Endecotts Air Sizer 200 User manual

46 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVING MACHINE MODEL:

Air Sizer 200

General Information

The Air Sizer 200 has an air nozzle, which is set rotating. The sieve with a Plexiglas lid is put on top of that. A

vacuum unit generates a jet of air, which disperses the particles through the air nozzle on the sieve.

The material, which is smaller than the mesh size of the air jet sieve, is transported by the backflow of the air

into the filter unit or directly into the vacuum cleaner. The jet of air de-agglomerates the particles and cleans the

sieve mesh constantly.

The Air Sizer 200 is specially designed for the dry sieving and the particle size determination of fine-grained,

dry, pourable and dispersed bulk materials. The sieve holder is suitable for 8“(203 mm) diameter test sieves

(premium air jet sieves)

Advantages

xCompact and portable (weighing only 14 kg)

xRequires only small storage space due to small footprint

xThe device is essentially maintenance free if cleaned regularly

xEasy to use

xIdeal for electrostatic materials

xWide range voltage supply

xCan reduce the average sieving times in samples with a high fine fraction

xVariable vacuum control

The Air Sizer 200 is not recommended for any wet sieving operations!

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 47

1. Technical specifications

Specifications

Range 20 μm to 4 mm

Drive / sieving motion stepping motor

Max. Batch / feed capacity 100 g (depending on material and mesh)

Max. Number of fractions 1

Amplitude N/A

Speed 5 to 55 rpm

Time display digital, 00:10 – 99:50 min

Suitable for dry sieving yes

Suitable for wet sieving no

Sieve diameter 203 mm = 8” (premium air jet sieves)

Clamping device N/A

Model bench top

Protection code IP 40

Electrical supply 100 - 240V 50/60 Hz

Power connection 1-phase

W x H x D 430 x 235 x 435 mm

Net weight 14 kg

Standards CE

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

48 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

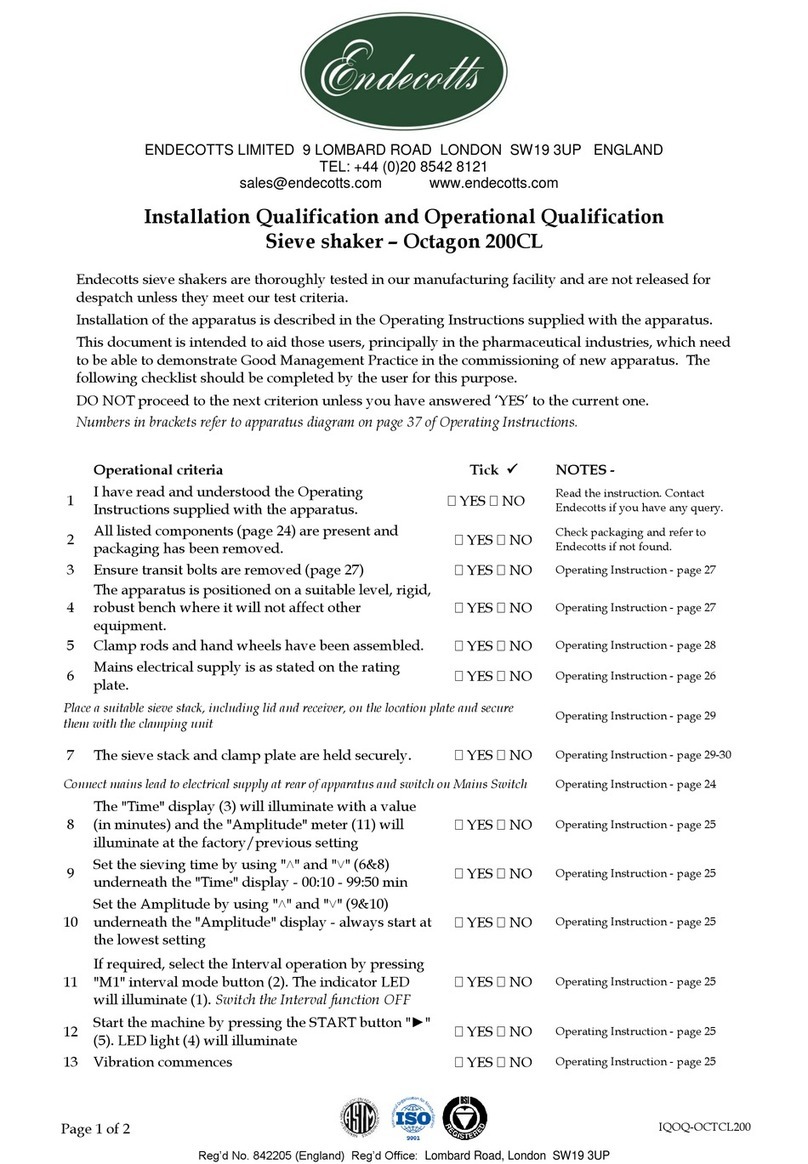

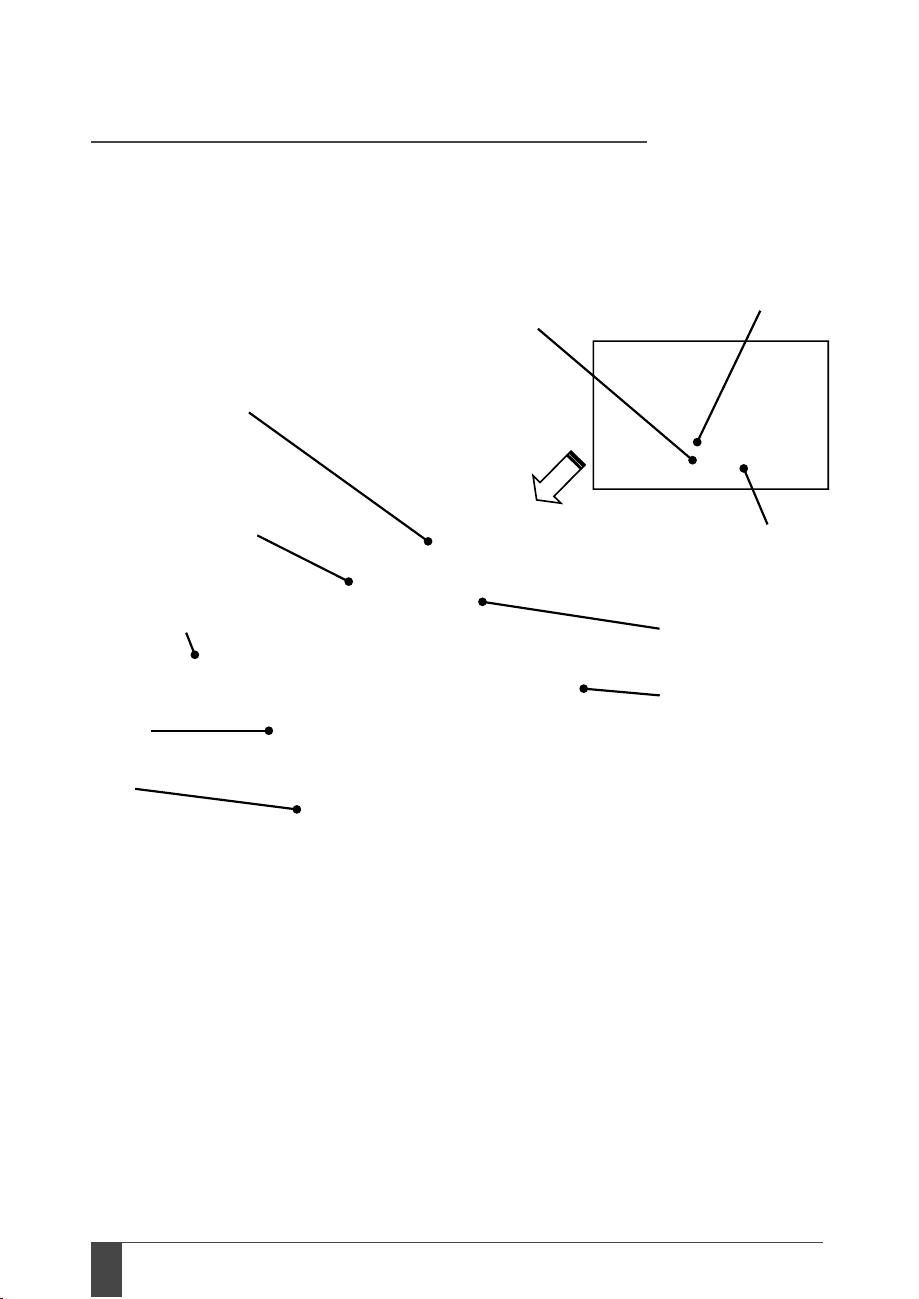

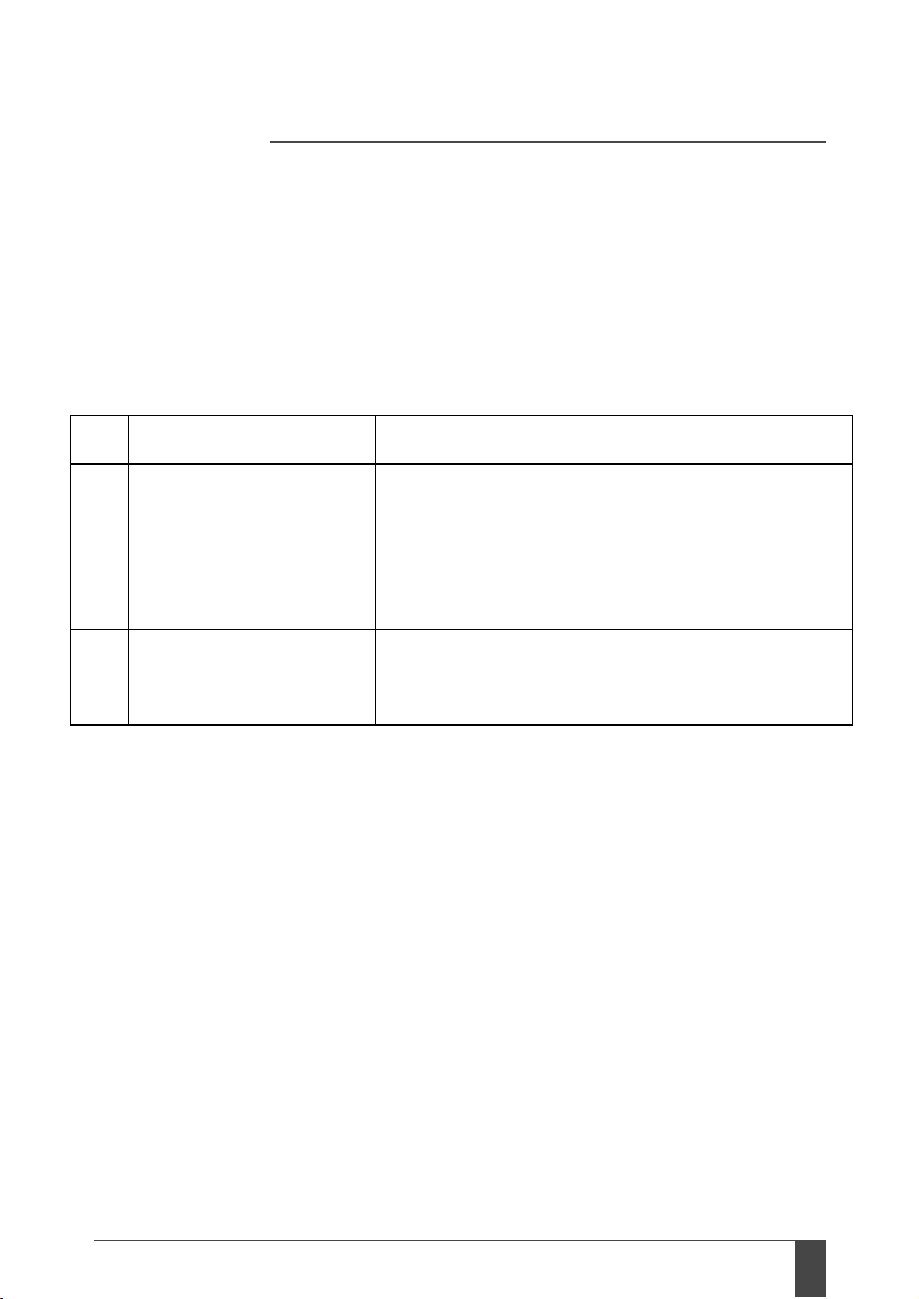

Controls and functions

Operators should be familiar with and fully understand the controls and indicators before

operating this machine.

PLEXIGLASS LID FOR AIR JET

SIEVING

TEST SIEVE

AIR OUTLET

CHANNEL

MAINS SWITCH

CONTROL

PANEL

COVER

BASE

NOZZLE

COMPARTMENT

MAINS POWER

CONNECTION

Electrical Connection

to vacuum cleaner

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 49

1. Technical specifications

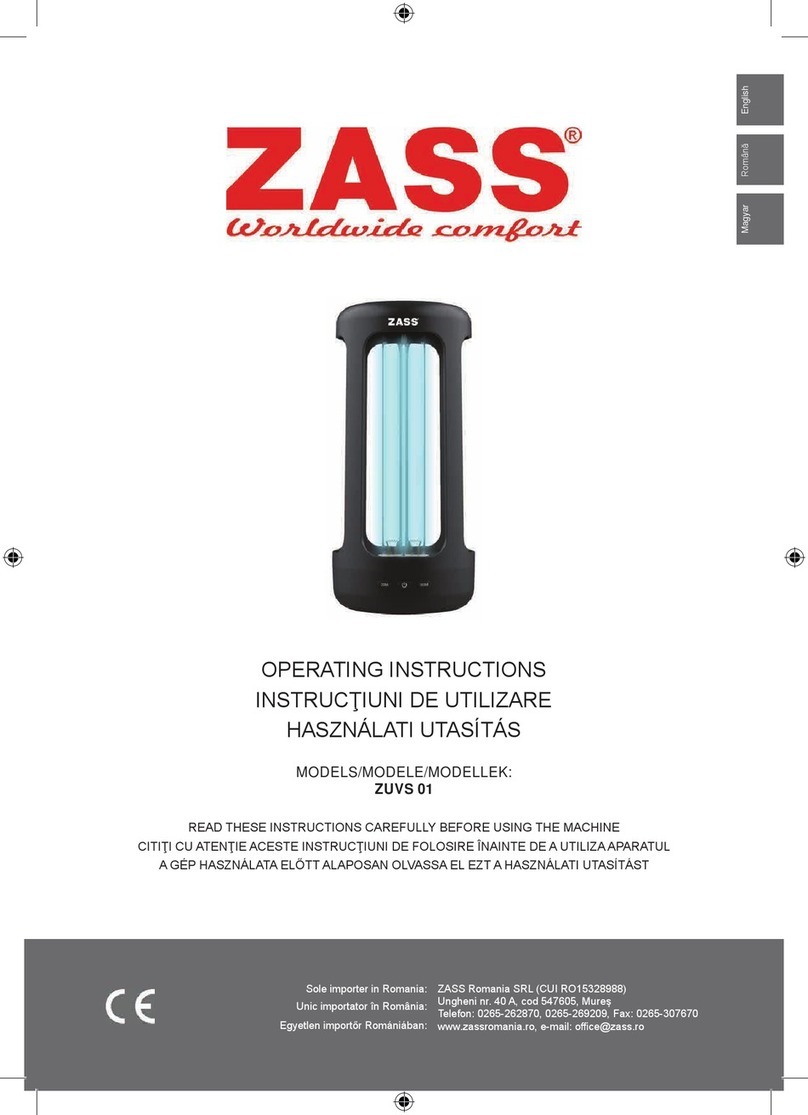

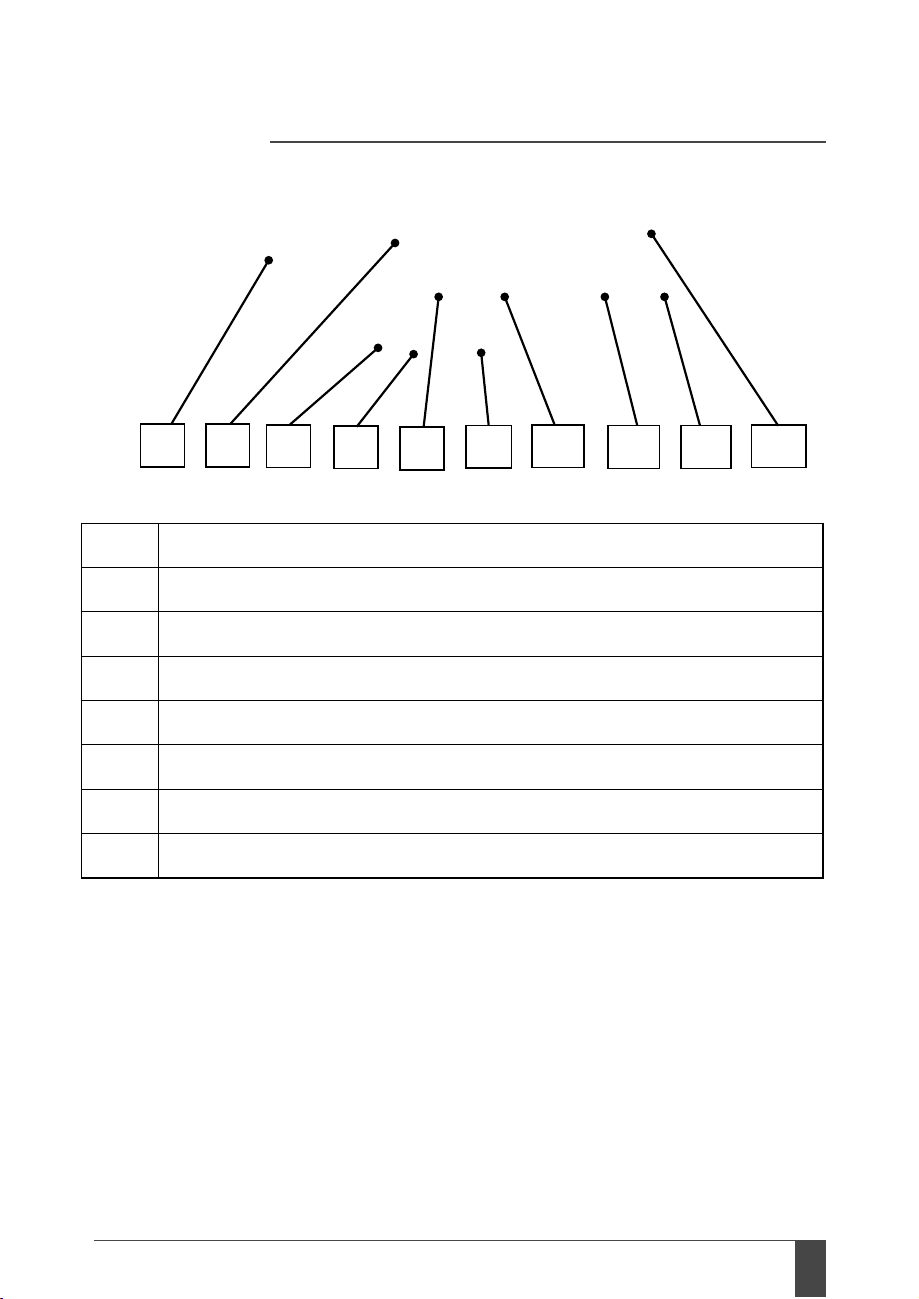

1 Vacuum pressure in mbar

2 Display shows the preselected sieving time, 00:10 – 99:50 min

3 LED light to indicate START button “>” ON.

4 Start the machine by pressing the START button “>”.

5 & 7 “ޕ“ and “ޔ” button reduces/increases the sieving time, 00:10 – 99:50 min

6 Stop the machine by pressing the STOP button “Ƒ“.

8 & 9 “ޕ“ and “ޔ” button reduces/increases the rpm, 5-55rpm, with digital display

10 Display speed shows the speed of 5-55rpm

5 6 103

14 8

29

7

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

50 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

Setting Up

Electrical connections

xEnsure that the voltage and frequency on the rating label, at the rear of the Air Sizer 200

correspond with the local electrical mains supply.

xConnect the Air Sizer 200 to the power supply using the connection cable provided.

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C,

with linear reduction down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

xMains power connection

Mains power connection with integral line filter. Ensure the IEC connector

on the mains lead is pushed fully into the mains inlet at the rear of the machine.

xMains Connection Indication

If the power of the Air sizer 200 is switched “ON”, the display LED lights up.

xProcess Timer

The process timer is a digital 00:10-99:50 minute timer. Operating periods

are increased by pressing the “ޔ” button and decreased by pressing the “ޕ“ button.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 51

1. Technical specifications

Start-up and commissioning

The machine should be set up according to the following procedure.

The following items should be removed from the carton and checked before the Air Sizer 200 is

operated (Take Care the Air sizer 200 weighs 14 kg):

x1 off Set-up Instructions.

x1 off Mains Cable.

x1 off Air Sizer fitted

x1 off Plexiglas lid

xSoft-Faced Mallet

xTest Sieving Manual.

Position the Air Sizer 200 on a level, rigid and robust bench, suitable for the operation of the Air

Sizer. Being placed on a level surface ensures symmetrical distribution of the sample over the sieve,

during operation.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

52 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

Operating Instructions

Switching On and Off

xPress the on/off switch at the back to turn on the device.

When the switch is in the "off" position, the device must be disconnected completely from the mains

power supply (f.e. before cleaning the device).

Inserting the test sieve

The Air Sizer 200 is intended for test sieves with a diameter of 203mm (8 inches). The range of mesh

fineness extends from 10μm to approx. 4mm.

xPlace the sieve in the nozzle compartment.

xFit the Plexiglas lid provided.

NOTE:

The Air Sizer 200 cannot be started until the sieve has been inserted and the lid put on.

Soft-faced mallet – Application and Use

Any caking that has built up during the sieving process is knocked off the inside of the lid by means

of the soft-faced mallet.

Tap lightly, striking the centre of the knob as far as possible.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 53

1. Technical specifications

Use of the machine for the intended purpose

Risk of explosion or fire

xOn account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

xDo not operate the device in a hazardous atmosphere.

Risk of explosion or fire

Changing sample characteristics

xNote that the characteristics and accordingly the danger presented by a sample

can change during sieving.

xDo not sieve any potentially explosive or combustible materials in this device.

Danger of personal injury

Dangerous nature of the sample

xDepending on the dangerous nature of your sample, take the necessary

measures to rule out any danger to persons.

xObserve the safety guidelines and datasheets of your sample material.

Note: Area of use of the machine

xThis machine is a laboratory machine designed for 8-hour single-shift operation.

xThis machine may not be used as a production machine nor is it intended for

continuous operation.

Note: Defects in components due to liquids

Penetration of liquids inside the housing

xComponents are damaged and the correct functioning of the device is no longer

assured.

xDo not use this device for any wet sieving.

Hearing damage or hearing loss

Suction noise at the suction opening

xThe volume and/or force of drawn-in air can damage hearing or cause hearing

loss.

xKeep your ears away from the air inlet in the channel. Use hearing protection.

Failure to hear acoustic signals

Loud suction noise on the air inlet

xIt is possible that some acoustic warnings and voice communication may not be

noticed.

xTake the strength of the suction noise into consideration when designing your

acoustic signals in the working environment. Possibly additionally use visual

signals.

Noise characteristics:

The Air Sizer 200 itself is constructed in a manner that prevents any significant development of noise. The noise

characteristics of the connected industrial vacuum cleaner depend on the set suction force and suction load.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

54 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

Note: Ensure that the differential pressure or vacuum generated by your vacuum cleaner or

the suction is not greater than 99 mbar.

The maximum quantity of material to be sieved depends on the mesh size and sieve

size.

Rated Power: Air Sizer 200 : maximum 50 watts

Air Sizer 200 + vacuum cleaner: maximum 1450 watts

When connecting the power cable to the mains supply, use an external fuse that

complies with the regulations applicable to the place of installation .

xPlease check the rating label for details on the necessary voltage and frequency

for the device.

xMake sure the levels agree with the existing mains power supply.

xUse the supplied connection cable to connect the device to the mains power

supply.

The external fuse must be at least T15A (230V) T15A (100/120V).

Danger to life through electric shock

xAn electric shock can lead to burns and to cardiac arrhythmias or to respiratory

arrest and cardiac arrest.

xThe device may only be operated with plugs that have a protective conductor

(earthed).

Connecting the external Industrial Vacuum cleaner

Electric shock

Faulty power cable

xWhen you switch the device on there is danger of an electrical shock if the power

cable for the external suction device is damaged.

xBefore use, check the power cable between the sieve device and the suction

device for possible damage.

xNever use a damaged power cable!

Objects thrown-out or falling down

Connection of compressed air instead of vacuum cleaner

xIf compressed air is connected to one of the two air openings, the sieve lid and

the sieve will be hurled out.

xThis device may not be operated with compressed air.

The Air Sizer 200 can be operated only with a suction extractor, such as for example a vacuum

cleaner.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 55

1. Technical specifications

Connection of the industrial vacuum cleaner

• Connect your vacuum cleaners suction tube to the air outlet channel

• Insert the type F IEC C14 connector on the vacuum cleaner into the IEC C13 panel-mounted

outlet. The power for the industrial vacuum cleaner is supplied from the Air Sizer 200.

Negative Pressure

Display shows the neg. Pressure........... (Range from 00 to 99 mbar)

NOTE:

If the neg. pressure is more than 99 mbar -> sensor could be destroyed

The air jet can be changed by turning the manual air jet setting.

[1] Air entry opening closed è maximum air jet

[2] Air entry opening open è minimum air jet

The difference in air pressure (differential pressure) between the air inlet and air outlet at a given

moment is displayed.

Operating Software

The operating software version is displayed for 5 seconds having switched on the machine.

¾Starting, Stopping

• Switch the device on by pressing the on/off switch at the back.

• set the sieving parameters you want.

• Put the test sieve with the sample onto the nozzle compartment.

• Place the lid on the sieve.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

56 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

NOTE:

The sieving will not start if the lid is not on.

• Start sieving by pressing the START button “>”.

• Stop the sieving by pressing the STOP button “Ƒ“.

Filter (Option)

Electrostatic charge inside the devices is prevented by earthing the device via the protective

conductor on the electrical connection. Ensure the correct assembly of filter unit in order to

guarantee sufficient earthing.

NOTICE:

Despite this, electrostatic charge separation may however still occur between the sample and

receptacle wall inside the collecting receptacle depending on the sample property, flow speed and air

humidity.

Cleaning and service

WARNING:

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac arrhythmia, respiratory arrest

or cardiac arrest.

• Do not clean the machine under running water. Use only a cloth dampened with water.

• Disconnect the power supply plug before cleaning the blender.

¾Cleaning

We recommend ultrasonic baths for thorough, gentle and time-saving cleaning of your test sieves.

Clean the air outlet channel regularly using a brush to remove any deposits.

xVacuum cleaner – changing the vacuum cleaner bag

xChange the vacuum cleaner bag or empty the dust container on your vacuum cleaner

regularly as required.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

1. Technical specifications

Copyright © ŘŖŗŜ by Endecotts Ltd. 57

1. Technical specifications

xCheck the degree of soiling of the vacuum cleaner filter regularly and change the filter

where applicable.

xThe vacuum or differential pressure generated by the vacuum cleaner may otherwise be

too low for sieving.

xMaintenance

This device is essentially maintenance-free if cleaned regularly.

E11 MOTOR

FAULTY/BLOCKED

Service required

E83 VACUUM TOO LOW Check whether

• the suction apparatus is connected;

• the suction apparatus is generating

sufficient vacuum;

• The collecting receptacle in the suction

apparatus is full;

• the sieve cover is attached.

E84 DROP IN VACUUM Check whether

• the sieve cover is attached;

• the suction hose has been connected;

• the vacuum cleaner bag is full.

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

58 Copyright © ŘŖŗŜ by Endecotts Ltd.

1. Setting up

CERTIFICATE OF CE-CONFORMITY

ANALYTICAL SIEVE SHAKER

Air Sizer 200

Certificate of CE-Conformity according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN55011:2009+A1:2010, Group 1, Class B Radio disturbance characteristics –

Limits and methods of measurement

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN61326-1:2006

Additional applied standards, in particular

EN 61010 Safety prescriptions concerning measuring, operating, controlling and laboratory equipment

Authorised for the compilation of technical documents:

Endecotts Ltd (technical documentation)

The following records are held by Endecotts Ltd in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required

for conformity assurance, analysis of the residual risks involved and operating instructions in due form

according to the approved regulations for preparation of user information data.

The CE-conformity of the Endecotts Analytical Sieve Shaker Type Air Sizer 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed

spare parts and accessories this certificate will lose its validity.

Endecotts Ltd London, July

QAQC LAB 589 Rappahannock Drive White Stone Va 22578 TEL (804) 318-3686

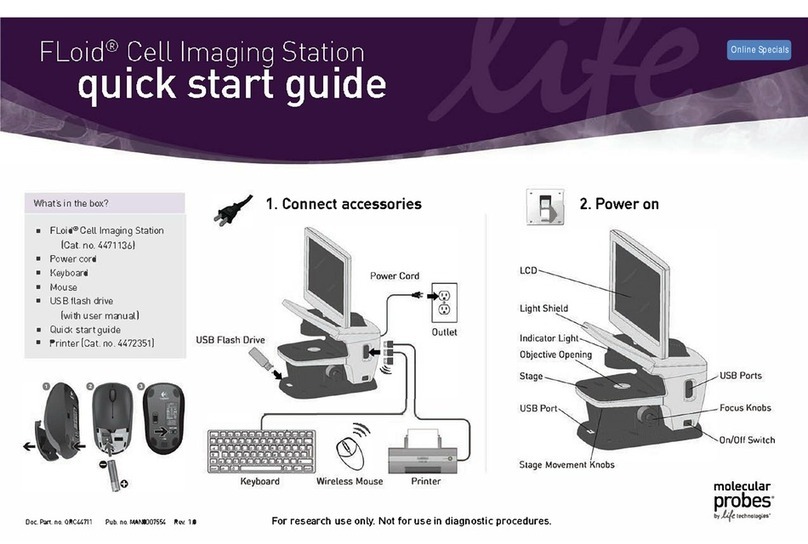

Table of contents

Other Endecotts Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Nippon Genetics Europe

Nippon Genetics Europe FastGene FAS-DIGI PRO manual

Optika Italy

Optika Italy B-290 Series instruction manual

Life technologies

Life technologies FLoid quick start guide

Tuttnauer

Tuttnauer Valueklave 2540 Technician manual

Beckman Coulter

Beckman Coulter CytoFLEX LX manual

CORNING

CORNING Axygen Axypet Pro instruction manual