Endecotts Minor 200 User manual

WHEN PARTICLE SIZE MATTERS

Minor 200 Octagon 200 Octagon 200CL Air Sizer 200 EFL 300 Titan 450

SIEVING MACHINES

Operating Instructions

Content

Copyright © 2015 by Endecotts Ltd.

1

Contents

1. OPERATING INSTRUCTIONS NOTES……………………………….. 5

Warnings 5

Repairs 6

Safety 7

Safety instructions 7

Summary of safety instructions 8

Confirmation 10

2. TRANSPORT AND INSTALLATION………………………………… 11

Transport 11

Temperature fluctuations 11

Intermediate storage 11

3. OPERATING INSTRUCTIONS MINOR 200………………………… 13

Technical specifications 14

General Information 14

Specifications 15

Controls and Functions 16

Setting Up 17

Electrical connections 17

Start-up and commissioning 18

Certificate of CE-Conformity 20

4. OPERATING INSTRUCTIONS OCTAGON 200…………………… 21

Technical specifications 22

General Information 22

Specifications 23

Controls and functions 24

Setting Up 26

Electrical connections 26

Transport protection 27

Mount sieve clamping unit 28

Operating Instructions 29

Wet sieving 31

Certificate of CE-Conformity 32

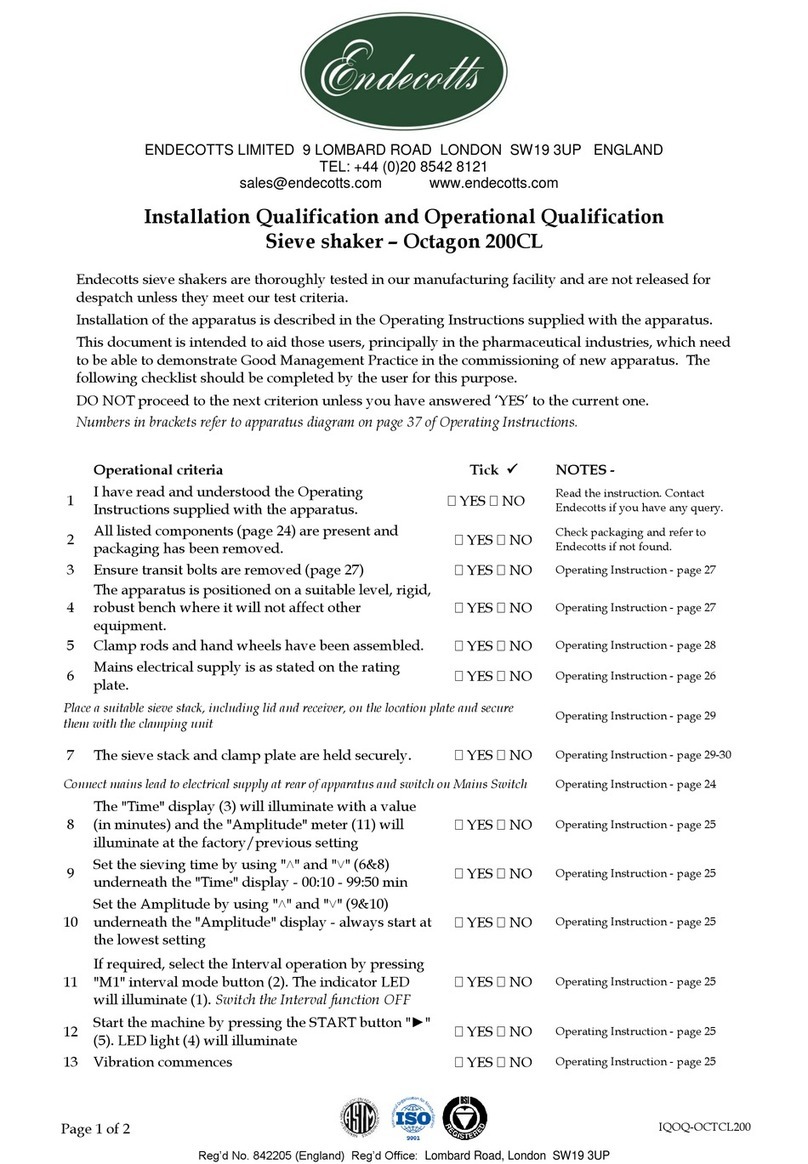

5. OPERATING INSTRUCTIONS OCTAGON 200CL……………….. 33

Technical specifications 34

General Information 34

Specifications 35

Controls and functions 36

Content

2

Copyright © 2015 by Endecotts Ltd.

Setting Up 38

Electrical connections 38

Transport protection 39

Mount sieve clamping unit 39

Operating Instructions 41

Wet sieving 43

Certificate of CE-Conformity 44

6. OPERATING INSTRUCTIONS AIR SIZER 200…………………….. 45

Technical specifications 46

General Information 46

Specifications 47

Controls and functions 48

Setting Up 50

Electrical connections 50

Start-up and commissioning 51

Operating Instructions 52

Switching On and Off 52

Inserting the test sieve 52

Soft-faced mallet – Application and Use 52

Use of the machine for the intended purpose 53

Negative Pressure 55

Operating Software 55

Filter (Option) 56

Cleaning and service 56

Certificate of CE-Conformity 58

7. OPERATING INSTRUCTIONS EFL 300……………………………… 59

Technical specifications 60

General Information 60

Specifications 61

Controls and functions 62

Setting Up 64

Electrical connections 64

Transport protection 65

Mount sieve clamping unit 67

Operating Instructions 68

Wet sieving 70

Certificate of CE-Conformity 71

8. OPERATING INSTRUCTIONS TITAN 450…………………………. 73

Technical specifications 74

Content

Copyright © 2015 by Endecotts Ltd.

3

General Information 74

Specifications 75

Controls and functions 76

Setting Up 78

Electrical connections 78

Transport protection 79

Mount sieve clamping unit 81

Operating Instructions 82

Wet sieving 83

Certificate of CE-Conformity 84

GENERAL INFORMATION……………………………………………… 85

Use of Sieves 85

Test Sieves Available from Endecotts 85

EVALUATION SOFTWARE: SIEVEWARE……………………………… 87

General Information 87

Specifications 88

Function 88

4

Copyright © 2015 by Endecotts Ltd.

Copyright © 2015 by Endecotts Ltd.

All rights reserved, including the right to copy, distribute and translate this text. No part of this

document may be reproduced in any way without written consent of Endecotts Ltd. nor may be

modified, copied or distributed with the help of electronic systems.

Manual can be subject to technical modification and errors.

1. Technical specifications 1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

5

1. Operating instructions notes

These operating instructions for the Endecotts test sieving machines give all

necessary information on the sections mentioned in the contents.

They give instructions to the target group(s) defined in the respective sections for

safe, correct handling of the Endecotts machines. It is important that each target

group(s) is (are) familiar with the relevant section, in order to ensure safe, reliable

handling of the machine according to its intended use.

This technical documentation is for use as a reference work and as a learning aid.

The information of each individual product (sieving machines) is complete within

their section.

Repair instructions are not included in this manual. If repairs are necessary please

contact your supplier or Endecotts Ltd directly.

Endecotts Ltd www.Endecotts.com

Warnings

The following signs are used to warn of hazards:

Personal injuries

Material damage

1. Setting up 1. Setting up 1. Setting up

6

Copyright © 2015 by Endecotts Ltd.

Repairs

This operating manual does not contain any repair instructions.

In the interests of your own safety, repairs should only performed by Endecotts Ltd or

an authorised representative (service technician).

In this case, please notify the following:

The local Endecotts representative

Your supplier

Endecotts Ltd direct

Your address for service:

1. Technical specifications 1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

7

Safety

Target group:

All persons concerned with the machine in any way.

The entire Endecotts machine range is a modern, highly efficient product of

Endecotts Ltd, corresponding to state of the art works. If the machine is used

according to the intended purpose with knowledge of this technical

documentation it is completely safe and reliable to operate.

Safety instructions

As the operator it is your duty to ensure that all persons charged with working on

the Endecotts machine:

•Have read and understood all the instructions on safety,

•Before beginning work know all the instructions and regulations for the target

group relevant to their work,

•Have access to the technical documentation for this machine at all times,

without problems.

•New personnel should be familiarised with safe, proper handling of the

machine before beginning work on the Endecotts machine, either by verbal

instruction from a competent person or through this technical documentation.

•Improper operation can cause injury to persons or damage to the equipment.

You are responsible for your own safety and that of your employees.

•Ensure that unauthorised persons have no access to the Endecotts machine.

For your own protection have your employees confirm that they have been

instructed in operation of the Endecotts machine. The draft of a suitable form is

given at the end of the section on safety.

We exclude claims for damages in any form for damage to persons or

property caused through non-observance of the following safety

instructions.

8

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Summary of safety instructions

Safety instructions

Technical data

Do not make any changes to the machine and use only spare parts and

accessories which have been approved by Endecotts.

The declaration of conformity to the European directives by Endecotts will

otherwise lose its validity. Furthermore this will result in the loss of any kind of

guarantee claims.

Packing

Please keep the packing material during the guarantee period in case of a

complaint your guarantee claim will be at risk if the machine is returned in

inadequate packing.

Transport

The Endecotts machine must not be knocked, shaken or thrown during

transport; otherwise the electronic and mechanical components may be

damaged.

Temperature fluctuations

If subjected to high temperature fluctuations (e.g. during transport by plane) the

Endecotts machine must be protected against condensed water. If not damage to

the electronic components may be caused.

Supply schedule

If the delivery is incomplete and/or transport damage has occurred, you must

immediately notify the transport agent and Endecotts Ltd (within 24 hrs.). It is

possible that later complaints may not be considered.

Ambient temperature

If the ambient temperature is exceeded or drops below the normal value the

electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

We exclude claims for damages in any form for damage to persons or property

caused through non-observance of the following safety instructions.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

9

1. Technical specifications

Atmospheric humidity

At high atmospheric humidity the electrical and mechanical components may

become damaged and the performance data can change to an unknown degree.

Installation / transport protection - IMPORTANT

If the machine is operated with the transit bolts, or is transported without transit

bolts, mechanical components may become damaged.

Electrical connection / connecting the mains power supply

If the values given on the rating label are not observed electrical and mechanical

components may become damaged.

Wet sieving

Never operate your Endecotts machine directly in water.

Danger through current surge.

During wet sieving always operate your Endecotts machine connected to a

mains socket which is protected by an FI protective (safety) switch.

The water quantity added should always be dosed in such a way that the sieve

surface is only just wetted.

Sieving aids

Make sure that the wire mesh of the sieves is not excessively stretched through

overloading with sieving aids, since this will impair the precision of your test

sieves.

Damage may occur if the

shaker is allowed to operate with a loose clamping

plate.

10

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Cleaning

Do not clean the Endecotts machine under running water.

Danger to life through current surge.

Use only a cloth moistened with water; solvents are not allowed.

Wearing parts

These operating instructions do not include repair instructions.

For your own safety, repairs should be carried out only by Endecotts Ltd or an

authorised agency or Endecotts service technicians.

Confirmation

I have read and taken note of the sections – preliminary

comments and safety

________________________________________________

Signature of operator

________________________________________________

Signature of service technician

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

11

1. Technical specifications

2. Transport and installation

Packing has been adapted to the transport method and conforms to generally applicable

packing guidelines.

Packing

Please keep the packing material during the guarantee period in case of a

complaint, your guarantee claim will be at risk if the machine is returned in

inadequate packing.

Transport

The Endecotts Machine must not be knocked, shaken or thrown during transport;

otherwise the electronic and mechanical components may become damaged.

Please make sure you have removed all transit bolts before using the Endecotts

machine.

Specific operating instructions can be found on the relevant pages

for every single

Endecotts machine in this manual.

Temperature fluctuations

If subjected to high temperature fluctuations (e.g. during transport by plane) the

Endecotts machine

must be protected against condensed water. If not damage to

the electronic components may be caused.

Intermediate storage

Ensure that the Endecotts machine is kept dry also during intermediate storage.

12

Copyright © 2015 by Endecotts Ltd.

1. Setting up

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

13

1. Technical specifications

3. Operating instructions:

Minor 200

14

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVE SHAKER MODEL:

Minor 200

General Information

The Minor 200 has been developed and manufactured to combine low cost with the benefits of a well-

designed and engineered shaker. It incorporates many features usually found only on larger, more

expensive models. It is ideal for the use in laboratories and a plant since it is compact and genuinely

portable (weighing only 16 kg).

The sieve stack is held firmly in position by a clamping belt system. Removing it allows the whole

unit to be stored in a space less than 200 mm high. There are no rotating parts in the Minor 200 -

consequently it is quiet in operation and maintenance free.

Advantages

•Electromagnetic drive for quiet and virtually maintenance free operation

•Compact and portable (weighing only 16 kg)

•Requires only small storage space due to small footprint

•Easily removable clamping belt system (included)

•Easy to use

•Different voltages available

•Complies with the requirements of AASHTO T 27

The Minor 200 is not recommended for any wet sieving operations!

Do not make any changes to the machine and use only spare parts and

accessories approved by Endecotts Ltd.

The declaration of conformity to the European directives by Endecotts

will otherwise lose its validity.

Furthermore this will result in the loss of any kind of guarantee claims.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

15

1. Technical specifications

Specifications

Range 38 µm to 125 mm

Drive / sieving motion electromagnetic

Max. Batch / feed capacity 3 kg

Max. Number of fractions 8 full height / 16 half height (200 mm or 8”)

Amplitude ~ 1.6 mm* fixed

Speed 3,000 min-1 at 50 Hz

Time display analogue, 0 - 60 min or continuously

Suitable for dry sieving yes

Suitable for wet sieving no

Sieve diameter 100 / 200 mm or 3” / 8"

Clamping device clamping belt system (included)

Model bench top

Protection code IP 20

Electrical supply different voltages available

Power connection 1-phase

Ø x H 262 x 126 mm

Net weight 16 kg

(*) depending on load

16

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Controls and Functions

Operators should be familiar with and fully understand the controls and indicators before

operating this machine.

PLUG

(Removable knob for lid)

CLAMP PLATE

CLAMPING LATCH

ADJUSTABLE CAM

BUCKLES

MAINS SWITCH

STRAP

COVER

BASE

ANTI-VIBRATION FEET

LED (indicates

mains power to

instrument)

PROCESS TIMER

On /Off Switch

LOCATION PLATE

SIEVE STACK

MAINS POWER

CONNECTION

FUSE HOLDER

60 MIN

OFF

CONTINUOUSLY

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

17

1. Technical specifications

Setting Up

Electrical connections

Ensure that the voltage and frequency on the rating label, at the rear of the

shaker, correspond with the local electrical mains supply.

•Connect the Minor 200 to the power supply using the connection cable

provided.

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, with linear reduction

down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

•Mains power connection

Mains power connection with integral line filter. Ensure the IEC connector on the mains

lead is pushed fully into the mains inlet at the rear of the machine.

•L.E.D (Mains Connected Indication)

This is a green L.E.D that indicates electrical power is connected to the equipment. The

L.E.D is illuminated when the IEC connector is pushed fully into the inlet and power is

switched on at the local outlet.

If the L.E.D fails to light with the local outlet switch in the ON position then the fuse (see

“Fuse holder”) has blown or power is not present at the mains.

•Fuse (Fuse Holder)

The fuse is a ceramic fuse. It is important that the recommended current rating is not

exceeded and the fuse is replaced with the same type and size. If the fuse blows after

replacement then a fault exists in the equipment which must be rectified.

18

Copyright © 2015 by Endecotts Ltd.

1. Setting up

•Process Timer

The process timer is a mechanical 0-60 minute timer which also provides continuous

running if desired. Operating periods are increased by rotating clockwise and decreased by

rotating anticlockwise (the timer will commence timing down as soon as the knob is

released, regardless of electrical power being connected or not). When the knob is turned

anti-clockwise from off position to the continuous running mark, the shaker will continue

running until the knob is returned to the off position.

Start-up and commissioning

The shaker should be set up according to the following procedure.

The following items should be removed from the case and checked before the shaker is operated

(Take care the shaker weighs 16 kg):

•1 off Set-up Instructions.

•1 off Instruction Manual.

•1 off Mains Cable.

•1 off Clamp Plate Assembly.

•1 off Minor Shaker fitted with Clamping Straps and Buckles.

Position the shaker on a level, rigid and robust bench, suitable for the operation of the sieve shaker.

Being placed on a level surface ensures symmetrical distribution of the sample over the sieves, during

operation.

Operating Instructions

1. Place the receiver centrally on the location plate..

2. Stack the required test sieves on top of the receiver (min. 1x receiver + 2x sieves + 1x lid).

3. Put the sample in the top sieve and fit the lid.

In order to guarantee exact results under fast sieving conditions, the quantity of material to be sieved

should be adapted to the sieve diameter and the nominal mesh size.

More detail information is displayed in our “TEST SIEVING MANUAL”.

4. Place the clamp plate on top of the sieve stack.

5. Raise the clamping latch lever upwards to expose the latch hook.

This manual suits for next models

5

Table of contents

Other Endecotts Laboratory Equipment manuals