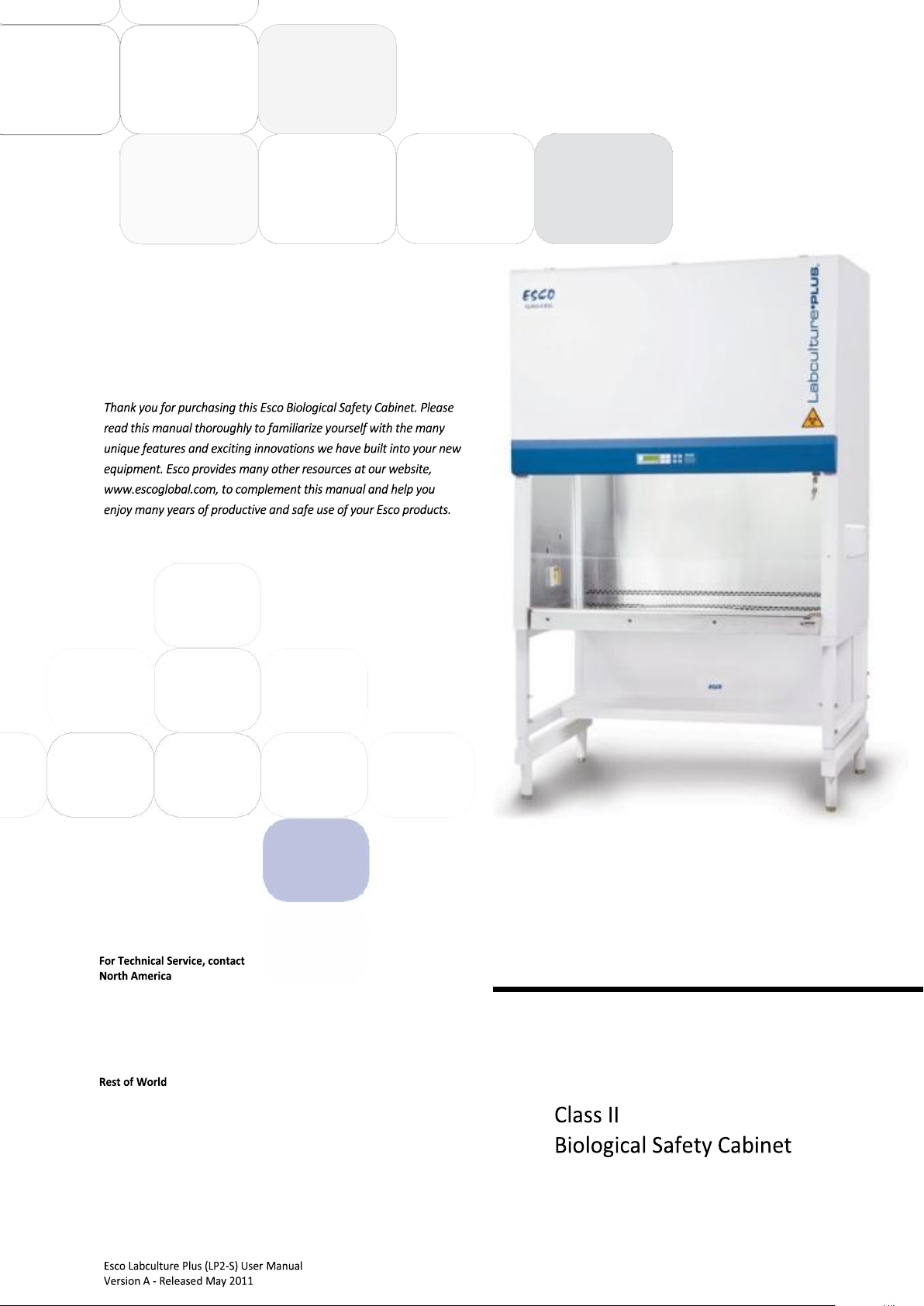

Class II Biological Safety Cabinet

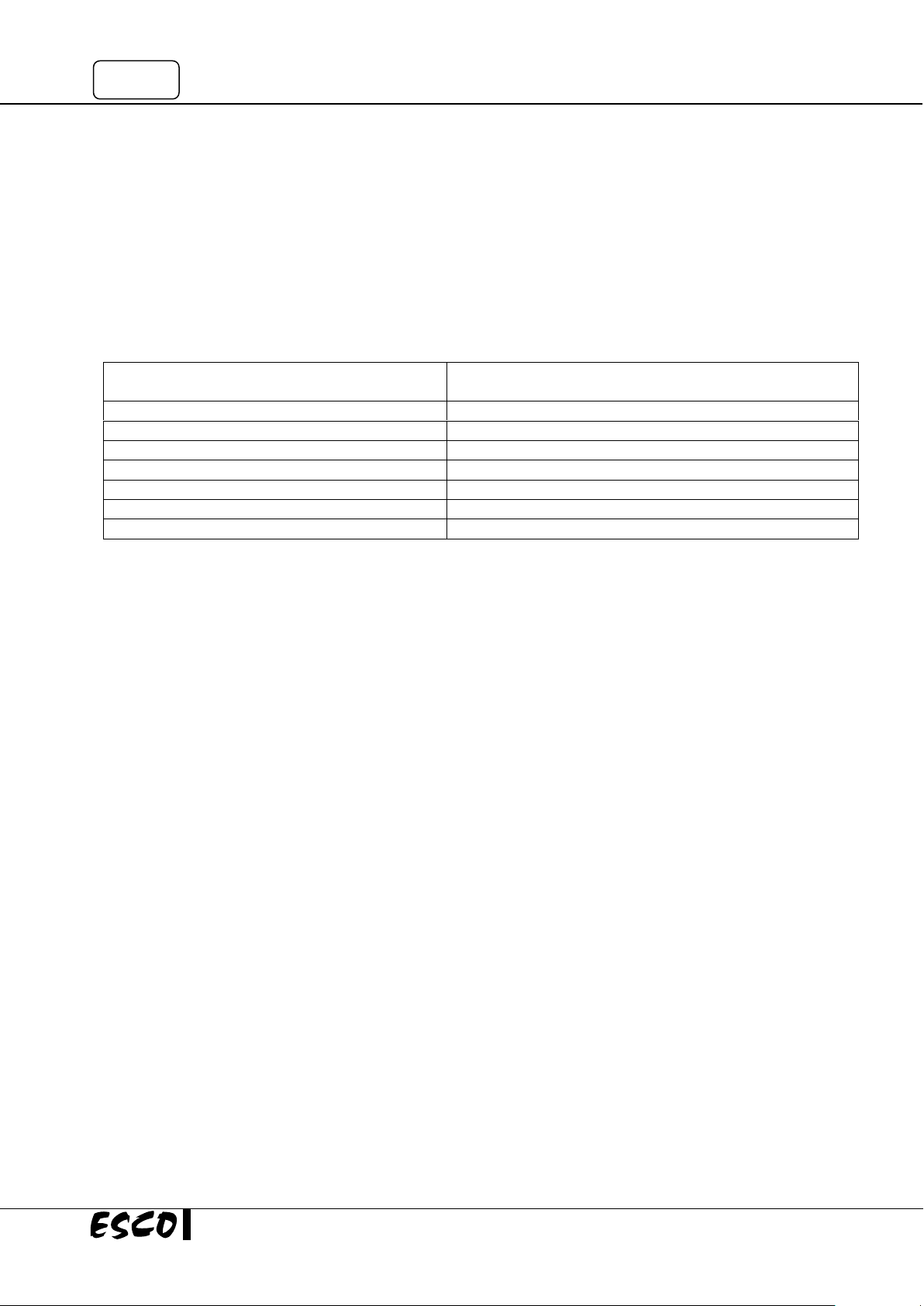

Esco products come with either a 1, 2 or 3 year limited warranty, depending on the product purchased,

beginning on the date of shipment from any Esco international warehousing location. To determine which

warranty applies to your product, refer to the appendix below.

Esco's limited warranty covers defects in materials and workmanship. Esco's liability under this limited

warranty shall be, at our option, to repair or replace any defective parts of the equipment, provided if proven

to the satisfaction of Esco that these parts were defective at the time of being sold, and that all defective parts

shall be returned, properly identified with a Return Authorization.

This limited warranty covers parts only, and not transportation/insurance charges.

This limited warranty does not cover:

Freight or installation (inside delivery handling) damage. If your product was damaged in transit, you

must file a claim directly with the freight carrier.

Products with missing or defaced serial numbers.

Products for which Esco has not received payment.

Problems that result from:

oExternal causes such as accident, abuse, misuse, problems with electrical power, improper

operating environmental conditions.

oServicing not authorized by Esco.

oUsage that is not in accordance with product instructions.

oFailure to follow the product instructions.

oFailure to perform preventive maintenance.

oProblems caused by using accessories, parts, or components not supplied by Esco.

oDamage by fire, floods, or acts of God.

oCustomer modifications to the product

Consumables such as filters (HEPA, ULPA, carbon, pre-filters) and fluorescent / UV bulbs.

Esco is not liable for any damage incurred on the objects used on or stored in Esco equipment. If the

objects are highly valuable, user is advised to have in place independent external preventive

measures such as connection to a centralized alarm system.

Factory installed, customer specified equipment or accessories are warranted only to the extent guaranteed by

the original manufacturer. The customer agrees that in relation to these products purchased through Esco, our

limited warranty shall not apply and the original manufacturer's warranty shall be the sole warranty in respect

of these products. The customer shall utilize that warranty for the support of such products and in any event

not look to Esco for such warranty support.

Esco encourages all users to register their equipment online at www.escoglobal.com/warranty or complete the

warranty registration form included with each product.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTIES AND CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED IN TIME TO THE TERM OF THIS LIMITED WARRANTY. NO WARRANTIES, WHETHER EXPRESS OR

IMPLIED, WILL APPLY AFTER THE LIMITED WARRANTY PERIOD HAS EXPIRED. ESCO DOES NOT ACCEPT LIABILITY

BEYOND THE REMEDIES PROVIDED FOR IN THIS LIMITED WARRANTY OR FOR SPECIAL, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT LIMITATION, ANY LIABILITY FOR THIRD-

PARTY CLAIMS AGAINST YOU FOR DAMAGES, FOR PRODUCTS NOT BEING AVAILABLE FOR USE, OR FOR LOST

WORK. ESCO'S LIABILITY WILL BE NO MORE THAN THE AMOUNT YOU PAID FOR THE PRODUCT THAT IS THE

SUBJECT OF A CLAIM. THIS IS THE MAXIMUM AMOUNT FOR WHICH ESCO IS RESPONSIBLE.