Emotron AB 01-4135-01r1 3

Contents

1. General information ....................................... 5

1.1 How to use the Instruction Manual.......................... 5

1.2 Integrated safety systems ........................................ 5

1.3 Safety measures ....................................................... 5

1.4 Notes to the Instruction Manual .............................. 5

1.5 Type number.............................................................. 5

1.6 Standards .................................................................. 6

1.7 Tests in accordance with norm EN 60204

standard..................................................................... 6

1.8 Transport and packing.............................................. 6

1.9 Unpacking MSF-310 and larger types ..................... 6

1.10 Glossary ..................................................................... 7

2. Description...................................................... 9

2.1 Background theory.................................................... 9

2.2 Reduced voltage starting........................................ 10

2.3 Other starting methods........................................... 12

2.4 Use of softstarters with torque control .................. 13

3. Mounting ...................................................... 15

3.1 Installation of the softstarter in a cabinet............. 15

4. Connections ................................................. 19

4.1 Connecting mains and motor cables ..................... 20

4.2 Control Connection ................................................. 24

4.3 Minimum wiring....................................................... 25

4.4 Wiring examples ...................................................... 25

5. How to get started....................................... 27

5.1 Checklist .................................................................. 27

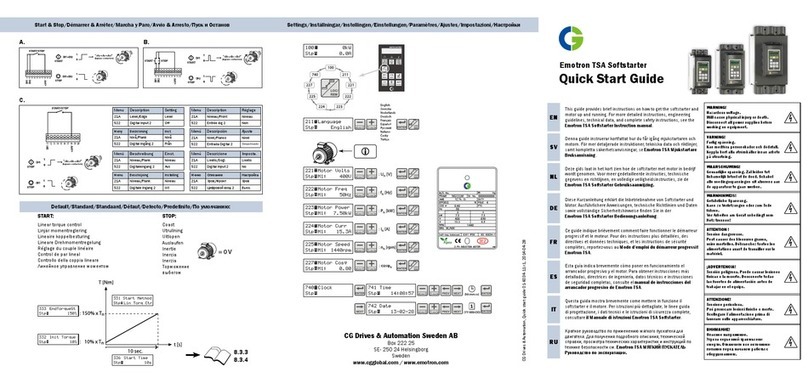

5.2 Applications ............................................................. 27

5.3 Motor data ............................................................... 28

5.4 Start and stop.......................................................... 28

5.5 Setting the start command..................................... 29

5.6 Viewing the motor current ...................................... 29

5.7 Starting .................................................................... 29

6. Applications and functions selection ........ 31

6.1 Softstarter rating according to AC53a ................... 31

6.2 Softstarter rating according to AC53b ................... 31

6.3 The Applications Rating List ................................... 32

6.4 The Application Functions List ............................... 34

6.5 Special conditions ................................................... 36

7. Operation of the softstarter........................ 39

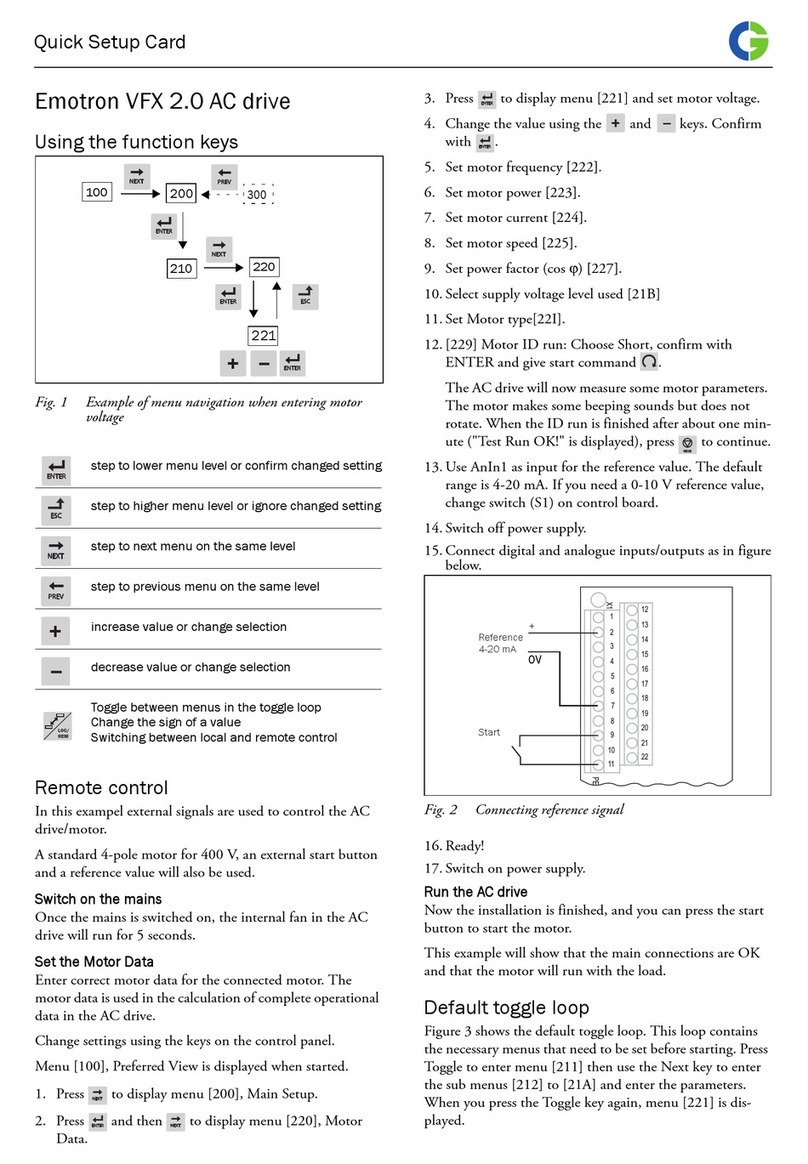

7.1 General description of user interface .................... 39

7.2 Control panel ........................................................... 39

7.3 LED indication ......................................................... 40

7.4 The menu structure................................................. 40

7.5 The keys................................................................... 40

7.6 Control panel lock ................................................... 41

7.7 Overview of softstarter operation and parameter set-

up ............................................................................. 42

8. Functional description................................. 43

8.1 General settings ...................................................... 44

8.2 Motor data ............................................................... 45

8.3 Motor protection...................................................... 46

8.4 Parameter set handling .......................................... 51

8.5 Autoreset ................................................................. 52

8.6 Serial communication ............................................. 54

8.7 Operation settings................................................... 55

8.8 Process protection .................................................. 69

8.9 I/O settings .............................................................. 77

8.10 View operation......................................................... 91

8.11 Alarm list .................................................................. 94

8.12 Softstarter data ....................................................... 95

9. Protection and alarm ................................... 97

9.1 Alarm codes............................................................. 97

9.2 Alarm actions........................................................... 97

9.3 Reset........................................................................ 97

9.4 Alarm overview ........................................................ 98

10. Troubleshooting ......................................... 101

10.1 Fault, cause and solution ..................................... 101

11. Maintenance .............................................. 105

11.1 Regular maintenance ........................................... 105

12. Options........................................................ 107

12.1 Serial communication........................................... 107

12.2 Fieldbus systems................................................... 107

12.3 External control panel........................................... 107

12.4 Terminal clamp...................................................... 108

13. Technical data............................................ 109

13.1 Electrical specifications ........................................ 109

13.2 General electrical specifications.......................... 114

13.3 Fuses and power losses ....................................... 115

13.4 Mechanical specifications including mechanical

drawings ................................................................ 116

13.5 Derating at higher temperature ........................... 117

13.6 Environmental conditions..................................... 117

13.7 Standards .............................................................. 117

13.8 Power- and signal connectors. ............................. 118

13.9 Semi-conductor fuses ........................................... 119

14. Set-up menu list ......................................... 121

St Conel Street Nudgee SPS SP043 Electrical Switchboard Operation and Maintenance Manual (Whelan)