EnergAir Metacentre User manual

MANY0703A.GB - Metacentre CX Box Technical Manual

TM

CX Box

bar

Metacentre CX Box

Page 1

Index

1.0 Safety Precautions

1.1 Installation

1.2 Operational

1.3 Maintenance and Repair

2.0 Introduction

2.1 Management System Connectivity

2.2 Interface Mode: Regulation Types

3.0 Installation

3.1 Unit Location

3.2 Power Supply

3.3 Delivery Pressure Sensor

3.4 Internal Pressure Sensor (Option)

3.5 System Pressure Sensor (Option)

3.6 Auxiliary Fault Input (Options)

3.7 Inhibit Function (Option)

3.8 Speed Monitoring Input (Option)

3.9 R2 – 24Vac Output (Option)

3.10 AR1/2 Auxiliary Output (Options)

3.11 Temperature Sensor (Options)

3.12 CX Extension Unit, A01 to A04

3.13 RS485 Network Connection

3.14 Compressor Interface PCB

4.0 Commissioning

4.1 Commissioning Procedure

4.2 Physical Checks

4.3 Management System

4.4 Delivery Pressure Sensor

4.5 Pressure Set Points

4.6 Regulation Mode

4.7 Optional Features and Functions

5.0 Menu Navigation

5.1 Menu Items

5.2 Diagnostics

6.0 Operation

6.1 User Interface

6.2 User Menu Items

6.3 Status

6.4 Active Functions

6.5 Compressor Identification

6.6 Operation

6.7 Power Failure Auto-Restart

6.8 Failure Modes

6.9 Compressor Shutdown (Trip)

6.10 Compressor Alarm (Warning)

6.11 Sensor Fault Levels

6.12 Sensor Fault

6.13 Fault Input (Options)

6.14 Fault Codes

7.0 Parts List

8.0 Technical Data

9.0 Connection Diagrams

10.0 Wiring Diagrams

Refere to Section Indicated

Note

Important or Caution, Safety

Technical Manual

Page 2

1. Safety Precautions

ALWAYS EMPLOY SAFE WORKING

PRACTISE AND PROCEDURES

WARNING:

Risk of Danger

WARNING:

Risk of Electric Shock

WARNING:

Risk of High Pressure

WARNING:

Consult Manual

When installing, commissioning, operating or

carrying out service or maintenance on a product,

personnel must use safe working practise and

observe all relevant local health and safety

requirements and regulations. Attention of users in

the UK is drawn to the Health and Safety at Work

Act, 1974, and to the Regulations and

Recommendations of the Institution of Electrical

Engineers (IEE).

Lethal voltages are used within the product. Use

extreme caution when carrying out electrical checks.

Isolate the power supply before starting any

maintenance work.

It is not possible to anticipate every circumstance

that might represent a potential hazard. If the user

employs an operating procedure, an item of

equipment or a method of working which is not

specifically recommended the user must ensure the

product will not be damaged or made unsafe and

that there is no risk to persons or property. Failure to

observe safety precautions or implement safe

working practises may be considered dangerous

practice or misuse of the product.

1.2 Installation

Installation work must only be carried out by a

competent person under qualified supervision.

A fused isolation switch must be fitted between the

main power supply and the product.

The product should be mounted in such a location

as to allow operational and maintenance access

without obstruction or hazard and to allow clear

visibility of indicators at all times.

If raised platforms are required to provide access to

the product they must not interfere with normal

operation or obstruct access. Platforms and stairs

should be of grid or plate construction with safety

rails on all open sides.

1.3 Operation

The product must only be operated by competent

personnel under qualified supervision.

Never remove or tamper with safety devices, guards

or insulation materials fitted to the unit.

The product must only be operated at the supply

voltage and frequency for which it is designed.

When mains power is switched on, lethal voltages

are present in the electrical circuits and extreme

caution must be exercised whenever it is necessary

to carry out any work on the unit.

Do not open access panels or touch electrical

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

This work must only be carried out by a qualified

electrician or technician equipped with the correct

tools and appropriate protection against electrical

hazards.

All air compressors and/or other machine equipment

connected too, and controlled by, the product should

have a warning sign attached stating ‘THIS UNIT

MAY START WITHOUT WARNING' next to the

display panel.

If an air compressor and/or other machine

equipment connected too, and controlled by, the

product is to be started remotely, attach warning

signs to the machine stating ‘THIS UNIT CAN BE

STARTED REMOTELY’ in a prominent location,

one on the outside of the machine, the other inside

the machine control compartment.

1.3 Service Maintenance and Repair

Service, maintenance, repairs or modifications must

only be carried out by competent personnel under

qualified supervision.

If replacement parts are required use only genuine

parts from the original equipment manufacturer, or

an alternative approved source.

Carry out the following operations before opening or

removing any access panels or carrying out any

work on the product :-

• Isolate from the main electrical power supply.

Lock the isolator in the 'OFF' position and

remove the fuses.

• Attach a label to the isolator switch and to the

product stating ‘WORK IN PROGRESS - DO

NOT APPLY VOLTAGE'. Do not switch on

electrical power or attempt to start the unit if

such a warning label is attached.

Ensure that all instructions concerning operation

and maintenance are strictly followed and that the

complete product, with all accessories and safety

devices, is kept in good working order.

The accuracy of sensor devices must be checked

on a regular basis. They must be renewed when

acceptable tolerances are exceeded. Always ensure

any pressure within a compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

The product must only be cleaned with a damp

cloth, using mild detergents if necessary. Avoid the

use of any substances containing corrosive acids or

alkalis.

Do not paint the control facial or obscure any

indications, controls, instructions or warnings.

Metacentre CX Box

Page 3

2. INTRODUCTION

The CX Box is intended as an advanced

compressor interface unit with inherent

functionality for monitoring and regulation of a

compressor that is equipped with a compatible

variable output regulation system.

PD

DP

PS

The CX Box provides optional ‘local pressure

sensor’ connections. The compressor delivery

pressure (PD), local system pressure (PS) and

air treatment differential pressure (DP) can be

monitored and displayed. The detected local

pressure (delivery or system) is available on

the system network and can be utilised by a

management system unit for advanced

pressure related functions. A local air

treatment differential pressure alarm can also

be implemented.

PI

PD

The CX provides ‘Internal’ reclaimer vessel, or

sump, pressure detection. The differential

pressure between the internal pressure (PI)

and delivery pressure (PD) can be monitored

and displayed. An internal air/oil filtration

differential pressure alarm, and excessive

internal pressure alarm, can be implemented.

The CX Box is equipped with several digital

(remote volt-free contact) and analogue

temperature/pressure inputs. Each can be set

to monitor and display status or value with the

option to respond with an Alarm(Warning) or

Trip(Shutdown) condition. With the addition of

the optional CX Expansion Box, additional

digital and analogue inputs can be made

available.

The CX Box is equipped with a ‘compressor

control mode’. This mode enables total control

and monitoring (including Star/Delta motor,

Fan and Load solenoid control) of a

compressor unit that is not equipped with it’s

own control system.

2.1 Management System Connectivity

CX Box

The CX Box connects to a Management

System using an industrial two wire RS485

data network (Multi485).

2.2 Interface Mode: Regulation Types

The CX Box provides advanced monitoring

and control functionality for the following

compressor types:

Load/Unload (L mode)

For a compressor equipped with single

pressure switch, or remote load/unload digital

input, regulation.

3-Step (3S mode)

For a 3-step reciprocating type compressor

fitted with two pressure switches.

5-Step (5S mode)

For a 5-step reciprocating type compressor

fitted with four pressure switches.

Poppet Valve (V mode)

Rotary Screw; where each valve can be

energised from a volt-free relay contact.

The CX Box can accommodate 2 valve, 3

valve and 4 valve regulation systems.

Modulation Valve (AR mode)

Rotary Screw or Vane; where the modulation

valve can be controlled with the use of a 4-

20mA proportional pressure regulation valve.

Spiral Valve (AR mode)

Rotary Screw; where a pressure activated

spiral valve can be controlled with the use of a

4-20mA proportional pressure regulation

valve.

Variable Speed Inverter Drive (AR mode)

Inverter Drive; where the inverter drive can be

regulated from a 4-20mA signal.

Technical Manual

Page 4

3. Installation

It is recommended that installation and

commissioning be carried out by an authorised

and trained product supplier.

3.1 Unit Location

The CX is wall mounting using conventional

screw fixings. The CX can be located remote

from the compressor but within 10 m (33ft)

cable length from the compressor and within

100 m (330ft) cable length from the system

pressure sensor.

3.2 Power Supply

A fused switching isolator must be installed to

the main incoming power supply, external to

the CX. The isolator must be fitted with a fuse

of the correct rating to provide adequate

protection to the power supply cable used (in

accordance with local electrical and safety

regulations).

1

VOLTAGE SELECT

234

X04

1

VOLTAGE SELECT

234

X04

230Vac

115Vac

EE

N

L

LNE

X01

1234

XPM-TAC24

Check the input voltage select links on the CX

power supply PCB (XPM-TAC24).

Adjust if necessary before applying power.

3.3 Delivery Pressure Sensor

The compressor delivery pressure sensor (Pd)

must be located in a position suitable to be

able to continuously detect the delivery

pressure of the compressor package; prior to

any external air treatment, non-return valve or

isolation valve.

Pd

NRV

The delivery pressure sensor is a

mandatory CX Box requirement.

The pressure sensor must be connected to

terminal X07 of the CX using an earth

screened, two-core (0.5mm2CSA minimum),

cable no greater than (10m) 33ft in length.

X07

26

25 +

-

+

-

Pd

Pd

100m

(330ft)

max

Wire polarity is important

3.4 Internal Pressure Sensor (option)

The compressor internal pressure sensor (PI)

must be located internal to the compressor in

a position that will detect internal, or sump,

pressure prior to air/oil filter separation and

minimum pressure valve.

PI

PD

The internal pressure sensor is optional.

The pressure sensor must be connected to

terminal X07 of the CX using an earth

screened, two-core (0.5mm2CSA minimum),

cable no greater than (10m) 33ft in length.

X07

+

-

+

-

PI

10m

(33ft)

max

30

29

PI

Wire polarity is important

Internal Pressure Sensor

Metacentre CX Box

Page 5

3.5 System Pressure Sensor (option)

The system pressure sensor (PS) must be

located in a position that is downstream of any

air treatment associated with the compressor

and is common to the air system network.

Pd

DP

PS

The system pressure sensor is optional.

The pressure sensor must be connected to

terminal X07 of the CX using an earth

screened, two-core (0.5mm2CSA minimum),

cable no greater than (10m) 33ft in length.

X07

28

27 +

-

+

-

PS

PS

10m

(33ft)

max

Wire polarity is important

System Pressure Sensor

3.6 Auxiliary Fault Inputs (option)

Aux Fault #3

X05

20

22

19

21

18

17

Aux Fault #2

Aux Fault #1

F1

F2

F3

Fault Inputs

3.7 Inhibit Function (option)

14

16

X04

13

15 Inhibit

IH

Inhibit Function

3.8 Speed Monitoring Input (Option)

Only applicable in ‘L’ load/unload mode;

ignored in all other control modes.

The CX Box is equipped with a ‘speed

detection’ input designed to function with a

‘VSD Speed Monitoring Kit’ (available

separately). This optional feature is intended

for use when the CX Box is utilised for

frequency inverter drive variable speed

control. The feature will provide a percentage

speed/output display and all required

functionality to enable total synergy with the

energy control, VSD compressor aware,

functions of a management system equipped

with this capability.

14

16

X04

13

15 +rpm

3.9 R2 - 24Vac Output (option)

Output R2 is 24Vac and must be connected to

the coil of a 24Vac relay to provide a remote

volt-free output function contact.

S02-RT = ‘L’ (load/unload regulation Mode)

R2 = Fan Function

Menu Items; ‘Fan’ Function, AR1/2

S02-RT = ‘AR’ (load/unload regulation Mode)

R2 = Active Function

Menu Items; ‘Active’ Function, AR1/2

S02-RT = ‘3S’, ‘5S’ or ‘V’ regulation modes:

R2 is used for regulation control dependant of

regulation mode type.

3.10 AR1/2 Auxiliary Outputs (option)

31323334

X08

X09

R5

R6

AR2

AR1

Volt-free relay contact outputs

CE: 240V, UL 115V @ 4A maximum).

Menu Items, AR1/2 Functions

Technical Manual

Page 6

3.11 Temperature Sensor (options)

Connections for temperature sensor T1 to T4

options are located on the XPM-Ai4 module

that is mounted inside the CX Box unit.

Connect the temperature sensor(s) wires

directly to XPM-Ai4 module terminal X03.

X03

Ai3

Ai2

0VDC

Ai1

0VDC

Ai4

0VDC

1

2

3

4

5

6

7

8

T1

T2

T3

T4

XPM

Ai4 #1

0VDC

10m (33ft) max

Temperature Sensor Functions

The XPM-Ai4 module is equipped with ACM

(Analogue Conditioning Modules: hardware

PCB) designed for ‘KTY 6’ type temperature

sensors. For other types of temperature

sensor the ACM module must be changed to

suit the sensor type.

3.11.1 ACM (Analogue Conditioning Module)

The electrical input

characteristics of the four

adjustable temperature

inputs (T01 to T04) can be

individually altered to

different types of

temperature sensor using

ACM devices.

ACM devices are hardware modules that

plug in to the analogue input circuit and

condition the incoming signal.

For a particular temperature sensor type the

correct ACM device must be selected and

fitted.

1

2

34

43 1

X04

XPM-Ai4

XPM-Ai4

1234

X01 X02 X03

X04

ACM

XPM-Ai4

134

432

Ai1 Ai2

Ai1

Ai2Ai3Ai4

12345678

Ai1

Ai2Ai3Ai4

XPM-Ai4

X03

T01

T02T03T04

Metacentre CX Box

Page 7

3.11.2 To change an ACM device:

Remove the power from the unit.

ACM devices for temperature sensor inputs

T1 to T4 are located within the unit’s XPM-

Ai4 module.

To gain access to the ACM devices remove

the cover of the XPM-Ai4 module. The ACM

devices can be removed and inserted by

hand without the use of a tool.

To remove an ACM device:

2

1

Never use a metallic tool (screwdriver tip

for example) to remove an ACM device.

To install an ACM device:

Before inserting an ACM device check the

pins of the ACM and the XPM-Ai4 socket.

1 2 3

4

ACM devices are designed to mount in the

XPM-Ai4 socket at an angle. This is intended

to retain the device securely in the socket in

the instance of mechanical vibration.

Antistatic Precaution

ACM devices contain electronic components;

take all necessary antistatic precautions

including:

1) Before handling an ACM device

touch an exposed earthed surface to

discharge any body static.

2) Always store in an anti-static

container or package; never place

on a non anti-static surface.

3) Handle the device by the edges;

never touch the electronic

components on the device.

Technical Manual

Page 8

3.11.3 ACM Identification

#ACM devices are classified by a number

and can be readily identified by colour:

ACM types 5 to 8 can be fitted to a

temperature sensor input socket. ACM

devices can be fitted in the XPM-Ai4 module

in any required combination.

Do not use ACM types 1 to 5 for

temperature sensor inputs.

Example: for temperature input 1 (Ai1):

1

2

34 #

Ai4 Ai3 Ai2 Ai1

ACM

When an ACM device is fitted the ‘AM:

ACM Type’ menu setting for the temperature

sensor input must be adjusted to match the

ACM type number.

Menus: T01 to T04

Temperature Sensor

5: KTY KTY

5: RTD RTD

6: PT1 PT100

7: PTk PT1000

8: NTC NTC 10k

5

6

7

8

ACM

X03

1

2

T01

1

2

34

1

#

#

2

3

4

XPM-Ai4 Ai4 Ai3 Ai2 Ai1

ACM

COPPER

RED (Blue)

GREEN (Blue)

BLUE (Blue)

1

2

1

2

1

2

1

2

T04 T03 T02 T01

Metacentre CX Box

Page 9

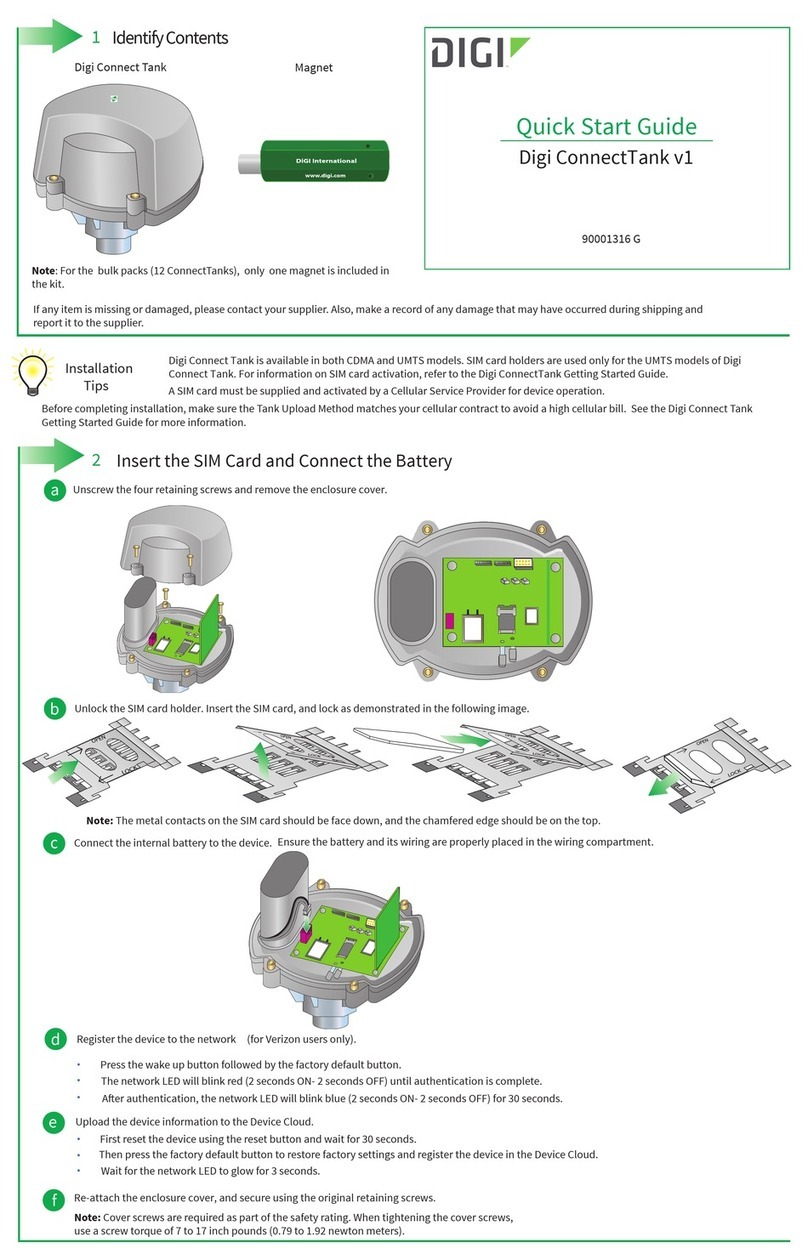

3.12 CX Extension Unit A01 to A04

The CX Extension unit is equipped with an

XPM-Ai4#2 module with four ‘mA’ type inputs.

As standard the XPM-Ai4#2 module is fitted

with type 3 ACM’s. In some instances it may

be necessary to fit a type 4 ‘mA’ ACM module

where the sensor device is ‘earth’ referenced

and the ‘mA’ signal is detected on the +24VDC

power supply wire.

The location of ACM devices within the

XPMAi4#2 module is identical to the main CX

Box XPM-Ai4 module (see: 4.11).

Only ACM type 3 (20mA active) or type 4

(20mA passive) can be fitted to a CX

Extension XPM-Ai4#2 module. (see 4.11 for

ACM removal and insertion).

ACM

X03

A01

1

2

34

1

#

#

2

3

4

Ai4 Ai3 Ai2 Ai1

ACM

A04 A03 A02 A01

3: 0mA 0-20mA

+24VDC

3: 4mA 4-20mA

+24VDC

4: 0mA 0-20mA

4: 4mA 4-20mA

3

4

32

31

32

31

32

31

32

31

GREEN

BLUE

XPM-Ai4 #2

A GND

32

31

+V +

-

32

31

+V

+

0V

32

31

+V +

-

34

Technical Manual

Page 10

3.13RS485 Network Connection

The CX Box is intended to operate as part of a

management system.

CX Box

Connection to the management unit network is

two-wire, twisted pair, earth shielded RS485

data cable. Connect the RS485 data cable

wires to terminal X07 located on the rear of the

CX Box ‘S1’ main controller.

L2

L1

X07

L2

L1

Polarity is important.

The maximum ‘total’ network cable length is

1250m (4000 ft).

RS485 data communications and other

low voltage signals can be subject to electrical

interference. This potential can result in

intermittent malfunction or anomaly that is

difficult to diagnose. To avoid this possibility

always use earth shielded cables, securely

bonded to a known good earth at one end. In

addition, give careful consideration to cable

routing during installation.

1) Never route an RS485 data

communications or low voltage signal cable

alongside a high voltage 3-phase power

supply cable. If it is necessary to cross the

path of a power supply cable(s), always cross

at a right angle.

2) If it is necessary to follow the route of power

supply cables for a short distance (for

example: from a compressor unit to a wall

along a suspended cable tray) attach the

RS485 or signal cable on the outside of an

earthed cable tray such that the cable tray

forms an earthed electrical interference shield.

3) Where possible, never route an RS485 or

signal cable near to equipment or devices that

may be a source of electrical interference (for

example: 3-phase power supply transformer,

high voltage switchgear unit, frequency

inverter drive module, radio

Metacentre CX Box

Page 11

3.14 Compressor Interface PCB

The ‘i-PCB’ is designed to interface a

compressor with the CX using a 6-core, earth

shielded, cable no greater than 100m (330ft)

in length.

Each compressor in the system must be

assigned a unique identification number from

1 up to the number of compressors in the

system. The identification number should be

clearly indicated on each compressor for

operational reference.

For each compressor connected to the CX

utilising an ‘i-PCB,’ the signal wires must be

connected to the CX terminals dedicated for

the assigned compressor reference number.

i-PCB

LED 1 LED 2

C01 C02 C04

C03

246135

X01

24613 5

#1

C05

The ‘i-PCB’ is a DIN rail mountable module

designed to be installed within the compressor

control or switchgear area.

Each air compressor must be equipped with a

load/unload regulation system and, if not

regulated with a single electro-mechanical

pressure switch, have a facility for a remote

load/unload control with the ability to accept a

volt-free switching contact input for remote

load/unload.

Consult the air compressor manual or your

air compressor supplier/specialist for details

before installing the CX.

The ‘i-PCB’ uses a 12V to 250V input voltage

detection system and universal relay contact

control outputs (240V ‘CE’ / 115V ‘UL’ @ 5A

maximum). Integrated directly into the circuits

of an air compressor, the ‘i-PCB’ avoids the

need for additional relays or remote inputs.

The ‘i-PCB’ also acts as an electrical barrier

between the compressor and the CX providing

protection and voltage isolation.

4.14.1 Input Functions

The ‘i-PCB’ is fitted with a six-pin terminal C04

for compressor monitoring. The ‘i-PCB’ uses

two inputs (Ready and Run) to determine

compressor status. An Alarm input can be

used if compressor alarm indication is

available and required. The Alarm input is

optional and is not necessary for system

operation.

Ready Input:

The ‘Ready’ connection is intended to indicate

that the compressor is in a ‘started’ state, has

no operational inhibiting fault condition and is

ready to respond to CX regulation without

manual intervention.

0V

+V

READY LAMP

RUN READY

ALARM C04

The READY input will accept 12V to 250V ac

(50/60Hz) or dc.

Do not connect a voltage greater than

250Vac/dc to this input.

This input must be connected to the terminals

of a ‘ready’ or ‘operational’ lamp, or other

circuit of the compressor control system, that

will be energised when the compressor is in a

started (standby or running) condition.

The voltage to this input must de-energise

when the compressor is stopped and

unavailable to produce air upon a load signal,

or the Emergency Stop button is pressed, or

when the compressor experiences a fault that

prevents the compressor from running.

Technical Manual

Page 12

When the compressor ready lamp, or other

control circuit, is energised the ‘i-PCB’ will

detect the voltage and signal the CX that the

compressor is ready and available to load and

produce air when a load request signal is

given.

The ‘i-PCB’ input common terminal must

always be connected to the neutral, common

or 0V line of the applied input voltage.

Ready Input, Alternative Connection Method:

In instances where a convenient voltage signal

for a compressor ready condition is not

available the ‘Ready’ input can be connected

directly to a constant compressor control

system power supply voltage (12V to 250Vac

or dc). This will signal the CX that the

compressor is ready and available at all times

when power is applied to the compressor. The

CX has a built-in function to determine when a

compressor is not responding, or is in a

shutdown condition, regardless of a constant

ready signal. If the CX requests a compressor

to run/load, but fails to detect a RUN signal

within 60 seconds, the CX will regard the

compressor as ‘not ready’ and indicate the

compressor as not available. If a RUN signal

is detected at any time, the CX will

automatically reset the compressor ‘not ready’

condition and re-establish control.

F1

+Vac

0Vac

READY

Never connect the READY input positive

connection directly to the output of a control

system transformer, always connect after a

fuse or circuit breaker.

If a normally closed contact of an Emergency

Stop button is included in the compressor

power supply circuit, connect after the

Emergency Stop button contacts. This will

instantly indicate a compressor ‘not ready’

condition if the Emergency Stop button is

activated.

Run Input:

0V

RUN READY

ALARM

+V

MAIN (LINE) CONTACTOR

C04

The RUN input will accept 12V to 250V ac

(50/60Hz) only (DC cannot be used).

Do not connect a voltage greater than

250V to this input.

12V to 250Vac must be applied to the ‘Run’

terminals when the compressor motor is

running.

This input can be connected to the control

terminals A1 and A2 (coil) of the main starter

contactor of the compressor. When the

compressor control system energises the main

contactor, the ‘i-PCB’ will detect the voltage

across the contactor coil terminals and signal

the CX that the compressor is running.

Alternatively, if the main contactor coil voltage

is greater than 250Vac, a contactor auxiliary

switch can be used to apply a suitable voltage

to the ‘Run’ input terminals.

0V

+V

MAIN (LINE) CONTACTOR

0V

+V

AUXILIARY SWITCH

RUN READY

ALARM C04

In instances where a motor starter contactor is

not available or accessible, any part of a

compressor control circuit that is energised

when the compressor is running can be

monitored. For example: fan contactor or

voltage signal to a remote starter.

Metacentre CX Box

Page 13

The ‘i-PCB’ input common terminal must

always be connected to the neutral, common

or 0V line of the applied input voltage.

Alarm Input (optional):

The ‘i-PCB’ is equipped with an alarm (or

warning) input that can be used to detect

alarm or warning conditions.

A fault, that stops the compressor, and/or

prevents the compressor from running, is

determined from the ‘Run’ and ‘Ready’ inputs;

Alarm detection is optional and is not a

requirement.

Alarm Run Ready

Alarm Lamp 0V

+V

C04

The Alarm input will accept 12V to 250V ac

(50/60Hz) or dc.

Do not connect a voltage greater than

250Vac/dc to this input.

This input can be connected to the terminals of

an alarm lamp or other accessible part of the

control circuit that is energised when the

compressor is in an alarm condition.

If an alarm condition is experienced the

compressor alarm lamp, or alarm circuit, will

energise. The ‘i-PCB’ will detect the voltage

and signal the CX that an alarm has occurred.

If the compressor has no accessible alarm

circuit, or this function is not required, the ‘i-

PCB’ alarm terminals can be ignored.

The ‘i-PCB’ input common terminal must

always be connected to the neutral, common

or 0V line of the applied input voltage.

4.14.2 Output Functions

The CX will control the ‘i-PCB’ load/unload

relay outputs in accordance with the active

system load and unload pressure set points.

The ‘i-PCB’ load/unload relay contacts can be

used for compressor controllers that have

‘pressure switch’ load/unload regulation.

‘i-PCB’ Internal Output Circuits

OUT

NO

IN

NO

OUT

NC IN

NC

IN

C

Load

C

Seq

SEQ

Relay

1&2

LOAD

Relay

3

OUT

C

+20VDI2DI1GND

LOAD

UNL

SEQ

CONT

Contacts :-

250Vac/dc @ 5A

maximum

24Vac

C

C03

1

2

3

The C01 and C02 terminal functions of the ‘i-

PCB’ are intended to control load and unload

regulation of the compressor.

Pressure Switch Regulation:

For air compressors fitted with an electro-

mechanical pressure switch a six-pin terminal

C02 has been provided to enable connection

to a pressure switch that has a two wire or

three-wire connection.

When connected the pressure switch can be

switched in and out of circuit automatically. If

the CX is stopped or experiences a failure or

loss of power, pressure control will

automatically revert back to the pressure

switch and the compressor will continue to

operate in ‘Local’ mode.

The local pressure settings of all

compressors in the system should be set in a

cascaded manner such that the system will

operate normally in the event of CX

inoperability.

Technical Manual

Page 14

The NC (normally closed) and NO

(normally open) terminal references of the ‘i-

PCB’ are related to internal connection

functions and should not be referenced to the

connections of a compressor pressure switch;

which will generally be in reverse order.

Lethal voltages may be present on the

terminals of the air compressor pressure

switch. Isolate the air compressor power

supply before starting any work.

Two Wire Pressure Switch Connections:

+V

0V

LOAD

SOLENOID

C02

NO

OUT

C

NC

NO

C

NC

IN

Three Wire Pressure Switch Connections:

+V 0V

LOAD

SOLENOID

RUN-ON

TIMER

C02

NO

OUT

C

NC

NO

C

NC

IN

Remote Load/Unload Regulation:

For air compressors controllers fitted with

‘Remote/Local Pressure Regulation’ digital

inputs, a 4-pin connector C01 has been

provided.

This terminal provides volt free contact closure

for load control and also provides volt free

contact closure for remote pressure control

enable.

A remote load enable input provides the facility

to change the compressor load regulation from

internal control to a remote switching source.

Note: Compressors that use electronic

pressure detection but are not equipped with a

remote pressure control enable feature will not

automatically revert to local control if the CX is

stopped or experiences a fault or loss of

power.

Load and Sequence Connection:

Inputs Common

Remote Load Local/Remote

or

Remote Load Enable

COMPRESSOR CONTROLLER

INPUTS

C01

C

LOAD

C

SEQ

Compressors that use electronic pressure

detection but are not equipped with a remote

pressure control enable feature will not

automatically revert to local control if the CX is

stopped or experiences a fault or loss of

power.

Compressor controller inputs common

voltage may be 0V or +V.

Metacentre CX Box

Page 15

The local/remote pressure regulation input

and/or remote load input logic of some

electronic pressure sensor type controllers are

reversed, in this instance the ‘pressure switch’

outputs (terminal C02) can be used to

establish alternative logic control connections.

For Example:

If the compressor controller ‘Local/Remote

Pressure Control’ input is a normally open

type; remote when closed, but the ‘Remote

Load’ input is a normally closed type; load

when open, the ‘i-PCB’ pressure switch

terminal contacts can be used to achieve the

correct switching logic.

C02

NO

OUT C

NC

NO

C

NC

IN

common

common

Local/Remote

Remote Load

Examine the ‘i-PCB’ internal output circuit

diagram to establish any desired switching

logic that may differ from normal practise.

Do not attempt to utilise ‘Digital Pressure

Regulation Control’ (terminal C01) and the

‘Pressure Switch Control’ (terminal C02)

output connections at the same time for

different products. These two output functions

are internally connected and a short circuit

condition and/or malfunction may result.

The ‘i-PCB’ connection examples shown in

this manual are intended to provide a guide

for the majority of compressor control

systems in use. Some compressors have

variations in operation and/or function;

consult your compressor

supplier/specialist for advice.

Service Maintenance Switch:

The ‘i-PCB’ is equipped with a volt-free input

(terminal C05) that can be used to remove the

compressor from management system control,

without generating a fault condition, during

short-term maintenance or servicing periods.

1

2

C05

When the ‘Service Maintenance Switch’ input

terminal pins are connected together, using a

volt-free switching contact, the CX will indicate

that the compressor is not available but will not

generate an Alarm, Trip or Shutdown

condition. The management system unit will

remove the compressor from the sequence

strategy and substitute with an alternative

available compressor if necessary. When the

‘Service Maintenance Switch’ inputs are open

circuit again the compressor will automatically

be accepted back in to the sequence strategy

and will be utilised as and when next required.

The use of a ‘key switch’ is recommended for

this purpose in order to prevent the switch

contacts being inadvertently left in the closed

circuit condition after service maintenance is

complete.

DO NOT connect any external voltage

source to the pins of terminal C05.

Technical Manual

Page 16

4. COMMISSIONING

4.1 Commissioning Procedure

Commissioning Procedure

It is recommended that an authorised and

trained product supplier carry out

commissioning.

4.2 Physical Checks

Before applying power to the CX Box ensure

that the power supply connections are correct

and secure and that the operating voltage

selector is set correctly for the power supply

voltage in use; 115Vac or 230Vac (+-10%),

50/60Hz; see ‘Installation’.

1

VOLTAGE SELECT

234

X04

1

VOLTAGE SELECT

234

X04

230Vac

115Vac

EE

N

L

LNE

X01

1234

XPM-TAC24

General Checks:

Check and ensure all connections from remote

sensors or devices, and other connections,

are correctly installed and secure.

Close the front panel of the CX Box and apply

power.

Installation

Switch on the power supply to the CX Box.

The control program identification will be

displayed for a short period followed by the

normal operational User display.

4.3 Management System

For each compressor connected to the

Metacentre management unit using a CX Box,

ensure the connection type for the compressor

is defined as “I-485” for load/unload, or “V-

485” for regulating type, (RS485 network

communication) in the Metacentre

management system configuration.

Each compressor connected to a Metacentre

management system must be assigned a

unique compressor identification number (1 to

12). This number will be the ‘network address’

number for the compressor.

The number should be clearly marked on the

compressor for identification purposes.

CX Box

12 3

Example:

Compressor 3 = RS485 network address 03

S02 – AD ID and Network Address

Menus and Menu Items

4.4 Delivery Pressure Display

Check the displayed delivery pressure. If the

pressure is incorrect, or inaccurate, check the

type and range of the sensor and carry out the

pressure sensor commissioning and

calibration procedure.

P01 – Po Sensor Offset Calibration

P01 – Pr Sensor Range Calibration

Also set the high delivery pressure Alarm

(Warning) and shutdown Trip levels.

P01 – PA Maximum Delivery P. Alarm

P01 – PT Maximum Delivery P. Trip

Menus and Menu Items

4.5 Pressure Set Points

Set the local operating pressure set points to

suit system requirements when the CX Box is

functioning in local mode.

S01-PH High Pressure Set Point

S01-PL Low Pressure Set Point

For variable speed or variable regulation type

compressors the ‘PL’ lower pressure set point

will be the ‘Target’ pressure.

Metacentre CX Box

Page 17

4.6 Regulation Mode

Set the regulation mode for the CX Box to suit

the compressor regulation type.

S02 – RT Regulation Type

Dependant on the regulation mode, set the

regulation parameters in the appropriate

control regulation menu:

C01-RC Regulation Control

C01-AC Analogue Output

Control

C01-VC Valve Control

Menus and Menu Items

4.7 Optional Features and Functions

Installation requirements may involve the

implementation of additional or optional

functions and features; implement as required.

As default additional and optional functions are

deactivated or inhibited.

Features and Functions; Menu Items

Technical Manual

Page 18

5.0 Menu Navigation

Display Item Structure:

All operational system status and values are

accessible from the normal User display. To

view status or values, that are not normally

visible on the default screen, press UP or

DOWN. All standard User display items are

view only and cannot be adjusted. The

standard User display items are regarded as

‘Menu Page 00’ items.

All adjustable value, parameter or option item

displays are grouped into ‘menu mode’ lists.

Items are assigned to a list according to type

and classification. Item lists are identified by

page number (or menu number); All adjustable

parameters and options are assigned to menu

mode pages ‘P01’ or higher.

Normal Operational Display (Menu Page P00):

At controller initialisation, all LED indicators

are switched on for several seconds before

initialisation is complete and the normal

operating display (Page P00) is shown. In

normal operational display mode the main

display will continuously show the detected

system pressure and the Item display will

show the first item of the ‘Page 00’ menu. User

menu ‘Items’ can be selected using the Up or

Down buttons at any time. Pressing the Enter

button will lock any selected Item display and

inhibit return to the default display. When an

Item display is locked the lock key symbol will

be shown. To unlock an Item display press Up

or Down to view an alternative Item display or

press Reset or Escape. No Item values,

options or parameters can be adjusted in page

‘P00’. If a fault condition occurs the fault code

becomes the first list item and the display will

automatically jump to display the fault code.

More than one active fault code item can exist

at any one time and can be viewed by

pressing UP or DOWN. The most recent

‘active’ fault will be at the top of the list.

Access Code:

Access to adjustable menu page items is

restricted by access code. To access menu

mode pages press MENU (or UP and DOWN

together); an access code entry display is

shown and the first code character will flash.

0 0 0 0

Use UP(plus) or DOWN(minus) to adjust the

value of the first code character then press

ENTER. The next code character will flash;

use UP or DOWN to adjust then press

ENTER. Repeat for all four code characters.

If the code number is less than 1000 then the

first code character will be 0(zero). To return

to a previous code character press ESCAPE.

When all four code characters have been set

to an authorized code number press ENTER.

An invalid code will return the display to

normal operational mode; page ‘P00’.

Access Code Accepted

Access Code Rejected

Access Code Timeout:

When in menu mode, if no key activity is

detected for a period of time the access code

is cancelled and the display will automatically

reset to the normal operational display.

Menu Mode Navigation:

In menu mode the menu ‘page’ number will be

highlighted at the top of the display.

P00

To select a menu ‘page’ press UP or DOWN.

To enter the highlighted menu ‘page’ press

ENTER; the first item of the menu ‘page’ will

be highlighted. Press UP or DOWN to scroll

though the selected menu ‘page’ items.

Metacentre CX Box

Page 19

To select an item value or parameter for

modification press ENTER; an adjustment

screen for the item will be displayed.

The value or option can now be modified by

pressing UP(Plus) or DOWN(Minus). To enter

a modified value or option in to memory press

ENTER.

Press ESCAPE at any time in menu mode to

step backwards one stage in the navigation

process. Pressing ESCAPE when the page

number is flashing will exit menu mode and

return the display to normal operational mode.

All menu items have a unique reference

consisting of the menu page ID (a) and the

menu page item number (b). Each item in a

menu also has a unique two alphanumeric

character code (c). All three references are

visible at the top of every menu item display.

P01 01.02 AB

a b c

Some menu items may consist of several

individual settings. Each setting of the menu

item is also referenced as a sub-item number.

For example: P01-01.02 references sub-item

‘02’ of menu item ‘01’ in menu page ‘P01’.

Sub-item settings, where applicable, are

always displayed together on the same ‘Item’

adjustment display screen. Most menu items

are single value or single option only in which

case the single item is referenced as sub-item

number ‘01’ (for example: P01-01.01).

Press and hold RESET for several

seconds at any time to immediately exit menu

mode and return to the normal operational

display. Any value or option adjustment that

has not been confirmed and entered into

memory will be abandoned and the original

setting maintained.

The CX will retain an ‘access code’ for a

short period after menu exit allowing the menu

structure to be re-entered without the need to

re-enter the access code again. To

immediately clear access code retention press

and hold RESET for several seconds.

A ‘locked’ symbol displayed with any item

indicates the item is locked and cannot be

modified. This will occur if the Item is view only

(not adjustable) or in instances where the item

cannot be adjusted while the CX is in an

operational state; stop the CX first.

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value Page 5

Page 4

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value Page 5

Page 4

This manual suits for next models

1

Table of contents

Other EnergAir Control System manuals

Popular Control System manuals by other brands

Spohn & Burkhardt

Spohn & Burkhardt FSMMD operating instructions

FingerTec

FingerTec AC900 user guide

energy sentry

energy sentry 9312 Owners and installation manual

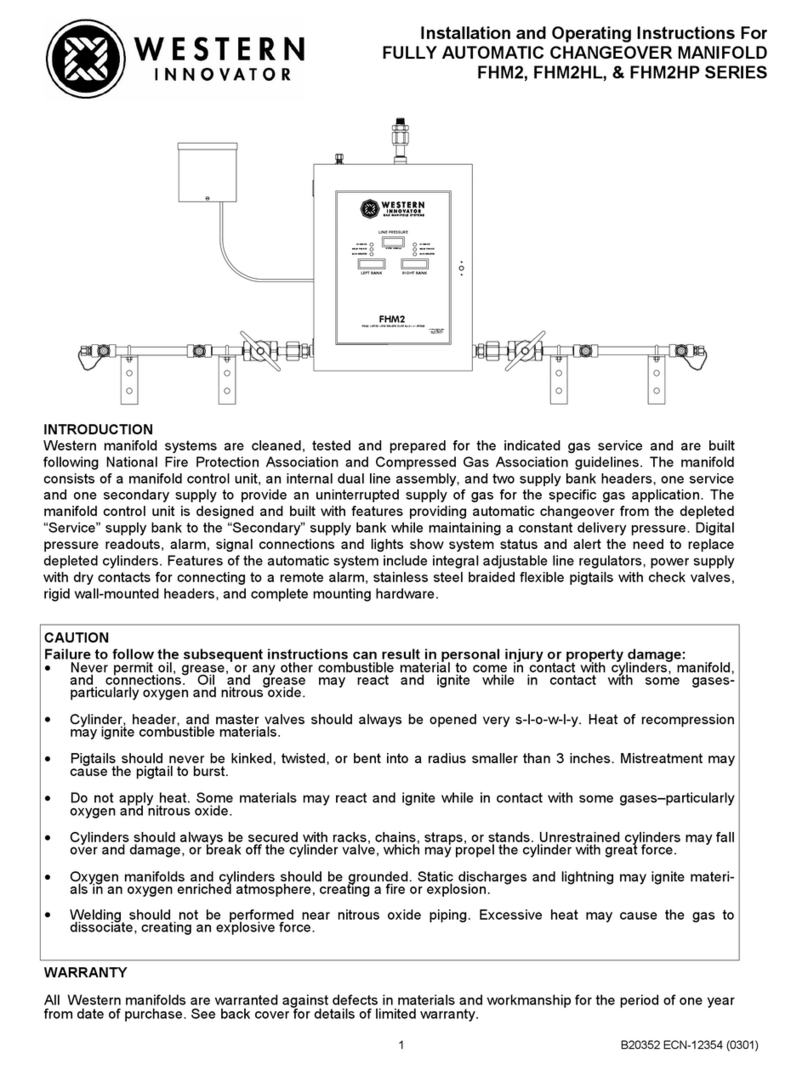

Western Innovator

Western Innovator FHM2 SERIES Installation and operating instructions

Aybey Elektronik

Aybey Elektronik AE-SMART installation manual

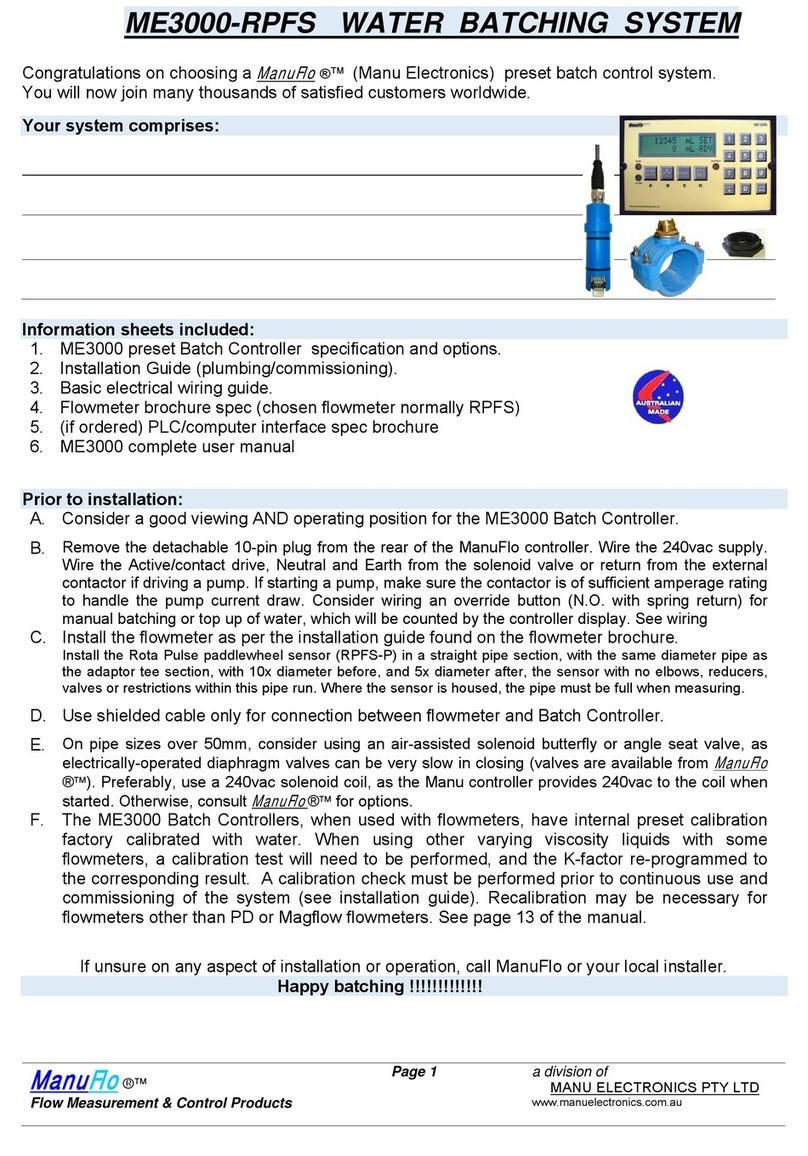

MANU ELECTRONICS

MANU ELECTRONICS ManuFlo ME3000-RPFS Information sheet