EMTEST AN 200 Series Instruction Manual

Manual

For Operation

AN 200 Series

Voltage Transient Emission Test

¾AN 200

¾AN 200B

The AN 200 is used to evaluate automotive electrical and

electronic components for conducted emissions of transients

along battery fed or switched supply lines of a Device Under

Test (DUT). A device under test which is considered a potential

source of conducted disturbances should be tested according to

ISO 7637 part 2.

The AN 200 includes an electronic switch for repeatable

switching of inductive loads as well as an artificial network as

specified in ISO.

•ISO 7637 Part 2

Version: 2.00 / 21.11.2003

emc test equipment Replaces: 1.00 / 24.11. 1997

Filename: AN200x operating manual V200.doc

Printdate: 21.11.03

EM TEST AN 200

Bedienungsanleitung V 2.00 2 / 16

Contens

1. Standards covered by AN 200......................................................................................................................3

1.1. Family Series AN 200 ...........................................................................................................................3

2. Operating Functions .....................................................................................................................................4

2.1. Front view..............................................................................................................................................4

2.2. Rear view ..............................................................................................................................................6

3. Equipment description .................................................................................................................................7

3.1. Switch Normal, Switch and Artifical Network ........................................................................................7

3.2. Electronic switch ...................................................................................................................................8

3.3. Ersatzwiderstand...................................................................................................................................8

3.4. Artificial network ....................................................................................................................................9

4. Technical Data .............................................................................................................................................10

5. Calibration / Measuring procedure............................................................................................................11

5.1. Test load .............................................................................................................................................11

5.2. Test voltage.........................................................................................................................................11

5.3. Switch-off times...................................................................................................................................11

5.4. Blockdiagram ......................................................................................................................................11

5.5. Measuring results................................................................................................................................12

5.5.1. Voltage drop in dependence of the test load ......................................................................................12

5.5.2. Measuring results with calibration according to standards .................................................................12

6. Maintenance.................................................................................................................................................13

6.1. General................................................................................................................................................13

6.2. Function check ....................................................................................................................................13

6.3. Test setup ...........................................................................................................................................13

6.4. Safety aspects.....................................................................................................................................13

7. Delivery Groups...........................................................................................................................................14

7.1. Basic equipment..................................................................................................................................14

7.2. Options ................................................................................................................................................14

8. Appendix ......................................................................................................................................................15

8.1. Declaration of CE-Conformity .............................................................................................................15

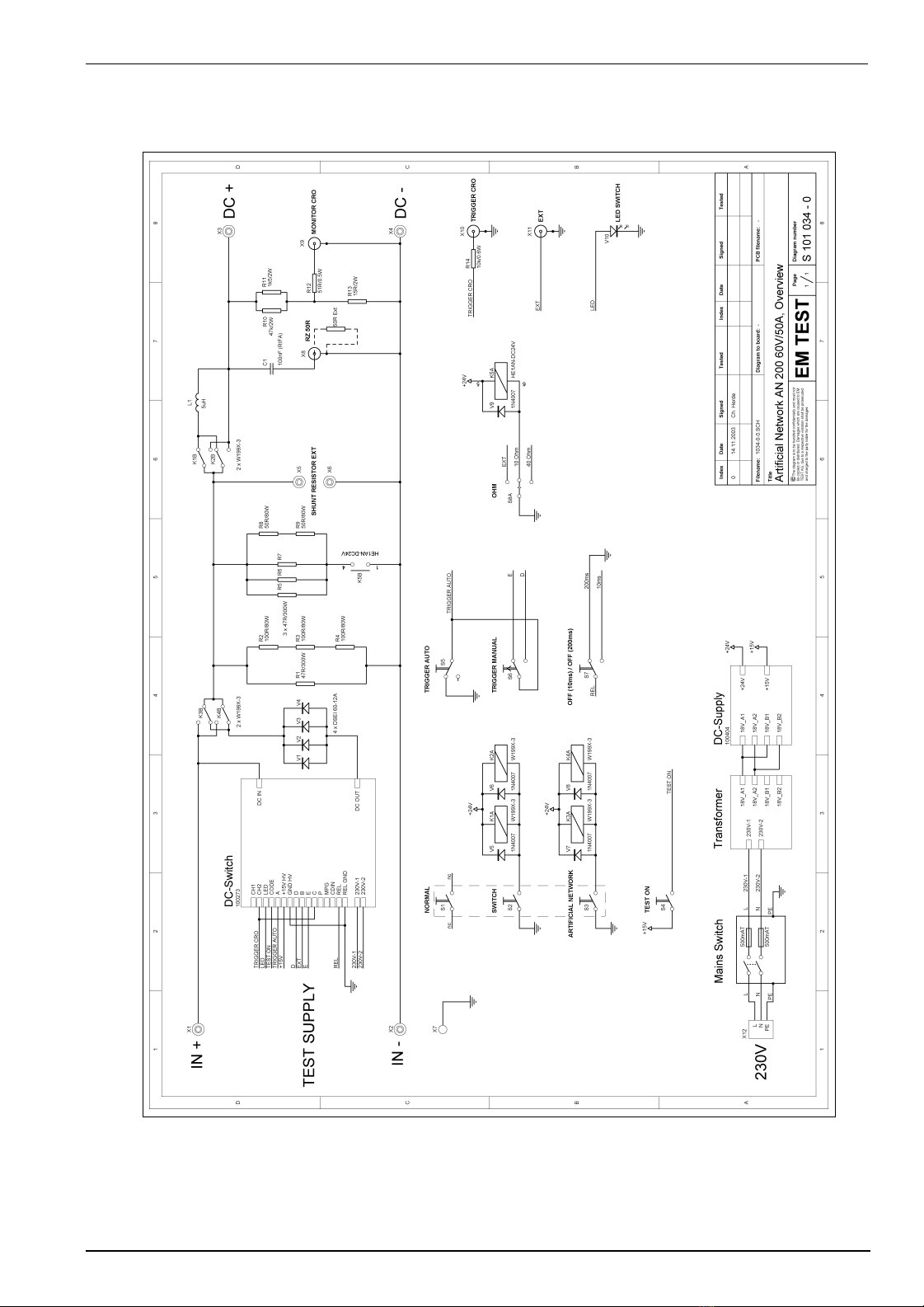

8.2. AN 200 - Overview ..............................................................................................................................16

EM TEST AN 200

Bedienungsanleitung V 2.00 3 / 16

1. Standards covered by AN 200

With the AN 200 the user covers the following standards for conducted emission transients:

- ISO 7637 Teil 2 Road vehicles; Electrical disturbances by conduction and

cpouling ;

Part 2 : Electrical transients conduction along supply lines

only

- several standards In accordance with ISO 7637 Teil 2

1.1. Family Series AN 200

This manual is written for the following devices:

AN 200 30V 35A

AN 200 B 60V 50A

EM TEST AN 200

Bedienungsanleitung V 2.00 4 / 16

2. Operating Functions

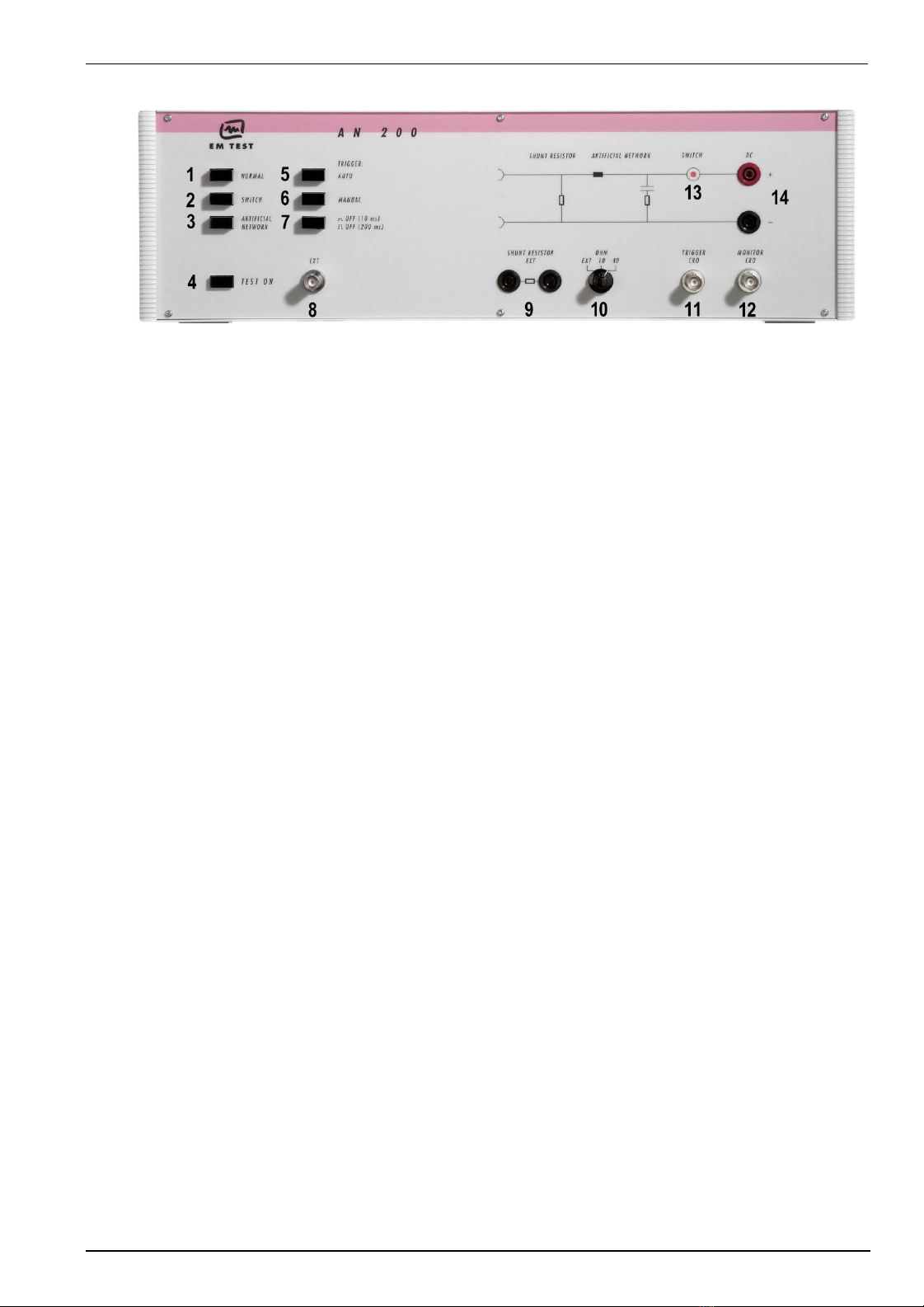

2.1. Front view

Figure 1 : AN200 front side

1NORMAL operation

2Switch operation

3Artificial network operation

4TEST ON

5AUTO Trigger

6MANUAL Trigger

7Selection of time off

8External Trigger

9Connection external shunt resistor

10 Selection of shunt resistor

11 CRO Trigger (output)

12 CRO measuring output (1:100)

13 LED indication switch-on

14 Connection DUT

1 Normal operation

By pressing the „NORMAL“ button the electronic battery supply switch and the artificial network are both in

operation. Pushing the TEST ON button will start the procedure.

2 Switch operation

By pressing the „SWITCH“ button the electronic battery supply switch is put into operation. Pushing the

TEST ON button will start the switching operations. The artificial network is not used in this mode of

operation. (the switch may be used together with the LD 200 for generaze Field Decay pulses; read details

in the LD 200B manual)

3 Artificial network operation

By pressing the „ARTIFICIAL NETWORK“ button the artificial network is put into operation. The electronic

battery supply switch is short-circuited. The AN 200 can be used as an artificial network only.

4 TEST ON

By pushing the TEST ON button the electronic battery supply switch is put into operation. The switch starts

working with the preselected triggering parameters.

5 AUTO Trigger

By pushing the „AUTO“ button the switching procedures (battery supply OFF – ON) are released in

automatically with a repetition rate of 1Hz. To start the test or measuring procedure the Test On button must

be pushed in.

6 MANUAL Trigger

In Manual Trigger operation (AUTO button must not be pushed in) a single switching event, OFF – ON. To

start the test or measuring procedure the Test On button must be pushed in.

7 Selection of the OFF-time

The operator can select the OFF-time by pushing the button 200ms / 10ms" into the related position. The

user can select between 200ms and 10ms.

8 External Trigger

In Manual Trigger operation (AUTO button must not be pushed in) a single switching event, OFF-ON can be

released by remote control. The external trigger input at the BNC connector EXT must be connected to

ground (short-circuit) to release one single event.

EM TEST AN 200

Bedienungsanleitung V 2.00 5 / 16

Figure 1 : AN200 front side

1NORMAL operation

2Switch operation

3Artificial network operation

4TEST ON

5AUTO Trigger

6MANUAL Trigger

7Selection of time off

8External Trigger

9Connection external shunt resistor

10 Selection of shunt resistor

11 CRO Trigger (output)

12 CRO measuring output (1:100)

13 LED indication switch-on

14 Connection DUT

9 Connections of external shunt resistors

An external shunt resistor of R = 2.5Ω/ 400W (at U = 30VDC) may be connected to the related safety

banana sockets. Together with the existing incorporated resistors it results a total resistor value of 2Ω. The

2Ωvalue is required when measuring transient emissions as per ISO/DIN 7637 standard.

10 Selection of the shunt resistor

With this knob the shunt resistor can be switched to 40Ω, 10Ωor to an external resistor (see point 9.)

11 CRO Trigger

During the switching-off ramp a trigger signal (+ 15V) is generated and is available at the CRO Tigger

output.

12 CRO measuring output

The measured transient emission signal is available at the Monitor output. The AN 200 includes a resistive

divider with a divider ratio of 1:100 and an accuracy of ±2% .

13 LED display indication of Switch-On status

The LED indicates the On-status of the electronic battery supply switch. In this case the DUT is connected to

battery supply.

14 Connection for device under test (DUT)

The DUT is connected at the safety banana output sockets.

EM TEST AN 200

Bedienungsanleitung V 2.00 6 / 16

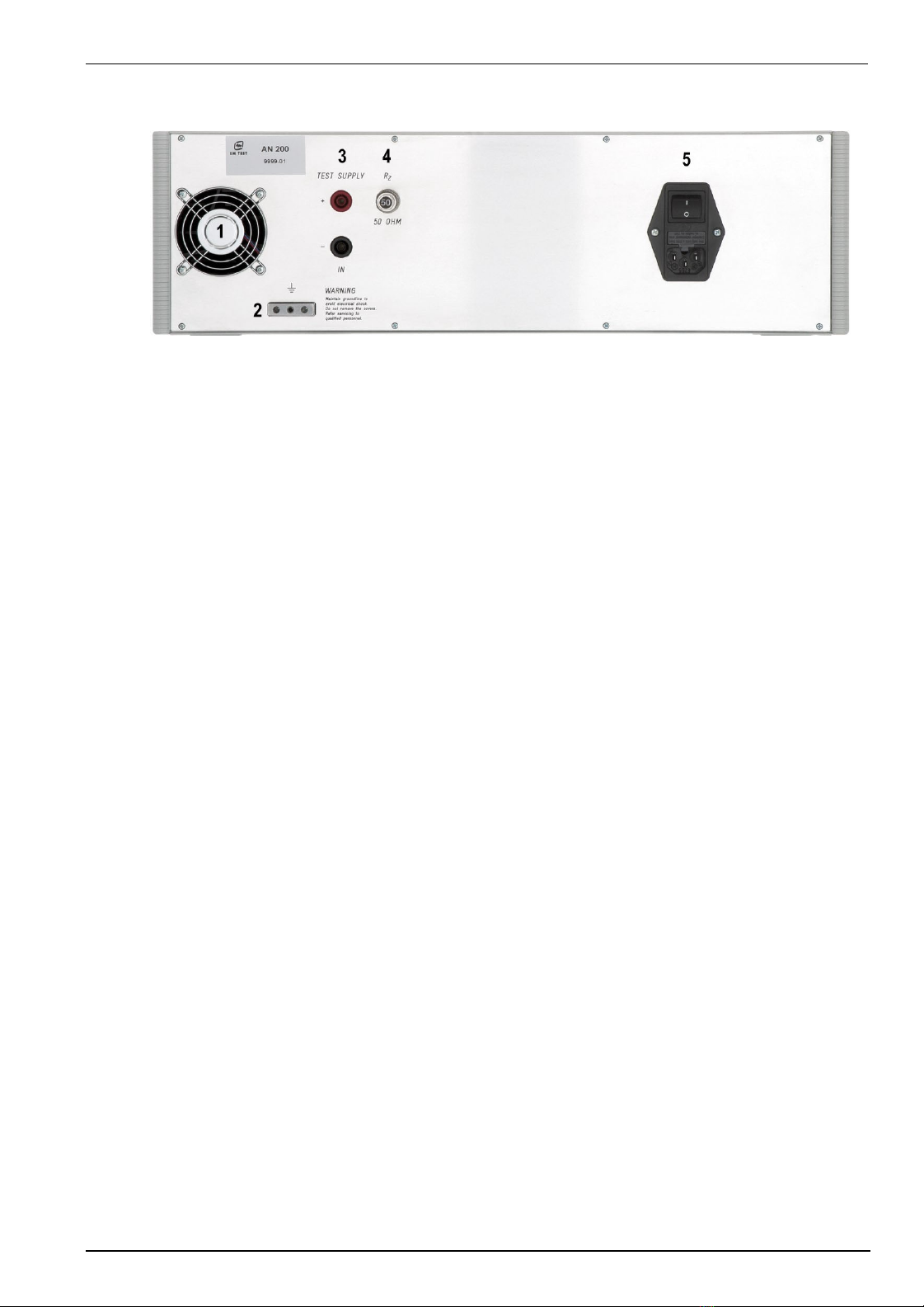

2.2. Rear view

Figure 2 : AN 200 rear side

1Ventilation grid

2Reference earth connection

3Input DUT supply

4Measuring output BNC plug

5Power On switch

1 Ventilation

This guarantees cooling of the battery supply switch. Ventilation grid and ventilator (blower) must be kept

away from other devices in order to allow sufficient air flow through the battery supply switch.

2 Reference earth connection

This plug is for connecting the AN 200 to the ground reference plane.

3 DUT supply

The battery supply (+) & (-) for the DUT is connected to this input. The nominal dc supply parameters

allowed are 30V / 25A .

4 Measuring output with 50 Ωcoaxial resistor

For measuring conducted emission spectrum on battery supply lines as per ISO/DIN 7637 and

DIN/VDE 0879 an artificial network, as illustrated in chapter 3.3, is compulsory. For this the required the 50Ω

resistor Rz is coaxial and located on the BNC plug.

For measuring the interference spectrum a test receiver or spectrum analyzer with 50Ωinput impedance is

used. The instrument is connected to this BNC socket and the 50Ωcoaxial resistor is replaced by the 50Ω

input impedance of the measuring device.

5 Power on switch

The switch is part of the mains filter. Mains fuses are part of the filter.

230V / 1A and 115V / 2A

EM TEST AN 200

Bedienungsanleitung V 2.00 7 / 16

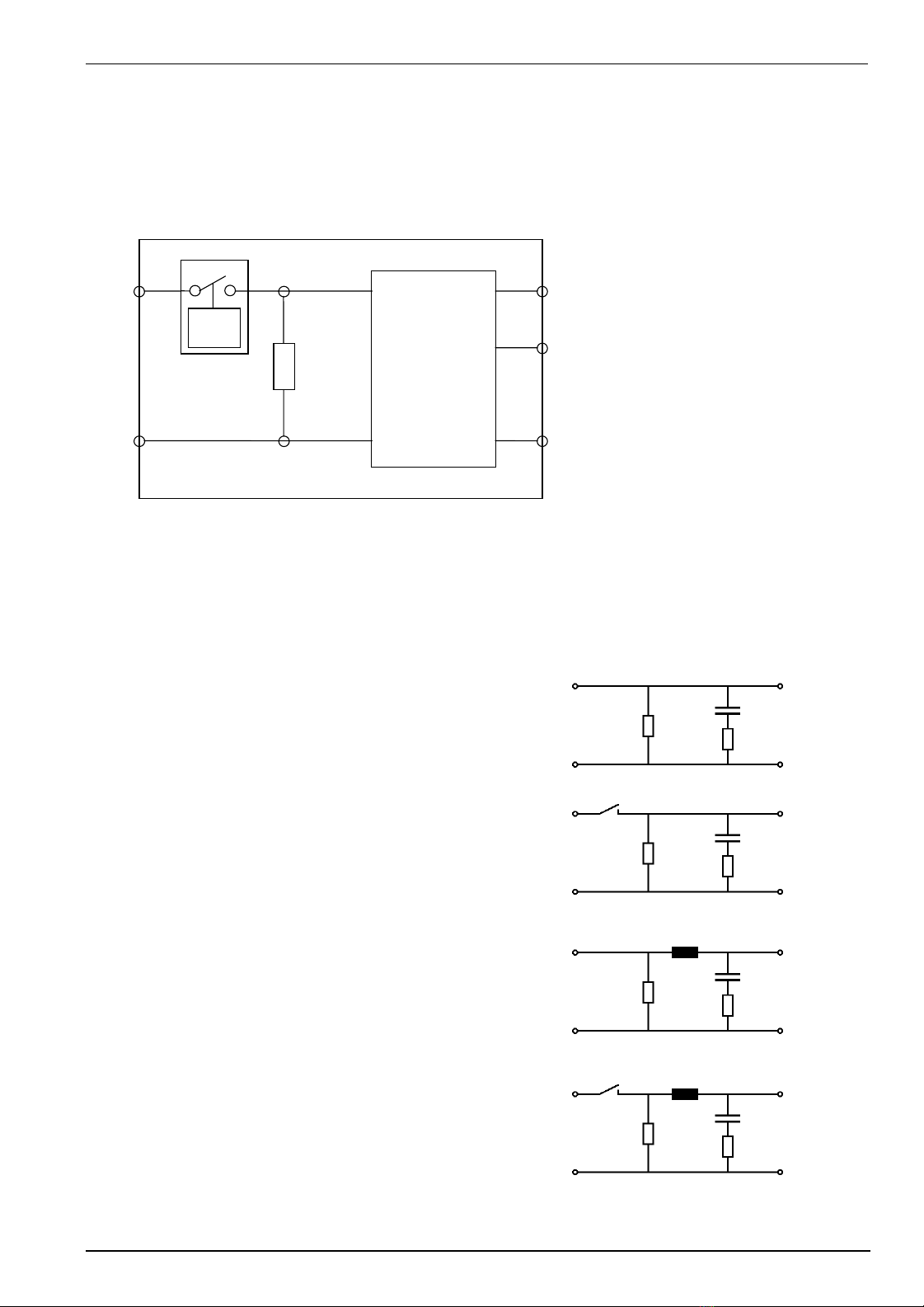

3. Equipment description

The battery supply switch AN 200 is generally divided into three main parts:

- Electronic switch;

- Shunt resistor RS;

- Artificial network.

ARTIFICIAL

NETWORK

RS SHUNT

RESISTOR

CONTROL

ELECTRONIC

DISCONNECTING

SWITCH

Bild 3: Blockschaltbild

CRO

OUT +

OUT -

IN +

IN -

3.1. Switch Normal, Switch and Artifical Network

Depend of the switching position the AN 200 offers different networks. By switching of one of the switches will

release automatically the others. They will go into normal position.

Normal

The internal switch and the inductance are bypassed inthe AN

200. Only the RC network and the shunt resistor are in the circuit.

For remove the RC network you must disconnect the 50Ω

Resistor Rz at the rear side of the AN 200.

Figure 4

Switch

The switch inside the AN 200 is active and the inductance is

bypassed. The switch will open according the setting:

AUTO : 1Hz repetition

MANUAL : Manual release or with ext. Trigger

Interruption : 10ms or 200ms depends on switch position. Figure 5

Artifical Network

In the AN 200 the artifical network is active. The switch is

bypassed. Please check that the 50ΩResistor Rz at the rear side

of the AN 200 is mounted. Otherwise the Artifical network does

not confirm with the standard ISO 7637 part 2

The shunt resistor is switchable between 10Ωand 40Ω.

umschaltbar. Figure 6

Switch and Artifical Network

This mode is not official. The user get this network, when the

switches Switch and Artifical Network are pressed at the same

time.

Figure 7

EM TEST AN 200

Bedienungsanleitung V 2.00 8 / 16

3.2. Electronic switch

The electronic switch disconnects the DUT from battery supply voltage for a specified time in a well specified and

reproducible manner.

The electronic switch is in On status during NORMAL and SWITCH operation while TEST ON is pushed in.. The

red LED indicates On status.

In AUTO mode the electronic switch is triggered internally with 1Hz repetition rate. In MANUAL mode the switch

is triggered either by pushing the MANUAL button or by remote trigger.

The electronic switch can switch currents up to 25A and is able to withstand voltages up to 1000V.

The electronic switch are electronically protected against overload and can withstand short-circuit conditions.

Specific protection requirements of the EUT must be separately assured by the user.

Inrush currents

Inrush currents up to 500A are permitted.

Overvoltage

The switch is protected against over voltages higher than 1000V by internal varistors.

3.3. Shunt resistor

The shunt resistor shall simulate the dc impedance of other connected consumers in the cable tree.

According to ISO/DIN 7637 when measuring transient overvoltage a shunt resistor of 40Ωis required, whereas

when measuring transient overcurrent a shunt resistor of 2Ωis required. For this purpose an external resistor of

2.5 Ω/ 400 W (at 30 V DC) is connected to the safety banana plugs. The external shunt resistor shall be a non-

inductive one.

EM TEST AN 200

Bedienungsanleitung V 2.00 9 / 16

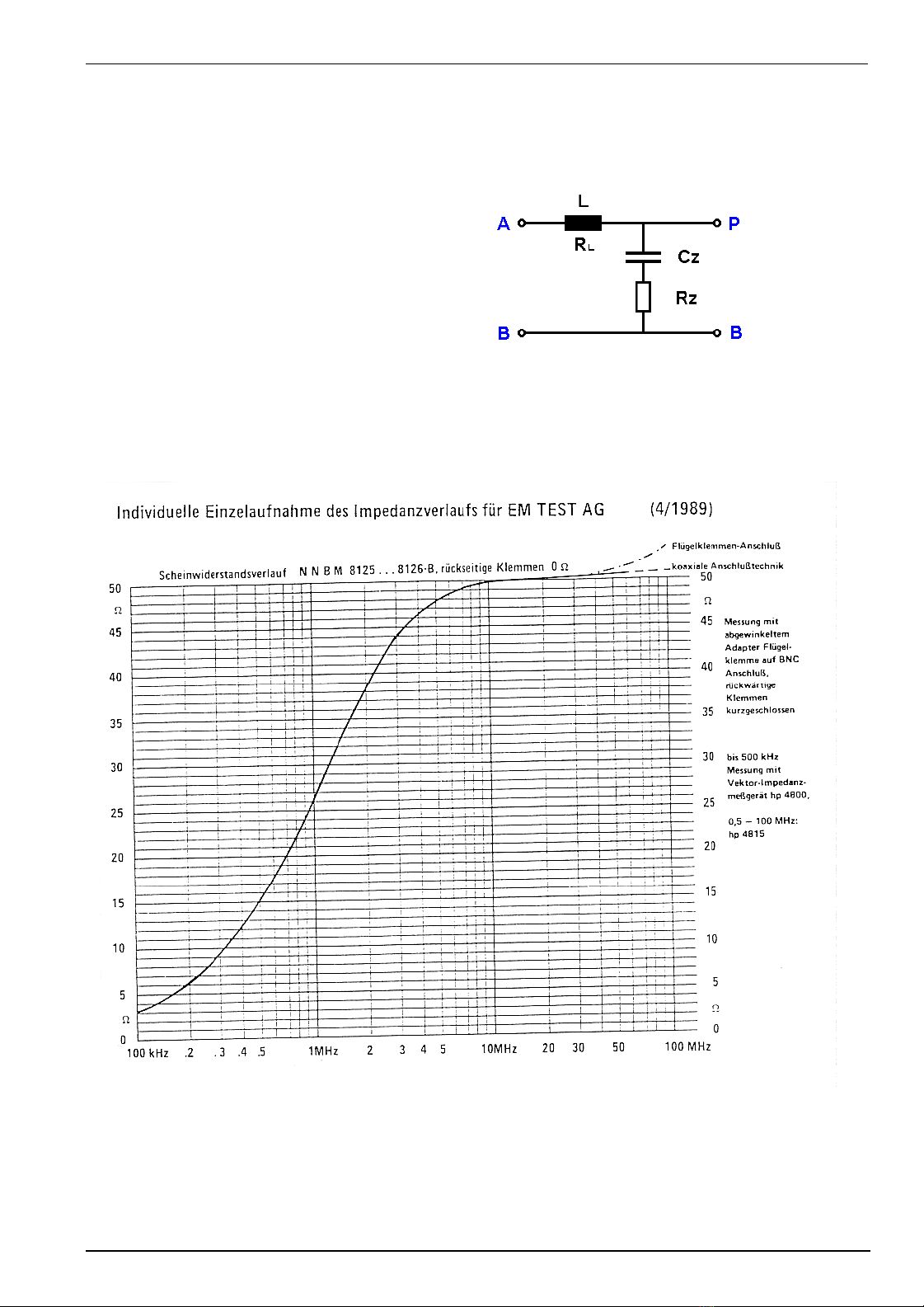

3.4. Artificial network

The artificial network is used to carry out the measurements of conducted emission under constant impedance

parameters. According to ISO/DIN 7637 the following substitute diagram is provided.

Parameter of artifical network

Inductance : L = 5µH Rl < 5mΩ

RC Network : Cz = 0.1µF ( 250V ac )

Rz = 50Ω

Source input: Connectors A, B

Output DUT : Connectors P, B Figure 8

The parallel resistor Rz = 50Ωis built as a coaxial resistor and is placed on the BNC connector at the rear panel.

The impedance characteristic is shown within the following diagram.

The enclosed illustration of a measured curve (impedance characteristic) shows typical impedance values in the

frequency range.

Figure 9 : Impedance of the artifical Network

EM TEST AN 200

Bedienungsanleitung V 2.00 10 / 16

4. Technical Data

Test supply AN 200 AN 200B

Voltage range 0-30 VDC 0-60 VDC

Rated current 25 A 50 A

Short circuit protected

max. inrush current > 500 A

Peak voltage capability 1000 V

Overvoltage protection by varistors

Electronic switch

Switching time (test load L=7 µH / R=0.6 Ω)300 - 400 ns

Switch-off time can be selected 10 ms / 200 ms

Artificial network

Impedance according ISO/DIN 7637 5 µH - 50 Ω

Inductance (5 µH / 5 mΩ)

Shunt resistor (Rs)

Internal selectable 40 Ω/ 10 Ω

Option:

External shunt resistor (Rs = 2 Ω)2 Ω

Trigger

MANUAL Manual trigger of a single event

AUTO Automatic trigger with 1Hz

EXT External trigger 0V, BNC

Mode

NORMAL Switch and artificial network are activated

SWITCH Only the switch is activated

ARTIFICIAL NETWORK Only the network is activated

Measurement

Trigger output for CRO BNC, positive edge + 15 V

Measuring probe included BNC, 1 : 100 ±2%

Switch-on indication LED-display

Dimensions (L x B x H) AN 200 AN 200B

425 x 530 x 180 mm 425 x 530 x 360 mm

19“ 3HE 19“ 6HE

Weight 10 Kg 28 kg

EM TEST AN 200

Bedienungsanleitung V 2.00 11 / 16

5. Calibration / Measuring procedure

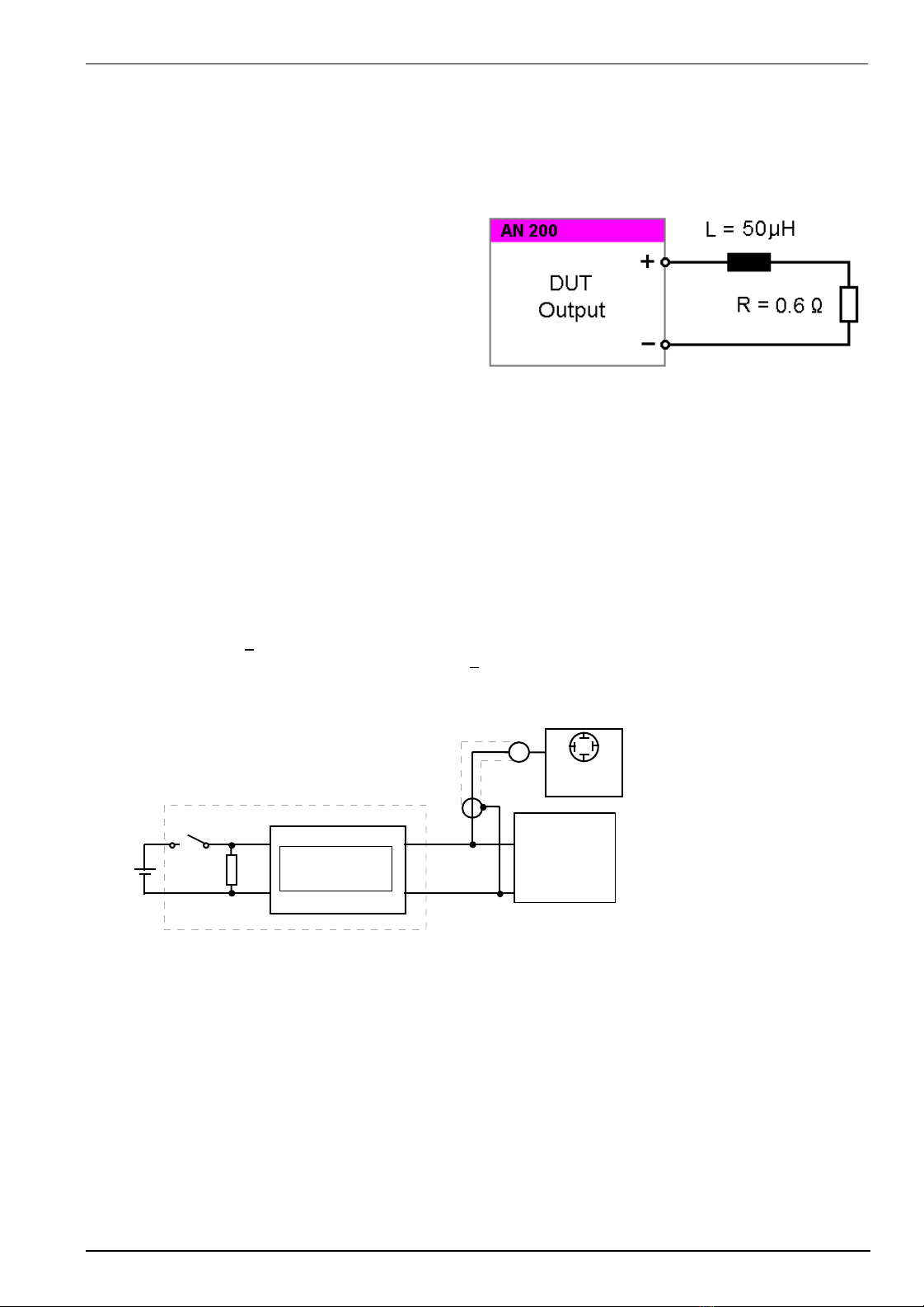

5.1. Test load

For measuring the switch-off time the following test load (DUT) is specified in relevant standard references:

Test load => R (total) = 0,6 Ωin series with

L (total) = 50 µH (1 kHz)

Both R and L also include the variations of the cable and

the structure. The parallel capacity which cannot be

avoided is approx. 50pF. The test must be constructed

such that the permanent current can be used at

maximum test voltage.

Figure 10 : Testlast

5.2. Test voltage

According to the standards the switch-off times should be determined under varying test voltages.

Proposals: for Va : U1 = 13.5V and U2 = 27V

Consequently constant currents of 22.5A or 45A must be considered. Due to the fact that the AN 200 is only

constructed for currents up to 25 A, calibration is only carried out with U1 = 13.5V. The resulting energy consumption

at the test load is approx. 300W.

5.3. Switch-off times

The switch-off times are specified as follows, whereas fall time of the switch-off pulse is involved and measured

between 10 and 90% of the maximum amplitude:

ISO 7637 (old version < 1992) tf = 200 ..... 400ns

ISO 7637 new and DIN 40839 part 1 tf = 300ns + 20%

5.4. Blockdiagram

Rs

Source

AN 200

xx

xx

artificial

network

xx cable length 0,5 m

EUT or

standard

load for

calibration

Figure 11 : Blockdiagram test setup

EM TEST AN 200

Bedienungsanleitung V 2.00 12 / 16

5.5. Measuring results

5.5.1. Voltage drop in dependence of the test load

DUT current voltage drop ( reference value ) Tolerance

1A 1.8 V ±30%

10 A 3.0 V ±30%

23 A 3.5 V ±30%

45 A (only AN200B 60V50A) 4.5 V ±30%

Îmanufacturer values

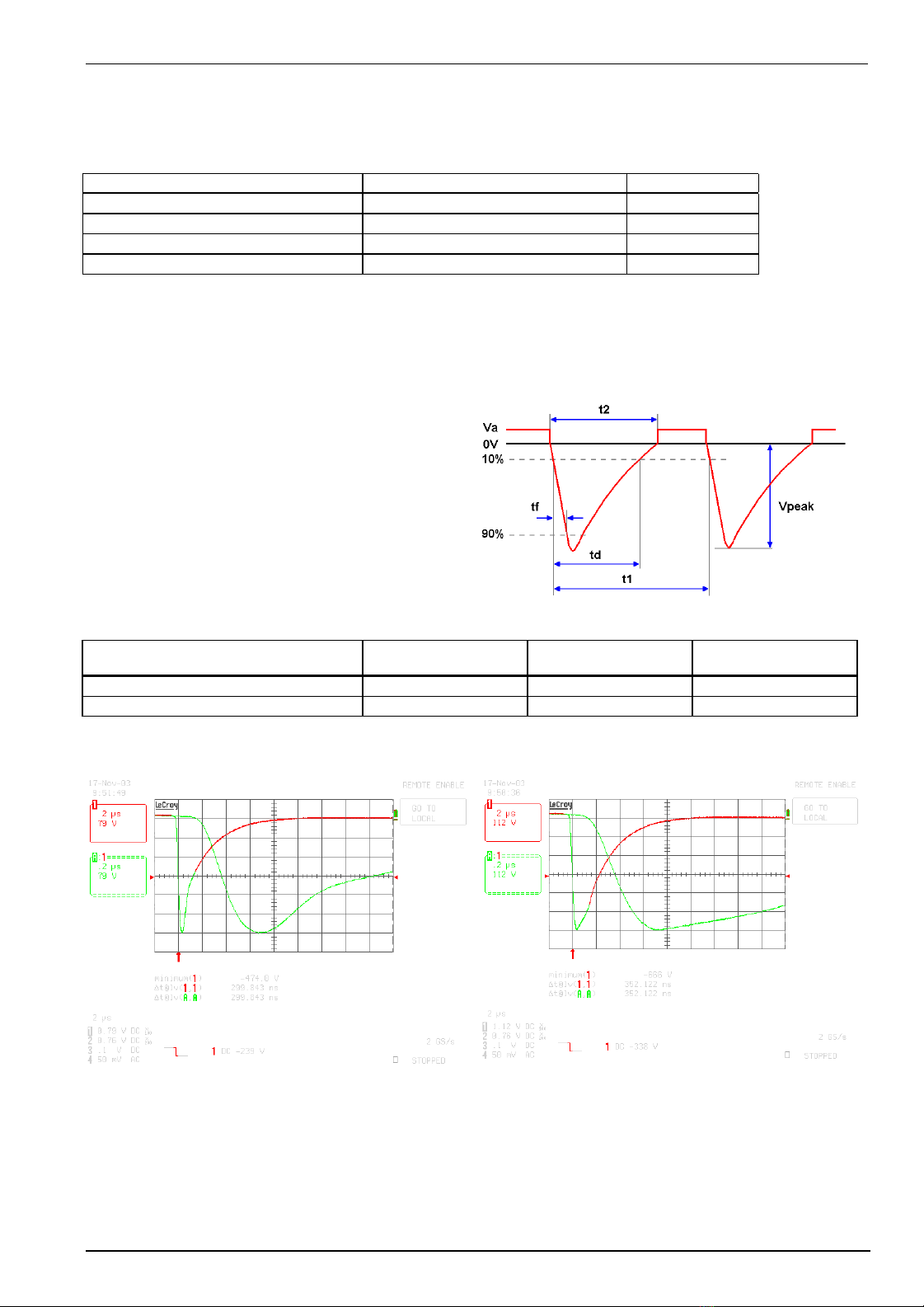

5.5.2. Measuring results with calibration according to standards

All measuring values indicated as well as the curve illustrated have been recorded with a serial model.

Reference values measured with AN 200

Input Voltage: 17.75 V

Output Voltage: 13.50 V

Upeak: - 401 V

tf (90% - 10%): 323 ns

Figure 12 : Pulse parameters

Impedance setting 40ΩVa

output voltage

Vpeak tf 90% - 10%

fall time

Mit Normlast -13.5V ±10% 400V ±30% 300ns ±20%

Mit Normlast ( nur AN200B 60V50A)-27V ±10% 600V ±30% 300ns ±20%

Example for the switch off impulse

Figure 13 : Test load at 13.5V Figure 14 : Test load at 13.5V 27V ( AN 200B )

EM TEST AN 200

Bedienungsanleitung V 2.00 13 / 16

6. Maintenance

6.1. General

The internal switch is absolutely maintenance-free by using a solid state semiconductor .

6.2. Function check

Similar to all measuring and test instruments the correct function of the battery supply switch should be checked from

time to time. The check is best carried out according to the following procedure:

- Switch on the power mains supply and connect the DUT battery supply.

- Select NORMAL operation;

- Select the Off time to 200ms;

- Select the shunt resistor to 10Ω;

- Select the AUTO trigger mode.

After pushing the TEST ON button the LED should now blink at a frequency of 1Hz and the EUT supply is switched

off for 200ms each time. This can be checked at the Monitor CRO output. For this purpose a storage oscilloscope of

at least 20MHz bandwidth is needed.

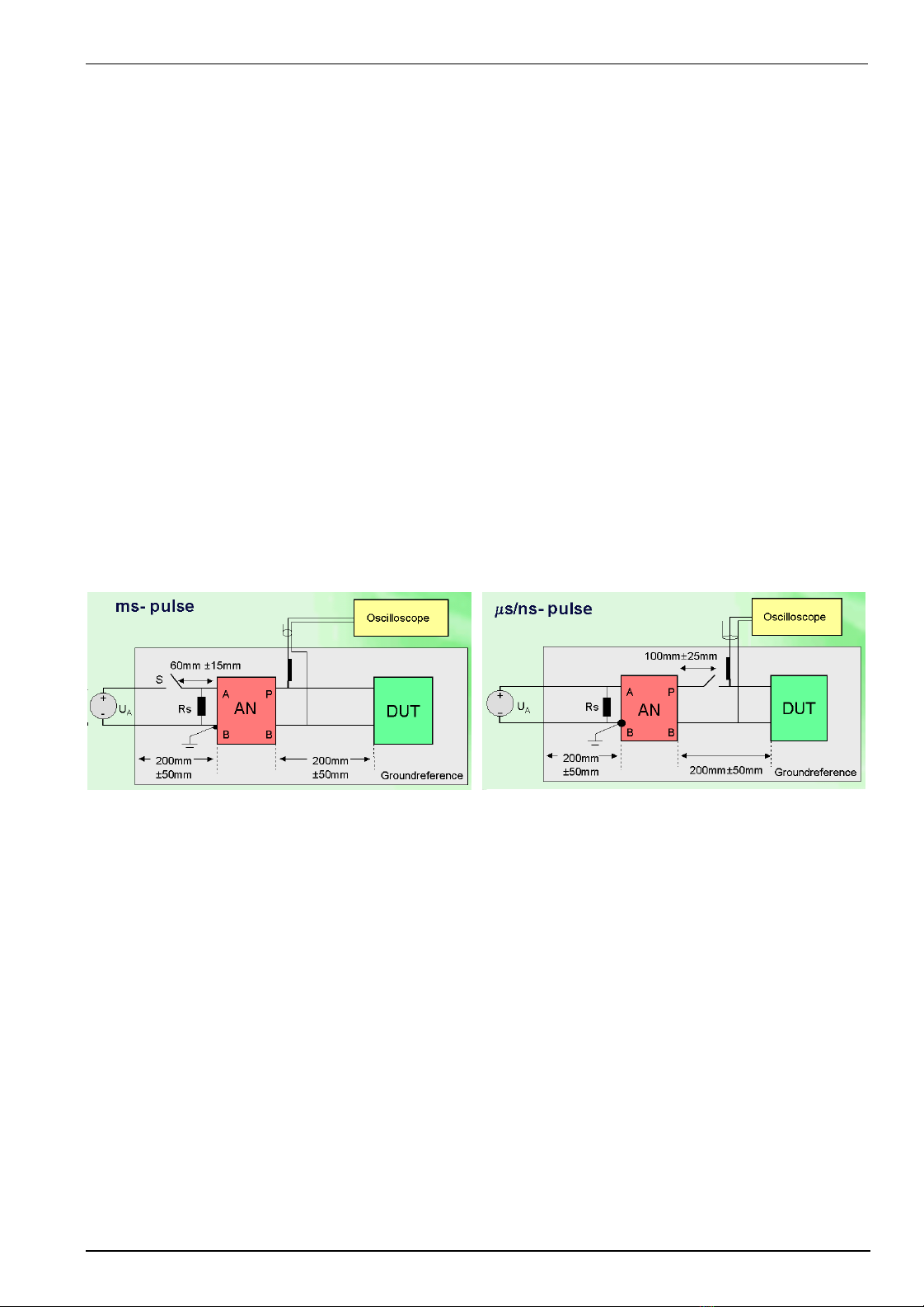

6.3. Test setup

The test offered by the AN 200 generator is a immunity test on electronic equipments or devices. Therefore it is

the responsibility of the user to avoid critical failures and risks to the environment and operator.

Please refer to the safety manual before starting to work with the AN 200

Figure 15 : Setup for pulses in the ms range Figure 16 : Setup for pulses in the µs / ns range

Important

- The artificial network AN shall be connected directly to the ground

reference plane.

- All wires between AN and the DUT shall be isolated from the

ground plane by 50mm.

- The DUT will be placed on the ground plane as in real installation.

- directly grounded to the ground plane or

- 50mm isolated from the ground plane

- The position of the instruments shall be as specified in the standard.

6.4. Safety aspects

National and international recommendations regarding human safety must be followed. When setting up the test

national and international regulations regarding human safety have to be guaranteed.

The test offered by the AN 200 generator is a immunity test on electronic equipments or devices. Therefore it is

the responsibility of the user to avoid critical failures and risks to the environment and operator.

Long and distributed lines of the EUT are able to radiate a certain energy to their vicinity. Therefore it is also the

responsibility of the user to decide whether it is allowed to conduct immunity tests in a given installation.

EM TEST AN 200

Bedienungsanleitung V 2.00 14 / 16

7. Delivery Groups

7.1. Basic equipment

•Artifical network AN 200 / AN 200B

•Mains cable

•1 set safety labor cables red / black

•Manual on CD

•Calibration certificate

7.2. Options

•AN 200B Artifical network for 60V 50A

Figure 17 : AN 200B front view Figure 18 : AN 200B rear view

EM TEST AN 200

Bedienungsanleitung V 2.00 15 / 16

8. Appendix

8.1. Declaration of CE-Conformity

Manufacturer : EM TEST AG

Address: Sternenhofstr. 15CH 4153 Reinach

Switzerland

declares, that under is sole responsibility, the product’s listed below, including all their options, are conformity with the

applicable CE directives listed below using the relevant section of the following EC standards and other normative

documents.

Product‘s name: Artifical Network

Model Number(s) AN 200, AN 200B

Low Voltage Directive 73/23/EEC

Standard to which conformity is declared:

EN 61010-1:1993 Safety

EMC Directive 89/336/EEC

Standard(s) to which conformity is declared:

Emissions:

EN 61000-6-4 2001

EN 55022:1998 +A1:2000, Class A

EN 61000-3-2 A14: 2000

Conducted and radiated.

Harmonics

Immunity: EN 61000-6-2 2001 EN 61000-4-2:1995 +A1:1998 +A2:2001 Electrostatic Discharges

EN 61000-4-3:2002 +A1:2001 RF Electromagnetic Field

EN 61000-4-6:1996 + A1:2001 Conducted RF

EN 61000-4-4: 1995+A1:2001 +A2:2001 Electrical Fast Transient / Burst

EN 61000-4-5: 1995+A1:2001 Surge

EN 61000-4-11: 1994+A1:2000 DIPS & Voltage Variations

European representative Manufacturer

EM TEST GmbH EM TEST AG

Lünenerstr. 211 Sternenhofstr. 15

D 59174 Kamen CH 4153 Reinach

Tel: 00492307-18042 Tel: 004161-7179191

Fax: 00492307-17050 Fax: 004161-7179199

By U. Flor

General manager

H. Kunkel

Design and Research

Place Kamen, Germany Reinach BL , Switzerland

Date 20. November 2002 20. November 2002

EM TEST AN 200

Bedienungsanleitung V 2.00 16 / 16

8.2. AN 200 - Overview

Figure 19 : Overview AN 200 / AN 200B

This manual suits for next models

2

Table of contents

Other EMTEST Test Equipment manuals

EMTEST

EMTEST dito User manual

EMTEST

EMTEST CNI 503 Series Technical Document

EMTEST

EMTEST CWS 500A / 75 User manual

EMTEST

EMTEST CNI 508 N2 User manual

EMTEST

EMTEST PFS 200N Series Instruction Manual

EMTEST

EMTEST PFM 200N200 User manual

EMTEST

EMTEST variac-NX 1-260-16 User manual

EMTEST

EMTEST PFM 200N100.1 User manual

EMTEST

EMTEST VDS 200Q10 Series User manual

EMTEST

EMTEST esd NX30 User manual