EMTEST VDS 200Q10 Series User manual

M a n u a l

f o r O p e r a t i o n

VDS 200Q10 series

Voltage Drop Simulator pulses 2b, 4

➢VDS 200Q10, VDS200Q10.1

Testing of electronic modules in 12V/24V or 42V supply

systems.

The VDS 200Q10 series is four-quadrant linear power amplifier

with a very low source impedance. It simulates the battery

power supply of a vehicle and complex power supply distortions

in the power range up to 600W. Many different waveforms are

integrated as standard such as pulse 2b required by ISO 7637

and the starting profile from ISO 16750 as well as requirements

from many manufacturers’ standards like LV 124.

•ISO 7637

•ISO 16750

•SAE J1113

•Manufacturer spec

LV 124, LV 148, GM,

Ford, Chrysler, BMW,

VW, PSA, Renault,

Fiat ....

Version:

1.00 / 13.04.2021

the benchmark for emc

Replaces:

-

File Name:

UserManual-VDS200Q10.x-E-V1.00

Print Date:

13.4.2021

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 3 / 35

Contents

1. Model Overview .............................................................................................................................................4

1.1. VDS 200Q10 series models .........................................................................................................................4

1.2. Construction..................................................................................................................................................4

2. Operating Functions .....................................................................................................................................5

2.1. Front view VDS 200Q10.x ............................................................................................................................5

2.2. Rear view VDS 200Q10.x.............................................................................................................................6

2.3. Safety with voltage setting............................................................................................................................8

3. Operation......................................................................................................................................................10

3.1. Description of the menus............................................................................................................................10

3.2. Main Menu ..................................................................................................................................................10

3.2.1. Change of parameters................................................................................................................................11

3.3. Wave Simulator...........................................................................................................................................12

3.3.1. ISO 7637.....................................................................................................................................................13

3.3.1.1. Pulse 4 voltage drop..................................................................................................................................13

3.3.1.2. Pulse 2b......................................................................................................................................................13

3.3.2. ISO 16750-2 WD 03/2000-2.......................................................................................................................14

3.3.2.1. Short voltage drop.......................................................................................................................................14

3.3.2.2. Slow decrease / increase............................................................................................................................14

3.3.2.3. Supply voltage profile..................................................................................................................................15

3.3.2.4. Pulse ’Starting profile’ .................................................................................................................................15

3.3.2.5. Sinus Sweep...............................................................................................................................................16

3.3.2.6. Overvoltage Vmax ......................................................................................................................................16

3.3.3. Functions ....................................................................................................................................................17

3.3.3.1. Sine wave ...................................................................................................................................................17

3.3.3.2. Jump Start...................................................................................................................................................18

3.3.3.3. VDS Externally via the analog input ...........................................................................................................18

3.3.3.4. Pulse 4 ( GM 9105 P) .................................................................................................................................19

3.3.3.5. DC source...................................................................................................................................................20

3.4. Service........................................................................................................................................................21

3.5. Setup...........................................................................................................................................................22

3.6.Source Settings...........................................................................................................................................23

4. Technical Data.............................................................................................................................................27

4.1. Test level.....................................................................................................................................................27

4.2. Trigger.........................................................................................................................................................27

4.3. Input/output.................................................................................................................................................27

4.4. Interfaces ....................................................................................................................................................27

4.5. General .......................................................................................................................................................28

4.6. Environmental conditions............................................................................................................................28

5. Maintenance.................................................................................................................................................29

5.1. General .......................................................................................................................................................29

5.2. Test set-up..................................................................................................................................................29

5.3. Test set-up with software iso.control ..........................................................................................................29

5.4. Example Test setup with VDS 200Q10.x, AutoWave and PFM 200N100 .................................................30

5.5. Example Test setup with AutoWave and VDS 200Q10.x...........................................................................31

5.6. Calibration and Verification.........................................................................................................................32

5.6.1. Factory calibration.......................................................................................................................................32

5.6.2. Guideline to determine the calibration period of AMETEK CTS instrumentation.......................................32

5.6.3. Calibration of Accessories made by passive components only:.................................................................32

5.6.4. Periodic In-house verification......................................................................................................................32

6. Delivery Groups...........................................................................................................................................33

6.1. Basic equipment VDS 200Q10.x ................................................................................................................33

6.2. Accessories and options.............................................................................................................................33

6.3. Connectors..................................................................................................................................................33

7. Appendix ......................................................................................................................................................34

7.1. Declaration of CE-Conformity.....................................................................................................................34

7.1.1. Declaration of CE-Conformity VDS 200Q10...............................................................................................34

7.1.2. Declaration of CE-Conformity VDS 200Q10.1............................................................................................35

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 4 / 35

1.

Model Overview

1.1.

VDS 200Q10 series models

Standard models

Model Voltage

voltage

current

inrush current

Sine f max

VDS 200Q10-100

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

VDS 200Q10-120

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

VDS 200Q10-230

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

VDS 200Q10.1-100

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

VDS 200Q10.1-120

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

VDS 200Q10.1-230

-60 to +60 V

Imax = ±10 A

Not supported

180 kHz

1.2.

Construction

The Voltage Drop Simulator VDS 200Q10.x is built in a 19" / 6HU housing.

On request the VDS 200Q10.x generator could also be built into a rack.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 5 / 35

2.

Operating Functions

2.1.

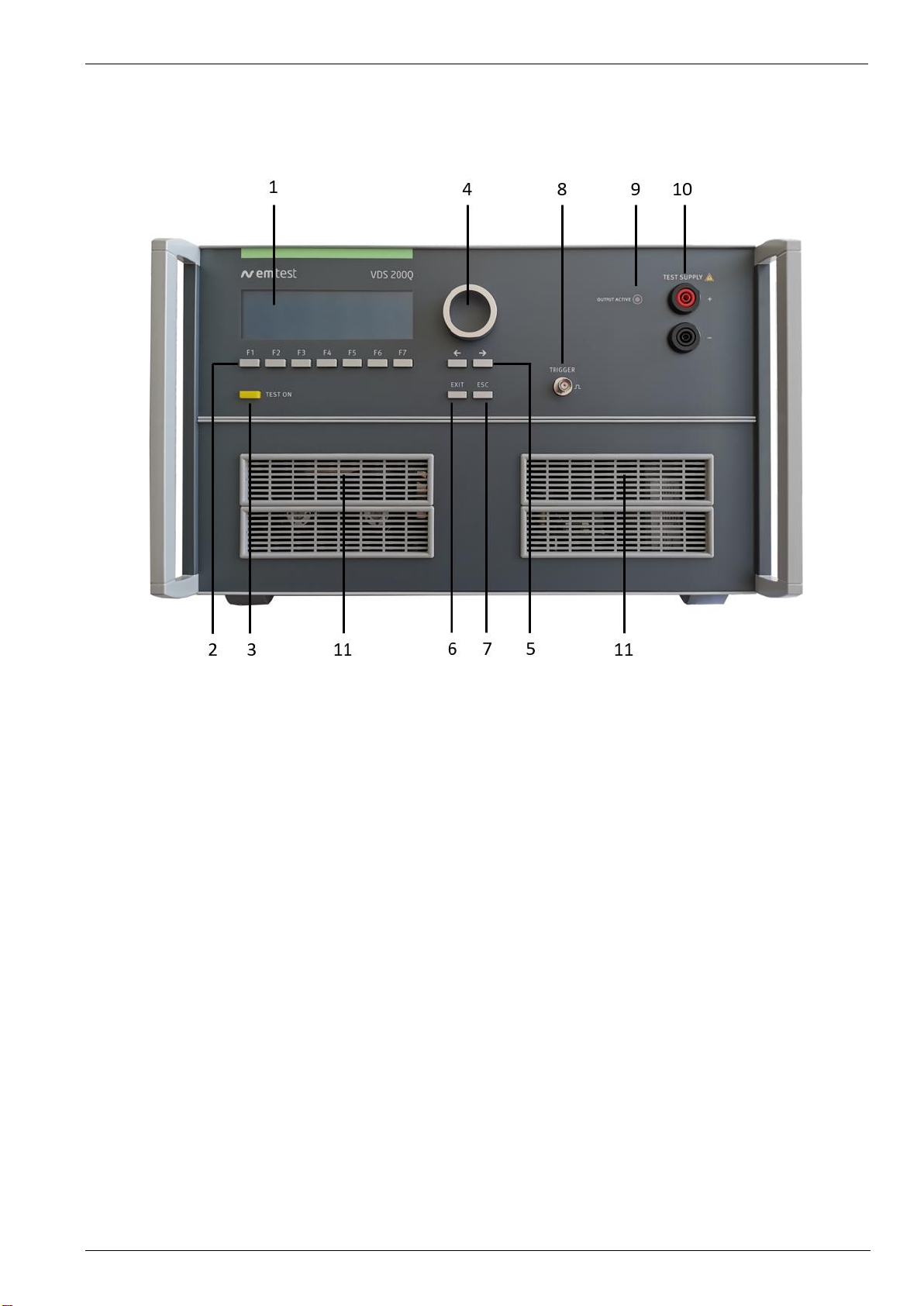

Front view VDS 200Q10.x

1Display

2Function keys "F1..F7"

3"TEST ON"

4Knob (Inc/Dec)

5 Cursor keys "" and "→"

6EXIT

7ESC

8BNC CRO Trigger ( for oscilloscope)

9 LED OUTPUT ACTIVE

10 Test Supply

11 Cooling

1 Display

All functions and parameters are displayed (8 lines with max. 40 characters).

2 Function keys "F1 .. F7"

Parameters and functions, displayed in the lowest line, can be selected with the related function key.

3 Test On

By pressing the key "TEST ON" the test procedure is initiated with the preselected parameters. The yellow

button is illuminated and indicates the Test ON status. After “Test OFF” or when no test is started, the output

voltage and the current will be set to zero.

4 Knob (Inc / Dec)

The knob increments or decrements test parameters with a numeric value or selects from a list of parameters.

5 Cursor keys

Parameters and functions can be changed on-line. The selection of these parameters is realized with the cursor

moving to the left or to the right.

6 Exit

Pressing the "EXIT" function will return to the previous menu. This is only possible if no test routine is running.

7 ESC

When pressing the ESC button the user moves back one page in the menu.

8 BNC CRO Trigger

At the BNC connector CRO TRIGGER a signal is available to trigger an oscilloscope.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 6 / 35

9 LED OUTPUT ACTIVE

This LED is on during the power on status.

10 Test Supply

Output to the DUT or other generators.

4mm banana connectors.

11 Cooling

Grid with fans for cooling behind. Ensure nothing blocks the air circulation (distance > 0.5m)

2.2.

Rear view VDS 200Q10.x

1

TEST SUPPLY OUT

8

Mains switch

2

SENSE

9

Mains fuse

3

Reference ground connection

10

Mains input

4

Cooling

11

IEEE 488.1

5

FRAME BUS

12

USB port

6

TRIGGER IN

13

CN interface

7

ANALOG IN

14

FAIL1 / FAIL2

1 TEST SUPPLY OUT

Output to DUT

2 Sense

Sense lines to compensate voltage drop across connection VDS –DUT (max. 4V)

Note: Sense lines are only supported for VDS 200Q10.1 models and higher.

3 Reference ground connection

Massive metal ground point to be connected to a reference ground point in the system during testing.

4 Cooling

Grid with or without fans for cooling behind. Ensure you do not block these grids.

Minimum distance to a wall or other blocking objects >20cm

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 7 / 35

5 FRAME BUS

EM Test internal communication bus. Daisy chain all equipment connected to the bus, terminate

at the end of the chain.

6 TRIGGER IN

External trigger IN signal

7 ANALOG IN

-10 / +10VDC. Connection to AutoWave or an external arbitrary waveform generator.

8 Mains switch

To power up the equipment

9 Mains fuse

230 Vac, 6.3 A, 5 x 20 mm

115 Vac, 10 A, 5 x 20 mm

100 Vac, 16 A, 5 x 20 mm

10 Mains input

Max. 16A, depending on power mains voltage.

11 IEEE 488 / GPIB

Parallel IEEE 488 interface to remote control the generator with a software tool.

12 USB Port

USB interface “USB B” connector. For data transfer a USB interface is available. The internal RS 232

interface is converted to USB standard. Therefore the user must set the same Baudrate in the device and

control software.

Interface is supported for iso.control, but not for autowave.control (either IEEE or FRAME BUS).

13 CN interface

Interface to other EM TEST devices, currently not used

14 FAIL1 / FAIL2

FAIL 1 can be used for failure detection at the DUT. If the input is set to ground (chassis) the generator

stops and terminate the test. The SW test routine than can be stopped completely continued at the break

point. A message of FAIL 1 is indicated in the LCD display as well as in the ISM software.

FAIL2 can be used for failure detection at the DUT. If the input is set to ground (chassis) the actual test

routine is paused as long as the low level signal is available at the FAIL 2 input. With no longer set to ground

signal the test procedure continues automatically. A message of FAIL 2 is indicated in the LCD display as

well as in the ISO.CONTROL software.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 8 / 35

2.3.

Safety with voltage setting

To ensure a safe operation of the DUT (Device Under Test) some restrictions in the operation of the instrument

are built in. These restrictions are explained within this paragraph.

CAUTION:

The VDS 200N and VDS 200Q series, as well as most linear power amplifiers will create spikes at

start and stop. Do not touch any conducted parts of the system and be sure to remove the DUT

during power up and shut down or damage may occur.

Do not use the VDS 200Q10.x with a parallel battery.

A four-quadrant source, like the VDS 200Q10.x can supply both positive and negative voltage as well as positive

or negative current in any combination. It can also sink current that may be supplied from external sources.

Often, using a classic 'source' (power supply or 1 - 2 quadrant source) the user felt the need to buffer the voltage

in order to get inrush or to properly simulate the impedance of the battery in the car. This, of course, can no

longer be controlled as the source simply becomes a charger the the battery.

However, when using a four-quadrant source like the VDS 200Q10.x and the source's voltage is set lower than

the battery, the battery can discharge through the source.

This can result in a dangerous condition, not only for the four-quadrant source, but also because you've

effectively short-circuited the battery when setting the voltage to zero (or switching the four-quadrant source off!).

Remember that all sources must have a source impedance of <10 mOhm according to ISO 7637.

Finally, by shorting (or overcharging) the battery, the battery can actually overheat, crack (releasing acid!) or

even explode due to the release of hydrogen.

CAUTION:

Do not use a parallel battery with the VDS 200Q10.x or a dangerous condition can occur by

exceeding the current of the VDS 200Q10.x, or overheating the battery.

CAUTION:

While the output of the VDS 200Q10.x is floating, the battery negative pole should be within 10V

of earth for safety reasons.

Do not put the simulator in parallel with other sources.

The VDS 200Q10.x basically is divided into 2 different operation modes, which includes their individual test

routines and supply voltage setting. The different modes can be listed as follows:

DC Source (VDS Generator - User Test Routines - DC Source)

Within this mode the VDS 200Q10.x is used as a simple DC power source in the range of up to 60V / 0-10A and

an integrated current limiter.

Arbitrary Wave Simulator

Within this mode the VDS 200Q10.x generates arbitrary waveforms and signals which are specified in different

standards, such as pulse 4 of ISO 7637.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 9 / 35

All these different test modes are changing generally the voltage supply setting of the generator in a different

way. This would mean a certain risk for the operator to burn out the connected DUT by higher DC supply

voltages as intended. Therefore it is decided to clearly separate the two test modes by the following structure

listed:

Analogue input +10/-10V

The amplifier can be controlled by an external signal generator. The operator therefore shall select the User

Test Routines of the VDS 200Q10.x part and start the menu Extern. The amplifier is then able to be remotely

controlled.

The input signal range is +10 to -10V in the frequency range of 0-180kHz. The output power (EUT test

supply) is capable of +60V / -60V and a nominal current depending on setting. For example, a 2V input

signal would result in 14V output.

1. DC source

When entering the Arbitrary Wave test mode the dc output voltage of the VDS 200Q10.x is automatically set to

the nominal voltage of the DUT. The actual nominal voltage can be defined in the service menu under "Set-up".

When starting the related test routines the output voltage will be generated as per the setting shown up in the

display for each individual test routine.

- The operator can accept this setting and start the test immediately.

- The operator can first change the parameters and than start the test.

When leaving the test mode DC source the output voltage is automatically reset to the nominal supply voltage of

the DUT. The previous voltage setting will be stored in the test file.

2. Arbitrary Wave Simulator

When selecting the Arbitrary Wave mode, the output voltage will be set automatically to the nominal voltage of

the DUT. The actual nominal voltage can be defined in the service menu under "Set-up".

When starting the related test routines, the output voltage will be generated as per the setting shown up in the

display for each individual test routine.

- The operator can accept this setting and start the test immediately.

- The operator can first change the parameters and then start the test.

When leaving the test mode Arbitrary Wave Simulator, the output voltage is automatically reset to 0V. The

previous voltage test parameters will be stored and can be used for the next test.

The consequence of the structure is that between the different test modes

the DUT supply is automatically switched off.

Be sure to select the appropriate bandwidth (Capacitive, Standard, High Freq.) in the Service

menu appropriate for the necessary test frequency.

While the full voltage and frequency can be programmed, bandwidth is typically measured at

the -3dB point. Therefore, please keep in mind that there will be some attenuation at the

maximum frequencies of each range that may have to be compensated for.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 10 / 35

3.

Operation

3.1.

Description of the menus

The simulator VDS 200Q10.x is operated by an easy menu control system.

Seven function keys are available to select parameters and functions. All

functions are indicated on the display; max. 8 lines and 40 characters.

The selected parameter is blinking and can be changed by turning the knob (incr./decr.).

➔ : The digit to be changed can be selected with the cursor (➔ ).

- Set values are directly indicated on the screen.

- Status on the bottom lines shows the desired status after pressing the function key.

ESC : ESC will take you back to the previous level in the menu and set the displayed

values. The latest settings are stored automatically and will be recalled when the

menu is selected again.

EXIT : The firmware will reset to the main screen.

AMETEK CTS

V D S 2 0 0 Q10.1

Voltage Drop Simulator

V 1.00.00

Int. V1.00.00

Waveforms

SWN: 001234

The serial number and the version number SWN are

used for traceability reasons. These numbers are listed

in the factory test reports and calibration certificates.

These numbers also are listed within the test reports

generated by the iso.control software

Start-up display example VDS 200Q10.1

3.2.

Main Menu

MAIN MENU

F1 : Wave Simulator

F7 : Service

F1

F2

F3

F4

F5

F6

F7

F1 Wave Simulator

In this mode, the internal signal generator is used to generate arbitrary waveforms as required in different

standards.

The operator can use the generator in this mode as a,

- DC power supply source,

- powerful power arbitrary wave generator with integrated test routines

- or simply as a battery simulator

The amplifier can be remote controlled by any external arbitrary generator. External generators shall be

connected at the rear part of the equipment. Any waveform can be generated up to the upper bandwidth of the

unit.

F7 Service

Set-up, self-test, source settings and addresses of AMETEK CTS can be selected and displayed.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 11 / 35

3.2.1.

Change of parameters

Easy and very fast operation of all standard functions of the equipment. The latest simulator settings are stored

automatically and will be recalled when Quick Start is next selected.

Page 5 (Show parameters)

ISO Pulse 4

Vb = 12.0V Va1 = -7.0V

Va2 = -3.0V t1 = 0.2s

t6 = 5ms t7 = 5ms

t8 = 5ms tf = 5ms

Va = 13.5V tri = Auto

I = 5A

Start Change

F1

F2

F3

F4

F5

F6

F7

Press START and the test routines begin to work.

Press CHANGE and the actual parameter can be changed.

Page 6 (Change of page 1/2) Page 6 (Change of page 2/2)

ISO Pulse 4

ISO Pulse 4

Vb: 0.0V - 60.0V

t8: 0.1 s - 99.9 s

Vb Va1 Va2 t1 t6 t7

t8 tf Va tri I

12.0 -7.0 -3.0 0.2 5 5 1/2

13.5 5 13.5 Auto 5 2/2

F1

F2

F3

F4

F5

F6

F7

F1

F2

F3

F4

F5

F6

F7

The user can select the parameter to be changed with the related function key and change the value by turning

the knob. The cursor allows the user to define the value of the digit to be changed (fast or slow change).

Pressing of the ESC button will bring the user back to the previous level from where the test can be

restarted with new parameters.

Page 6 (Start)

ISO Pulse 4

After start the actual voltage and current measurements

are displayed. All function keys except F2 (Man) within

the manual trigger mode can stop the test routine. The

latest setting will be displayed.

Pressing the key F3 while the test is running, the

display change to the ZOOM mode and is indicating the

actual voltage and current measurement in big letters.

Vb = 12.0V Va1 = -7.0V

Va2 = -3.0V t1 = 0.2s

t6 = 5ms t7 = 5ms

t8 = 5ms tf = 5ms

Va = 13.5V tri = Auto

I = 5A I = 3.5 A

Stop Zoom V = 7.0 V

F1

F2

F3

F4

F5

F6

F7

Page 6 (Stop)

ISO Pulse 4

By pressing any function key the Start, Change or

Continue mode will come up in the display. F3 will

continue the same test routine. Also the test time will

continue running. If the user first selects Start or

Change, the test will be stopped completely.

Vb = 12.0V Va1 = -7.0V

Va2 = -3.0V t1 = 0.2s

t6 = 5ms t7 = 5ms

t8 = 5ms tf = 5ms

Va = 13.5V tri = Auto

I = 5A I = 3.5 A

Stop Zoom V = 7.0 V

F1

F2

F3

F4

F5

F6

F7

Start Change Cont.

F1

F2

F3

F4

F5

F6

F7

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 12 / 35

3.3.

Wave Simulator

Page 2

Waveform Simulator

F1 : Standards

F2 : Functions

F3 : DC Power Supply

F1

F2

F3

F4

F5

F6

F7

Page 3

STANDARDS

F1 : ISO 7637

F2 : ISO 16750-2 or WD 03/2000-2

F1

F2

F3

F4

F5

F6

F7

Pages 4

ISO 7637

ISO 16750-2 WD 03/2000-2

F1: Pulse 4

F1: Short voltage drop

F2: Pulse 2b

F2: Slow decrease / increase

F3: Supply voltage profile

F4: Pulse ’Starting profile’

F5: Sweep

F6: Overvoltage Vmax

Page 3

FUNCTIONS

F1 : Sinus

F2 : Jumpstart

F3 : VDS Extern

F4 : Pulse 4 (GM 9105P)

F1

F2

F3

F4

F5

F6

F7

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 13 / 35

3.3.1.

ISO 7637

3.3.1.1.

Pulse 4 voltage drop

This pulse simulates supply voltage reduction caused by energizing the starter-motor circuits of internal

combustion engines, excluding spikes associated with starting.

tf [Vb-Va1] < 5ms

Input restrictions

0.0 V <= Vb + Va1 <= 60.0V

0.0 V <= Vb + Va2 <= 60.0V)

Parameters:

Vb

0.0V

-

+60.0V

Va1

- 60.0V

-

+ 60.0V

Va2

-60.0V

-

+ 60.0V

t1

0.1s

-

99.9s

t7

5ms

-

999ms

t8

5ms

-

999ms

t9

0.1s

-

99.9s

t11

5ms

-

999ms

Va

0.0V

-

+ 60.0V

I

1A

-

(Imax)

tri

Auto / Manual

3.3.1.2.

Pulse 2b

This pulse simulates transients from DC motors acting as generators after ignition is switched off.

tr, tf ( 10/90%) =1ms 50%

Input restrictions

Va1 0.0V

0.0 V Vb + Va1 60.0V

Parameters:

Vb

0.0V

-

+60.0V

Va1

- 60.0V

-

0.0V

t1

0.1s

-

99.9s

t6

1ms

-

999ms

td

5ms

-

9999ms

int

0.1s

-

99.9s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 14 / 35

3.3.2.

ISO 16750-2 WD 03/2000-2

3.3.2.1.

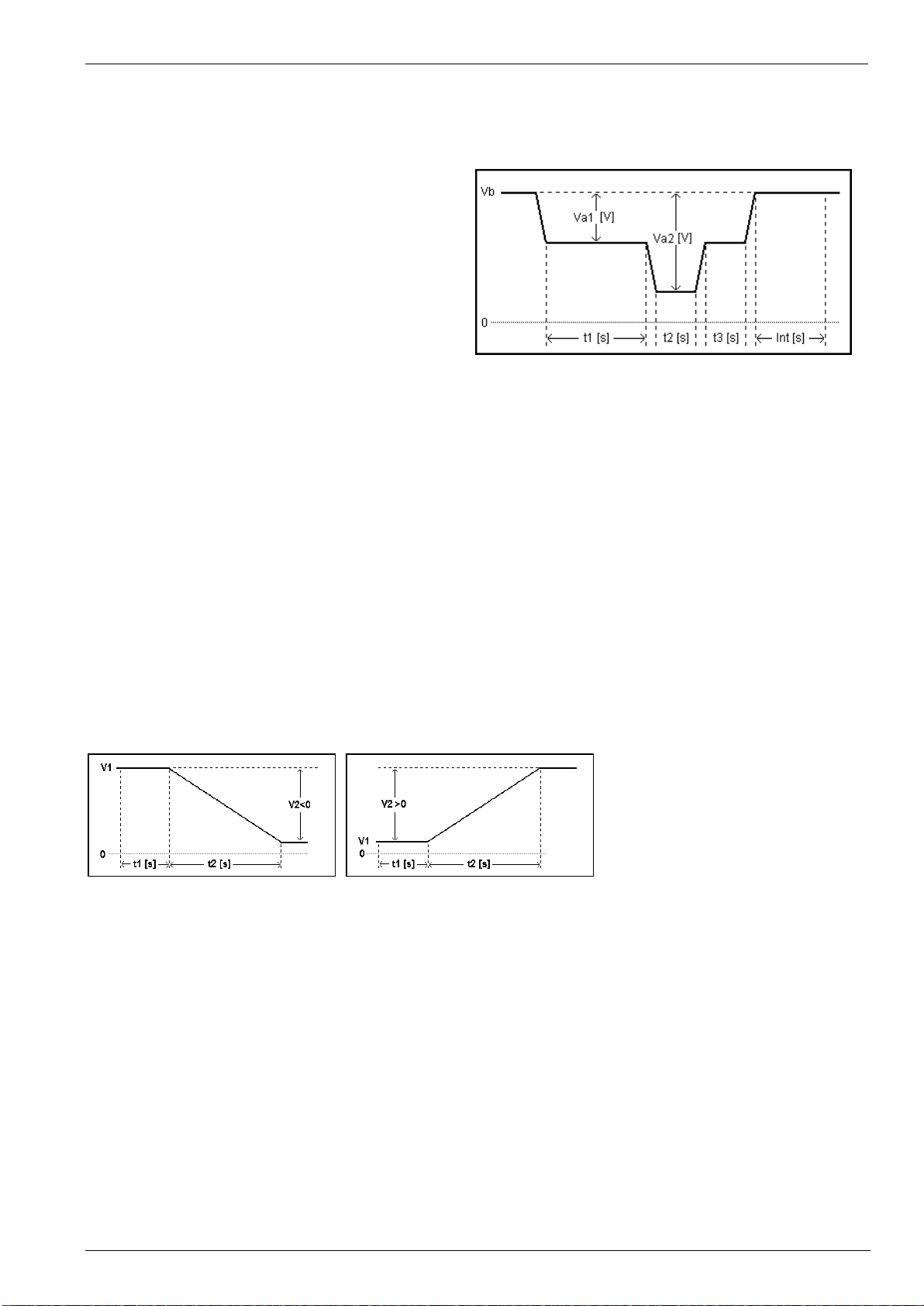

Short voltage drop

This test is to simulate the effect of a classical fuse actuation in another circuit.

tr, tf = 10ms

Input restrictions

0.0 V Vb + Va1 60.0V

0.0 V Vb + Va2 60.0V

Parameters:

Vb

0.0V

-

+60.0V

Va1

- 60.0V

-

+60.0V

Va2

- 60.0V

-

+60.0V

t1

0.1s

-

99.9s

t2

0.1s

-

99.9s

t3

0.1s

-

99.9s

int

0.1s

-

99.9s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

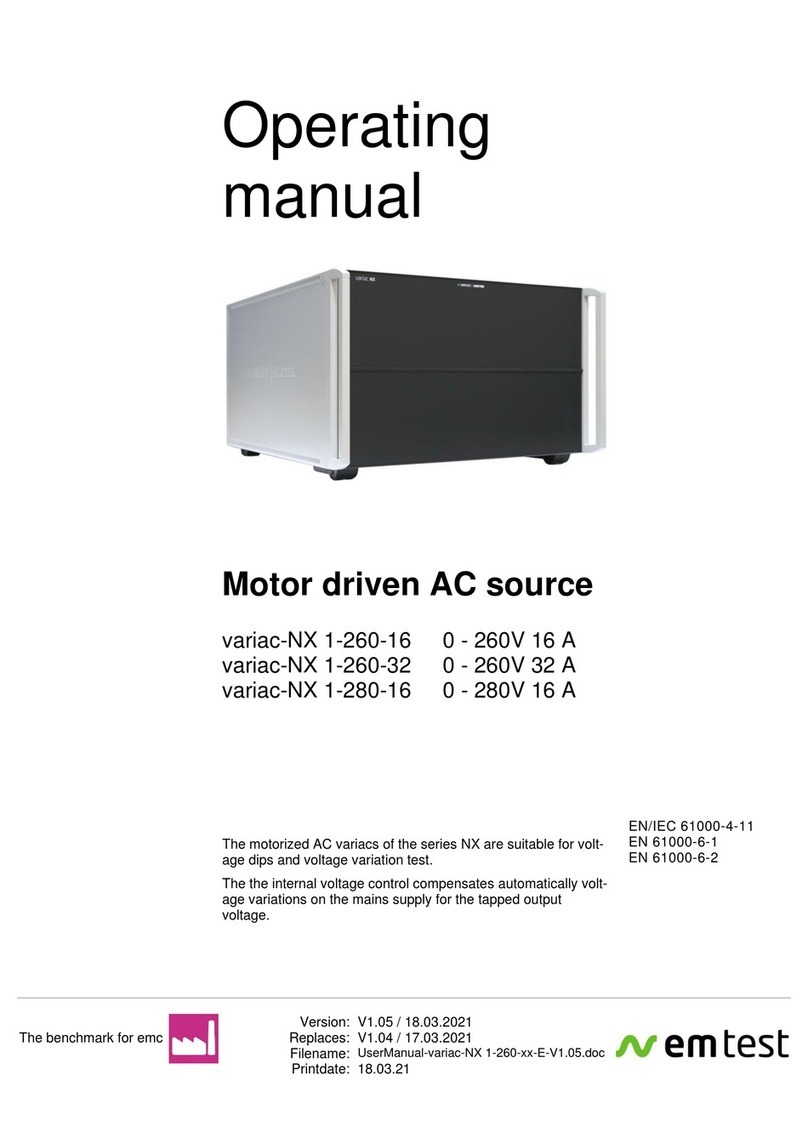

3.3.2.2.

Slow decrease / increase

This test is to simulate a gradual discharge and recharge of the battery.

Parameters:

V1

0.0V

-

+60.0V

V2

- 60.0V

-

+60.0V

t1

0.1s

-

99.9s

t2

0.1s

-

9999.9s

I

1A

-

(Imax)

Remarks:

WD 03/2000-2 Voltage change rate = ( 3 0.1 ) V per minute

ISO 16750-2 Voltage change rate = ( 0.5 0.1 ) V per minute

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 15 / 35

3.3.2.3.

Supply voltage profile

This test is to determine the reset behavior of the device under Test at different voltage drops. This test is

applicable to equipment with reset function.

Parameters:

Vb

0.0V

-

60.0V

Va1

- 60.0V

-

60.0V

Va2

- 59.9V

-

60.0V

Ve

- 60.0V

-

60.0V

dVa

- 60.0V

-

60.0V

t1

0.1s

-

99.9s

t2

0.1s

-

99.9s

t3

0.1s

-

99.9s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

3.3.2.4.

Pulse ’Starting profile’

This test simulates a motor startup including a possible ripple.

tr, tf = 10ms

Ripple = 2Hz

Input restrictions

0.0 V Vb + Va1 60.0V

0.0 V Vb + Va2 60.0V

Parameters:

Vb

0.0V

-

60.0V

Va1

- 60.0V

-

60.0V

Va2

- 60.0V

-

60.0V

t1

0.1s

-

999ms

t7

5ms

-

999ms

t8

5ms

-

999ms

t9

0.5s

-

99.5s

t11

5ms

-

999ms

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 16 / 35

3.3.2.5.

Sinus Sweep

This test simulates a residual a.c. on the dc supply

During Int f3 is applied.

Limitations

Vb + Vp <= 60.0V

Vb - Vp = 0.0V

Parameters:

Vb

0.0V

-

60.0V

Vp

0.0V

-

0.1 –60V

f1

0.001Hz

-

180.000kHz

f2

0.001Hz

-

180.000kHz

f3

0.001Hz

-

180.000kHz

t1

0.1s

-

999.9s

t2

0.1s

-

999.9s

int

0s

-

999s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

3.3.2.6.

Overvoltage Vmax

This test simulates a high energy load dump pulse.

Input restrictions

0.0 V V1 + V2 60.0V

Parameters:

V1

0.0V

-

60.0V

V2

0.0V

-

60.0V

t1

0.01s

-

999.99 s

t2

0.01s

-

999.99 s

t3

0.01s

-

999.99 s

int

0.1s

-

99.9s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 17 / 35

3.3.3.

Functions

3.3.3.1.

Sine wave

Limitations

Vb + Vp <= 60.0V

Vb - Vp = 0.0V

Parameters:

Vb

0.0V

-

60.0V

Vp

0.1V

-

60.0V

t1

0.1s

-

99.9s

f1

0.001kHz

-

180.00kHz

f< 100Hz 1.2Hz

t2

1.0s

-

999.9s

n

1

-

30’000 / endl.

I

1.0A

-

(Imax)

Be sure to select the appropriate bandwidth in the Service menu appropriate for the

necessary test frequency.

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 18 / 35

3.3.3.2.

Jump Start

Limitations

V1 + V2 <= 60.0V)

V1 + V2 = 0.0V

Parameters:

V1

0.0V

-

60.0V

V2

- 60.0V

-

60.0V

t1

0.01s

-

999.99s

t2

0.01s

-

999.99s

t3

0.01s

-

999.99s

int

0.1s

-

99.9s

n

1

-

30,000 / endl.

tri

Auto / Manual

I

1A

-

(Imax)

3.3.3.3.

VDS Externally via the analog input

The power amplifier can be driven by an external control voltage (-10 to 10V), e.g. from an external waveform

generator.

For this purpose the operator must select VDS Extern

by pressing the related function key. The Extern mode

is displayed and the unit can only be operated via the

coaxial BNC input ANALOG IN at the rear part.

Parameters:

Input voltage at BNC input :-10...10V dc

Page 6 (Change of page 1/2) Page 6 (Change of page 2/2)

Extern

Extern

I = 10A

Voltage Current

13.5 V 3.5 A

I = 5A

Start Change

Stop

F1

F2

F3

F4

F5

F6

F7

F1

F2

F3

F4

F5

F6

F7

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 19 / 35

3.3.3.4.

Pulse 4 ( GM 9105 P)

In addition to the ISO pulse 4 a 5Hz ripple of 1Vp-p is superimposed during t9 to Va.

tr, tf = 10ms

Input restrictions

0.0 V Vb + Va1 60.0V

0.0 V Vb + Va2 60.0V

Parameters:

Vb

0.0V

-

60.0V

Va1

- 60.0V

-

60.0V

Va2

- 60.0V

-

60.0V

t1

0.1s

-

99.9s

t7

5ms

-

999ms

t8

5ms

-

999ms

t9

0.4s

-

99.8s

t11

5ms

-

999ms

tri

Auto / Manual

I

1A

-

(Imax)

AMETEK CTS VDS 200Q10 Series

Manual for Operation V 1.00 20 / 35

3.3.3.5.

DC source

Page 3 (Show parameters)

DC POWER SUPPLY

Vb = 13.5 V - I = 5.0A

Stop Change

F1

F2

F3

F4

F5

F6

F7

The user can select the parameter to be changed with the related function key and change the value by turning

the knob. Pressing of the ESC button will bring the user back to the previous level from where the test can be

restarted with new parameters.

Page 4 (Change)

DC POWER SUPPLY

Vb = -60.0V-60.0V

I = 1A - 10A

Vb I

13.5 5

F1

F2

F3

F4

F5

F6

F7

Page 5 (Start)

DC POWER SUPPLY

Vb = 13.5 V - I = 7.0A

I = 5.8 A

Stop ChangeZoom U = 13.4 V

F1

F2

F3

F4

F5

F6

F7

After Start the actual voltage and current values are displayed. All function keys. The latest setting will be

displayed.

Pressing the key F3 while the test is running, the display is switched over to the ZOOM mode and is indicating

the actual voltage and current measurement in zoomed letters.

Note: The measured values are for indication only. Low current values are indicated with the value “LOW”.

The blinking value can be changed with the knob Inc/Dec. To select other values for change use the cursor keys.

This manual suits for next models

2

Table of contents

Other EMTEST Test Equipment manuals

EMTEST

EMTEST esd NX30 User manual

EMTEST

EMTEST variac-NX 1-260-16 User manual

EMTEST

EMTEST PFM 200N100.1 User manual

EMTEST

EMTEST CNI 508 N2 User manual

EMTEST

EMTEST dito User manual

EMTEST

EMTEST CWS 500A / 75 User manual

EMTEST

EMTEST AN 200 Series Instruction Manual

EMTEST

EMTEST PFS 200N Series Instruction Manual

EMTEST

EMTEST PFM 200N200 User manual

EMTEST

EMTEST CNI 503 Series Technical Document