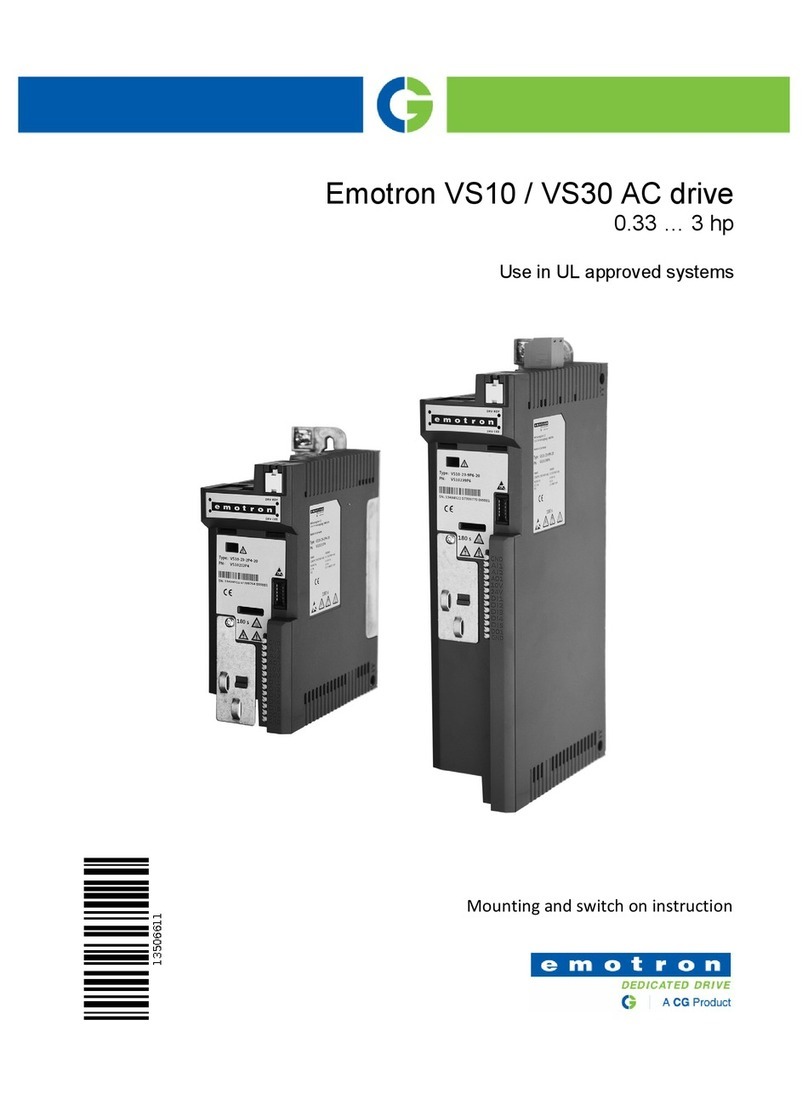

Thank you for choosing Emotron VSB S eries General Purpose AC Motor Drives from CG

Drives & Automation. This user manual presents a detailed description of Emotron VSB series

with respect to product features, structural characteristics, functions, installation, parameter

setting, troubleshooting, commissioning and daily maintenance, etc. Be sure to carefully read

through the safety precautions before use, and use this product on the premise that personnel

and equipment safety is ensured.

IMPORTANT NOTES

Please assure the intactness of product enclosure and all safety covers before

installation .Operation must conform to the requirements of this manual and local industrial

safety regulations and/or electrical codes.

Contents of this manual may be subject to appropriate modification as a result of product

upgrade, specification change and update of the manual.

In the event of damage or loss of user manual, users may ask local distributors, offices or

our Technical Service Department for a new one.

If any item as stated in this manual is not clear, please contact our Technical Service

Department.

If any anomaly occurs after power up or during the operation, it is essential to stop the

machine and identify the fault or seek technical services as soon as possible.

Emotron VSB

Instruction manual - English

400V: Software type/version: 50101/08.01.0085 (main drive and control board)

50201/08.01.0086 (Aux terminal control board)

230V: Software type/version: 50101/08.01.0087 (main drive and control board)

50201/08.01.0088 (Aux terminal control board)

Document number: 01-5577-01 Edition: r0

Date of release: 30-05-2014

© Copyright Crompton Greaves Ltd 2014

Crompton Greaves Ltd retains the right to change specifications and

illustrations in the text, without prior notification. The contents of this document may

not be copied without the explicit permission of Crompton Greaves Ltd.