2 Safety

2.1 Application

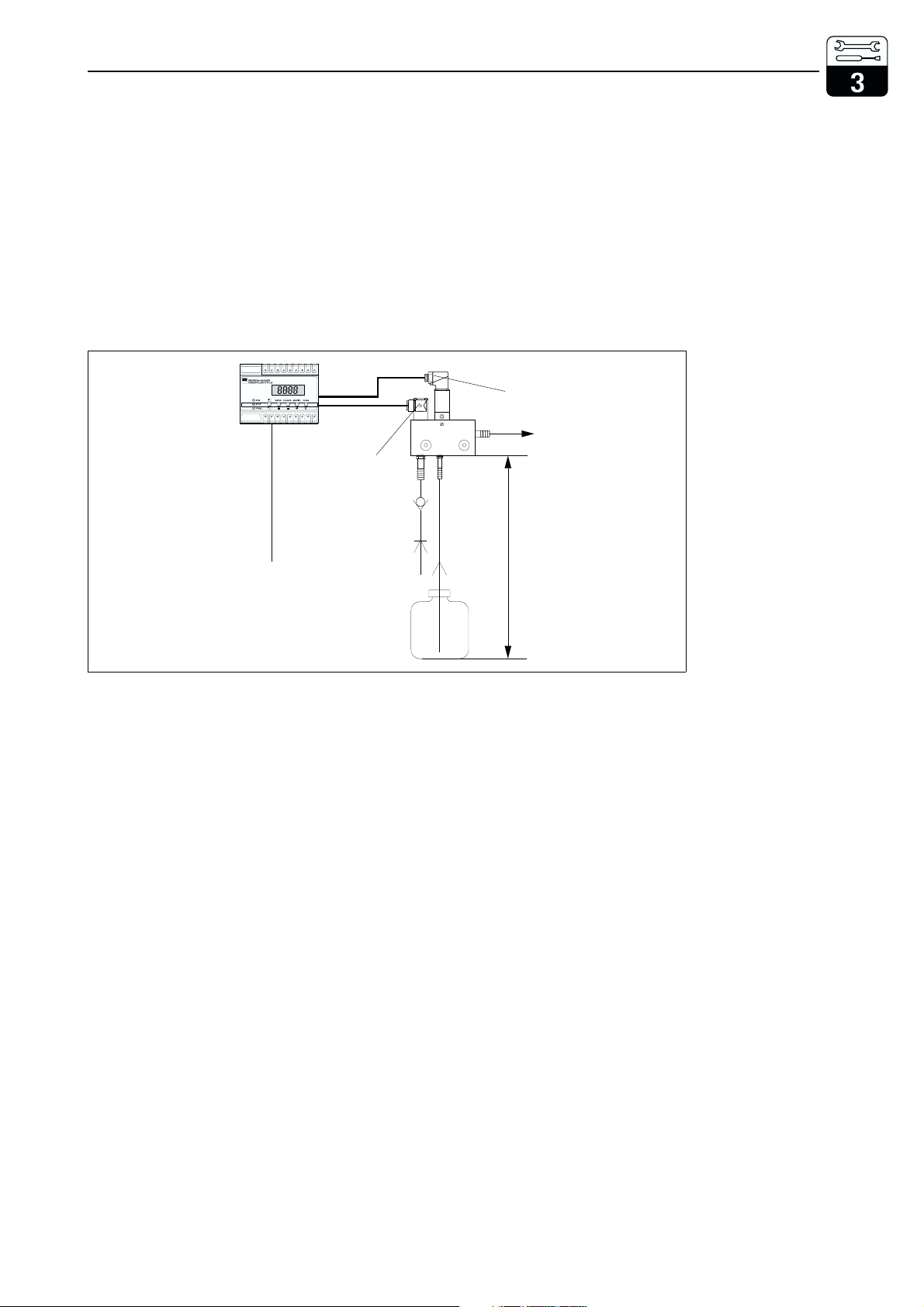

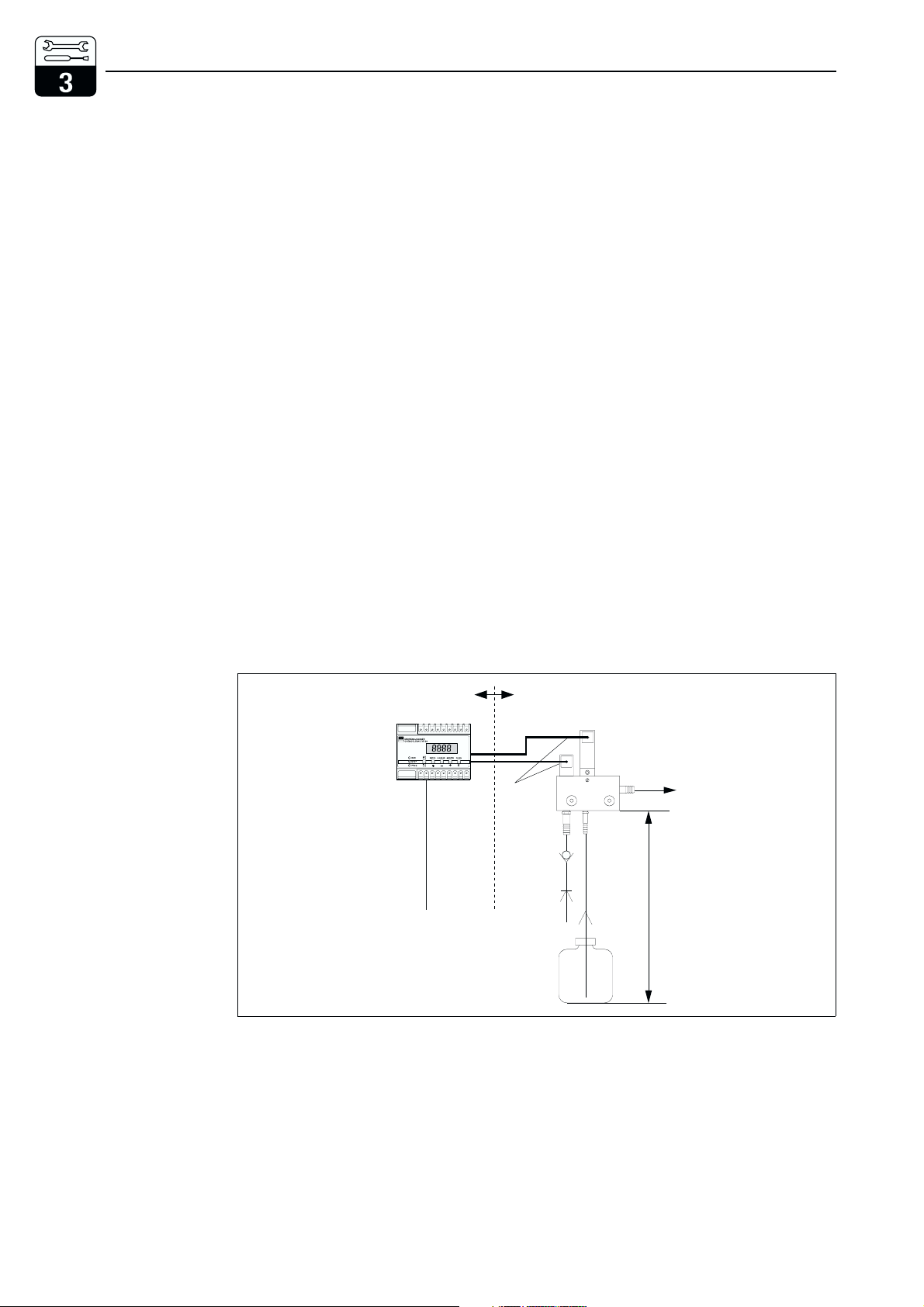

The ChemoClean Plus CYR 10 / CYR 20 is a

spray cleaning system for pH / redox

electrodes, oxygen and turbidity sensors. It is

used with the appropriate cleaning agents to

obtain optimal cleaning and sensor activation

results for various types of soiling, in particu-

lar:

•limestone deposits and encrustations

•clogging with mud, e.g. by hyodroxides or

strongly soiled wastewater

•formation of coating by oil, grease and

emulsions

•other deposited reaction products in

process engineering

2.2 Safety notes

This device has been built and tested in

accordance with EN 61010-1 and left the

manufacturer’s works in perfect condition.

However, if it is used improperly or other than

for its intended purpose, it may pose a

hazard, e.g. due to incorrect installation or the

wrong operating conditions.

Warning:

•If the device is used for any appli-

cation other than those described

in this manual, it may lead to un-

safe and improper functioning of

the measuring system and is there-

fore not permitted!

•Make sure you strictly adhere to

the warnings and notes in these

Operating Instructions.

2.3 Mounting, Start-up, Operation

Warning:

•Installation, electrical connection,

start-up, operation and

maintenance of the cleaning

system must be carried out

exclusively by trained specialists

authorised by the system operator.

•Technical personnel must be

familiar with the instructions in this

manual and must adhere to them.

•When the system is operated in

explosive atmospheres, it is

imperative to comply with the

regulations applicable (see

chapter 3.5.2).

•Before connecting the system

please verify that the value of

supply corresponds with the value

on the nameplate.

•Before switching on the system

check all the connections again

for correctness.

•Never start-up the CYR 20 without

protective earth.

•Do not operate damaged systems

which could pose a danger, and

mark them as defective.

•Measuring systems faults may

only be repaired by authorised

and trained personnel.

•If faults cannot be repaired, the

system must be taken out of

service and secured against

unintentional start-up.

•Repairs may only be carried out

by the manufacturer or by the

Endress+Hauser service organisa-

tion.

YR10E02.CHP

ChemoClean CYR 10 / CYR 20 Safety

Endress+Hauser 5