Emist EPIX360 User manual

EPIX360™ Electrostatic Sprayer

User Manual

Ver. 072420

Thank you for choosing the EMist EPIX360™ Electrostatic Sprayer.

We’ve created an easy-to-use system that combines advanced liquid application technologies with improved

mobility. The result is superior application and enhanced disinfection, as well as a convenient design for users.

We recommend you read through this entire instruction manual before beginning.

Included are assembly, operating, and safety instructions. Following these manufacturer guidelines will help

the system perform at peak eectiveness, extend the life of the product, and ensure operator safety.

Questions?

Each component has been inspected prior to your purchase. However, in the event that there is a problem,

please contact our customer care center at Emist.com.

EPIX360™ Electrostatic Sprayer User Manual

2©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072320

3

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

1. General Precautions & Safety Warnings

The EMist EPIX360™ electrostatic sprayer is a

battery-powered liquid spray system designed to

improve the performance of water soluble or water

based disinfectant solutions used on touchable and

other exposed surfaces. This is accomplished by

applying an electrostatic charge to the surface of the

liquid droplets as they leave the spray nozzle. This

unique process improves liquid adhesion to targeted

surfaces.

The hazards associated with the liquids you choose to

apply represent their own unique and important safety

requirements. Refer to each chemical manufacturer’s

documentation to establish best use steps and any

need for personal protective equipment (PPE).

Never point the spray applicator at another person

and never touch or handle the charging ring within the

applicator (front end) during spraying. This will help

avoid chemical splash and other possibly unsafe

spraying conditions.

DO NOT USE LIQUIDS THAT ARE NOT

WATER SOLUBLE OR WATER BASED

WITHIN THE SPRAYER. HIGH ALCOHOL

CONTENT LIQUIDS MUST NEVER BE

SPRAYED NEAR AN OPEN FLAME OR

OTHER POSSIBLE IGNITION SOURCES.

• Read the User Manual thoroughly. Failure to read the

manual is considered misuse of the equipment.

• Use the sprayer only for its intended use as directed

in this manual.

• Familiarize yourself with all components, including

caution and warning labels.

• Only trained and qualied personnel should operate

the sprayer.

• Do not use the equipment while under the inuence

of drugs or alcohol.

• Remove the tank and battery when leaving the

equipment unattended.

• Store the system in a cool, dry place. Do not expose

to extreme temperatures.

• Flush the system before storing.

Lack of attention to safety can result in reduced

eciency, accident(s), or personal injury. Use the following

safety precautions as a guide when using this machine:

• Do not place body parts or any foreign object into

any opening of the sprayer.

• Never reach inside of the sprayer while the

system is powered on.

• Never place equipment in standing water or liquid.

• Never operate the sprayer if it has been damaged

or if it is not working properly.

Safety Warning:

Do not use the electrostatic sprayer if you have a

pacemaker or an Implantable Cardioverter Debrillator

(ICD) or stand within 10 feet if you use such devices,

as this product contains an electrostatic device that

may interfere with these type of devices. Contact your

physician prior to operation if you are unsure if this

system will interfere with your implant.

Safety Notes:

Users are required to read this User Manual,

understand the safe and correct operating procedures

that pertain to the operation of the sprayer, and

maintain the product according to the User Manual. It

is the operator’s responsibility to ensure that any

person who uses this equipment has read this manual.

Chemical Safety Precautions:

Read and follow all instructions on the chemical

manufacturer’s label.

• Follow the chemical manufacturer’s recommendations

to handle, mix, apply, store, and dispose of their chemicals.

• Follow the personal protective equipment (PPE)

requirements as recommended by the chemical

manufacturer’s safety data sheet (SDS).

To reduce the risk of electrical shock or injury, follow

these guidelines:

Electrical Warning

4©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

65 7

1 42 3

Storage Case

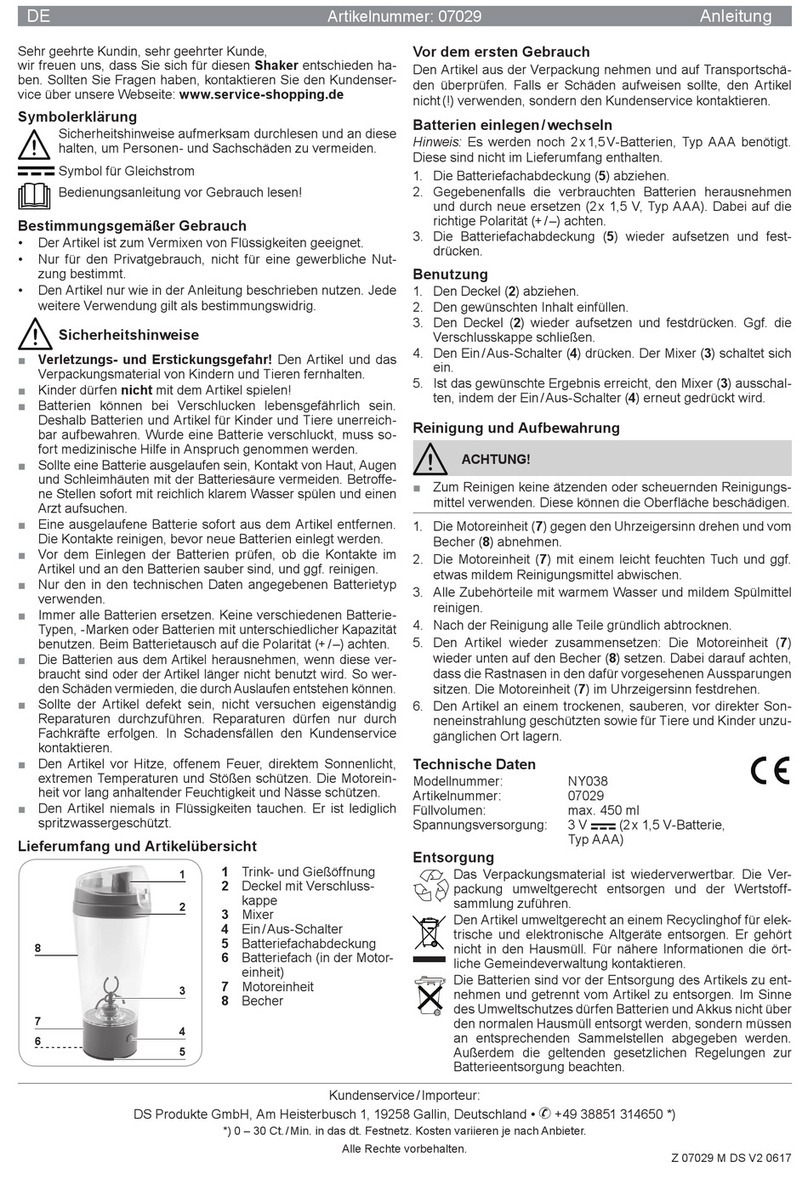

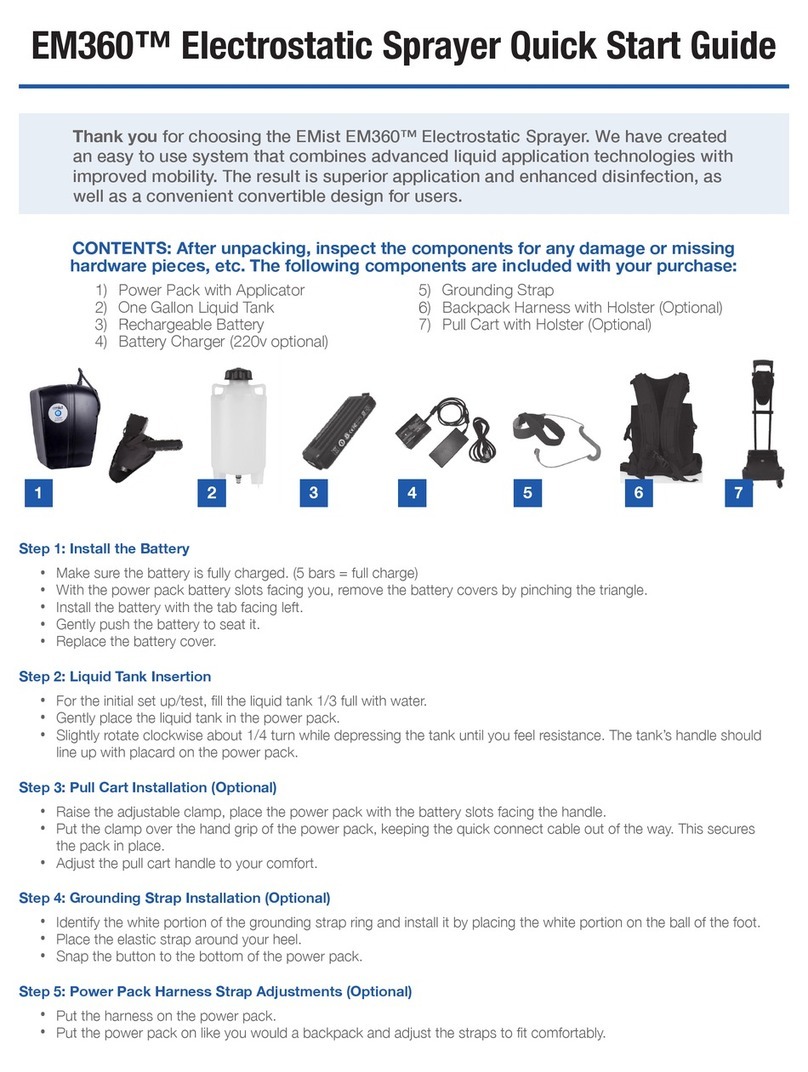

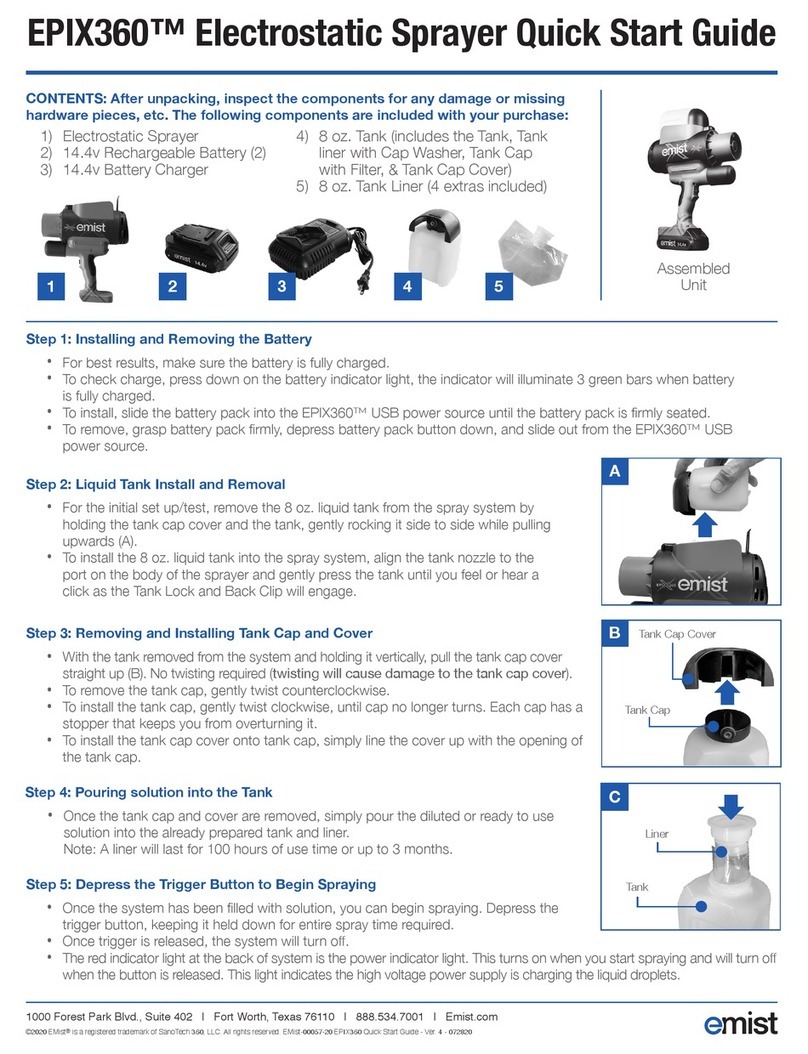

2. Initial Inspection & Set Up - Inventory

After unpacking, inspect components for any damage or missing hardware pieces, etc. The following should be included in

your bundle package:

1. Electrostatic Sprayer: a cordless, handheld electrostatic sprayer that is powerful, durable, and provides breakthrough

disinfectant application performance.

2. 8oz. Tank: Interchangeable 8oz liquid tank includes 8oz liner with cap washer, cap with strain lter and tank cap cover.

The tank was specically designed to t securely onto the sprayer and is easy to use. The tank has a tab along the threads

to keep a user from over rotating the tank cap.

3. 8oz Liquid Tank Liners: The purpose of our 8oz tank disposable tank liners is to provide all directional spraying and the

ability to use all the disinfectant within the tank. Our tank liners are manufactured to be used up to 100 hours or 3 months

before an actual liner physically must be replaced.

4. Tank Cap Assembly: The tank cap assembly comes with the cap, a check valve, O-ring and strain lter. This cap is

designed to t securely onto the tank. The cap has a tab in order to stop over rotation onto the tank.

5. Tank Cap Cover: The cap cover is the main piece that locks the tank in place on the sprayer along with the clip on the

back of the unit. This allows for all directional spraying, including upside down when needed.

6. Rechargeable Battery: The system comes with 2 14.4v lithium ion batteries. Each has a 3-bar green indicator light to

determine charge. If the battery shows no bars, then place on the charger for recharging.

7. Battery Charger: The battery charger comes with 110-120v standard plug. It provide approximately 45 minutes to

recharge a battery.

1. Electrostatic Sprayer

2. Tank

3. Tank Liners (qty. 4)

4. Tank Cap Assembly

5. Tank Cap Cover

6. 14.4v Batteries (2)

7. 14.4v Battery Charger

EP36BTLI20 -

EP36CHLI20 -

EP36CHEU20 -

EP36TK0820 -

EP36TKL820 -

EP36TCA820 -

EP36TCC820 -

EP36NZT820 -

Battery

Battery Charger (US)

Battery Charger (EU)

Tank

Tank Liners (qty. 5)

Tank Cap Assembly

Tank Cap Cover

Nozzle Tip

Items Included: Accessories & Parts Sold Separately:

5

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

Tip: Charge battery rst

1. Plug charger cord into wall outlet.

2. Install battery into charger.

3. Reference power indicator (3 bars = full charge)

Step 1: Install Battery into Charger.

• To install, slide battery pack into the charger until the battery pack is rmly seated. It will click into the slot.

- Note: Some chargers might require more force on rst seat.

• Once battery is on the charger, a ashing red light indicates the battery is charging.

• Once the battery is fully charged, a solid red light will indicate fully charged

- Tip: A fast blinking light on the charger indicates battery pack is not seated correctly.

• To remove battery from charger, grasp battery pack rmly, depress battery pack button down, and slide out from

the charger.

• To check charge, press down on the battery indicator light, the light will illuminate 3 green bars when battery is fully

charged.

Step 2: Liquid Tank Removal:

• To remove the 8oz tank from the spray system by holding the tank cap cover and the tank while gently pulling up on the

front of the tank from the spray system to remove it from the tank lock. Then pull up on the back to remove it from the

tank back clip.

• This removes the whole tank assembly from the sprayer.

Step 3: Removing the Tank Cap Cover & Cap.

• With the tank removed from the sprayer and holding it vertically, pull the tank cap cover straight up. No twisting is required.

• To remove the tank cap, gently turn the cap counterclockwise until it is fully removed from the tank.

Step 4: Installing the Tank Liner:

Tip: When you rst receive your sprayer bundle, a tank liner is already installed in the tank for you. It includes the

cap washer which is required for the liner to sit correctly into the tank itself. The liner is manufactured to last 100

spray hours or up to 3 months.

• When replacing your tank liner, rst remove the used liner from the tank with the black cap washer by rmly holding

the tank.

• Once removed from the tank, remove the liner from the black cap washer by holding the liner rmly in one hand, and

pushing upwards on the washer to remove it from the liner threads.

• Get new liner, push the black cap washer on by pushing it down around the spout of the liner. Push the cap washer until

the top of the liner spout and washer are ush with each other.

• Once the liner is installed with cap washer, fold the liner in an accordion style and slide it into the tank until the cap

washer is ush with the tank opening.

Tip: When a new liner is rst installed it requires air to be blown into it for the liner to fully expand. By doing this

the liner becomes fully inated for all 8oz of uid to ll the tank.

Caution: If a tank liner is not used, then the liquid will leak from the small holes in the bottom of the tank.

These holes allow for air to escape through the tank itself to collapse the liner. Collapsing the liner, is what

makes the system capble of using all liquid solutions and provide all directional spraying.

3. Assembly & Operating Instructions

6©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

Warning: Do not plug the hole in the bottom of the tank to keep from using the tank liner. This will void the warranty if

done. There is high potential for burning up the pump if this is done.

• Once this is completed, pour the diluted or ready to use solution into the tank.

Step 5: Installing the Tank Cap and Cover:

• To install the tank cap, gently turn clockwise against the threads until the cap no longer turns.

• Each tank cap has a stopper along the tank that prevents overturning.

• To install the tank cap cover, simply line the opening of the cover with the nose of the tank cap.

Step 6: Installing the 8oz Liquid Tank:

• To install the 8oz tank onto the sprayer, align the tank nozzle to the port on the body of the sprayer and gently press

in until you hear a click. This is the tank lock locking into place along with the tank back clip. This is what holds the

overall tank in place.

Step 7: Depress the Trigger Button to Begin Spraying:

• Once the system has been lled with liquid solution, you can begin spraying.

• Depress the trigger button located on the front of the sprayer handle, hold it down for the entire spray time required

for surface treatment.

• The red indicator light at the back of the system indicates power on, and the high voltage power supply is charging the

liquid droplets and recognizes power to the system.

Tip: When rst starting to spray, the system needs to be primed with liquid, hold down the trigger button for 10 to 15

seconds or until the sprayer produces the mist. This needs to be done every time a tank is relled, or the liner has

been replaced.

3. Assembly & Operating Instructions

7

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

Battery Management

•

•

•

•

Fully charge each battery before use.

Always keep connectors clean and dry.

Do not expose batteries to standing liquid or

excessive heat.

Only charge battery packs with an EMist charger.

4. Spray Application

Begin at the farthest point from the doorway, work

toward the doorway so you can step out when

application is complete.

Aim the electrostatic sprayer 24” to 36” from the

surface target area, begin with a smooth gure “S”

movement aiming below, at, and above the surface

target area while walking at an average pace

continuously moving.

Make sure you are working in a methodical “S” pattern

and let your passes overlap when moving to the next

surface target area.

Allow treated area to sit for contact/dwell time as

recommended by the chemical manufacturer’s

label before re-entry into the area.

1.

2.

3.

4.

Spray Application Process

TIP: IF THE APPLICATOR BECOMES WET OR

BEGINS TO DRIP, YOU ARE MOVING TOO SLOW

OVER THE SURFACE TARGET AREA AND NEED TO

SPEED UP THE APPLICATION PROCESS. DO NOT

OVER-SATURATE THE SURFACE. IF YOU SEE RUNS

OR PUDDLES, YOU ARE APPLYING TOO MUCH

CHEMICAL. THE GOAL IS TO ACHIEVE EVEN

COVERAGE OVER THE TARGET SURFACE AREA.

Fluid Management

•

•

•

Stay in motion. Electrostatically charged droplets will

accumulate in higher levels at the tip of the applicator

if you move too slowly while the device is in use.

Do not over apply. The tendency to “paint the fence”

is an over usage of chemicals.

In between chemical changes press the trigger while

pointing to the oor or other safe target area for four

to ve seconds to clear the remaining chemical in the

system.

The sprayer is designed for single or multiple application

environments. Please use the multiple tank applications

carefully by marking tanks with your chemical identiers

when necessary.

Tips:

Preparing the Spray Area:

Loose debris must be swept from oors and other surfaces prior to application. Inspect the area for mechanical barriers such

as: magazines on tabletops, chairs touching each other, a table or a wall. The intended target surface area for application will

need to be accessible. Please cover and remove valuables. Electronics, furniture, paper or other common necessities do not

need to be removed from the area.

Once the area has been cleaned, application can begin.

This system in NOT a mechanical cleaner.

8©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

5. Maintenance & Cleaning

TIP: IT IS GOOD PRACTICE TO FLUSH THE

SYSTEM EVERY 24 HOURS WITH WATER.

DO NOT STORE CHEMICALS IN THE

RESERVOIR WHILE THE SYSTEM IS NOT IN

USE FOR MORE THAN 24 HOURS.

Flushing the Electrostatic Sprayer

•

•

•

Flush the system at least once a day by spraying at

least 4oz (1/2 a tank) of water through the sprayer for

at least 10-15 seconds.

Do this by lling the tank and liner with 4oz (1/2 a

tank) of water and continuously depressing the trigger

button, this will ush the entire system.

After ushing the system, inspect for any debris or

damage from the days use.

The sprayer is designed to require minimal maintenance

and cleaning.

Tips:

Storage

•

•

•

•

•

•

Insert at least 4 oz of water into the liquid tank.

Run the sprayer for at least 10 to 15 seconds to ush

active chemicals from the system.

Remove batteries and re-charge by placing on the

charger.

Wipe down exterior with water or alcohol to remove

dirt and soil.

Use the battery power indicator to determine the

`battery’s state of charge (3 bars = full charge).

Remove the tank and battery from the system when

not in use. This keeps the unit from leaking or getting

any uid into the battery compartment or the contacts.

CAUTION: DO NOT STORE THE SPRAYER IN AN

AREA THAT MAY FREEZE (TO AVOID DAMAGE FROM

LIQUID REMAINING IN THE SYSTEM AND LINES).

THIS WILL VOID THE WARRANTY. DO NOT STORE

THE UNIT IN EXTREME HEAT, AS IT DOES HAVE

CIRCUIT BOARDS AND ELECTRICAL COMPONENTS.

THIS WILL VOID THE WARRANTY.

TO PREVENT CROSS CONTAMINATION OF

CHEMICALS, YOU MUST PERFORM A FLUSH ANY

TIME YOU CHANGE THE TYPE OF CHEMICALS

BEING USED.

Battery Removal

•

•

•

•

Make sure the system is o.

Remove the battery from the sprayer by grasping the

battery pack rmly, depress the battery pack button

down and slide out from the bottom of the unit.

Place battery into charger to fully charge for next

usage. Each battery takes approximately 45 minutes

to fully charge

Store extra batteries in a cool, dry place.

Tips:

Empty uid or run until empty

TIP: IT’S IMPORTANT TO FLUSH THE SYSTEM IN

BETWEEN USES OR WHEN SWITCHING CHEMICALS

TO PREVENT RESIDUAL BUILD UP AND TO AVOID

MIXING CHEMICALS.

Changing Chemicals

•

•

•

•

Fill the tank and liner with 4oz (1/2) a tank) of water.

Spray for at least 10-15 seconds to ush the previous

chemistry from the system.

Pour the new solution into the recently ushed tank to

begin next surface treatment.

Make sure the system is primed with the new

solution by depressing the trigger button

continuously for about 5 to 10 seconds.

Tips:

9

©2020 EMist®is a registered trademark of SanoTech 360, LLC. All rights reserved.

EMist-00055-20-EPIX360 User Manual - Ver. 072420

6. Troubleshooting, Support & Repair

The EPIX360™ is designed and manufactured to function without defects. The system will operate

normally with properly maintained batteries and without abuse to any parts of the system.

Indications & Remedies

PLEASE SEE BELOW FOR EASY INSTRUCTIONS FOR ADDRESSING ISSUES THAT MAY ARISE WHILE USING THE EPIX360™

If your system fails to function, excluding obvious user damage, please contact EMist or your

authorized EMist distributor.

If an issue occurs that is not addressed in the troubleshooting methods, please contact an EMist Customer Care

representative at: 888.534.7001 or visit Emist.com to ll out a request for a warranty or repair form.

Support or Repair

BATTERY NOT INSTALLED CORRECTLY

BATTERY NOT CHARGED

BATTERY DOES NOT SLIDE EASILY

INTO THE SLOT (DO NOT TRY TO

SLAM THE BATTERY TO SEAT)

HIGH VOLTAGE POWER SUPPLY LED

IS BROKEN

HIGH VOLTAGE POWER SUPPLY IS

NOT WORKING

TANK EMPTY

TANK NOT SEATED CORRECTLY

SYSTEM LINES NOT PRIMED

BATTERY NOT FULLY CHARGED

NOZZLE CLOGGED

RELEASE CHECK VALVE MISSING

FROM PORT OF SYSTEM

INTERNAL COMPONENT LEAK

PUMP FAILURE

REMOVE TANK WHEN SYSTEM NOT

IN USE

NOZZLE EXTENSION & TIP ARE NOT

LINED UP OR CHECK VALVE IS NOT

SEATED CORRECTLY

TRIGGER BUTTON FAILURE

VERIFY BATTERY CONNECTOR ISSUE

BY TRYING THE 2ND BATTERY TO

DETERMINE IF IT WILL NOT SEAT

CORRECTLY. IF NOT, BATTERY IS

MECHANICALLY OBSTRUCTED

CALL CUSTOMER CARE

FILL TANK

REMOVE TANK AND RE-APPLY

PRIME SYSTEM FOR 5 TO 10

SECONDS AFTER REPLACING TANK

CHARGE TO FULL BATTERY

REMOVE NOZZLE TIP TO CHECK IF

ANY RESIDUAL OR CONTAMINANT IS

BLOCKING

REPLACE CHECK VALVE IF MISSING

CALL CUSTOMER CARE

CALL CUSTOMER CARE

WITH A ½” DEEP SOCKET, ADJUST TIP

BY SLOWING ROTATING A ¼ TURN

UNTIL FULL MIST CONE IS PRODUCED

CALL CUSTOMER CARE

NO POWER TO THE SYSTEM

(BATTERY)

SYSTEM OPERATES, BUT

RED INDICATOR LIGHT NOT

ILLUMINATING

NO MIST OR INADEQUATE MIST

NOZZLE TIP LEAKING OR

DRIBBLING

SYSTEM TURNS ON AND OFF

AUTOMATICALLY

RETURN TO NORMAL USE

RETURN TO NORMAL USE

RETURN TO NORMAL USE

RETURN TO NORMAL USE

RETURN TO NORMAL USE

Reason ResultIssue Troubleshooting

1000 Forest Park Blvd. Ste 402

Fort Worth, TX 76110

Emist.com •888.534.7001

Other manuals for EPIX360

5

Table of contents

Other Emist Paint Sprayer manuals

Emist

Emist Tru Electrostatic EX-7000 User manual

Emist

Emist EM360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EM360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EPIX360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Emist

Emist EM360 User manual

Popular Paint Sprayer manuals by other brands

WALTHER PILOT

WALTHER PILOT PILOT WA 500 operating instructions

Bartell Global

Bartell Global S151 owner's manual

Chapin

Chapin 63863 use and care manual

Iwata

Iwata Full Finish G-Series G6 Operating instructions manual

SATA

SATA HRS operating instructions

Lavo Solutions

Lavo Solutions CLEANJET quick start guide