑO EN LA BOQUILLA DEL PULVERIZADOR

PARA EVITAR DAÑAR EL EQUIPO O DESCARGAS

ESTÁTICAS.

• Desconecte el equipo electrostático de su fuente

de alimentación al reparar o reemplazar piezas.

PELIGRO DE INCENDIO, EXPLOSIÓN Y

DESCARGA ELÉCTRICA

Los vapores inflamables, como los vapores de disolvente y pintura,

en un área de trabajo pueden encenderse o explotar. Para ayudar a

prevenir incendios, explosiones y descargas eléctricas:

ADVERTENCIAS

ES

19

Copyright © 2021 SanoTech 360, LLC. Reservados todos los derechos. Todos los nombres de productos, logotipos

y marcas son propiedad de sus respectivos dueños. Los precios están en dólares estadounidenses. Los precios

están sujetos a cambios. Todo uso del sitio web y los recursos está sujeto a los Términos de uso. Manuales

multilingües EMI-018-21 - 052721

• Siga las instrucciones de uso

recomendadas por el fabricante del

producto químico que se encuentran en

la etiqueta del producto, incluido, entre

otros, el uso del equipo de protección

adecuado para ayudar a prevenir lesiones

graves.

DE PROTECCIÓN PERSONAL

Use el equipo de protección adecuado para ayudar a prevenir

lesiones graves.

ADVERTENCIAS

• No opere la unidad cuando esté

fatigado o bajo la inuencia de drogas o

alcohol.

• Utilice únicamente uidos solubles

en agua que sean compatibles con las

piezas húmedas del equipo.

• Revise el equipo a diario. Repare o

reemplace las piezas desgastadas o

dañadas inmediatamente con piezas de

repuesto originales de socios EMist de

conanza.

• No altere ni modique el equipo. Las

alteraciones o modicaciones anulan la

garantía de EMist y crean peligros para la

seguridad.

PELIGRO DE USO INDEBIDO DEL EQUIPO

El uso incorrecto puede causar lesiones graves o la muerte.

ADVERTENCIAS

ES

20

Copyright © 2021 SanoTech 360, LLC. Reservados todos los derechos. Todos los nombres de productos, logotipos

y marcas son propiedad de sus respectivos dueños. Los precios están en dólares estadounidenses. Los precios

están sujetos a cambios. Todo uso del sitio web y los recursos está sujeto a los Términos de uso. Manuales

multilingües EMI-018-21 - 052721

• Tenga en cuenta los procedimientos de primeros auxilios

relacionados con el producto en uso.

• Es una violación de la ley federal usar una sustancia química de

una manera

inconsistente con su etiqueta.

• Solo para uso con líquidos solubles en agua, no inflamables,

no combustibles y no volátiles. Nunca rocíe un producto químico

inflamable (punto de inflamación inferior a 60 ° C).

• Asegúrese de que el área que se está rociando tenga la

ventilación adecuada.

• Almacene todos los productos químicos en los envases

originales en un lugar fresco y seco, lejos del calor y las llamas

abiertas.

• No reutilice ni vuelva a llenar un recipiente de productos

químicos.

• Siga las instrucciones de uso recomendadas por el fabricante

del producto químico que se encuentran en la etiqueta del

producto.

PELIGRO DE USO DE PRODUCTOS QUÍMICOS

Cada producto químico, como un desinfectante, tiene un

conjunto único de peligros y debe manipularse correctamente

para garantizar la seguridad de los trabajadores.

ADVERTENCIAS

¡DE SEGURIDAD!

NO USE EL SISTEMA DE

APLICACIÓN ELECTROSTÁTICA

SI TIENE UN MARCAPASOS

O UNIMPLANTABLE

DESFIBRILADOR DE

CARDIOVERTER(ICD).

ADVERTENCIAS

ESTADO DE CALIFORNIA -

PROPOSICIÓN 65 ADVERTENCIA

• Este producto puede contener

sustancias químicas que el estado de

California reconoce como causantes de

cáncer y defectos de nacimiento u otros

daños reproductivos.

ADVERTENCIAS

Other manuals for EPIX360

5

This manual suits for next models

1

Table of contents

Languages:

Other Emist Paint Sprayer manuals

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360RC User manual

Emist

Emist Tru Electrostatic EX-7000 User manual

Emist

Emist EM360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual