EMTEST PFM 200N200 User manual

User’s Guide

PFM 200N100.1

PFM 200N200

Voltage Dips and Drops Interruptions

- E-10 Brief Voltage Drop

- E-13 Dropout Pin

- E-14 Dropout Connector

- E48-09 Short Interruptions

The PFM 200N Series has been specially engineered for

performing dropout pulses on battery and signal lines.

The PFM 200N contains a switch for battery voltage as well as

additional switches for battery return lines from 100 mA up to

100 A or 200 A depending on the model. An additional set of 16

switches are provided for data and signal line switching from

100 μA to 2 A.

BMW QV65013

GMW3172

LV 124 (2013)

LV 148

Renault 36-00-808/--M

Nissan 28401 NDS02

Version:

1.21 / 29.6.2020

emc test equipment

Replaces:

1.20 / 11.6.2020

File Name:

UserManual-PFM200Nx-E-V1.21.doc

Print Date:

29.06.20

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 3 / 45

Contents

1. Introduction....................................................................................................................................................5

1.1. Overview............................................................................................................................................5

2. Safety..............................................................................................................................................................6

2.1. Safety Instructions .............................................................................................................................6

2.2. Care During Testing...........................................................................................................................7

2.2.1. Switching Off ............................................................................................................................................7

2.2.2. Danger to the Device Under Test (DUT) .................................................................................................7

2.2.3. Input Capacitance ....................................................................................................................................7

3. Package Contents and Putting Into Service...............................................................................................8

3.1. Basic Equipment PFM 200N100.1 ....................................................................................................8

3.2. Basic Equipment PFM 200N200........................................................................................................8

3.3. Accessories........................................................................................................................................8

3.4. Options PFM 200N100.1 ...................................................................................................................9

3.5. Options PFM 200N200 ......................................................................................................................9

3.6. Installation........................................................................................................................................11

3.6.1. Unpacking...............................................................................................................................................11

3.6.2. Setup and Cabling the Test System......................................................................................................11

3.6.3. Software Installation and Setup.............................................................................................................12

4. Functions and Operation of the PFM 200N...............................................................................................14

4.1. Front Panel Elements ......................................................................................................................14

4.2.Back Panel Elements.......................................................................................................................15

4.3. Description of the Functions of the Device......................................................................................16

4.3.1. Front........................................................................................................................................................16

4.3.2. Back........................................................................................................................................................18

5. PFM 200N Dropout Simulator.....................................................................................................................19

5.1. Switch for DUT Battery Voltage.......................................................................................................19

5.2. Switches for Data and Signal Lines.................................................................................................19

5.3. Block Diagram PFM 200N ...............................................................................................................19

6. Testing According to LV 124 and LV 148 Using the AutoWave.control Software................................20

6.1. Locating the Standard Tests for LV 124 and LV 148 ......................................................................20

6.2. SW Settings for the PFM 200N Switch............................................................................................21

6.2.1. SW Settings Switch S1...........................................................................................................................21

6.2.2. SW Installation of Switch S2 –S5..........................................................................................................22

7. E-10 Short Interrupts According to LV 124 (2013-02)..............................................................................23

7.1. Test Case 1 S1 Switched, S2 Statically Open.................................................................................25

7.1.1. Testing with AutoWave.control Software...............................................................................................25

7.2. Test Case 2 S1 Switched, S2 Negated to S1..................................................................................26

7.2.1. Testing with the AutoWave.control Software.........................................................................................26

7.3. Reference Measurement .................................................................................................................27

7.3.1. Reference Measurement with the AutoWave.control Software ............................................................28

7.3.2. Test Setup for Reference Measurement................................................................................................29

7.3.3. Example Reference Measurement........................................................................................................29

8. E-13 Pin Interruption according to LV 124 (2013-02)...............................................................................30

8.1. Test Case 1 Slow Interval................................................................................................................31

8.1.1. Tests of Data Lines with the AutoWave.control Software .....................................................................31

8.2. Test Case 2 Burst of Interruptions on Each Pin as a Simulation of a Loose Contact .....................32

8.2.1. Testing Data Lines with the AutoWave.control Software ......................................................................32

8.3. Reference Measurement .................................................................................................................33

8.3.1. Reference Measurement with AutoWave.control Software...................................................................34

8.3.2. Test setup for the Reference Measurement..........................................................................................35

8.3.3. Example Reference Measurement........................................................................................................36

9. E-14 Connector Interruption.......................................................................................................................37

9.1. Tests on Battery Lines.....................................................................................................................38

9.2. Tests on Data Lines.........................................................................................................................38

9.2.1. Tests on Data Lines with the AutoWave.control Software....................................................................38

10. Technical Data.............................................................................................................................................39

10.1. Switch for Power Lines ....................................................................................................................39

10.2. Switches for Signal and Data Lines.................................................................................................39

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 4 / 45

10.3. Switchable Internal Loads for Battery Lines ....................................................................................39

10.4. Triggering.........................................................................................................................................39

10.5. Safety...............................................................................................................................................40

10.6. Interfaces.........................................................................................................................................40

10.7. Bus Systems (data lines).................................................................................................................40

10.8. General............................................................................................................................................41

10.9. Environmental..................................................................................................................................41

11. Accessories for LV 124...............................................................................................................................42

11.1. CA LV124 Calibration Load.............................................................................................................42

11.1.1. CA LV124 Calibration loads.....................................................................................................................42

12. Annex............................................................................................................................................................43

12.1. Declaration of CE-Conformity..........................................................................................................43

12.2. 100 A Connectors and Plugs 6mm (PFM 200N100.1)....................................................................44

12.3. 200 A Connectors and Plugs (PFM 200N200) ................................................................................44

12.4. PHOENIX connector DFMC for Data lines.....................................................................................45

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 5 / 45

1.

Introduction

1.1.

Overview

The PFM 200N Series has been specially engineered for testing virtually every known type of dropout pulses in

automotive applications.

One special feature of this device is the capability of the generator to switch a load in parallel to the DUT during

the dropout test.

For example, the PFM 200N series is for testing of E10 Short interruptions and E13 Pin Interruption for the

following tests:

- OEM LV 124 Version 2.20 (2013-02)

- VW 80000 2013-06

Note: Due to changes in LV 124, the 2009 version of the standard is no longer supported by the PFM 200N100.1

and PFM 200N200.

Additional standards refer to LV 124 und LV 148:

- BMW GS 95024-2-1 (2010-01)

- BMW GS 95026

- LVA 320: 2014

- Mercedes-Benz MBN LV 124-1

- VW 82148

Another feature of the PFM200N100.1, as well as the PFM 200N200 is a very fast switching time for other

dropout tests such as:

- BMW QV65013

- GMW3172

Finally, we the PFM 200N100.1 and PFM 200N200 fully support switching of BAT- lines for standards that require

it, such as:

- Renault 36-00-808/--M

- Nissan 28401 NDS02

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 6 / 45

2.

Safety

2.1.

Safety Instructions

In order to guarantee your personal safety, and the safety of personnel in your surroundings, it is

imperative that you read and understand the following safety instructions.

EM TEST devices are related to excess voltage category II.

Symbols on the device

DANGER

Warning of voltages that might involve the risk of electric shock. Pay special attention

to the User’s Guide.

CAUTION

Warns of a possibly dangerous situation. Careful attention should be made to avoid

damage to the device, device under test or its surroundings

Note

Important information about the operation of the device. Carefully read the User’s

Guide.

PE

Protective Earth Connector

Mains Power

The mains power that is used shall not exceed 230V +15% between hot and neutral. The protective earth

connection is made over the power cable and may not, under any circumstances, be removed.

Earthing of the Device and CDN

The device is earthed through the protective earth connection of the mains cable. Therefore, use only mains

sockets where you are sure that the protective earth is correctly used. It is important to verify earthing before

using the device. Any additional CDNs are to be earthed with the provided earth connectors.

Without a proper protective earth, conductive parts of the device may incur dangerous voltages. This may also

affect components that appear to be isolated.

Use Only Tested Mains Cables

Use only the original mains cable or a cable with proper markings to ensure safe operation. Do not use damaged

cables.

Use only Fuses of Specified Type

Solely for use with fuses that meet the specified type found on the mains connector or consult the User’s Guide.

Pay special attention to the type, voltage and current required.

Do not remove covers.

Do not use a device that is open. This is for your safety and the reproducibility of the test results.

Read this guide carefully before putting this device into operation.

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 7 / 45

2.2.

Care During Testing

All tests using high voltage or EMC generators are immunity tests for electrical devices. The device under test

(DUTs) can react incorrectly which may lead to a dangerous situation. The user is responsible to take care to

avoid the risk to man and material.

One must carefully follow all relevant international guidelines and requirements for the protection of people. This

is especially important in unusual setups or where pulses may be coupled.

People at risk are prohibited from using the system; for example, people with pacemakers.

Long cables leading to the DUT can radiate and effect devices in the area, including devices that do not belong to

the test setup. It is the user’s responsibility to decide if and when the use of an area is acceptable for EMC

testing.

Tests can lead to sparks. It is strictly forbidden to perform tests in areas where there exists a risk of explosion.

While the PFM 200N series produces no dangerous voltages, the very fast switching of inductive loads will result

in large inductive kickback that can be dangerous to life. The output of the PFM 200N is equipped with a GDT

(Gas Discharge Tube) that is designed to suppress voltage over 120V.

2.2.1.

Switching Off

- The generator has limited internal protection.

Switching off of the DUT is accomplished with an electronic switch that contains a current measurement that

can be overloaded to 400 A when the DUT power is switched off.

CAUTION

In extreme cases, like when using an automotive battery into a short, can result in currents well

over 400 A. In these cases, the electronic switch can no longer switch off.

Therefore, additional protection, like an inline fuse, is recommended to ensure safety when using

an automotive battery.

The user must provide a breaker for the DUT. Special adapters with switching and breakers are available, but

must be specified by the user.

- To couple a disturbance on a data or signal line, the coupling method must first be carefully defined.

- If a data or signal line is not to have pulses coupled, the lines shall be removed entirely from the CDN!

2.2.2.

Danger to the Device Under Test (DUT)

The pulses can lead to an unexpected condition of the DUT that results in a dangerous situation.

Therefore, the following conditions should be carefully observed:

•Stop the test when the DUT behaves abnormally.

•Due to an internal defect, high voltage components may make contact to the DUT housing.

•Cables and connectors can be overloaded by overvoltage.

•Internal destruction of components can lead to fire or explosion.

•Accidental operation of the DUT can cause dangerous situations.

DANGER

Never approach a DUT during test!

2.2.3.

Input Capacitance

In order to achieve the necessary switching time, the PFM 200N series contains capacitance at the battery input

PF1. Ripple tests may not be performed when the PFM 200N is connected because the capacitive reactance of

this buffer capacitor will cause the VDS 200Q or VDS 200N to go into current limit. The VDS 200Q series is

prepared with a jumper to easily isolate the PFM 200N when it is not needed. It is strongly recommended to

remove the PFM 200N from the test setup when it is not needed.

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 8 / 45

3.

Package Contents and Putting Into Service

3.1.

Basic Equipment PFM 200N100.1

•PFM 200N100.1 Generator

•Mains cable with country-appropriate connector

•3 m Frame Bus cable

•Frame Bus Termination

•2 sets of 2 m laboratory cables, 32A (red and black)

•Two pairs of 100A Multi Contact Sockets, 2 x 2 pairs

•2 x PHOENIX, DFMC Adapters, 1.5 mm2, with a push-in locking connection

•User’s Guide on a USB memory stick

Identical accessories are only delivered once for deliveries of multiple devices. Details may be found on the

packing list which is final.

3.2.

Basic Equipment PFM 200N200

•PFM 200N200 Generator

•Mains cable with country-appropriate connector

•3 m Frame Bus cable

•Frame Bus Termination

•2 mating connectors 200A

•2 x PHOENIX, DFMC Adapters, 1.5 mm2, with a push-in locking connection

•User’s Guide on a USB memory stick

Identical accessories are only delivered once for deliveries of multiple devices. Details may be found on the

packing list which is final.

3.3.

Accessories

•User Software "AutoWave.control"

- Test, analyze and document under Windows

- License for testing of most automotive standards

- Report generator featuring export to text

Figure 3.1

•Frame Bus Terminator

Terminating resistor for the Frame Bus interface

Figure 3.2

•Printed-circuit board connector - DFMC

PHOENIX, DFMC Adapters, 1.5 mm2, with a push-in locking connection

Poenix Contact

Type: DFMC 1,5/16-ST-3,5-LR

Order No: 1790629

Figure 3.3

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 9 / 45

3.4.

Optional Accessory CA LV124

Set for edge verification of the PFM 200N100.1 according to LV 124

•Case for LV 124 Calibration

- Rugged plastic case for storing the calibration loads for the CA LV 124

- 2 m BNC cable

- 2 laboratory cables 0.5 m (black, red)

- Calibration resistors for power and data lines

Figure 3.4

•CA LV124-P1R Calibration of Battery Lines

1,0 Ω± 1 %,

U max.: 12 V

P max.: 150 W

Figure 3.5

•CA LV124-P100R Calibration of Battery Lines

100.0 Ω± 1 %,

U max.: 100 V

P max.: 50 W

Figure 3.6

•CA LV124-D1R Calibration of Signal and Data Lines

1.0 Ω± 1 %

U max.: 2.0 V

P max.: 1 W, P Peak: 4W max.

Figure 3..7

•CA LV124-D1000R Calibration of Signal and Data Lines

1000 Ω± 1 %

U max.: 40.0 V

P max.: 1 W

Figure 3..8

3.5.

Optional Accessory CA LV124.1

Set for edge verification of the PFM 200N200 according to LV 124

•Case for LV 124.1 Calibration

- Rugged plastic case for storing the calibration loads for the CA LV 124

- 2 m BNC cable

- 2 laboratory cables 0.5 m (black, red)

- Calibration resistors for power and data lines

•CA LV124-P1R Calibration of Battery Lines

1,0 Ω± 1 %,

U max.: 12 V

P max.: 150 W

•CA LV124-P100R Calibration of Battery Lines

100.0 Ω± 1 %,

U max.: 100 V

P max.: 50 W

•CA LV124-D1R Calibration of Signal and Data Lines

1.0 Ω± 1 %

U max.: 2.0 V

P max.: 1 W, P Peak: 4W max.

•CA LV124-D1000R Calibration of Signal and Data Lines

1000 Ω± 1 %

U max.: 40.0 V

P max.: 1 W

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 10 / 45

3.6.

Optional Accessory CA LV148

Set for edge verification of the PFM 200N100.1 according to LV 148

•Case for LV 148 Calibration

- Rugged plastic case for storing the calibration loads for the CA LV 124

- 2 m BNC cable

- 2 laboratory cables 0.5 m (black, red)

- Calibration resistors for power and data lines

•CA LV148-P10R Calibration of Battery Lines

10,0 Ω± 1 %,

U max.: 48 V

P max.: 30 W

•CA LV148-P1000R Calibration of Battery Lines

1000.0 Ω± 1 %,

U max.: 48 V

P max.: 30 W

3.7.

Optional Accessory CA LV148.1

Set for edge verification of the PFM 200N200 according to LV 148

•Case for LV 148 Calibration

- Rugged plastic case for storing the calibration loads for the CA LV 124

- 2 m BNC cable

- 2 laboratory cables 0.5 m (black, red)

- Calibration resistors for power and data lines

•CA LV124-P10R Calibration of Battery Lines

10,0 Ω± 1 %,

U max.: 48 V

P max.: 30 W

•CA LV124-P1000R Calibration of Battery Lines

1000.0 Ω± 1 %,

U max.: 48 V

P max.: 30 W

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 11 / 45

3.8.

Installation

3.8.1.

Unpacking

Before shipment, the device is carefully tested and packed on a one-way pallet. Every box is marked with a

warning notice and packing list.

Before installation, check the contents the delivery contents for transport damage. Check that the packaging is in

good condition and ensure that the device does not exhibit any mechanical damage. If this is the case, please

immediately inform EM Test or their authorized representative before putting the device into operation.

Note: This guide uses the PFM 200N100.1 for illustrative purpose. Cases where the PFM 200N200 differs are

listed separately.

3.8.2.

Setup and Cabling the Test System

Control Cables

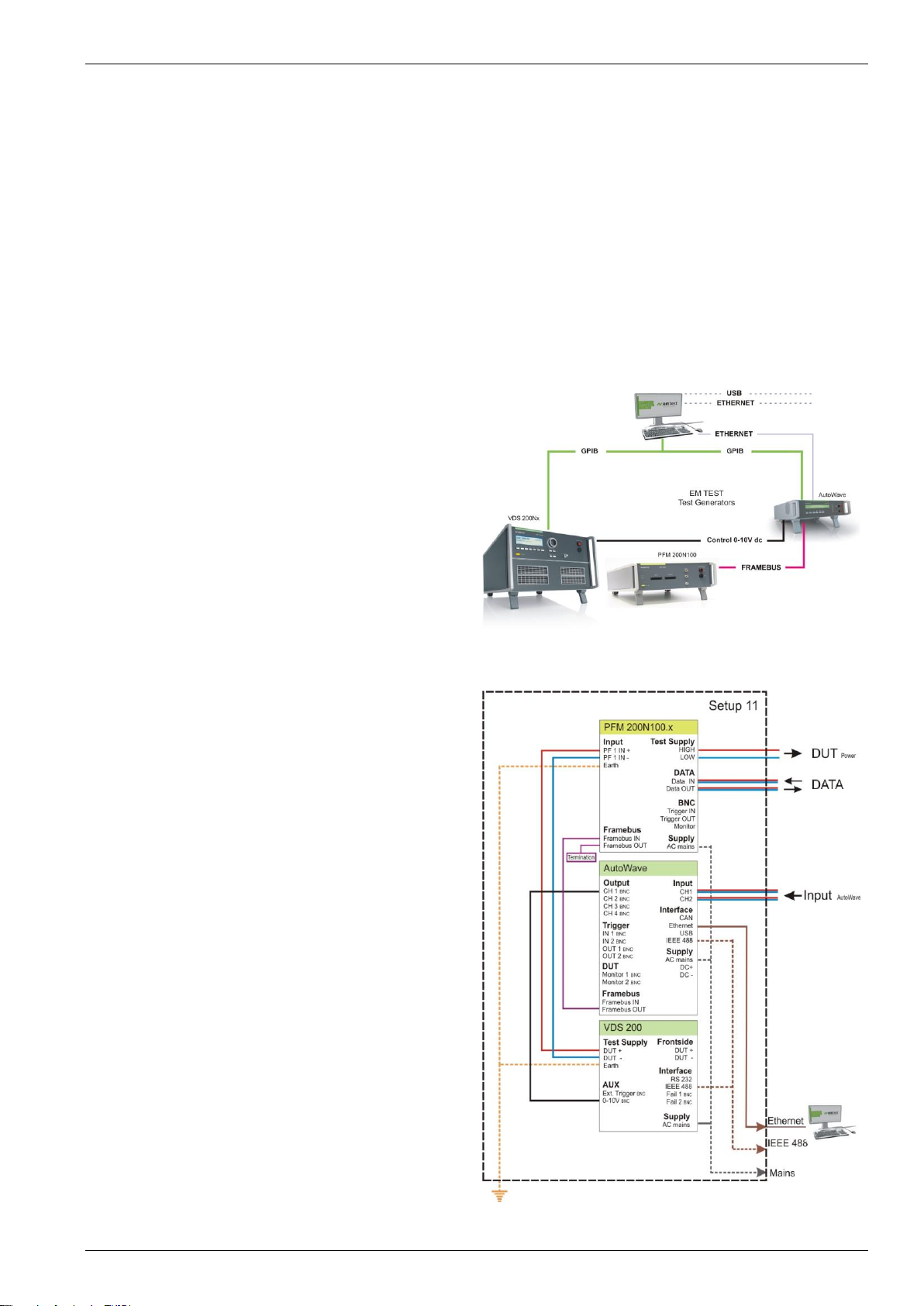

Figure 3.10 shows the typical usage of control cables

for the test system:

- AutoWave Controls the PFM

- PFM 200N100.1 Dropout simulator

- VDS 200Nx DC source for powering the DUT

AutoWave.control is required in order to operate the

PFM 200N100.1. This software contains all the test

routines for testing with the PFM 200N100.1

Figure 3.10: Control Cables

Cabling for the System

Figure 3.11 shows all connections necessary for the

PFM 200N100.1, AutoWave und VDS:

Cable List:

Computer –AutoWave

GPIB / IEEE488 or

Ethernet

AutoWave - VDS200N100

IEEE 488 IEEE488

CH 1 BNC 0-10V BNC

AutoWave - PFM 200N100.1

Framebus OUT Framebus IN 15 Pin D-Sub

VDS200Nx - PFM 200N100.1

DUT + PF1 IN + DUT power, 100A max.

DUT - PF1 IN - DUT power, 100A max.

PFM 200N100.1

Framebus OUT Framebus Termination

Earth Connection: VDS 200Nx and PFM 200N

Mains power: to all devices (1ph / 3ph)

Figure 3.11: Cabling for the System with a PFM 200N100.1

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 12 / 45

3.8.3.

Software Installation and Setup

To install the AutoWave.control, please consult the software user’s guide.

After installation use the Hardware Configuration tool to setup the AutoWave.

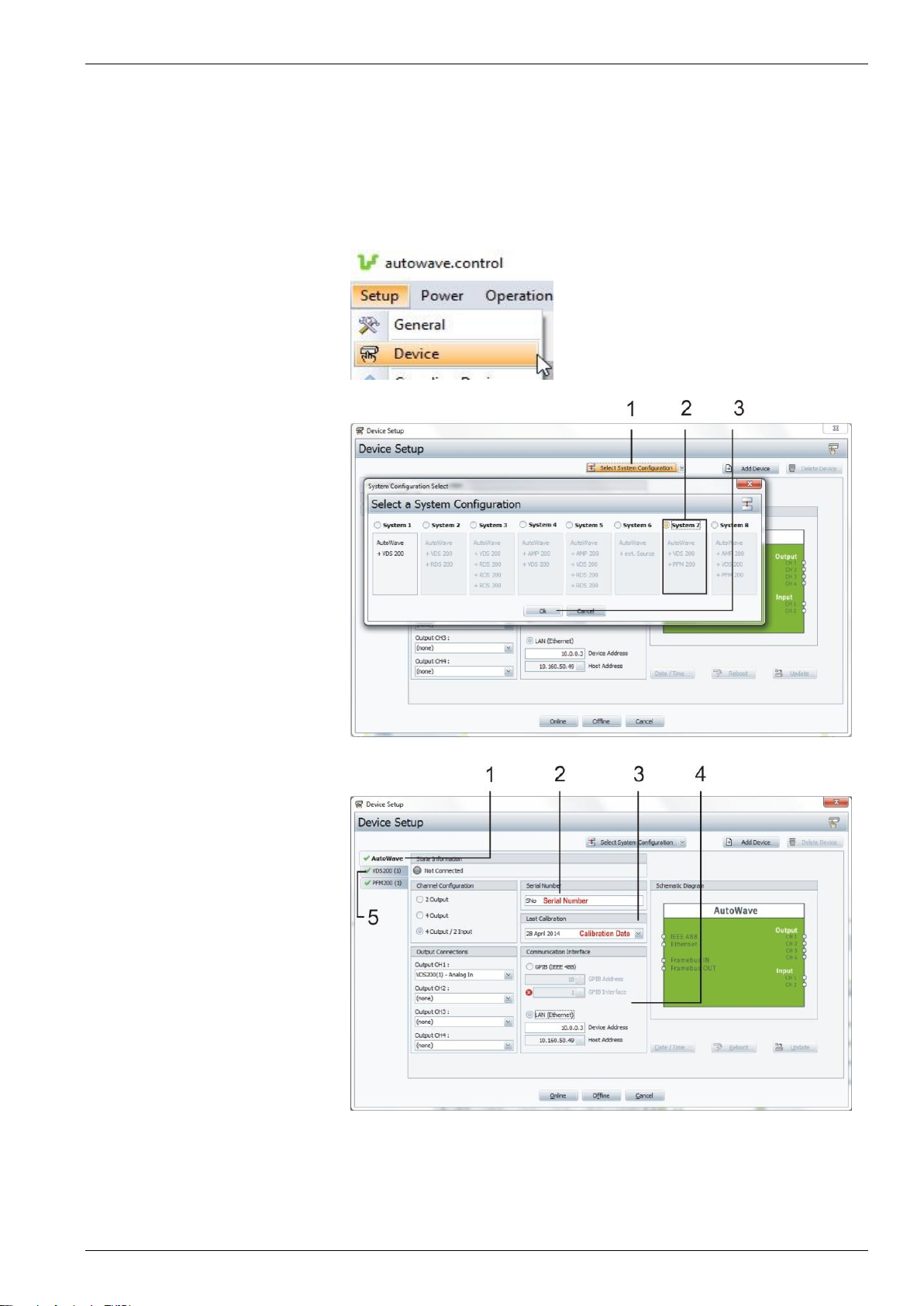

ASelect Setup / Device to open

the System Configuration.

Figure 3.12

B System Configuration

Here you can setup the software for

the correct system configuration.

1 Choose the selection

Select System Configuration

to open a typical configuration.

2 Select System 7 or System 8

or the one that most accurately

reflects your system.

3 Choose OK to close this

window.

Figure 3.13: System Configuration for a Typical PFM 200N100.1 Setup

C Device Setup

Here is where you enter the details

for the device.

1 First, select AutoWave

as the device to be edited.

2 Enter the Serial Number in the

list.

3 Enter the date from the

delivered certification.

4 Select the Interface to the

computer: GPIB or LAN.

5 Enter the details for the VDS.

Figure 3.14: Device Setup for AutoWave

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 13 / 45

D PFM 200N Series Setup

Here is where you enter the details

for the PFM 200N in the Software.

1 Select the PFM 200N

to be edited.

2 Enter the calibration date for

the PFM200N.

3 Enter the PFM 200N Serial

number in the provided field.

4 Click Online to connect the

system and the computer.

Figure 3.15: Device Setup for PFM 200N100.1

If you should encounter any problems during connection, please consult the AutoWave.control software user’s

guide. Here you’ll find more information for the installation.

For further information about software, please consult:

- The user’s guide for the AutoWave.control software

- The example applications in this guide

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 14 / 45

4.

Functions and Operation of the PFM 200N

4.1.

Front Panel Elements

Figure 4.1

1 Test enable button "TEST ON”

2 LED Power ON

3 LED Fail

4 Data line inputs L1 –L16

5 Data line outputs L1 –L16

6 Monitor BNC port

7 Trigger OUT BNC port

8 Trigger IN BNC port

9 DUT Test Supply LOW

10 DUT Test Supply HIGH

1 Test Enable Button “TEST ON”

Pressing the "TEST ON" button enables testing. The LED serves also as an optical indication when the switch

switches: the DUT power will be provided when the button is lit.

2 LED Power ON

This LED will light when the switch on the back of the device is switched on, indicating that the PFM is ready.

3 LED Fail

This LED will light when the PFM 200N detects an error. An error message will be displayed in a window in the

AutoWave.control software.

4 Data Line Inputs L1 –L16

16 pin PHOENIX, DFMC connector with 1.5 mm2, push-in locking connections.

Upper row: switched channel L1 to L16 (input)

Bottom row: return lines for the upper L1 to L16 switches

5 Data Line Outputs L1 –L16

16 pin PHOENIX, DFMC connector with 1.5 mm2, push-in locking connections.

Upper row: switched channel L1 to L16 (output)

Bottom row: return lines for the upper L1 to L16 switches

6 Monitor

Monitoring output for the DUT voltage at the test supply output using a differential measurement

Ratio 1:20, Amplitude 10 Vpp, ± 5 V

7 Trigger OUT, Oscilloscope Trigger

BNC trigger output (12 V pos. edge) for external measurement devices

8 Trigger IN

Trigger input to control the trigger the switch.

Signal (5 V neg. edge), delay ca. 100 µs

9 DUT Test Supply LOW

DUT output LOW with 4 mm (male) / 6 mm (female) connectors

10 DUT Test Supply HIGH

Switch DUT voltage output LOW 4 mm (male) / 6 mm (female) connectors

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 15 / 45

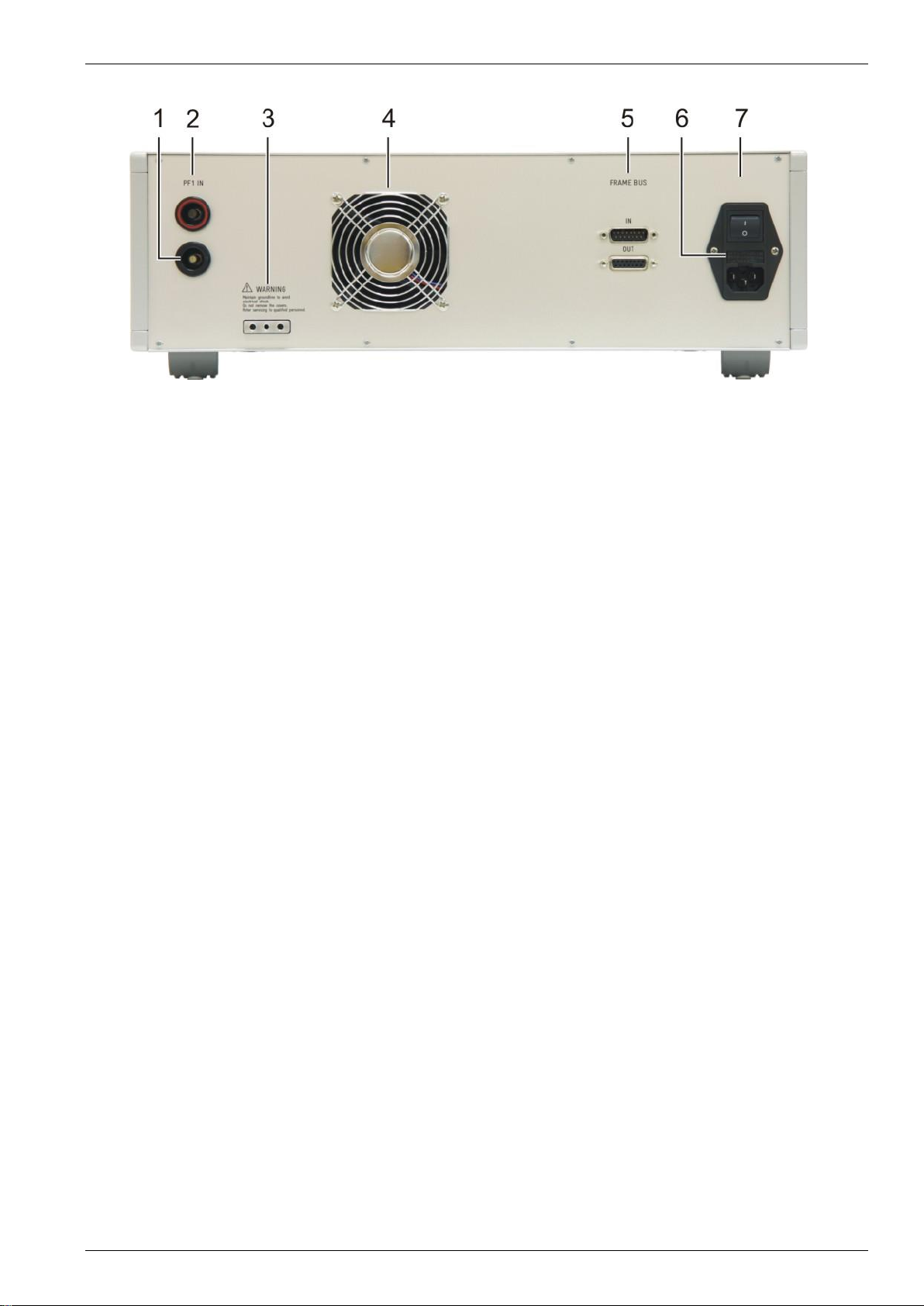

4.2.

Back Panel Elements

Figure 4.2

1PF1 IN, DUT power input High

2PF1 IN, DUT power input Low

3 Reference Earth

4 Cooling Fan

5 Frame Bus Interface

6 Mains Power Input and Fuse

7 Power Switch ON/OFF

1 PF1 IN, DUT Power Input Low (VDS)

Input connector 4 mm and 6 mm (PFM 200N100.1) or BVT 10 (PFM 200N200) for DC power for the DUT (Low).

The generator must be connected to the reference earth of the test setup.

2 PF1 IN, DUT Power Input High (VDS)

Input connector 4 mm and 6 mm (PFM 200N100.1) or BVT 10 (PFM 200N200) for DC power for the DUT from

an external source (High)

Max. DC Voltage ±100V

- 6 mm connector 100 A

- 4 mm connector 32 A max.

3 Reference Earth

Earth connector with an M5 screw terminal and 4mm banana connector. The generator must be connected

to the reference earth in the test setup.

4 Cooling Fan

Cooling unit. At least 20cm around should be allowed for proper ventilation.

5 Frame Bus Interface

Interface for controlling the PFM 200N from an AutoWave. The output of the Frame Bus must be terminated with

the Framebus Terminator part no. 101732.

6 Mains Input and Fuse

The mains input has an integrated filter and fuse for the generator using (2x 2 AT) fuses. The generator power

supply is a universal power supply with a range of 100 V - 265 VAC, 50/60 Hz

7 Power Switch

Power ON/OFF Switch

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 16 / 45

4.3.

Description of the Functions of the Device

4.3.1.

Front

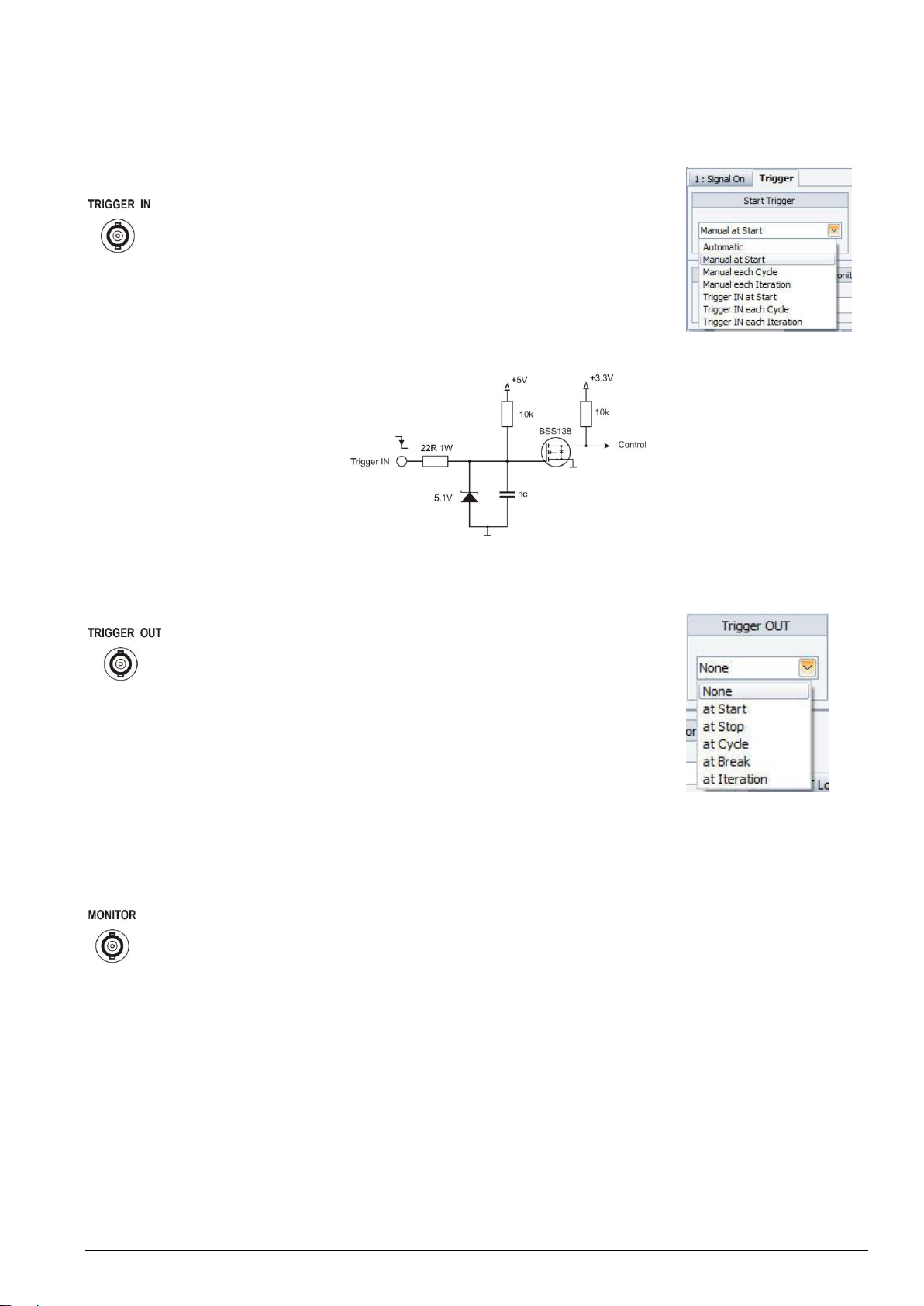

Figure 4.3

Trigger IN

Trigger to start an event

The trigger signal starts an interrupt. The

trigger can be set in the AutoWave software.

- Manual at Start

- Manual each Cycle

- Manual each Iteration

Figure 4.4 Trigger IN selection

Figure 4.5 Schematic - Trigger IN

Signal: 5 V, neg. edge

Delay: 100 µs

Jitter:

Figure 4.6

Trigger OUT

Output signal synchronized with the internal

switching control signal for an external

oscilloscope

Signal: 12 V, pos. edge

Current: 100mA

Delay: same as the switch control signal

Jitter:

Figure 4.7 Trigger OUT

selection

Figure 4.8

Monitor OUT

Allows monitoring of the output of the Test

Supply

Measurement: differential measurement

Ratio: 1:20

Amplitude: 10 Vpp, ± 5 V

Accuracy: ± 5%

Bandwidth: 10 MHz

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 17 / 45

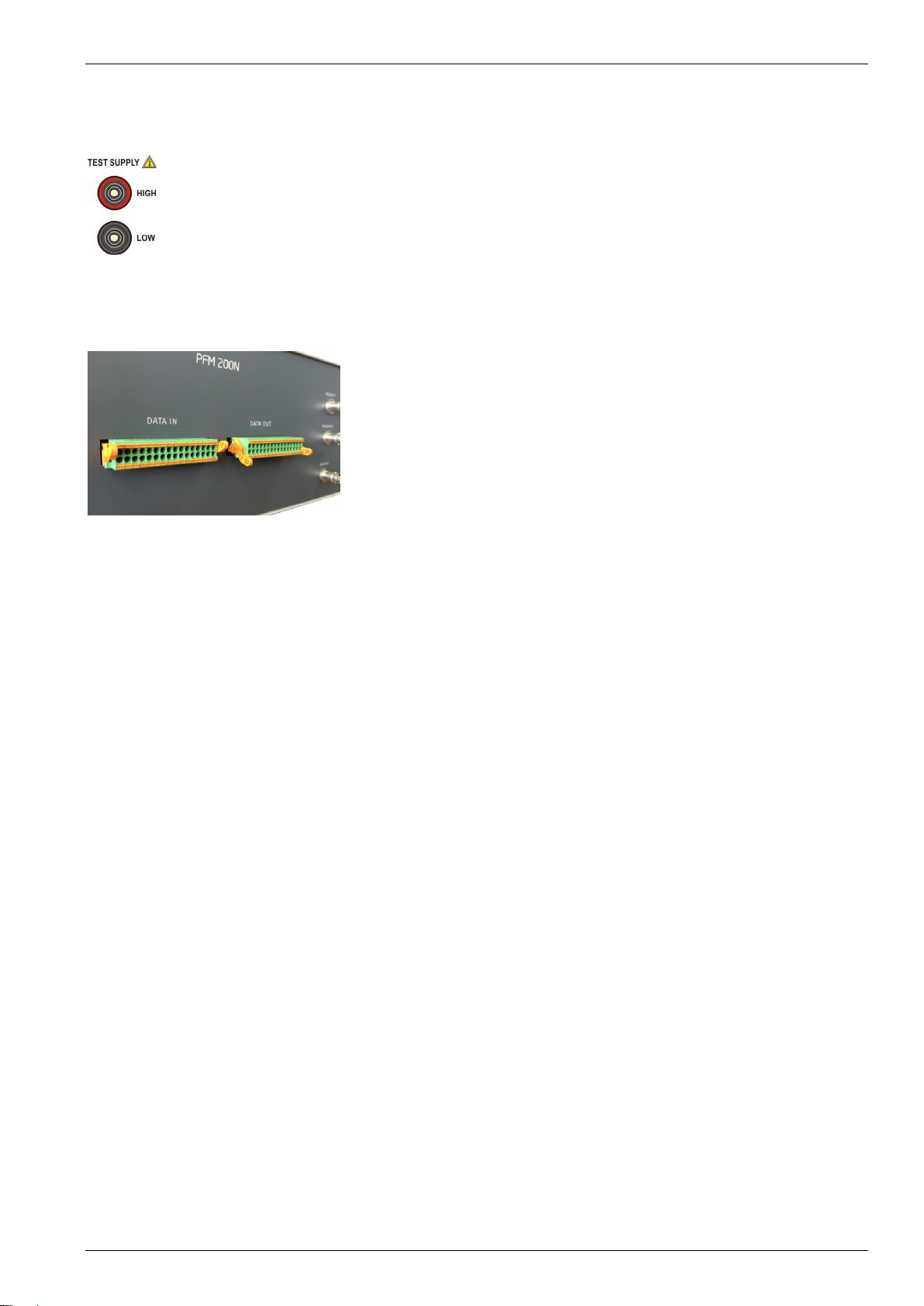

DUT Connections

Figure 4.9

DUT Power

Current capabilities PFM 200N100.1:

4 mm male: max. 32 A

6 mm female: max. 100 A

Current capabilities PFM 200N200:

KBT10: max. 200 A

(Mating connectors provided)

Figure 4.10

Data lines

The delivered connectors for the data lines are

equipped with spring-cage connections

Position of the spring-cage connector:

Open: upper position

Closed: lower position

Manufacturer: PHOENIX CONTACT

Model: DFMC series

Order No: 1790629

Poles: 16

Contacts: 32

Note: Depending on the signal, impedance and frequency, a small amount of crosstalk may be experienced when

using the data line switches.

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 18 / 45

4.3.2.

Back

Figure 4.10

Input for DUT Power

Current capabilities PFM 200N100.1:

4 mm male: max. 32 A

6 mm female: max. 100 A

Current capabilities PFM 200N200:

KBT10: max. 200 A

(Mating connectors provided)

Figure 4.11

Frame Bus

Daisy Chain Bus with 15 pin Sub-D

male /female connector.

This interface is used to control various EM Test

devices.

Figure 4.12

Power and Fusing

The main on/off switch of the PFM 200N series acts as the mains input

and contains a mains filter and fusing.

Mains: 100V - 265V, 50/60 Hz

Fuse: 2 x 2 AT, 5 x 20mm

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 19 / 45

5.

PFM 200N Dropout Simulator

The generator serves as the switching unit for dropout testing both power and signal lines required by

various requirements.

5.1.

Switch for DUT Battery Voltage

- Power Switch (S1P) for currents from 100 mA to 100 A (Inrush 400 A for 200 ms)

- Voltage ± 100 V DC

- Switching time < 1 µs (PFM 200N) < 200 ns (PFM 200N100.1 and PFM 200N200)

- Bidirectional switching capability

- Switch (S1N) on the ground line

- Integrated shorting-switch with < 100 mΩ during switch off (S2)

- Additional switchable impedances (R1…Rx), for predefined impedances of the on board power

system

5.2.

Switches for Data and Signal Lines

- Switch (S1 to S16) for currents from 100 µA to 2 A (Inrush 5 A for 200 ms)

- Bidirectional switching capability

- 16 switches for each sign or data lines

- Max. ± 40 VDC

The generator may only be used with AutoWave

5.3.

Block Diagram PFM 200N

Battery Lines

Switch S1 and S2 from the standards LV 124 and LV

148 have a slightly different name in the PFM 200N

Series and its associated software. Switch S2N in the

PFM 200N, used to interrupt the ground line, is not

found in the LV requirements, instead other standards.

Figure 5.1: Block Diagram PFM 200N100.1 with

descriptions corresponding to the AutoWave.control

software

LV Std.

PFM / Software

Power Switch High

S1

S1P

Shorting Switch

S2

S2

Power Switch Low

--

S1N

Data and Signal Lines

There are two connectors on the PFM 200N, each with

16 inputs and outputs. The upper row is switched and

the lower row is an unswitched return line.

EM TEST PFM 200N Series

User’s Guide Ver. 1.21 20 / 45

6.

Testing according to LV 124 and LV 148 using the autowave.control Software

Tests according to E-10, E-13 and E-14 uses an AutoWave for control. The user must use

AutoWave.control version 5.6.0 or newer.

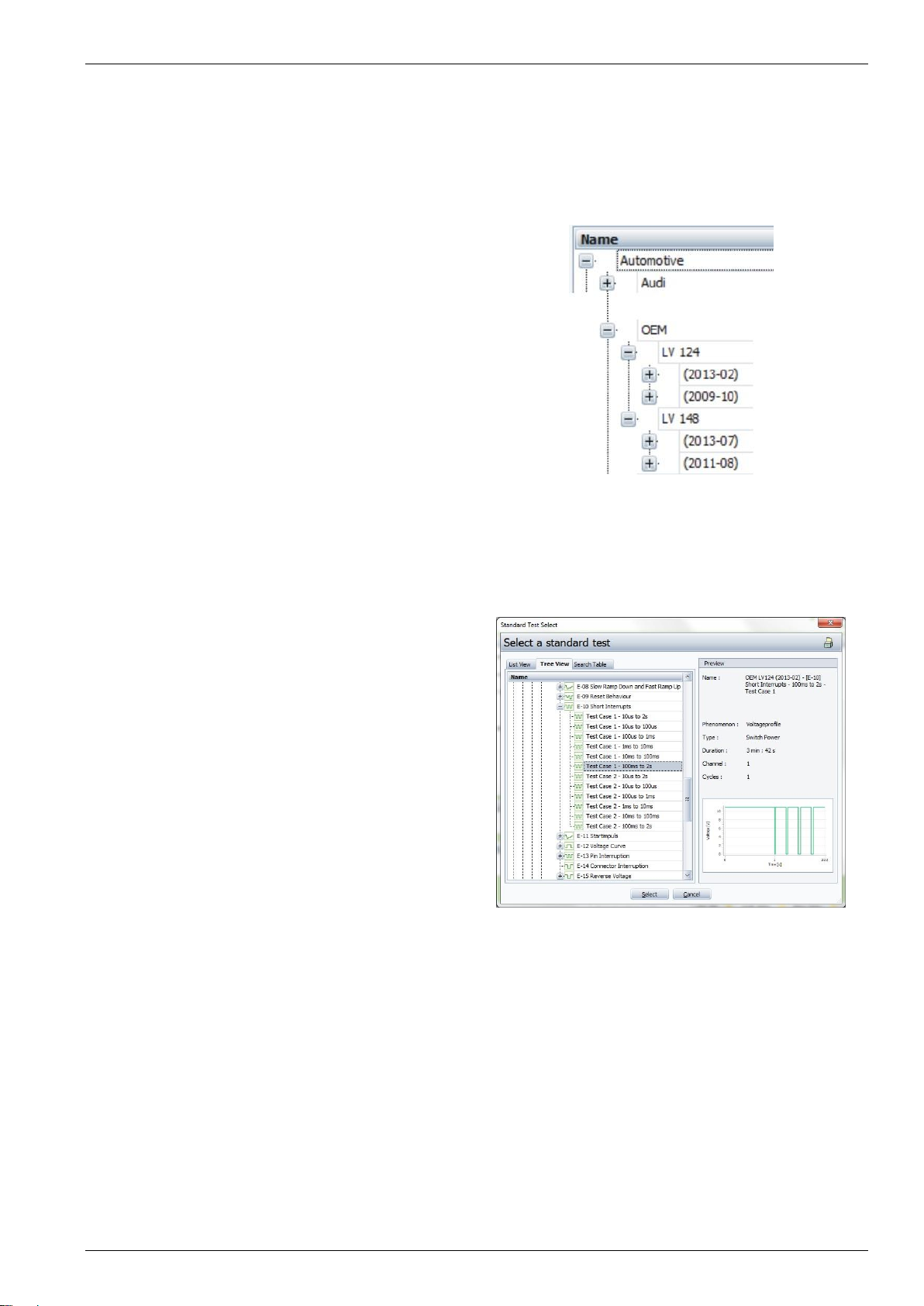

6.1.

Locating the Standard Tests for LV 124 and LV 148

LV 124 and LV 148 in the Standards Library

The standards LV 124 and LV 148 are found in

the Standards Library under Automotive –OEM.

Each standard contains various versions.

Figure 6.1: Standards list for LV 124 and LV 148

Selecting a Test

The user may choose the needed version and

test routine. Tests that do not user EM Test

equipment will not be found here. Each test step

is listed individually.

The example in Figure 6.2 the selection of a test:

LV 124(2013-02), E-10 Test Case 1 that includes

a dropout from 100ms to 2s.

Preview

In the right window of AutoWave.control a

preview of the selected test is displayed including

some general information about the selected test.

The picture in the preview window shows the test

run in a simplified way. The user has the

possibility to check the voltage profile of the test

run in a visual way.

Figure 6.2: Standard List for LV 124 Test Case 1 & 2

More Information about the Preview Window

Name: Standard name of the selected test

Phenomenon: Type of test (Voltage profile)

Duration: Duration of the entire test

Channel: Channel (AutoWave output)

Cycles: Number of Cycles

This manual suits for next models

2

Table of contents

Other EMTEST Test Equipment manuals

EMTEST

EMTEST esd NX30 User manual

EMTEST

EMTEST CWS 500A / 75 User manual

EMTEST

EMTEST AN 200 Series Instruction Manual

EMTEST

EMTEST VDS 200Q10 Series User manual

EMTEST

EMTEST PFM 200N100.1 User manual

EMTEST

EMTEST variac-NX 1-260-16 User manual

EMTEST

EMTEST CNI 508 N2 User manual

EMTEST

EMTEST dito User manual

EMTEST

EMTEST PFS 200N Series Instruction Manual

EMTEST

EMTEST CNI 503 Series Technical Document