Inficon TC1000 User manual

OPERATING MANUAL

iina11e1-a (0604)

Catalog No.

551-005

TC1000

test chamber for hermetically sealed

parts

1-2

iina22e1 chapter 0.fm Operating Manual(0604)

0.1 Imprint

INFICON GmbH

Bonner Straße 498

50958 Köln

Germany

0.2 About these instructions

These instructions are intended for users of the TC1000.

The aim of the instructions is to provide you with a rapid introduction to assembly and

operation of the test chamber.

The structure of the instructions enables you to read the instructions from start to

finish, or only the sections relevant to you if you are already familiar with the unit. In

this case, a glossary is also available at the end of the document.

0.3 Content

0.1 Imprint 1-2

0.2 About these instructions 1-2

0.3 Content 1-2

1 Test chamber TC1000 1-1

1.1 Explanation of terms and symbols 1-1

1.2 Technical data 1-2

2 Structure of the TC1000 2-1

2.1 The test chamber 2-1

2.2 The test chamber on the leak detector 2-2

2.3 The test leak adapter 2-3

2.4 Scope of supply 2-4

2.5 Accessories 2-4

3 Operating the TC1000 3-1

3.1 Starting up the TC1000 3-1

3.1.1 Unpacking 3-1

3.1.2 Starting up 3-1

3.1.2.1 Mount the test chamber 3-1

3.1.2.2 Setting the Auto Leak Test operating mode 3-2

3.1.2.3 Setting the test chamber for the test 3-3

3.1.2.4 Calibrating the leak detector 3-4

3.1.2.5 Measuring mode 3-5

3.1.2.6 Cancelling the test mode 3-5

3.1.2.7 Interrupting and restarting the test mode 3-5

3.1.2.8 Shutting down 3-6

3.1.3 Removal 3-6

3.1.4 Packing 3-6

3.2 Settings in the Auto Leak Test menu 3-6

1-3

iina22e1 chapter 0.fm Operating Manual(0604)

3.2.1 Setting the measuring time 3-7

3.2.2 Setting the verification limit (Trigger level 1) 3-8

3.2.3 Serial errors when testing 3-8

3.2.4 Counting tested components 3-8

3.2.5 Reducing the helium substrate (reference measurement) 3-9

3.3 Maintenance schedule 3-9

3.4 Displaying and reading out the warning table 3-9

4 Further documents 4-1

4.1 Replacement parts list 4-1

4.2 Decontamination declaration 4-1

1-4

iina22e1 chapter 0.fm Operating Manual(0604)

Test chamber TC1000 1-1

iina11e1 chapter 1.fm Operating Manual(0604)

1 Test chamber TC1000

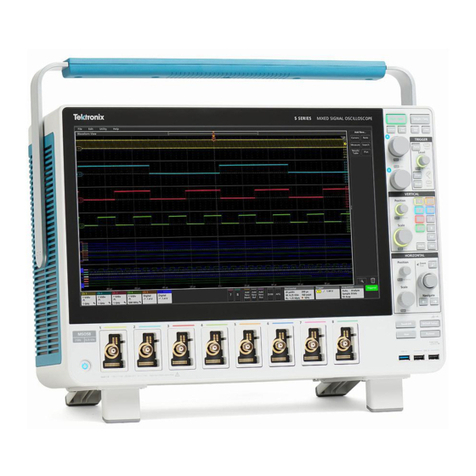

The TC1000 is a small vacuum chamber which allows you to carry out leak tests on

sealed, small solid bodies. These include e.g. quartzes, relays, sensors, ICs and

LEDs.

You can easily mount the test chamber on the leak detectors UL1000 and UL1000

Fab. It does not occupy much space thanks to its small size.

The test procedurefor the test chamber is very easy in conjunction with the INFICON

leak detectors. The test proceeds for the most part automatically.

You place the components in the test chamber and the process is activated by

closing the cover. Two large red and green light emitting diodes show you the results

of the test.

The procedure for dynamic calibration enables rapid and reliable testing of the

components.

1.1 Explanation of terms and symbols

Auto leak test

Refers to the operating mode of the leak detector UL1000 or UL1000 Fab, which

enables hermetically sealed components to be tested for leakproofness.

Dynamic calibration

The rise in a leakage rate signal is compared with the rise in the test leakage signal.

Increasing leakage rates can therefore be detected more rapidly.

Calibration and measurement have the same endurance. So the signals of the

underground that arouse because of a gas occupation of the surface can be better

suppressed.

ESD

Abbreviation for electrostatic discharge.

ESD mat

An ESD mat on the leak detector prevents electrostatic charges from discharging

e.g. onto components placed on it. The charge is removed via the mat.

(Coffee cup)

Indicates the button for the pause function.

1-2 Test chamber TC1000

iina11e1 chapter 1.fm Operating Manual(0604)

Warning triangle

Indicates a upcoming warning message which you can see by pressing the button.

1.2 Technical data

Diameter 130 mm

Depth 40 mm

Volume approx. 430 cm³

Weight 2.7 kg

Connecting flange DN 25 KF

Structure of the TC1000 2-1

iina11e1 chapter 2.fm Operating Manual(0604)

2 Structure of the TC1000

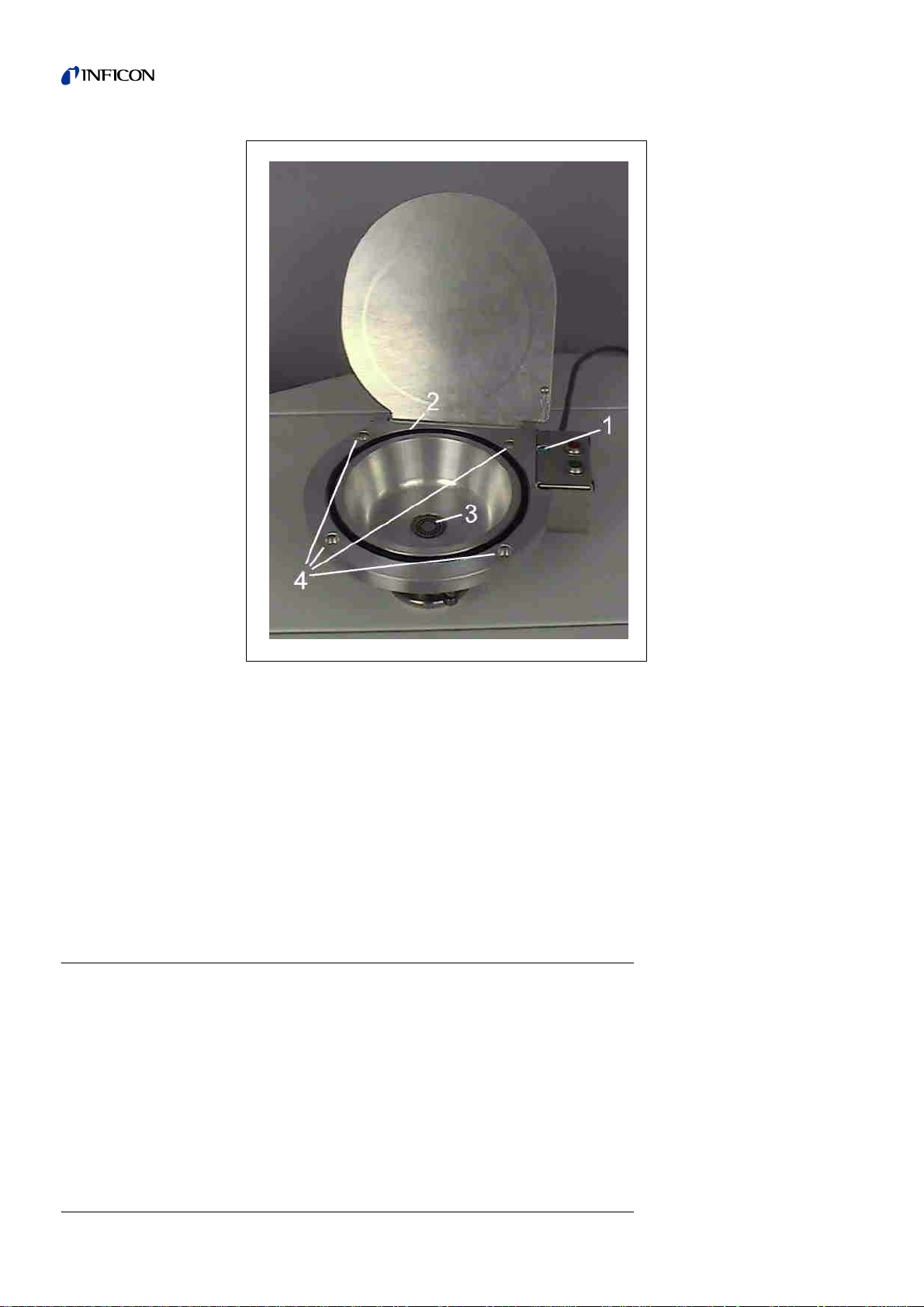

2.1 The test chamber

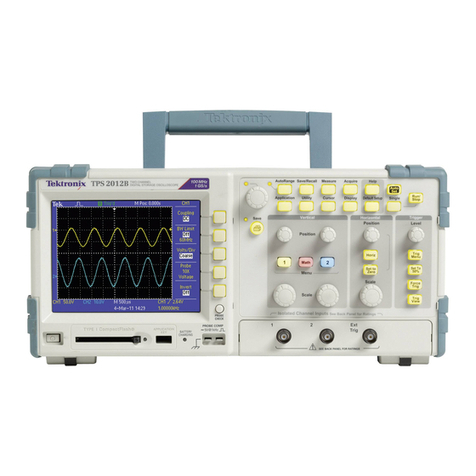

Abb. 2-1 The closed test chamber

Item Description

1 Cover The cover of the test chamber has a floating

mounting. It rests securely on the sealing lock.

2 Connecting cable The electrical connection to the leak detector.

3 Red light emitting diode The red light emitting diode lights up if a leak is

verified which is greater than the trigger

threshold set.

4 Green light emitting diode The green light emitting diode lights up if a leak

is verified which is less than the trigger

threshold set.

5 ESD bracelet connection

on the right of the test

chamber

You can connect the ESD bracelet to this

pushbutton.

Potential static charges are discharged via a

ESD bracelet. This prevents the components

you are testing from becoming damaged.

6 Handle area Hold the cover here for opening and closing.

2-2 Structure of the TC1000

iina11e1 chapter 2.fm Operating Manual(0604)

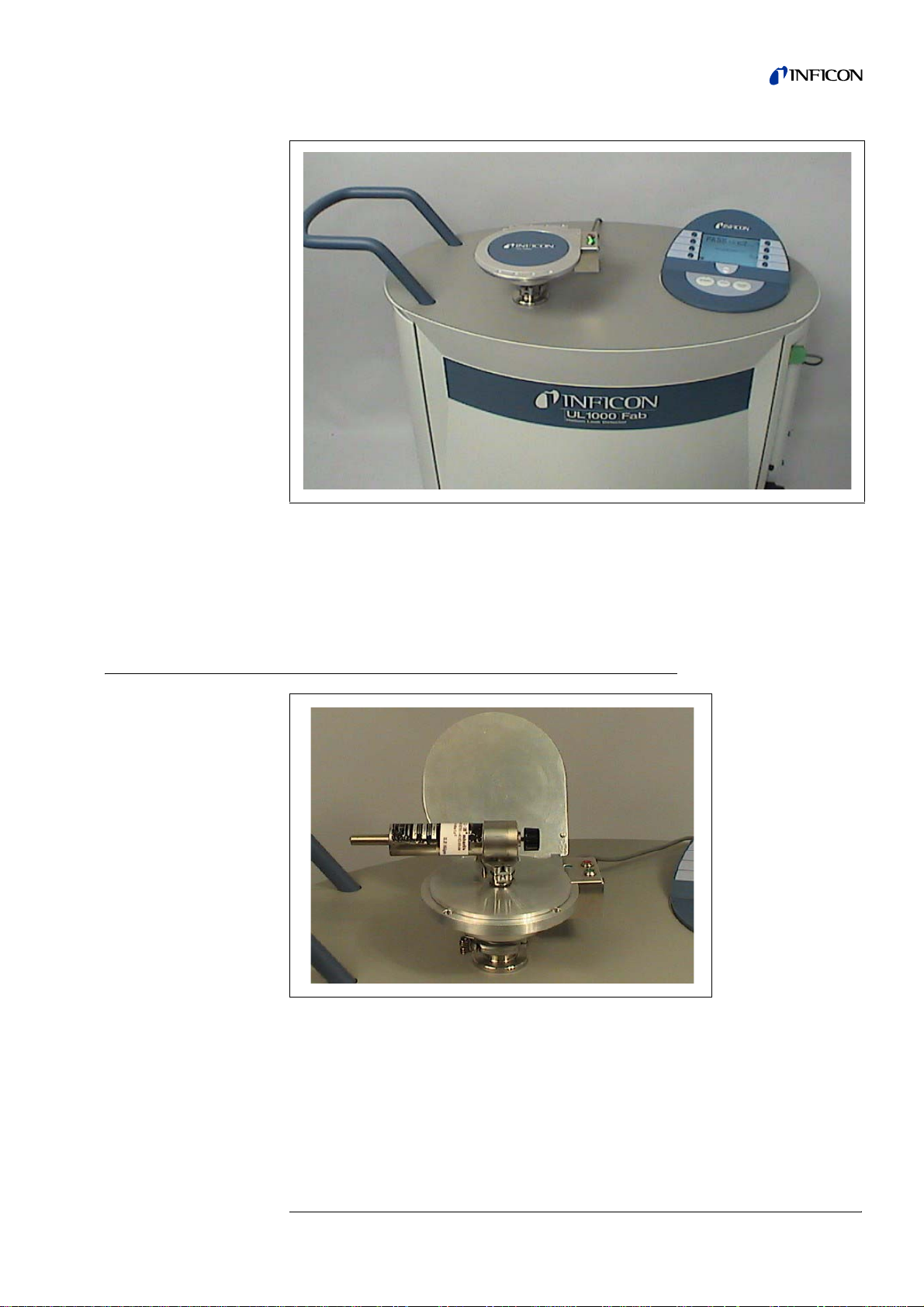

2.2 The test chamber on the leak detector

The test chamber can preferably be operated on the INFICON leak detectors

UL1000 or UL1000 Fab (software version 4.0 or higher).

In the following we describe use of the test chamber on a UL1000 Fab.

Abb. 2-2 The open test chamber

Item Description

1 Proximity switch Ifyou closethecover, you activate the evacuation

process via the proximity switch.

2 O-ring The sealing ring seals the test chamber against

the cover and can easily be replaced.

3 Screen The screen prevents components from falling into

the connecting flange.

4 Bore holes You can fasten the test chamber on a work table.

The bore holes are already provided for this.

Structure of the TC1000 2-3

iina11e1 chapter 2.fm Operating Manual(0604)

The test chamber is mounted on the leak detector with a tightening ring

You can find the instructions for this in Section 3.1.2.1, Removal.

2.3 The test leak adapter

If you carry outan external calibration,you will needan adapter cable anda test leak,

e.g. leak test TL7.

Section 3.1.2.4, Calibrating the leak detector describes how to calibrate the leak

detector.

Fig. 2-3 Mounted on the leak detector

Abb. 2-4

2-4 Structure of the TC1000

iina11e1 chapter 2.fm Operating Manual(0604)

2.4 Scope of supply

The delivery comprises:

• the test chamber TC1000,

• an ESD bracelet,

• the operating instructions for the unit (iina11d1)

2.5 Accessories

Catalogue number

• ESD mat 551-002

• Test leak adapter 200 00 1797

• Test leak TL 7 (leakage rate in the range10-7mbar l/s) 14210

• Test leak TL 8 (leakage rate in the range10-8mbar l/s) 16557

• Test leak TL 8 with DKD calibration 15593

• Test leak TL 9 (leakage rate in the range10-9mbar l/s) 14408

Operating the TC1000 3-1

iina11e1 chapter 3.fm Operating Manual(0604)

3 Operating the TC1000

3.1 Starting up the TC1000

3.1.1 Unpacking

1Now remove the plastic casing in which the TC1000 and accessories are packed.

2Check the delivery for completeness. The scope of supply are listed in Section 2.4.

3Keep the plastic casing and packaging so that you can store the test chamber in it

during periods when you are not using the test chamber.

3.1.2 Starting up

3.1.2.1 Mount the test chamber

1Place the test chamber on the inlet flange of the leak detector.

Fig. 3-1

Item Description

1 TC1000

2 Centerring ring

3Flange

3-2 Operating the TC1000

iina11e1 chapter 3.fm Operating Manual(0604)

2Connect the test chamber to the leak detector by mounting a tightening ring.

The test chamber is mounted on the unit. You can now establish the electrical

connection between the test chamber and the leak detector.

3Connect the cable to the Accessories socket of the leak detector UL1000 or

UL1000 Fab.

4Call up the Auto Leak Test submenu in order to start the automatic test sequence.

You can find further information on the Auto Leak Test operating mode in Section

3.1.2.2.

3.1.2.2 Setting the Auto Leak Test operating mode

1Switch on the leak detector.

2Press the Menu button.

The Display main menu appears on the screen of the leak detector.

Fig. 3-2

Fig. 3-3

Operating the TC1000 3-3

iina11e1 chapter 3.fm Operating Manual(0604)

3Press the following buttons in the correct sequence in order to prepare the leak

detector for operation of the test chamber.

MAIN MENU →MODE →AUTO LEAK TEST →OK

When first setting the Auto Leak Test operating mode, the leak detector refers to the

menu AUTO LEAK TEST SETTINGS.

4If you set the default settings (OK), you will be taken to operation. If you abort the

process (Cancel), you will leave the operating mode again at this point.

3.1.2.3 Setting the test chamber for the test

1When the leak detector isnot set to AUTO LEAK TEST menupleasepressthe following

buttons in succession:

MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS

2The Auto Leak Test Settings menu now appears.

To be able to work in measuring mode, you need to set at least the measuring time

and the rejection rate.

Fig. 3-4

3-4 Operating the TC1000

iina11e1 chapter 3.fm Operating Manual(0604)

3Now set the measuring time and rejection rate:

Setting the measuring time:

1Press the Measuring Time button.

2Set the measuring time you require and confirm with OK.

Setting the rejection rate:

3Press the Trigger Level button

4Set the leakage rate you require and confirm with OK.

You can find more detailed information on setting the test chamber for the test in

Section 3.2.

3.1.2.4 Calibrating the leak detector

Please calibrate the leak detector every now and then. Especially when it did not run

for a longer time.

When you set or change the measuring time the leak detector requests you to

calibrate.

Calibrating with the internal test leak:

1Press the CAL button.

You have now started the calibration.

2Follow the instructions on the display.

Calibrating with the external test leak:

1Connect a test leak with manual valve to the adapter cover.

Open the cover of the test chamber for this and place the adapter cover on it.

Fig. 3-5

Operating the TC1000 3-5

iina11e1 chapter 3.fm Operating Manual(0604)

2Press the CAL button.

You have now started the calibration.

3Follow the instructions on the display.

3.1.2.5 Measuring mode

1Place the component in the test chamber.

2Close the cover of the test chamber.

The test mode is automatically started.

The device ends the test after the set measuring time has expired:

If the unit has completed the test, it indicates whether the component has passed the

test (PASS) or whether leaks are present in the components (FAIL).

3.1.2.6 Cancelling the test mode

1Press the STOP button.

The leak detector interrupts the test mode.

The leak detector does not show any result.

3.1.2.7 Interrupting and restarting the test mode

1Press the button next to the pictogram of the coffee cup.

Fig. 3-6 Trigger level set to 1x10-9, no leak found

Fig. 3-7 Trigger level set to 1x10-9, a leak found

3-6 Operating the TC1000

iina11e1 chapter 3.fm Operating Manual(0604)

The leak detector is now in an operation-ready state.

2Press the Restart button.

The operation is started again.

3.1.2.8 Shutting down

1Ventilate the test chamber and

2press the mains switch.

This switches off the leak detector.

Notice We recommend to evacuate thetest chamber befor you switch off the leak

detector. So you can avoid defilement.

If the test chamber is to remain depressurised after switching off the leak detector:

1Press the Coffee Cup button.

3.1.3 Removal

You can remove the test chamber if you have switched off the leak detector.

1Loosen the tightening ring.

2Take the test chamber off the flange and remove the o-ring.

You can find photographs, in reverse order, in Section 3.1.2.1, Mount the test

chamber.

3.1.4 Packing

1Take out the cardboardbox with the padding paper which was provided with the test

chamber.

2Pack the TC1000 and accessories in the plastic casing.

3Place the TC1000 in the padded cardboard box.

3.2 Settings in the Auto Leak Test menu

You can access the AUTO LEAK TEST SETTINGS menu at any time from the measuring

mode.

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS

Operating the TC1000 3-7

iina11e1 chapter 3.fm Operating Manual(0604)

Several settings are available for selection.

1Select the setting you require and confirm with OK.

The display then jumps back to the superior menu.

3.2.1 Setting the measuring time

1Proceed as follows in the menu so as to be able to set the measuring time:

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS →

MEASURING TIME

2Enter the required measuring time.

A measurement lasts between 1 second and 30 minutes, depending on how you

have previously set the leak detector.

The measurement depends on three factors: the volume of the test chamber, the

volume of the components being tested and the rejection leakage rate (trigger level).

If you change the measuring time, the unit could require a calibration.

You can find further information at 3.1.2.4, Calibrating the leak detector.

Examples of settings for

time

The INFICON test chamber was used with a content of 430 cm³ for the settings in

these examples.

Fig. 3-8

Item Description Item Description

1 Back 5 Part number

2 Measuring time 6 Reference measurement

3 Trigger level 1

4 Serial error message

Rejection rate Measuring time (recommended)

10E-5 2 seconds

10E-6 2 seconds

10E-7 2 seconds

3-8 Operating the TC1000

iina11e1 chapter 3.fm Operating Manual(0604)

You have now specified the measuring time.

3.2.2 Setting the verification limit (Trigger level 1)

1Proceed as follows in the menu so as to be able to set the verification limit:

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS →

TRIGGER LEVEL 1

2Enter the required verification time.

3Press the button OK.

To test components, the verification limit (trigger level) can be set from 10E-1 to

10E-9 mbar l/s.

You have now specified the verification limit.

3.2.3 Serial errors when testing

1Proceed as follows in the menu in order to test the measuring accuracy:

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS →

SERIAL ERROR MESSAGE

You can specify the number of leaking components occurring in succession during a

test after which a serial error message is indicated by the leak detector.

2You can select between 1 to 9 messages with defective components or deactivate

the function.

You can typically enter the number 3.

The leak detector identifies 3 components in succession as defective in the following

tests.

3The leak detector prompts you to do a reference measurement.

You can find more detailed information in Section 3.2.5.

3.2.4 Counting tested components

1Proceed as follows in the menu in order to give a number to the components you are

testing.

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS →PART

NUMBER

2Enter the number of the first component. Afterwards the unit automatically counts up

the number of tested components.

The unit then counts the tested components and displays the result.

10E-8 >5 seconds

10E-9 >10 seconds*

* We recommend an external calibration with a test

leak TL9 (10E-9).

Rejection rate Measuring time (recommended)

Operating the TC1000 3-9

iina11e1 chapter 3.fm Operating Manual(0604)

3.2.5 Reducing the helium substrate (reference

measurement)

The leak detector responds to helium. This is to verify the helium which emerges

from openings in the components. After a series of tests, there might be so much

helium in the unit that the leak detector responds to this with an error message. It

does not then verify the helium which emerges from the component, but instead the

helium which is located in the unit for other reasons.

1Proceed as follows in the menu in order to reduce the helium substrate:

MAIN MENU →SETTINGS →VACUUM SETTINGS →AUTO LEAK TEST SETTINGS →

REFERENCE TEST

After a series error message has come up you can start the reference measurement

from the stand by display. Press the button reference measurement.

2Follow the instructions on the display

3and press the OK button.

The leak detector pumps the test chamber 3 times empty and then ventilates again

each time. The unit is calibrated internally.

After the reference test, the leak detector measures the helium substrate and

subtracts the value from the measurements which are carried out.

3.3 Maintenance schedule

The test chamber does not require maintenance.

O-ring

Check occasionally whether the o-ring is damaged. If necessary, replace it.

Cleaning

1Clean the test chamber with alcohol.

2Pump the chamber 3 to 4 times after the cleaning. In this way you can remove

residual vapours from the surface.

3.4 Displaying and reading out the warning table

A warning triangle appears on the display if faults occur.

If you wish to read out the fault display,

1press the button next to it.

2Follow the instructions to rectify the warning.

3-10 Operating the TC1000

iina11e1 chapter 3.fm Operating Manual(0604)

This manual suits for next models

1

Table of contents

Other Inficon Test Equipment manuals

Inficon

Inficon 122 20 Quick guide

Inficon

Inficon ULTRATEST UL3000 Fab PLUS User manual

Inficon

Inficon FTC3000 Quick guide

Inficon

Inficon TGF10 User manual

Inficon

Inficon TL3-5 User manual

Inficon

Inficon 12329 Quick guide

Inficon

Inficon VORTEX User manual

Inficon

Inficon E-Check Quick guide

Inficon

Inficon MPG400 User manual

Inficon

Inficon MCT150 User manual

Popular Test Equipment manuals by other brands

Anritsu

Anritsu Site Master S330A user guide

Softing

Softing CableMaster 210 quick start guide

Aimco

Aimco AUDITOR AUET quick start guide

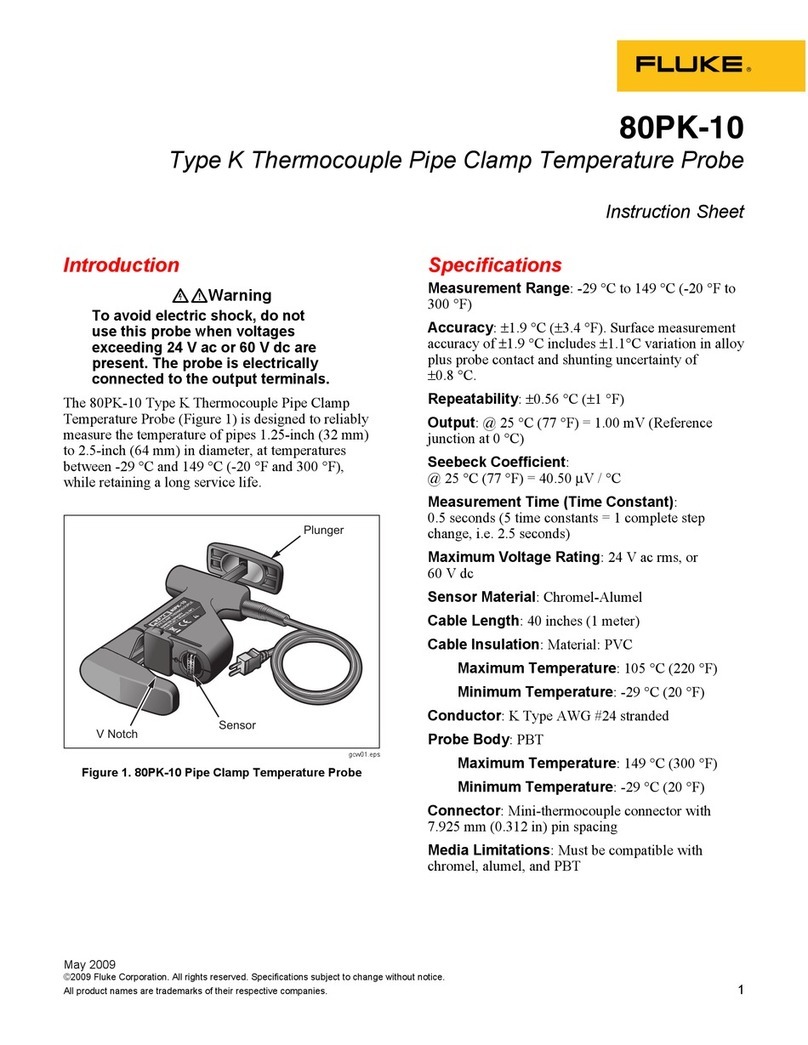

Fluke

Fluke 80PK-10 instruction sheet

EA Technology

EA Technology UltraTEV Monitor operating manual

Keysight Technologies

Keysight Technologies 85058E User's and service guide