GENERAL CAUTIONARY NOTES

The operating rules contained in this manual are an integral part

of the unit supply and are valid exclusively for the units covered by

this manual. They contain all the useful and necessary informa-

tion for safe operation and ideal, recommended use of the unit.

The declaration of conformity is attached individually to the litera-

ture kept on the machine, usually inside the control cabinet.

Please follow the instructions given below:

• Read carefully the instruction manual which should be consid-

ered an integral part of the unit.

• Every operator and the personnel in charge of unit maintenance

must read the manual throughout carefully and observe its pre-

scriptions.

• The employer is requested to make sure that the operator has the

necessary aptitude requirements for operating the unit and has

carefully read the manual.

• The instruction manual must be easily available to the operation

and maintenance personnel.

• Keep the manual for the entire working life of the unit.

• Make sure any updates that are received are integrated into the

text.

• Hand over the manual to any other user or subsequent owner.

• Use the manual so that the contents are not damaged - entirely

or in part.

• Do not remove, tear off or rewrite parts of the manual for any

reason.

• Keep the manual with care; it must be available at the unit, stored

in a special container, to protect it from moisture and heat, until

nal scrapping of the machine. The location where the manual is

kept must be known to the user of the unit, to the managers, to

the persons in charge of transportation, installation, use, mainte-

nance, repairs, and end-of-life dismantling and scrapping. If the

manual is lost or partially damaged, so that it is no longer possible

to read all of its contents, it is advisable to request a new one from

the manufacturer.

• Avoid hasty and incomplete preparation that lead to improvisa-

tion and cause many accidents.

Pay close attention to the safety symbols shown in the table on

the previous page and to their meaning.

Before starting to work, read through and strictly observe the fol-

lowing suggestions:

• the operator must always have the instruction manual readily

available at any time;

• plan each action carefully;

• before beginning to work, make sure that the safety devices work

properly and you have no doubts about their operation; otherwise,

do not under any circumstances start the unit;

• carefully observe the warnings relating to special hazards con-

tained in this manual;

• preventive and thorough maintenance guarantees constantly

high operating safety for the unit. Never delay repairs and always

have them carried out solely by qualied personnel; only original

spare parts are to be used.

THE MANUFACTURER shall not be liable for any accident to per-

sons or property which may occur due to:

• failure to comply with the instructions in this manual regarding

the operation, use and maintenance of the unit;

• violent actions or incorrect manoeuvres when performing main-

tenance on the unit;

• alterations made to the unit without prior written authorisation

from the MANUFACTURER;

• events that are, in any case, unrelated to the normal and correct

use of the unit;

• in any case, if the user attributes the incident to a defect in the

unit, he must prove that the damage caused was a main and direct

consequence of this “defect”.

This manual reects the state of the art at the time of unit sale:

The MANUFACTURER reserves the right to update its products

and manuals without any obligation to update earlier products

and manuals, except in special circumstances. These may not be

considered inadequate only because they have been subsequently

updated based on new experience.

BATTENTION

• The installer must provide adequate documentation that must

comply with EN 378-3 if applicable in the country of installation;

otherwise, reference should be made to the local regulations in

force.

• When installing or servicing the unit, the rules stipulated in this

manual must be complied with together with those on board the

unit and in any case all necessary precautions must be taken.

• The uids under pressure in the cooling circuit and the presence

of electrical components may cause hazardous situations during

installation and maintenance work.

• Any action on the unit must be carried out by qualied and au-

thorised personnel. In the event of a fault, do not attempt repairs

on your own and do not let unauthorised technicians carry out re-

pairs, or the guarantee will no longer be valid.

• The initial start-up must be carried out exclusively by qualied

personnel authorised by the marketing entity (see annex).

• Before performing any work on the unit, ensure it has been dis-

connected from the power supply.

• For maintenance service or repairs always and exclusively use

original spare parts. THE MANUFACTURER declines all responsi-

bility for damages that may occur due to non-compliance with the

above.

• The unit is guaranteed according to the contractual agreements

entered into upon its sale: however, failure to comply with the rules

and instructions contained in this manual and any modication in

the unit not previously authorised, will cause an immediate loss of

guarantee validity.

• This manual describes the intended use of the unit and provides

instructions for its handling, installation, assembly, adjustment

and use. It supplies information on the maintenance schedule,

how to order spare parts, the presence of residual risks, and staff

training. Therefore, before handling, installing, using or carrying

out any maintenance on the unit, read the manual very carefully.

• It is important to remember that the use and maintenance man-

ual can never replace adequate user experience. This manual

represents a reminder of the main operations to be performed by

operators who have received specic training, for example by at-

tending training courses held by the manufacturer, with reference

to particular maintenance operations.

• Make sure all the users have thoroughly understood the oper-

ating instructions together with the meaning of any symbols on

the unit.

• Possible accidents can be avoided by following these technical

instructions drafted in accordance with the Machinery Directive

2006/42/EC and subsequent additions.

• In any case, always comply with national safety regulations.

• Do not remove or damage guards, decals, stickers and wording,

especially any that are required by law.

• Adhesive labels intended for safer use are applied to the unit,

therefore, it is very important to replace them if they become il-

legible.

CWARNING

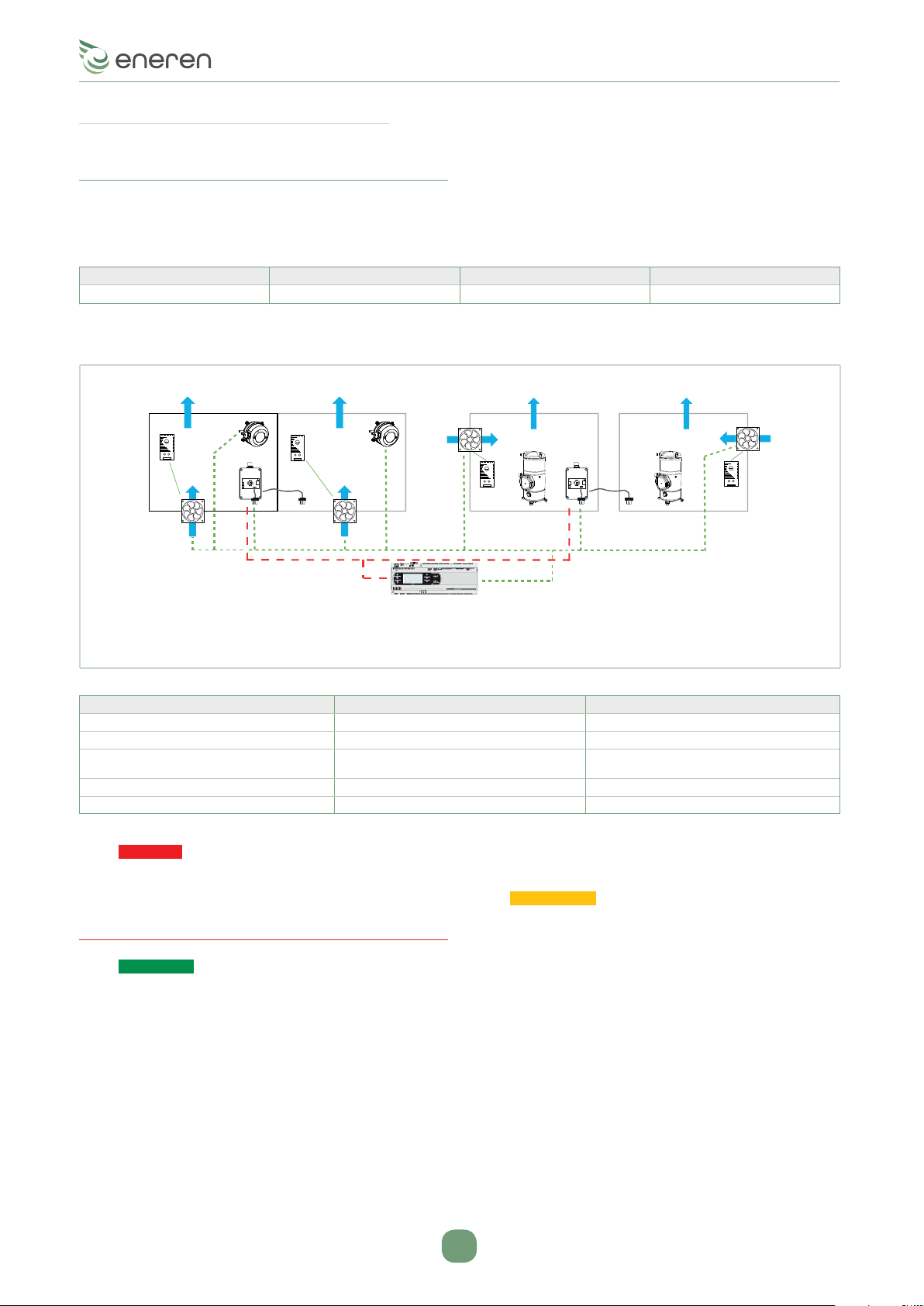

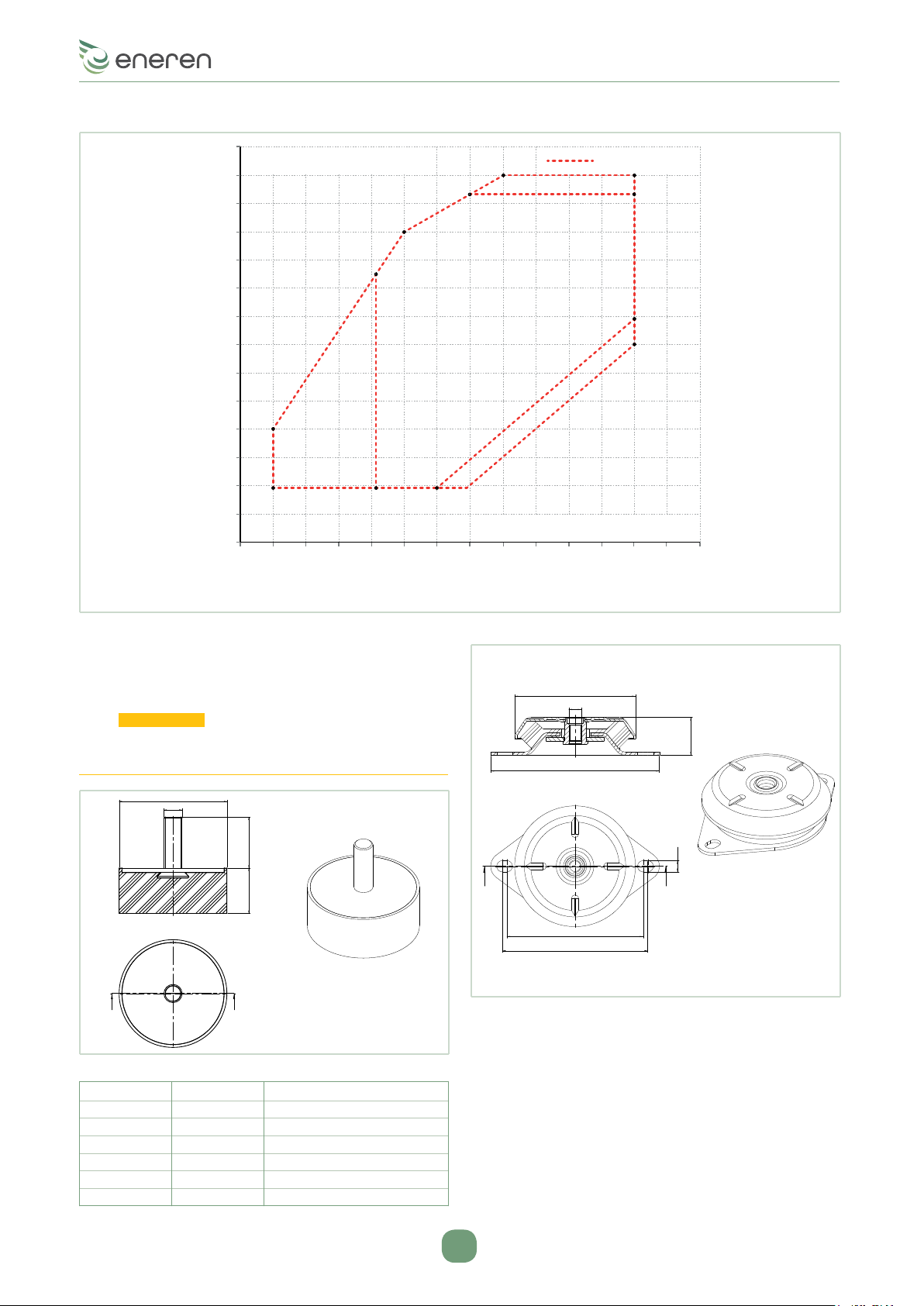

• The electrical wiring, hydraulic and refrigeration diagrams and

the technical data shown in this manual are supplied for guidance

only and may be changed without prior notice for the purpose of

improving the product range. For detailed information on specic

models, refer to the specic documentation attached to the each

product.

Any updates or additions to this use and maintenance manual

are to be considered an integral part of the manual and may be

requested via the contact phone numbers listed in this manual.

Contact the MANUFACTURER for additional information and to

share any feedback and recommendations aimed at improving

the manual.

If the unit is transferred to a new owner, the MANUFACTURER ex-

pects you to please notify the address where to send any manual

additions for the new user.

6