TB-6578 Page 1 of 10 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

Made in the

United States of America

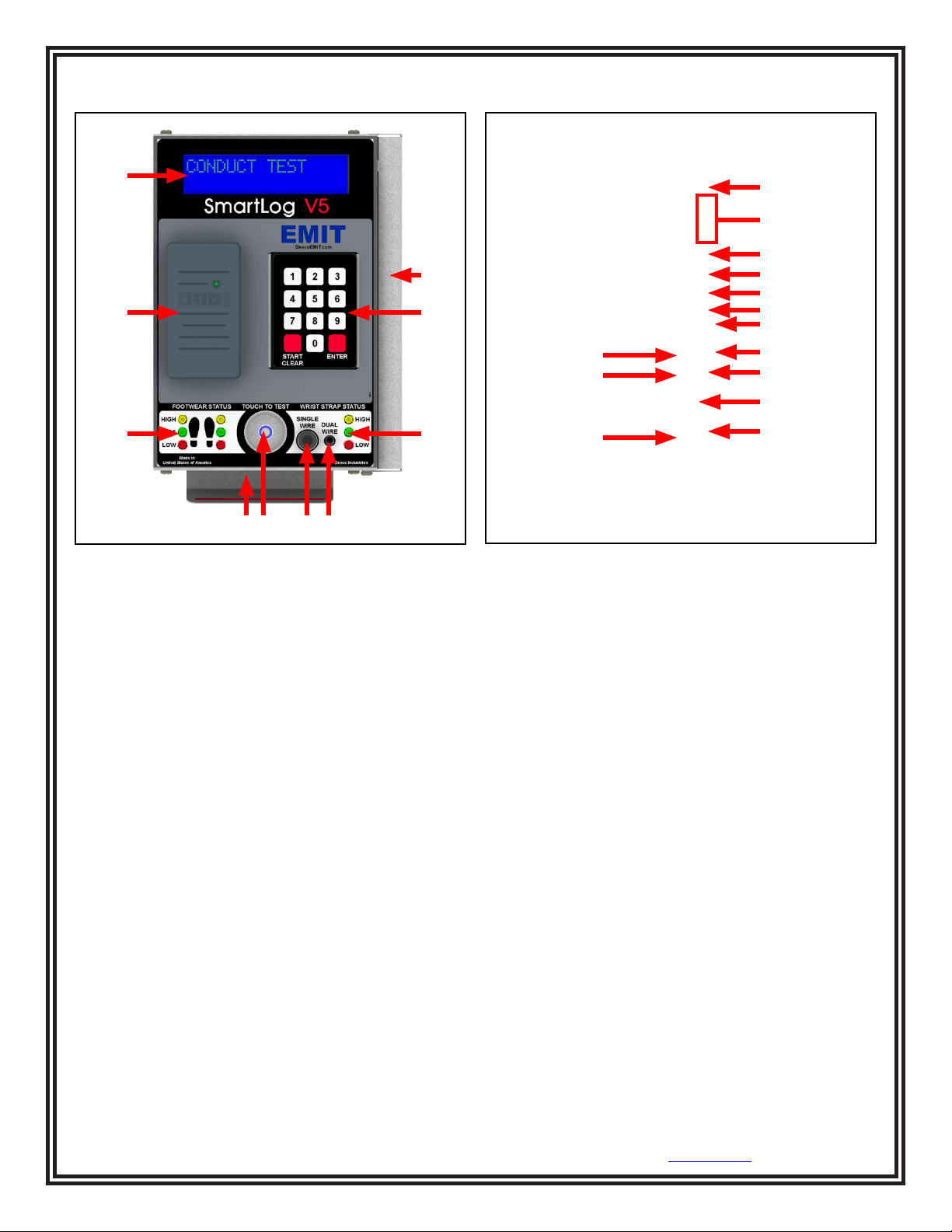

SmartLog V5

Installation, Operation and Maintenance

Description

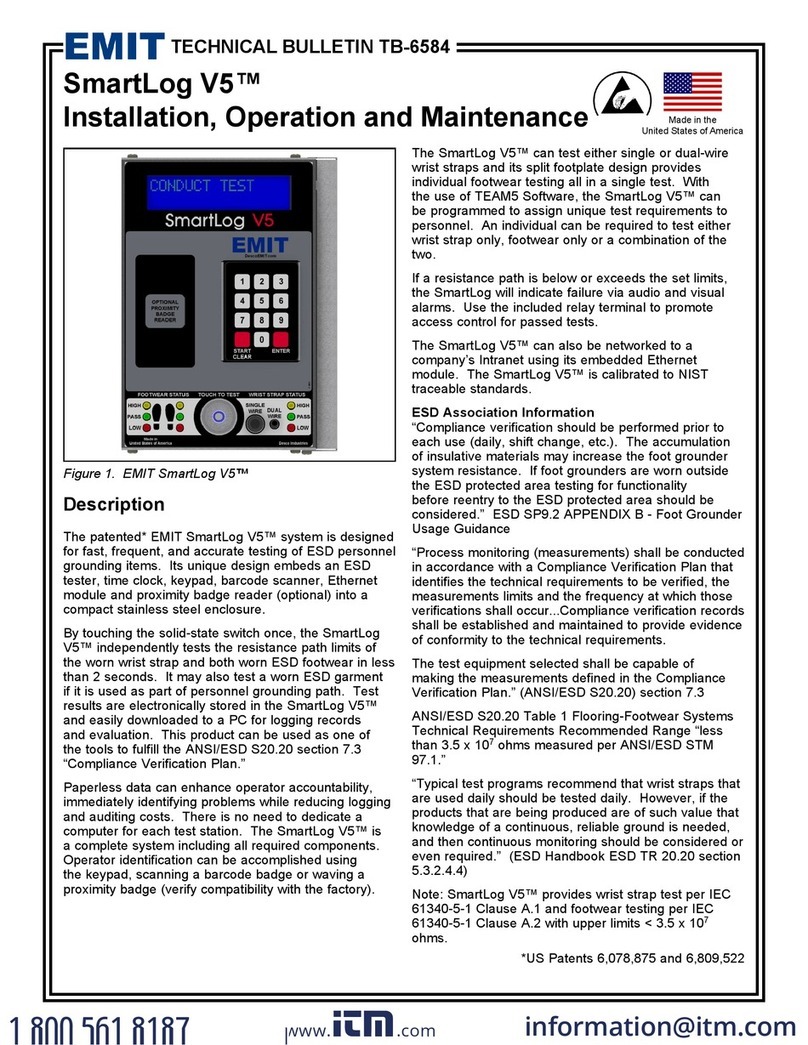

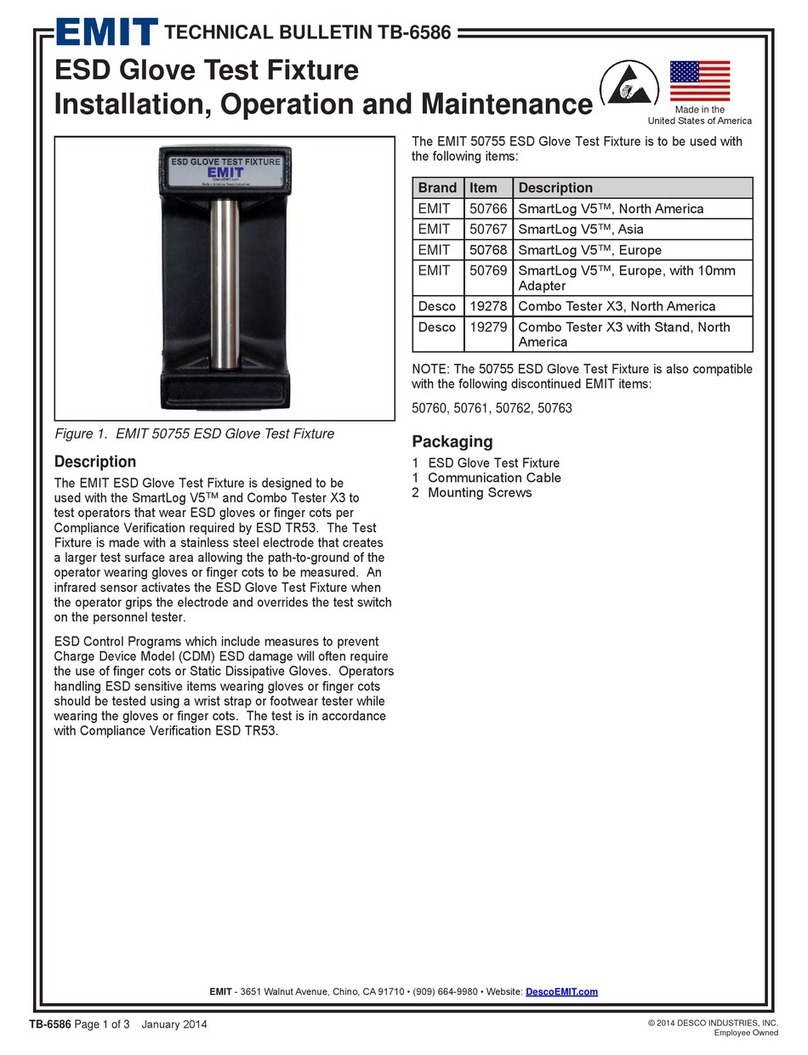

The patented* EMIT SmartLog V5 system is designed

for fast, frequent, and accurate testing of ESD personnel

grounding items. Its unique design embeds an ESD

tester, time clock, keypad, barcode scanner, Ethernet

module and proximity badge reader (optional) into a

compact stainless steel enclosure.

By touching the solid-state switch once, the SmartLog

V5 tests the resistance path limits of the worn wrist strap

and both worn ESD footwear independently in less than

2 seconds. It may also test a worn ESD garment if it is

used as part of personnel grounding path. Test results

are electronically stored in the SmartLog V5 and easily

downloaded to a PC for logging records and evaluation.

This product can be used as one of the tools to fulfill the

ANSI/ESD S20.20 section 7.3 “Compliance Verification

Plan.”

Paperless data can enhance operator accountability,

immediately identifying problems while reducing logging

and auditing costs. There is no need to dedicate a

computer for each test station. The SmartLog V5 is a

complete system including all required components.

Operator identification can be accomplished using

the keypad, scanning a barcode badge or waving a

proximity badge (verify compatibility with the factory).

December 2011

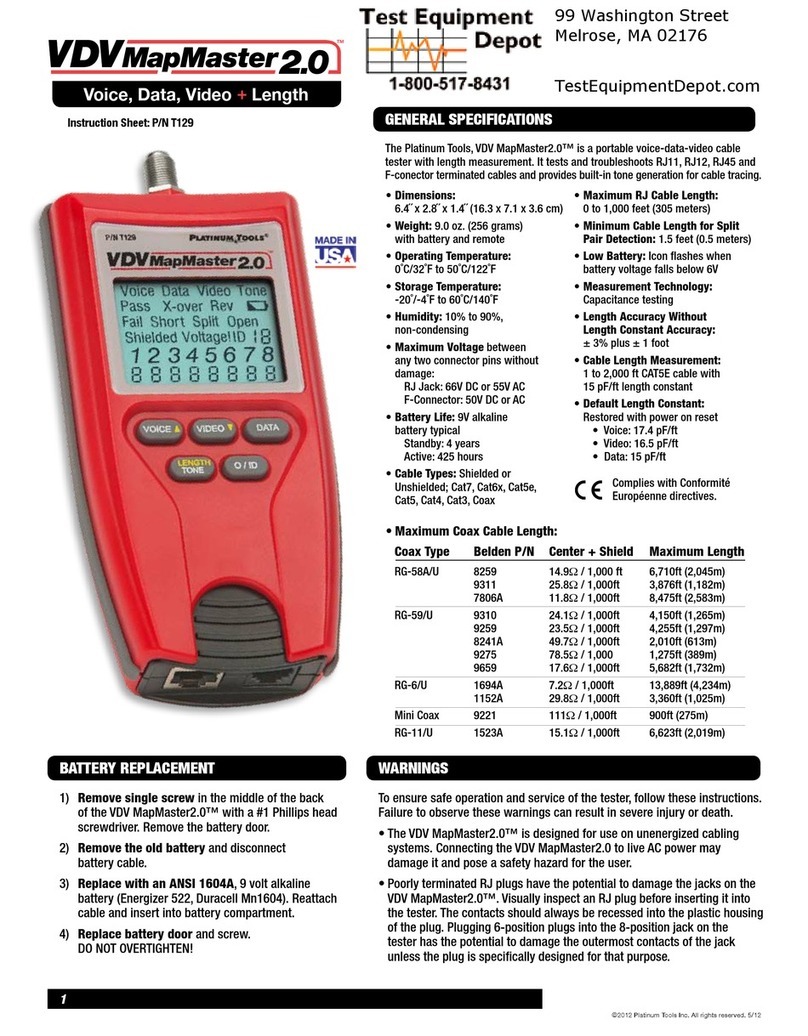

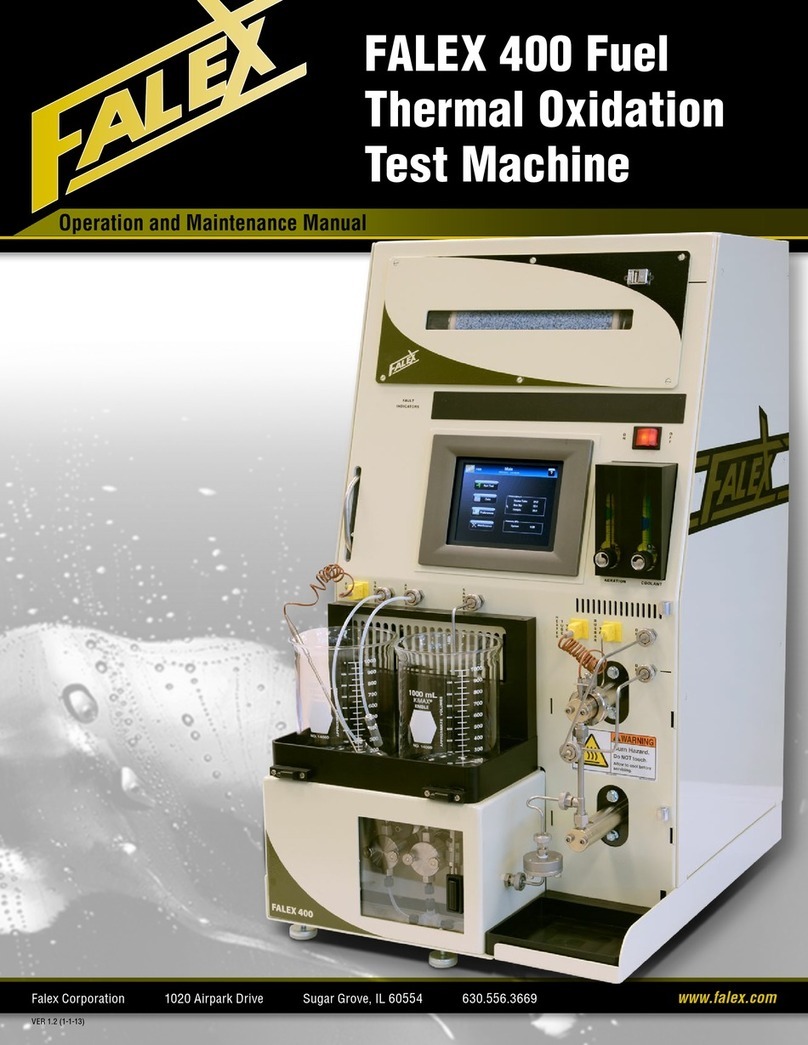

Figure 1. EMIT SmartLog V5

The SmartLog V5 can test either single or dual-wire

wrist straps and its split footplate design provides

individual footwear testing all in a single test. With

the use of TEAM5 Software, the SmartLog V5 can be

programmed to assign unique test requirements to

personnel. An individual can be required to test either

wrist strap only, footwear only or a combination of the

two.

If a resistance path is below or exceeds the set limits,

the SmartLog will indicate failure via audio and visual

alarms. Use the included relay terminal to promote

access control for passed tests.

The SmartLog V5 can also be networked to a

company’s Intranet using its embedded Ethernet

module. The SmartLog V5 is calibrated to NIST

traceable standards.

ESD Association Information

“Compliance verification should be performed prior to

each use (daily, shift change, etc.). The accumulation

of insulative materials may increase the foot grounder

system resistance. If foot grounders are worn outside

the ESD protected area testing for functionality

before reentry to the ESD protected area should be

considered.” ESD SP9.2 APPENDIX B - Foot Grounder

Usage Guidance

“Process monitoring (measurements) shall be conducted

in accordance with a Compliance Verification Plan that

identifies the technical requirements to be verified, the

measurements limits and the frequency at which those

verifications shall occur...Compliance verification records

shall be established and maintained to provide evidence

of conformity to the technical requirements.

The test equipment selected shall be capable of

making the measurements defined in the Compliance

Verification Plan.” (ANSI/ESD S20.20-2007) section 7.3

ANSI/ESD S20.20 Table 1 Flooring-Footwear Systems

Technical Requirements Recommended Range “less

than 3.5 x 10E7 ohms measured per ANSI/ESD STM

97.1.”

“Typical test programs recommend that wrist straps that

are used daily should be tested daily. However, if the

products that are being produced are of such value that

knowledge of a continuous, reliable ground is needed,

and then continuous monitoring should be considered or

even required.” (ESD Handbook ESD TR 20.20 section

5.3.2.4.4)

TECHNICAL BULLETIN TB-6578

*US Patent 6,078,875