EMIT SmartLog V4 Installation and operating instructions

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

TB-6572 Page 1 of 6 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

Made in the

United States of America

SmartLog V4

Installation, Operation and Maintenance

Description

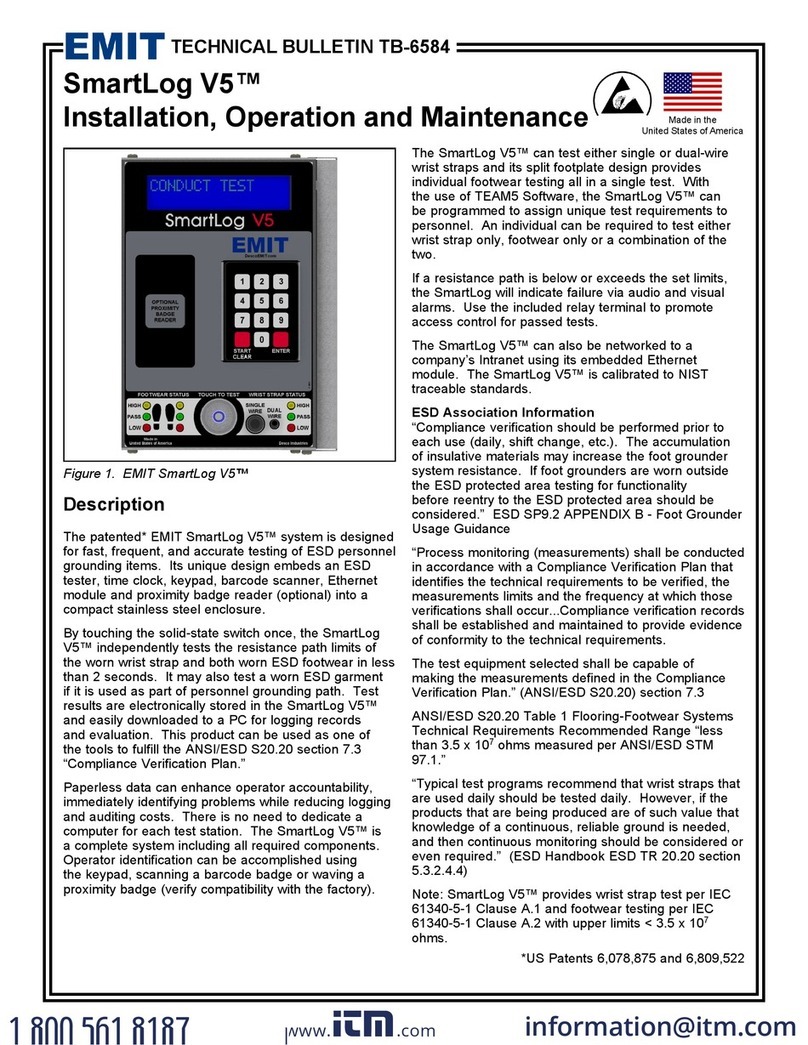

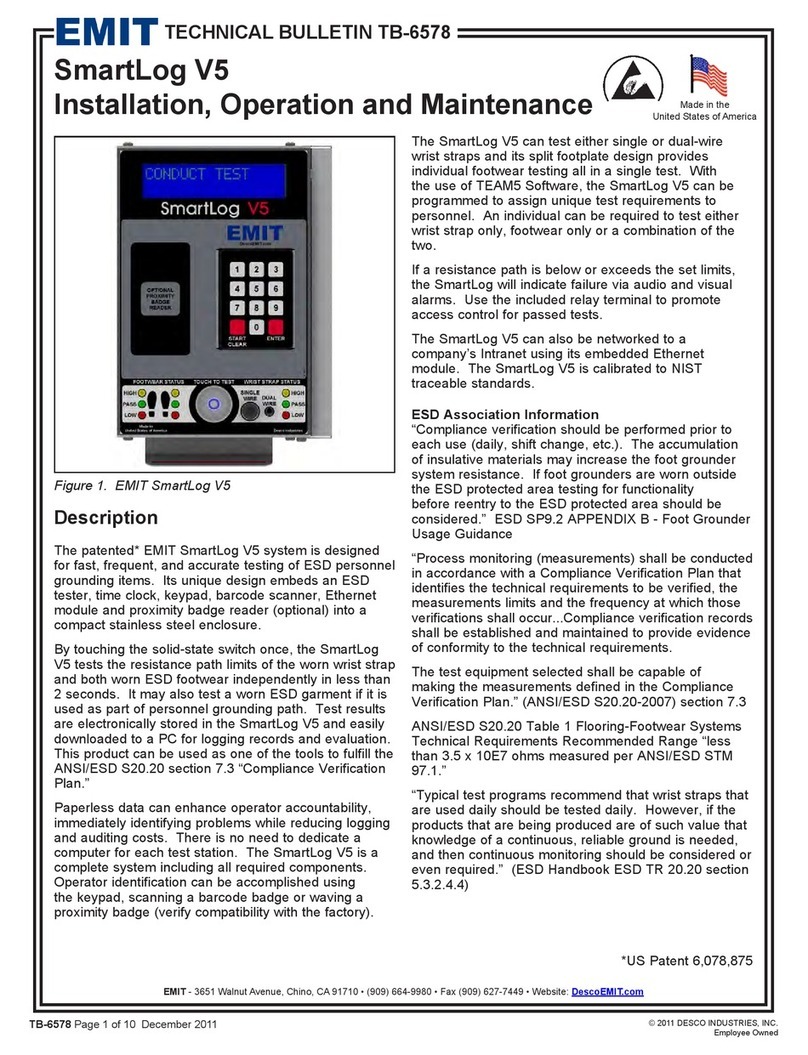

The patented* EMIT SmartLog V4 Data Acquisition System

is designed for fast, frequent, and accurate testing of ESD

personnel grounding items. By touching the electrode button

once the SmartLog V4 tests the resistance path limits of the

worn wrist strap and both worn ESD footwear independently

within one second. (Or worn ESD garment if it is used as part

of personnel grounding path). Test results are electronically

stored in the SmartLog V4 and are easily downloaded to a PC

for logging records and evaluation. This product can be used

as one of the tools to fulfill the ANSI/ESD S20.20 section 7.3

“Compliance Verification Plan”.

Paperless data can enhance operator accountability

immediately identifying problems while reducing logging and

auditing costs. There is no need to dedicate a computer for

each test station. The SmartLog V4 is a complete system

including all required components. Operator identification

can be accomplished by using the keypad, swiping a barcode

card, or waving a proximity card (verify compatibility with the

factory).

The SmartLog V4 can test either single or dual-wire wrist

straps; the split footplate design allows for individual footwear

testing all in one test. If a resistance path is below or exceeds

the set limits failure will be noted via audio and visual alarms.

Passing tests can enable a relay for automated door openers.

However, if the user desires to test the wrist strap and ESD

footwear separately this can be accomplished. The wrist

strap test is activated by inserting wrist strap plug into the

designated jack. See TEAM5 Operation Manual for more

information on setting individual test requirements.

As many as 32 SmartLogs can be daisy-chained and

connected to one computer allowing data to be collected

to one central computer for all SmartLogs. The SmartLog

V4 can also be networked to a company’s Intranet with

the optional 50461 Ethernet Adapter. The SmartLog V4 is

calibrated to NIST traceable standards.

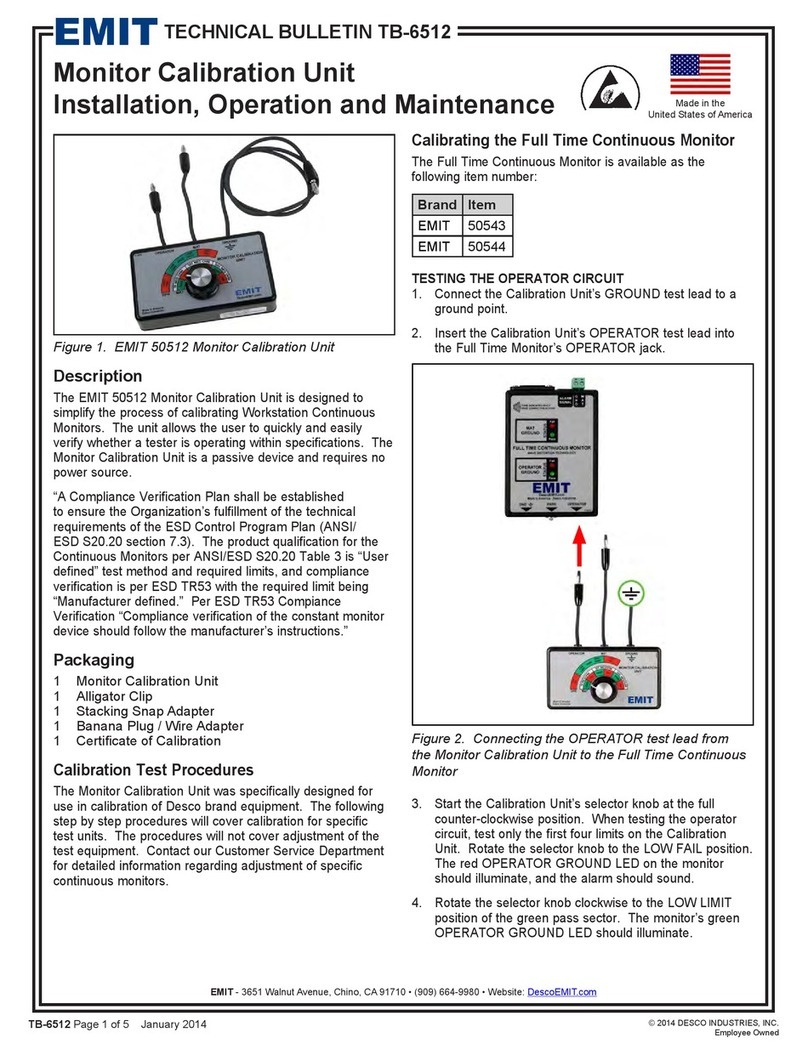

TECHNICAL BULLETIN TB-6572

November 2011

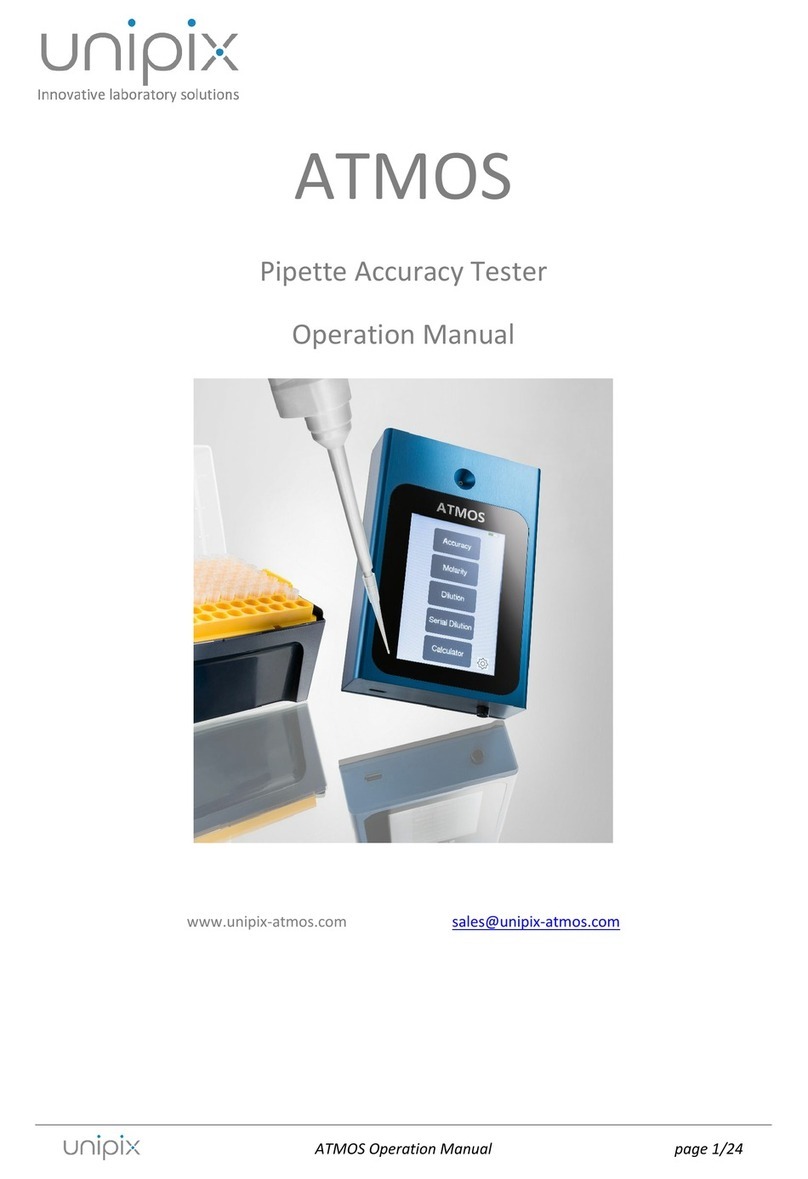

Figure 1. EMIT SmartLog V4

The SmartLog V4’s default Wrist Strap test range is 1 - 10

megohms, and the default Footwear test range is 1 - 35

megohms. The ranges are easily adjusted.

TEAM5 Software

Use the powerful versatile TEAM5 Software to collect and

analyze records.

1) Specify tests and shifts for each employee in

database

2) Auto or manual polling of data to computer

3) Auto archive and network data posting

4) Allow data to be saved and stored automatically

5) Data retrieval at selectable time intervals

6) Allow easy data analysis

7) Click Here to view the TEAM5 Comparison Chart

See TEAM5 Operation Manual for more information.

ESD Association Information

“Compliance verification should be performed prior to each

use (daily, shift change, etc.). The accumulation of insulative

materials may increase the foot grounder system resistance.

If foot grounders are worn outside the ESD protected area

testing for functionality before reentry to the ESD protected

area should be considered.” ESD SP9.2 APPENDIX B - Foot

Grounder Usage Guidance

“Process monitoring (measurements) shall be conducted in

accordance with a Compliance Verification Plan that identifies

the technical requirements to be verified, the measurements

limits and the frequency at which those verifications shall

occur...Compliance verification records shall be established

and maintained to provide evidence of conformity to the

technical requirements.

The test equipment selected shall be capable of making the

measurements defined in the Compliance Verification Plan.”

(ANSI/ESD S20.20-2007) section 7.3

ANSI/ESD S20.20 Table 1 Flooring-Footwear Systems

Technical Requirements Recommended Range “less than 3.5

x 10E7 ohms measured per ANSI/ESD STM 97.1”.

“Typical test programs recommend that wrist straps that are

used daily should be tested daily. However, if the products

that are being produced are of such value that knowledge of

a continuous, reliable ground is needed, and then continuous

monitoring should be considered or even required.” (ESD

Handbook ESD TR 20.20 section 5.3.2.4.4)

Carefully unpack the

SmartLog

. The

SmartLog

comes ready to

install without any changes to the clock’s configuration.

If multiple SmartLogs are to be installed in a daisy-chain

configuration refer to page 5 for instructions.

*US Patent 6,078,875

This datasheet has been downloaded fromhttp://www.digchip.com at this page

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

TB-6572 Page 2 of 6 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

Please see the following technical bulletins for more information on

the

SmartLog V4.

Document No. Description

TB-6546 Ethernet Adapter

TEAM5 Software Operation Manual

The EMIT

SmartLog V4

is available in four models:

Item Description

50741 SmartLog V4, N. America

50743 SmartLog V4, Asia

50747 SmartLog V4, Europe

50751 SmartLog V4, Europe, 10mm Adapter

SMARTLOG ACCESS CONTROLLER

The EMIT SmartLog Access Controller is designed to control the

access to areas where ESD testing is not required or has already

taken place (i.e. supply cage, gowning room, etc.). The built-in

relay terminal allows compatibility with electro-magnetic doors, turn

styles or light towers.

When used in conjunction with the SmartLog V4, a user with a

PASS condition can use the SmartLog Access Controller for entry

by simply entering their PIN or swiping their badge.

The EMIT

SmartLog Access Controller

is available in three

models:

Figure 2. SmartLog V4 features and components

(Items 50741, 50743, 50747)

A B

C D

Figure 4. SmartLog Access Controller features and

components (Items 50752, 50753, 50754)

J

KL

Figure 3. SmartLog V4 features and components

(Item 50751)

E F

GI

H

Item Description

50752 SmartLog Access Controller, N. America

50753 SmartLog Access Controller, Asia

50754 SmartLog Access Controller, Europe

NOTE:

SmartLogs

are not designed to work in high humidity

environments above 70 RH%.

Packaging

SMARTLOG V4

1 SmartLog V4,

Wrist Strap / Footwear Tester, and

Numeric Keypad on mounting plate

1 Dual Independent Foot Plate

1 Stereo Cable for Dual Foot Plate

1 AC Adapter 12VDC 500mA center pos.

1 DB9 Serial Adapter

1 25’ RS-232 Non-inverted Data Cable

4 Mounting Anchors

4 Mounting Screws

1 Banana-to-Ring Terminal ground Cable

1 10mm Adapter (50751 only)

SMARTLOG ACCESS CONTROLLER

1 SmartLog Access Controller

and Numeric Keypad on mounting plate

1 AC Adapter 12VDC 500mA center pos.

4 Mounting Anchors

4 Mounting Screws

Features and Components

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

TB-6572 Page 3 of 6 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

A. Numeric Keypad: Inputs numeric IDs.

B. Infrared Barcode Reader: Reads Code 39 and Code 128

Barcode.

C. Accessory Mount: The following accessories may be mounted

at this location:

50443

Laser Barcode Scanner

50461

Ethernet Adapter

Proximity Interface (contact manufacturer for more info)

D.

SmartLog V4 Wrist Strap / Footwear Tester:

Default wrist strap test range is 1 - 10 megohms. The

default footwear test range is 1 - 35 megohms. The default

test ranges may be changed to suit personal ground device

testing. See Technical Bulletin TB-6564 for instructions.

E. Numeric Keypad: Inputs numeric IDs.

F. Infrared Barcode Reader: Reads Code 39 and Code 128

Barcode.

G. Accessory Mount: The following accessories may be mounted

at this location:

50443

Laser Barcode Scanner

50461

Ethernet Adapter

Proximity Interface (contact manufacturer for more info)

H. 10mm Snap Adapter: Place 10mm wrist cord here to test wrist

strap.

I.

SmartLog V4 Wrist Strap / Footwear Tester:

Default wrist strap test range is 1 - 10 megohms. The

default footwear test range is 1 - 35 megohms. The default

test ranges may be changed to suit personal ground device

testing. See Technical Bulletin TB-6564 for instructions.

J. Infrared Barcode Reader: Reads Code 39 and Code 128

Barcode.

K. Numeric Keypad: Inputs numeric IDs.

L. Accessory Mount: The following accessories may be mounted

at this location:

50443

Laser Barcode Scanner

50461

Ethernet Adapter

Proximity Interface (contact manufacturer for more info)

Configuring the Clock, Mounting the Unit,

and Cable Connections

A. Clock’s Baud Rate, ID, Parity, Daylight Option and Port

Expand (see Figure 6)

1. Plug the power supply into the unit and then to the

appropriate AC source. Refer to Figure 6 to locate the

power input jack. The SmartLog will cycle through a

self diagnostic program. The time and date will appear on

the screen when the diagnostics is complete. Do not

continue until this step has been completed.

NOTE: If any of the below settings are not correct, proceed

to step 2 and press the Advance button until the correct

value appears on the display.

Power Requirement: It is highly recommended that these

units are installed on power lines separate from other devices.

The clock should not be installed on the same power line with

devices containing electric motors. These units have a built-in

self-healing fuse and surge, spike, and noise protection. The

clock should be powered on a dedicated electrical circuit. If

you are located in an area where there are frequent electrical

storms, power surges, blackouts, or other similar problems

we strongly recommend that the unit be placed on a surge

protector.

2. After the self diagnosis press the MENU button six times.

If you do not press the Menu button within 20 seconds the

clock will exit out of the set-up menu and will need to be

reset by disconnecting then reconnecting the power

supply. Refer to Figure 6 for button locations.

3. Baud Rate should be set at 9600 (factory default). Press

Enter for the next screen.

4. Parity should be set for ODD (factory default). Press Enter

for next screen.

5. The SmartLog ID is a 2 digit field with valid I.D.

numbers 00 through 63. Each SmartLog should have a

different I.D. number if they are connected to the same

communication line. The SmartLog should be

numbered sequentially starting with 00, so that automatic

polling in the software will not be interrupted.

6. The Daylight Option enables daylight savings in the clock.

7. Port Expand should be set to YES (factory default).

8. Press Enter button once more to cycle to the next setting

before hitting the Menu button to exit.

NOTE: The setting will not change if you do not cycle to the

next setting by hitting the Enter button.

B. Terminator Jumper, RS-485 Switch, RS-232 Switch and

Relay Terminal

1. The RS-485 is set default on SLAVE position (right side)

and does not need to be switched unless the unit is in a

daisy-chain. For units in a daisy-chain, set the RS-485 of

the first and last SmartLog to MASTER (left position).

All others in between need to be set to SLAVE.

2. The Relay Terminal connections can be made on the back

of the SmartLog (see Figure 5). They can be used to

control doors, gates, etc. The relay terminal is limited to a

maximum of 1A @ 30VDC or .5A @ 125VAC.

BELL

BUZZER

DOOR LOCK

LIGHT

OTHER

POWER

SOURCE

0 - 120 V

AC / DC

HOT NORMALLY

OPEN

COMMON / NEUTRAL

Figure 5. Relay installation

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

TB-6572 Page 5 of 6 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

3. The RS-232 Interface is described by the Electronic

Industries Association (EIA) as EIA-232 or RS-232. Special

consideration should be used when installing the

communications cable. Keep a 3 feet separation distance

from any EMF source (power wires, fluorescent lights, etc).

The cable length shall not exceed 50 feet from PC to unit.

The EMIT 50461 Ethernet Adapter should be used if

distance requirements exceed 50 feet.

C. Connecting the SmartLog

NOTE: Both the SmartLog and computer should be turned off

during the following procedures.

Connecting One SmartLog V4 (See Figure 7)

1. Connect the Serial Adapter to the desired PC.

2. Connect one end of the provided RS-232 Non-inverted

Data Cable to the Serial Adapter.

3. Connect the other end of the RS-232 Non-inverted Data

Cable to port labeled “RS-232” on the SmartLog.

NOTE: Ensure that the SmartLog ID is set to 00 and its

terminator jumper is left open.

Connecting More Than One SmartLog

(See Figure 8)

The following procedure provides an example on connecting 3

SmartLogs.

1. Connect the Serial Adapter to the desired PC.

2. Connect one end of the provided RS-232 Non-inverted

Data Cable to the Serial Adapter.

3. Connect the other end of the RS-232 Non-inverted Data

Cable to clock port labeled “RS-232” on the SmartLog.

4. Set first SmartLog ID to 00.

5. Connect one end of a pair of 18 gauge wires to the clock

port labeled “RS-485” on the first SmartLog.

6. Connect the other end of the pair of 18 gauge wires to the

clock port labeled “RS-485” on the second SmartLog.

7. Set second SmartLog ID to 01.

8. Connect one end of another pair of 18 gauge wires to the

clock port labeled “RS-485” on the second SmartLog.

9. Connect the other end of the same pair of 18 gauge wires

to the clock port labeled “RS-485” on the third SmartLog.

10. Set second SmartLog ID to 02.

D. Mounting the SmartLog

Use the provided anchors and screws to mount the entire

SmartLog plate. Be sure to place the SmartLog at a height

where all operators can clearly see the display and perform

the necessary tests.

EMIT also offers the 50415 Tester Stand as an alternative

mounting solution (see Figure 9).

When the hardware installation has been completed, refer to

the TEAM5 Operation Manual for installation. This manual will

take you through the necessary steps to begin using your new

SmartLog system.

Troubleshooting

Problem: The host computer is not recognizing the SmartLog.

a. Verify that the cable from the computer to the SmartLog is

properly connected. The cable should be flat non-inverted

(See Figure 7).

b. Verify that the communication setup on the clock is 9600

baud rate, parity ODD. Refer to the instructions on back of

SmartLog plate to enter configuration mode.

c. If there are more than 2 units, verify that their IDs are

unique by entering the SmartLog configuration mode.

d. Contact your local IT department to verify that the

computer’s comport is working properly.

e. Make sure that the SmartLog LED’s are blinking during

data transmission. If they are not blinking or remain on all

the time, please contact EMIT technical support at

(

909) 664-9980

for further support.

Figure 9. EMIT 50415 Tester Stand

EMIT - 3651 Walnut Avenue, Chino, CA 91710 • (909) 664-9980 • Fax (909) 627-7449 • Website: DescoEMIT.com

TB-6572 Page 6 of 6 © 2011 DESCO INDUSTRIES, INC.

Employee Owned

Contacts

USA

EMIT

3651 Walnut Ave

Chino, CA 91710

TEL: (909) 664-9980

FAX: (909) 627-7449

EUROPE

Charleswater

Unit 17, Millbrook Business Park, Sybron Way

Crowborough, East Sussex, TN6 3JZ, U.K.

TEL: +44 (0) 189 266 5313

FAX: +44 (0) 189 266 8838

Limited Warranty

EMIT expressly warrants that for a period of ve (5) years from

the date of purchase EMIT SmartLogs will be free of defects in

material (parts) and workmanship (labor). Within the warranty

period, a credit for purchase of replacement EMIT products,

or, at EMIT’s option, the product will be repaired or replaced

free of charge. If product credit is issued, the amount will be

calculated by multiplying the unused portion of the expected

one year life times the original unit purchase price. Call our

Customer Service Department at 909-664-9980 (Chino, CA)

for a Return Material Authorization (RMA) and proper shipping

instructions and address. Please include a copy of your original

packing slip, invoice, or other proof of date of purchase. Any unit

under warranty should be shipped prepaid to the EMIT factory.

Warranty replacements will take approximately two weeks.

If your unit is out of warranty, call our Customer Service

Department at 909-664-9980 (Chino, CA) or for a Return Material

Authorization (RMA) and proper shipping instructions and

address. EMIT will quote repair charges necessary to bring your

unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU

OF ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator

error, or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will EMIT or any seller be responsible or liable for

any injury, loss or damage, direct or consequential, arising out of

the use of or the inability to use the product. Before using, users

shall determine the suitability of the product for their intended use,

and users assume all risk and liability whatsoever in connection

therewith.

Table of contents

Other EMIT Test Equipment manuals

EMIT

EMIT SmartLog V5 Installation and operating instructions

EMIT

EMIT 50557 Installation guide

EMIT

EMIT eScan2 User manual

EMIT

EMIT SmartLog V5 Service manual

EMIT

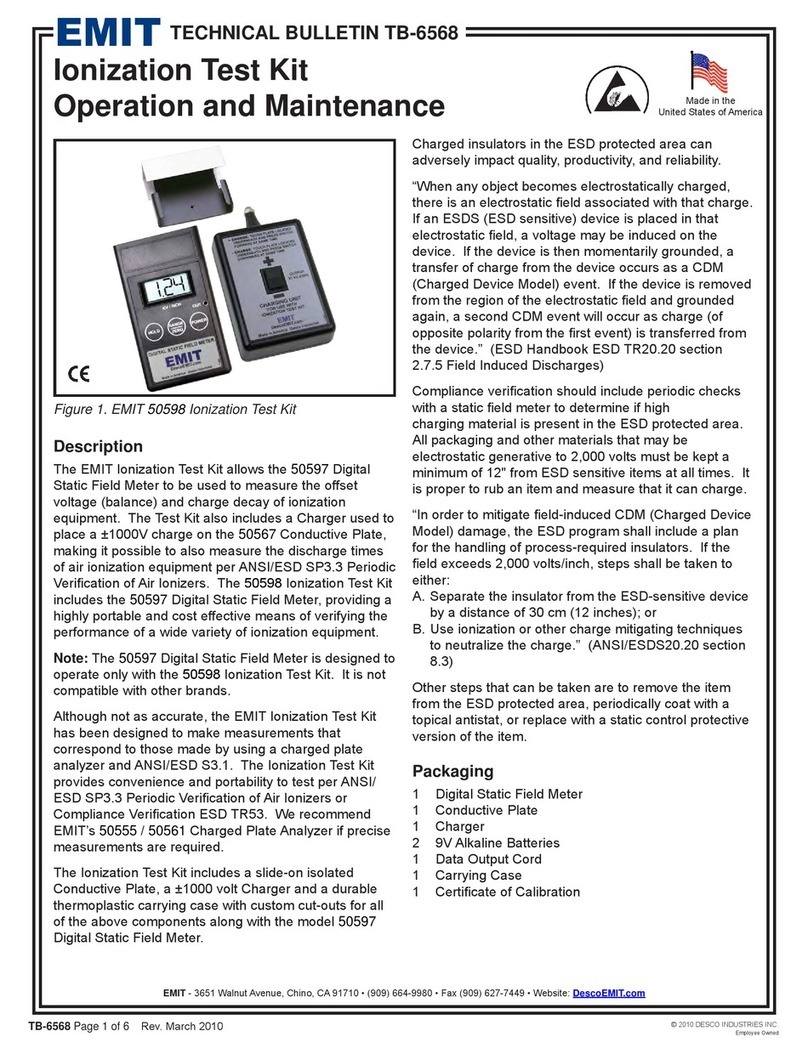

EMIT TB-6568 Installation guide

EMIT

EMIT 50512 Service manual

EMIT

EMIT ESD Glove Test Fixture Installation and operating instructions

EMIT

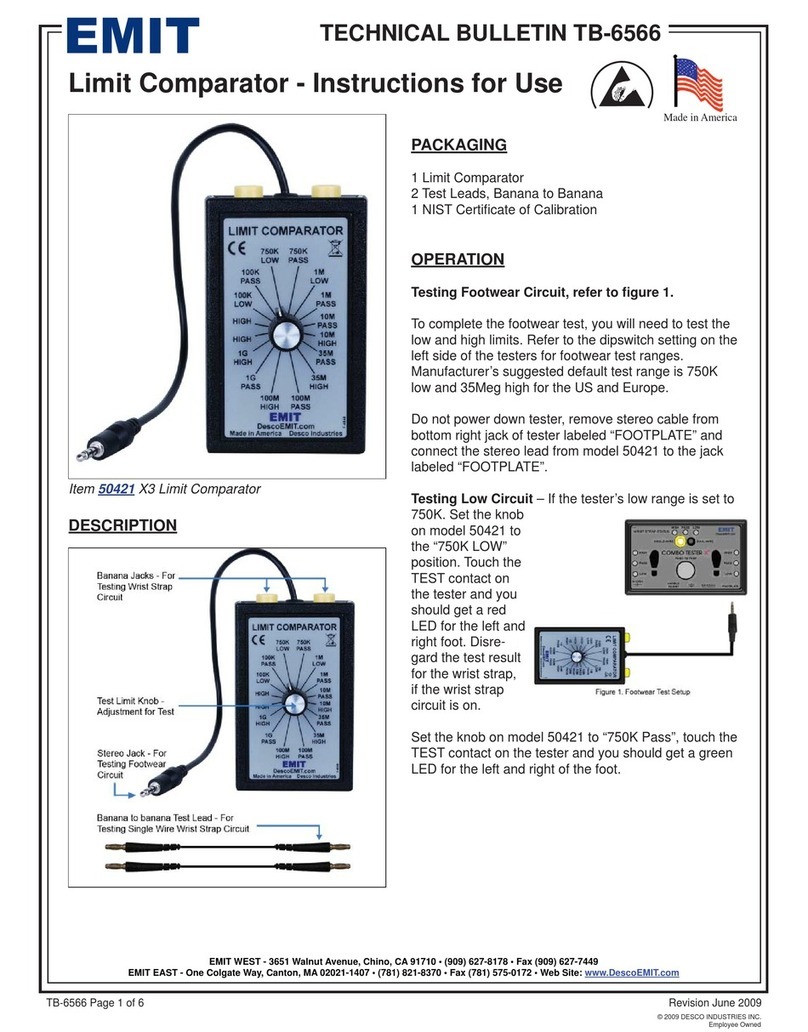

EMIT Limit Comparato User manual

Popular Test Equipment manuals by other brands

Klein Tools

Klein Tools VDV Commander VDV501-097 quick start guide

Agilent Technologies

Agilent Technologies InfiniiVision 2000 X-Series user guide

Microlife

Microlife PF 100 instruction manual

Agilent Technologies

Agilent Technologies U1602B User's and service guide

Timing

Timing TSC 5120A Operation and maintenance manual

Emos

Emos VT-110 manual