Emotron VFX 2.0 AC drive

Using the function keys

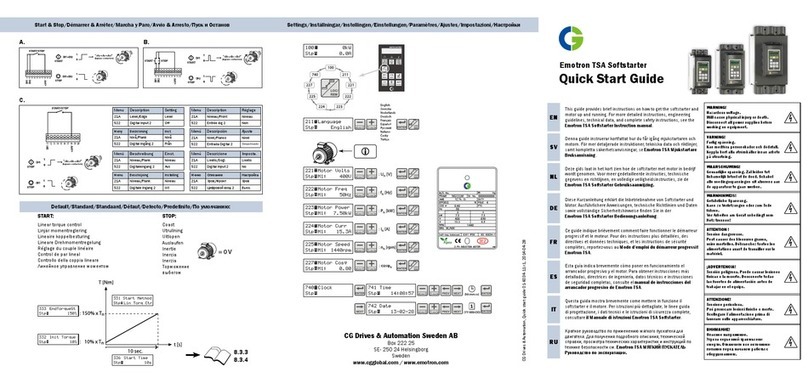

Fig. 1 Example of menu navigation when entering motor

voltage

Remote control

In this exampel external signals are used to control the AC

drive/motor.

A standard 4-pole motor for 400 V, an external start button

and a reference value will also be used.

Switch on the mains

Once the mains is switched on, the internal fan in the AC

drive will run for 5 seconds.

Set the Motor Data

Enter correct motor data for the connected motor. The

motor data is used in the calculation of complete operational

data in the AC drive.

Change settings using the keys on the control panel.

Menu [100], Preferred View is displayed when started.

1. Press to display menu [200], Main Setup.

2. Press and then to display menu [220], Motor

Data.

3. Press to display menu [221] and set motor voltage.

4. Change the value using the and keys. Confirm

with .

5. Set motor frequency [222].

6. Set motor power [223].

7. Set motor current [224].

8. Set motor speed [225].

9. Set power factor (cos ϕ) [227].

10. Select supply voltage level used [21B]

11. Set Motor type[22I].

12. [229] Motor ID run: Choose Short, confirm with

ENTER and give start command .

The AC drive will now measure some motor parameters.

The motor makes some beeping sounds but does not

rotate. When the ID run is finished after about one min-

ute ("Test Run OK!" is displayed), press to continue.

13. Use AnIn1 as input for the reference value. The default

range is 4-20 mA. If you need a 0-10 V reference value,

change switch (S1) on control board.

14. Switch off power supply.

15. Connect digital and analogue inputs/outputs as in figure

below.

Fig. 2 Connecting reference signal

16. Ready!

17. Switch on power supply.

Run the AC drive

Now the installation is finished, and you can press the start

button to start the motor.

This example will show that the main connections are OK

and that the motor will run with the load.

Default toggle loop

Figure 3 shows the default toggle loop. This loop contains

the necessary menus that need to be set before starting. Press

Toggle to enter menu [211] then use the Next key to enter

the sub menus [212] to [21A] and enter the parameters.

When you press the Toggle key again, menu [221] is dis-

played.

step to lower menu level or confirm changed setting

step to higher menu level or ignore changed setting

step to next menu on the same level

step to previous menu on the same level

increase value or change selection

decrease value or change selection

Toggle between menus in the toggle loop

Change the sign of a value

Switching between local and remote control