Energie SY250 Use and care manual

www.energie.pt 1

Assembly and User Manual

Thermodynamic Solar System

COMBI [6 | 12 | 16]

COMBI HT [12]

Energie Control Panel (SY250)

Directivas

2006/95/CE

2004/108/CE

R2V0 (23/03/2011)

EN

Review: 0

Version: 0

Date: 28/11/2014

CENTRAL HEATING

SWIMMING POOLS HEATING

LARGE VOLUMES HOT WATER

Energie Zuinig 2.0

Tel. 06 23605714

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

2 www.energie.pt

INDEX

1. ENERGIE CONTROL PANEL (SY250)........................................................................... 3

2. CONNECTION BOX........................................................................................................ 3

1. Remove the four screws on the corners (A), see on the above connection box scheme....... 4

3. CONTROL PANEL.......................................................................................................... 4

3.1. Keys.................................................................................................................................. 5

3.2. LEDs................................................................................................................................. 5

3.3. Display.............................................................................................................................. 5

4. SYSTEM MENU.............................................................................................................. 6

5. ACCESS TO PARAMETERS / PROGRAMMING .......................................................... 8

6. MENU OF PROGRAMMING OF PARAMETERS.......................................................... 9

7. PROGRAMMING MENU “BUFFER 1” ........................................................................ 10

8. PROGRAMMING MENU “BUFFER 2 DHW” .............................................................. 11

9. INSTALLATION PLANT .............................................................................................. 11

10. “COUNTER” MENU...................................................................................................... 13

11. “TEST OUTPUTS” MENU............................................................................................. 14

12. LIST OF ERRORS.......................................................................................................... 14

13. OPERATION MODE...................................................................................................... 15

13.1. “OFF” Mode .............................................................................................................. 15

13.2. “CHECK-UP” Mode.................................................................................................. 15

13.3. “NORMAL” Mode .................................................................................................... 15

13.4. “SAFETY” MODE .................................................................................................... 16

14. APPLICATIONS OF THE BACKUP SYSTEM ............................................................. 17

14.1. System: ENERGIE and BACKUP.............................................................................. 17

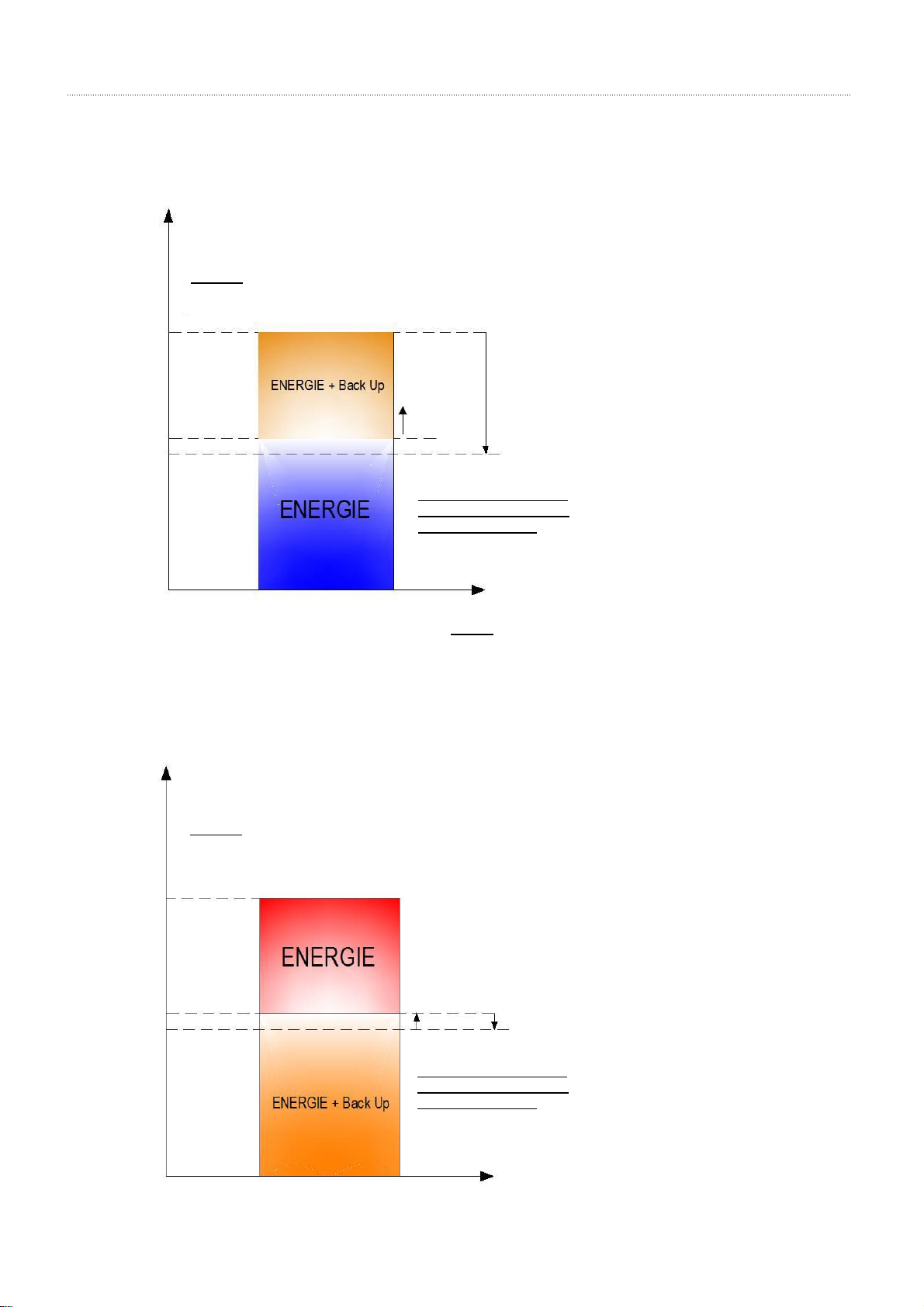

14.2. System: ENERGIE and (ENERGIE + BACKUP) ...................................................... 18

14.3. System: (ENERGIE + BACKUP) and ENERGIE ...................................................... 18

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 3

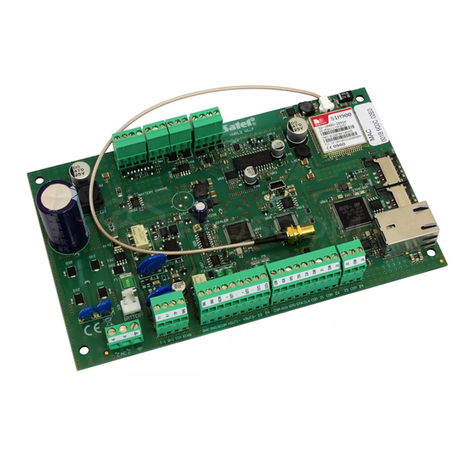

1. ENERGIE CONTROL PANEL (SY250)

The ENERGIE CONTROL PANEL SY250 is a control / command instrument for the ENERGIE thermodynamic

solar system.

It enables the setting of several functioning parameters of the equipment adapted to the system and user

operations.

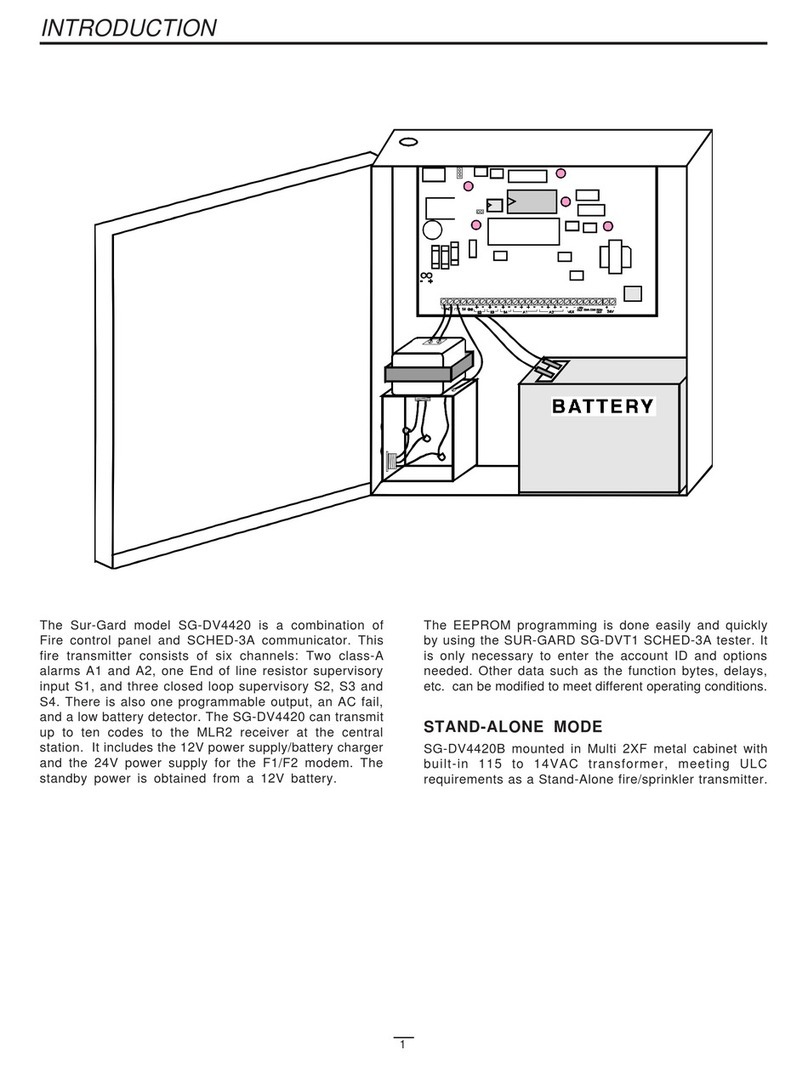

2. CONNECTION BOX

Connections

Function

Connections

Function

1-2

Power Supply 230VAC/ 50Hz

27-28

Probe 1 (return water temperature)

3-4

Pump 1

29-30

Probe 4 DHW

5-6

3 way valve (Central Heating circuit)

31-32

Probe 2 (gas)

7-8

3 way valve (DHW circuit)

33

Without connetion

9-10

Carter Resistance

34-35

Probe 3

11-12

Input TH (thermal)

36-37

Without connection.

13-14

Flow switch

38-39

Input LP (Low pressure switch)

15-16

Compressor

40

Without connection.

17-21

Back up 1 (support 1)

41-42

Input HP (High pressure switch)

18-19

Chante

43-44

Environment Thermostat

20

Without connection.

46-47

ON/OFF controller (V.E.E)

22-24

Back up 2 (support 2)

48

Without connection.

23

Without connection.

49-50

Digital input

25-26

External Thermostat

51-52

Controller input (V.E.E)

A

A

A

A

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

4 www.energie.pt

ELECTRONIC BOARD BATTERY

1. Remove the four screws on the corners (A), see on the above connection box scheme

2. Open the connection box

3. Check the battery on the electronic board

3. CONTROL PANEL

The control panel is the interface between equipment and user. It enables one to check on the system’s

functioning and consult / modify its parameters.

BATTERY

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 5

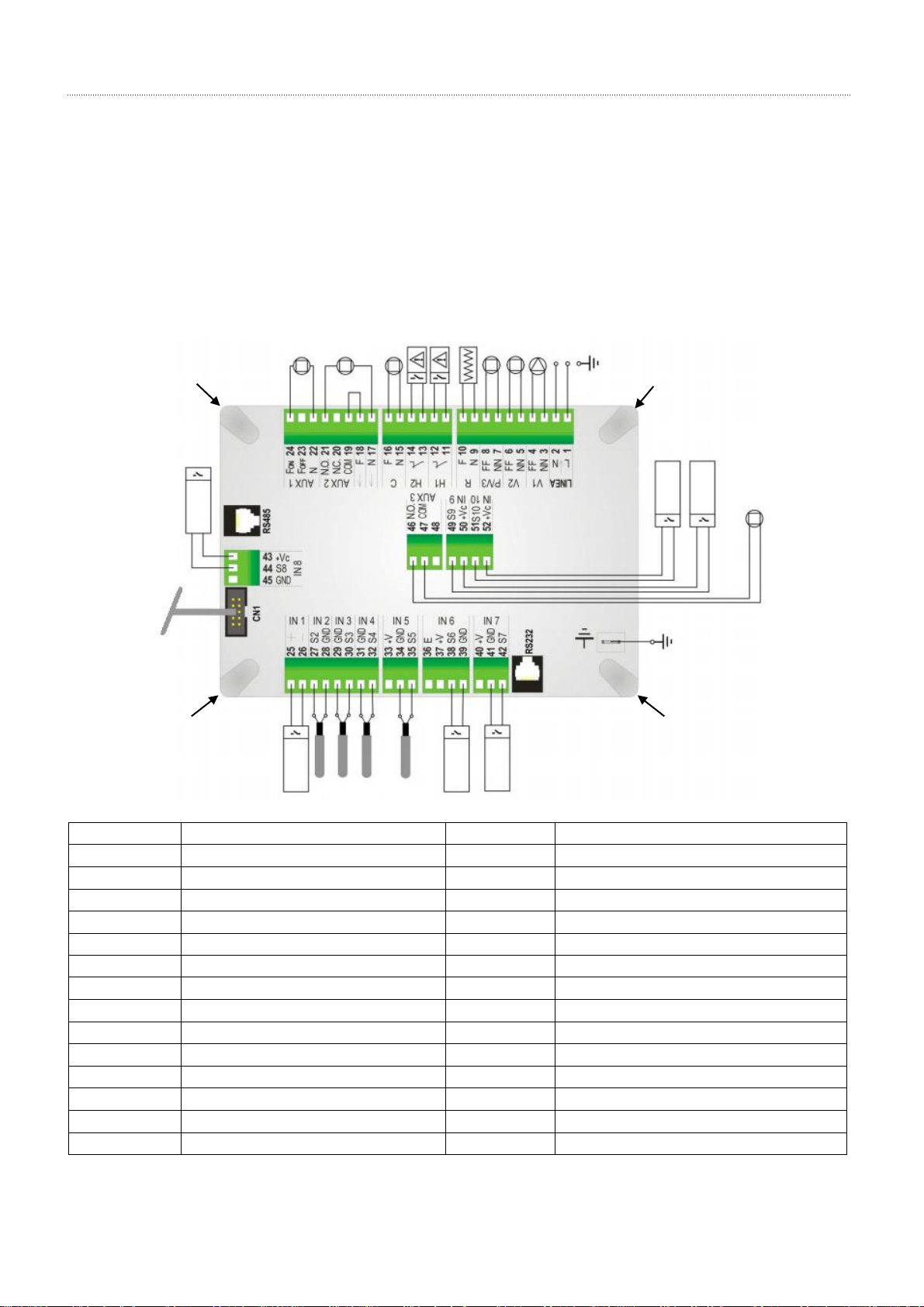

3.1. Keys

KEY

FUNCTION

DESCRIPTION

RETURN

ESC function enables leaving a menu or sub-menu.

UNBLOCK

When the system is frozen press the key for 3 seconds until

you hear the sound signal.

ON/OFF

Switch on/ switch off the equipment (press for 3 seconds).

MENU

Open menu and Sub-Menu.

MODIFY

Open the option to modify parameters.

SET

Save data.

CHANGE VALUES

It enables setting / modifying the values for the parameters.

RUN MENU / SUB-

MENU

Function for running menus and sub-menus.

DISPLAY

Function for consulting values of parameters.

ON / OFF

RESISTANCE

Pressing the key enables switching on and off the resistance.

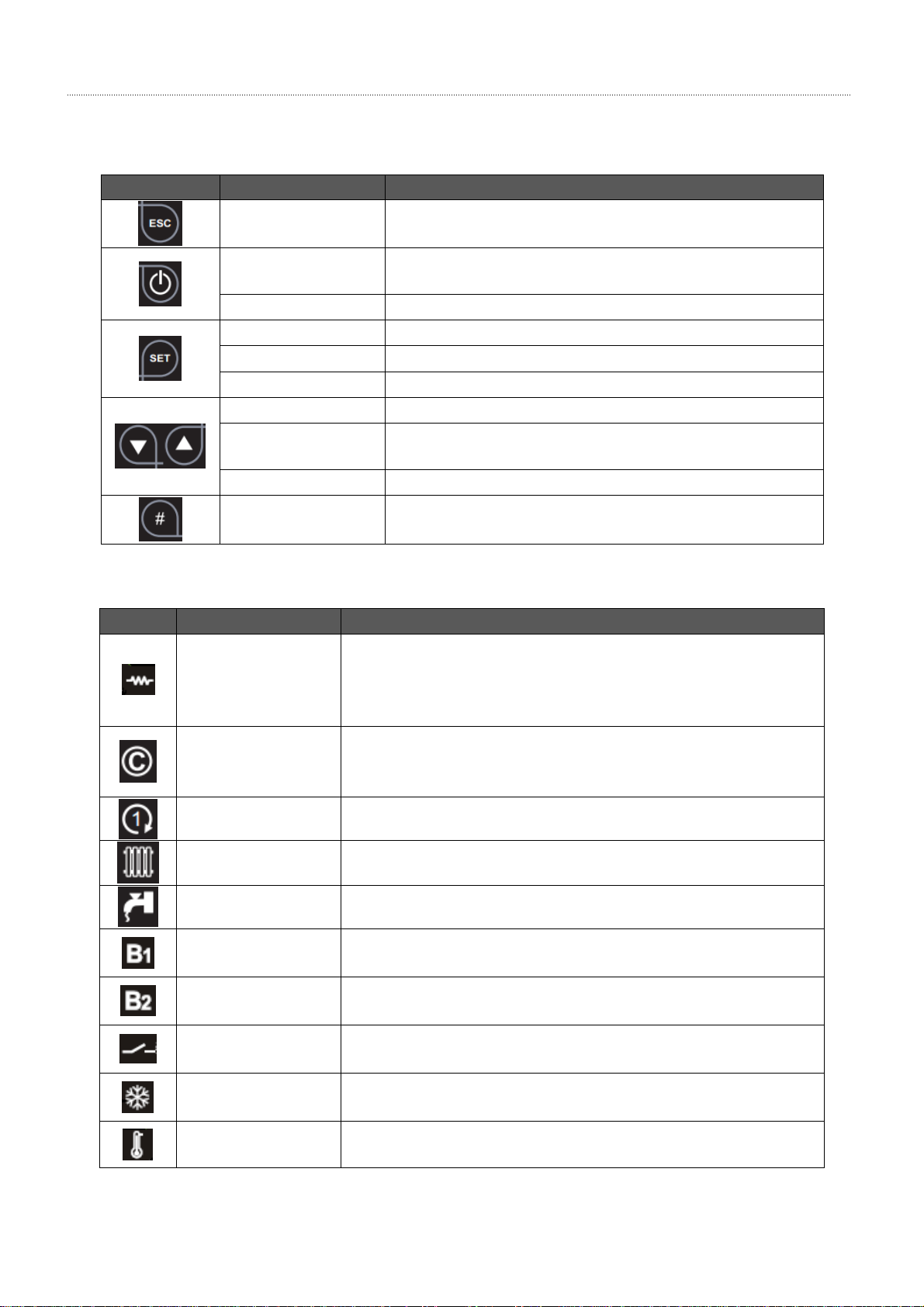

3.2. LEDs

LED

FUNCTION

DESCRIPTION

RESISTANCE

LED ON: On

LED OFF: Off

LED blinks: after pressing the key P5, the resistance may switch on

if the conditions are right.

COMPRESSOR

LED ON: On

LED OFF: Off

LED blinks: Time-setting (timer T06)

PUMP 1

LED ON: Pump is working

3 WAY VALVE

LED ON: Central Heating circuit

3 WAY VALVE

LED ON: DHW circuit

BACKUP 1

LED ON: Backup system 1 is on (CH)

LED blinks: Time-setting (timer T02)

BACKUP 2

LED ON: Backup system 2 is on (DHW).

LED blinks: Time-setting (timer T03)

INPUT V

LED ON: Closed contact

LED OFF: Open contact

EXTERNAL

THERMOSTAT

LED ON: Closed contact

LED OFF: Open contact

ENVIRONMENT

THERMOSTAT

LED ON: Temperature of the environment is below the set value

(closed contact)

3.3. Display

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

6 www.energie.pt

The Electrónico will have the following configuration as a display background, which enables the simultaneous

visualization of different parameters:

Display

Examples

Description

S1

Probe Temperature 1

S2

Probe Temperature 2

Chrono programming is active

4. SYSTEM MENU

This chapter will describe the menus that the user can access when he intends to carry out a modification of the

configuration of the display or equipment. The menu is divided in the following items:

Chrono Menu

Date and Time Menu

Language Menu

Keyboard Menu

System Menu

CHRONO MENU: Hourly programming of equipment according to the chosen mode.

Code of ERROR

System Status

Date and Time

CHRONO

Temperature Probes

de Temp.

LEDs

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 7

CHRONO PROGRAMMING

Daily program

For each day there are 3 possible switch on and switch off times.

Weekly program

Using this program the 3 switch on and switch off times are the same for all days of the week.

Week-end program

It is possible to select the periods “Monday-Friday” or “Saturday-Sunday”. For each period there are 3 switch on

and switch off times.

NOTE: After the Chrono programming to switch on the system by Chrono it is necessary to enable the

desired mode (Daily, Weekly or Week-end) from Modality menu.

The three programs modalities are saved separately: if you set for example the daily mode, the others

mode aren’t modified.

Date and Time Menu: Change time and date of system.

Language Menu: Change language of display.

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

8 www.energie.pt

Keyboard Menu: It enables the user to test the connection of display and controller; update the information of the

display when placed in a different controller; set contrast of display; set brightness of display.

System Menu: Change or consult system parameters.

5. ACCESS TO PARAMETERS / PROGRAMMING

In order to gain access to menus, submenus and consult / change system parameters, the user must insert a

system access password that is set by default to “0000”.

In order to introduce the access password simply press to show the first digit, press to change

the digit and select . Repeat the procedure for each digit of the password.

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 9

If the introduced password is correct the following information will be on display.

Display

Function

Description

Installation Plant

Set / consult system parameters

Set / consult parameters for Dep. of Inertia (Probe 3)

Set / consult parameters for AQS Dep. (Probe 4)

Counters

Test outputs

Restore factory parameters

To run through, change or consult the list of parameters, you must use the following keys:

Display

Function

Description

Gain access to selected parameter

Run through parameters

Save value for parameter and move to the next one

Cancel value for parameter or leave menu

6. MENU OF PROGRAMMING OF PARAMETERS

Menu in which you can display / modify the values for temperatures of probe 1, probe 2, circulation pumps,

timers, etc.

Code

Type

Name

Min(ºC)

Max(ºC)

Factory parameter

THS101

S1

Return Minimum Temperature

0

60

2 °C

THS102

S1

Return Maximum Temperature

10

70

45 °C

HYS102

S1

THS102 Temperature Gradient

1

10

5 °C

THS103

S1

Alarm Temperature

10

75

55 °C

THS201

S2

Alarm Temperature (gas)

10

80

60 °C

T01

Timer

Time Min Compressor OFF

1

2000 hours

12 hours

T06

Timer

Compressor Timer

0

20 min

1 min

T07

Timer

Delay in compressor start-up

0

60 min

20 min

P08

Conf.

DHW priority circuit

0

1

1

P09

Conf.

Set reading for input V

0

1

0

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

10 www.energie.pt

Note 1: T01 → Timer is activated every time the compressor comes to a halt. When the timer exceeds the set

time, and the compressor starts again, it will activate T07 and connect the carter resistance.

The value for T07 MUST NEVER be below 20 min.

Note 2: Sequence of circuits (priority)

P08 = 0 → Simultaneous circuits central heating and DHW.

P08 = 1 → DHW priority circuit.

The P08 value must never be changed to 0.

Note 3: Analog input configuration (S4 probe, pin 29-30)

P09 = 0 → Input V is set to “read” a temperature probe (Probe 4).

P09 = 1 → Input V is set to “read” a contact.

The P09 value must never be changed to 1.

7. PROGRAMMING MENU “BUFFER 1”

Code

Type

Name

Min(°C)

Max(°C)

Factory

parameter

T02

Timer

Delay Backup 1

1

60

10 min

THS301

S3

Minimum Temperature

10

50

10 °C

HYS301

S3

THS301 Temperature Gradient

1

10

1 °C

THS302

S3

Maximum Temperature

20

65

45 °C

HYS302

S3

THS302 Temperature Gradient

1

10

3 °C

THS303

S3

Alarm Temperature

10

80

65 °C

HYS303

S3

THS303 Temperature Gradient

1

10

3 °C

THS304

S3

Minimum Temperature Backup 1

10

60

10 °C

THS305

S3

Maximum temperature Backup 1

20

80

47 °C

HYS305

S3

THS305 Temperature Gradient

1

50

5 °C

THS306

S3

Minimum Temperature 2

10

50

10 °C

HYS306

S3

THS306 Temperature Gradient

1

10

1 °C

BUFFER 1 MANAGEMENT

The Back Up Output has the following functioning:

System State

Output state

Control

OFF

OFF

---

Check Up

Normal

Safety

ON

Probe S3 temperature<THS303 Thermostat and

THS304 Thermostat<Probe S3 temperature <THS305

Thermostat and Input T closed and Input Flowswitch closed

and External Thermostat closed

OFF

Off other cases

When the temperature decreases is considered the lowest between Thermostat THS302 and Thermostat THS304

to disable the output. The Back Up starts with a delay equal to the parameter T02.

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 11

8. PROGRAMMING MENU “BUFFER 2 DHW”

Code

Type

Name

Min(°C)

Max(°C)

Factory

parameter

T03

Timer

Delay Backup 2

1

60

1 min

THS402

S4

Maximum Temperature

20

65

20 °C

HYS402

S4

THS402 Temperature Gradient

1

10

2 °C

THS403

S4

Alarm Temperature

10

80

60 °C

HYS403

S4

THS403 Temperature Gradient

1

10

2 °C

THS404

S4

Minimum Temperature Backup 2

10

60

10 °C

THS405

S4

Maximum Temperature Backup 2

20

80

50 °C

HYS405

S4

THS405 Temperature Gradient

1

50

5 °C

THS406

S4

DHW Temperature

20

60

50 °C

HYS406

S4

THS406 Temperature Gradient

1

10

3 °C

BUFFER 2 MANAGEMENT

The Back Up Output has the following functioning:

System State

Output state

Control

OFF

OFF

---

Check Up

Normal

Safety

ON

Probe S4 temperature<THS403 Thermostat and THS404

Thermostat<Probe S4 temperature<THS405 Thermostat

and External Thermostat closed

OFF

Off other cases

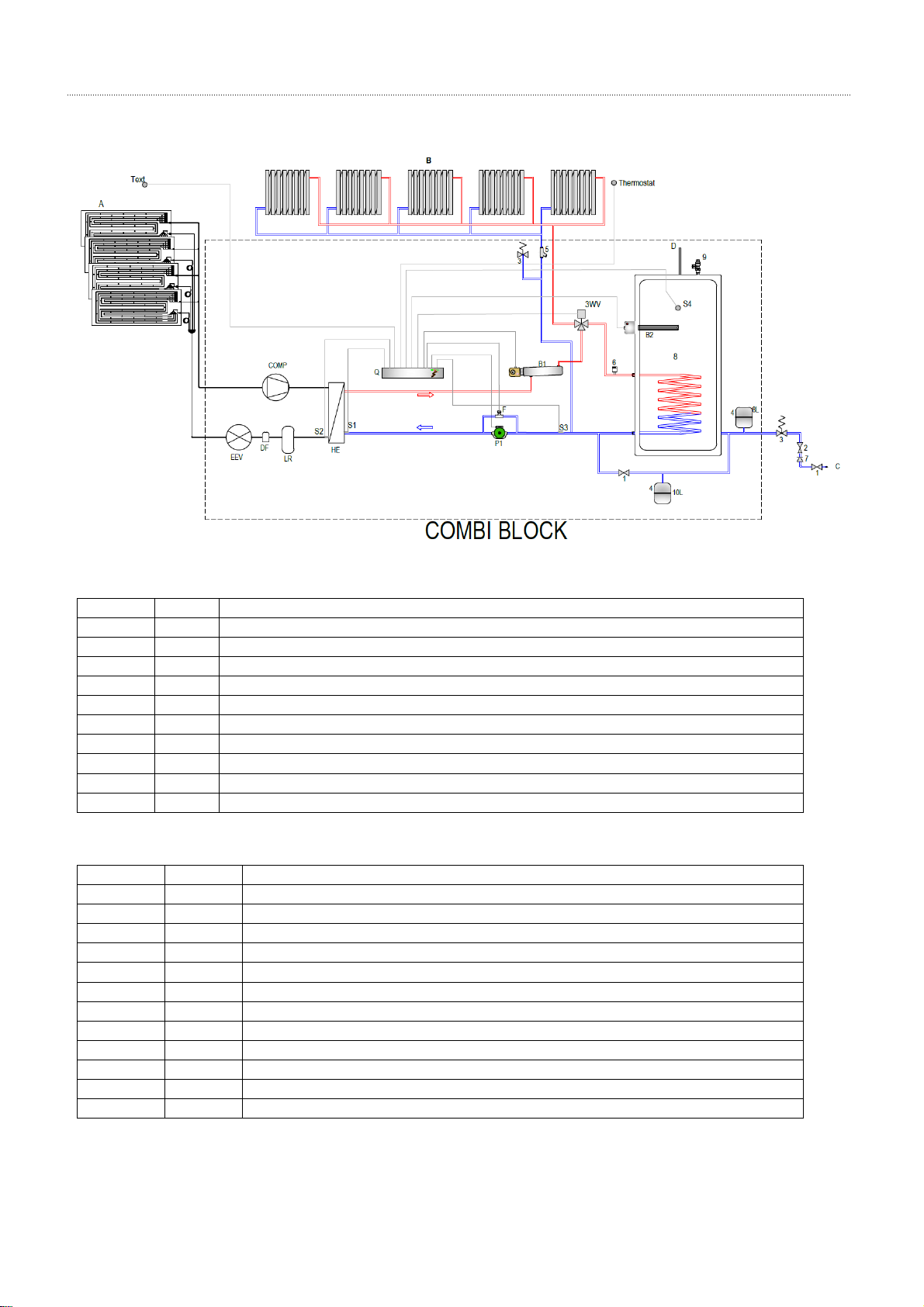

9. INSTALLATION PLANT

Representative plant [PLANT 12]

Inputs (Probes): S1, S2, S3 and S4

Outputs: Pump P1, 3 way valve (P1 and P2),Buffer B1 and Buffer B2

Note: B1 and B2 will not start unless the external thermostat is closed (LED ON).

The plant 12 must never be changed. Otherwise, there is the danger of injury and guaranty loss.

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

12 www.energie.pt

Plant

Parameters:

Code

Type

Description

THS101

S1

Minimum Temperature (water return)

THS102

S1

Maximum Temperature (water return)

HYS102

S1

THS102 Temperature Gradient

THS103

S1

Alarm Temperature (water return)

THS201

S2

Alarm Temperature (Gas)

T01

Timer

Time Min Compressor OFF

T06

Timer

Timer (delay in the compressor’s start-up)

T07

Timer

Timer (delay in the compressor’s start-up, carter resistance is ON)

P08

Conf.

Priorities of circuits

P09

Conf.

Set reading for input V

Buffer 1:

Code

Type

Description

T02

Timer

Delay in the start-up Backup 1

THS301

S3

Start-up Minimum Temperature P2

HYS301

S3

THS301 Temperature Gradient

THS302

S3

Maximum Temperature for STOP COMBI System.

HYS302

S3

THS302 Temperature Gradient

THS303

S3

Alarm Temperature

HYS303

S3

THS303 Temperature Gradient

THS304

S3

Start-up minimum temperature Backup 1

THS305

S3

Maximum Temperature for STOP Backup 1

HYS305

S3

THS305 Temperature Gradient

THS306

S3

Start-up Minimum Temperature P3

HYS306

S3

THS306 Temperature Gradient

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 13

Buffer 2:

Code

Type

Description

T03

Timer

Delay in the start-up Backup 2

THS404

S4

Start-up Minimum Temperature Backup 2

THS405

S4

Maximum Temperature for STOP Backup 2

HYS405

S4

THS405 Temperature Gradient

THS406

S4

AQS Temperature (Set point)

HYS406

S4

THS406 Temperature Gradient

10. “COUNTER” MENU

The counter menu will be divided into 3 submenus:

Compressor.

Reset.

List of Errors.

Compressor: Shows the number of hours of operation of the compressor.

Reset: Erases the record of all alarms and sets the counters to zero. In order to erase all records and set the

counters to zero, it is necessary to introduce a password (Manufacturer).

List of Errors: Shows a list of the last 5 errors in the following way:

Note: If the contact for the fluxostat is open, the system will not register any other type of error.

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

14 www.energie.pt

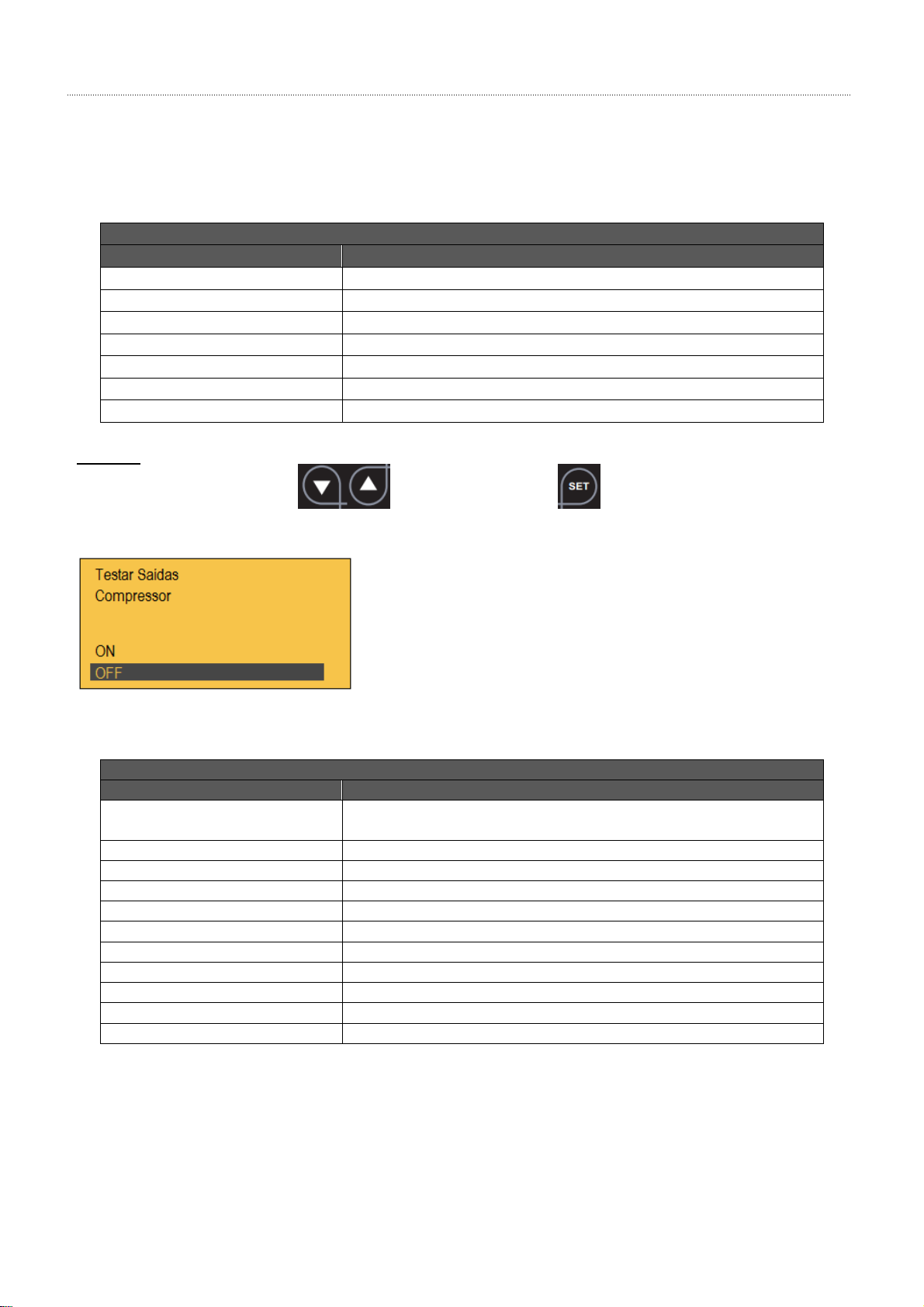

11. “TEST OUTPUTS” MENU

In order to test the outputs the system must be switched off. The test for each output is carried out individually.

Display

Submenu

Description

Compressor

Switches on the Compressor

Pump 1

Switches on the Circulation Pump 1

3 way valve (P2)

Switches on the Central Heating circuit

3 way valve (P3)

Switches on the DHW circuit

Resistance

Switches on the Carter Resistance

Backup 1

Switches on the Backup System 1

Backup 2

Switches on the Backup System 2 (DHW)

Example

Select icon “ON” with the keys and next press the key to switch on the compressor. Carry

out the process in reverse to switch off the compressor.

12. LIST OF ERRORS

Display

Error

Description

Er01 –Flow

(during check up is not an error)

Contact of flow switch is open (absence of flow or insufficient flow)

Er02 –TN

Safety Thermostat

Er03 –LP

Circuit Low Pressure Alarm

Er04 –HP

Circuit High Pressure Alarm

Er05 –TS1

Temperature Probe Alarm S1

Er05 –TS2

Temperature Probe Alarm S2

Er06 –TS3

Temperature Probe Alarm S3

Er07 –TS4

Temperature Probe Alarm S4

Er08 –RTC

Damaged Internal Clock or battery is discharged or weak

Er09 –TL

Probes S1, S2, S3 or S4 are damaged

Er11 –EVD

Electronic expansion valve controller

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 15

13. OPERATION MODE

The electronic ENERGIE (SY250) possesses 4 operation modes. In this chapter, the operation modes for inputs’

control and outputs’ control will be explained.

Modes:

OFF

CHECK-UP

NORMAL

SAFETY

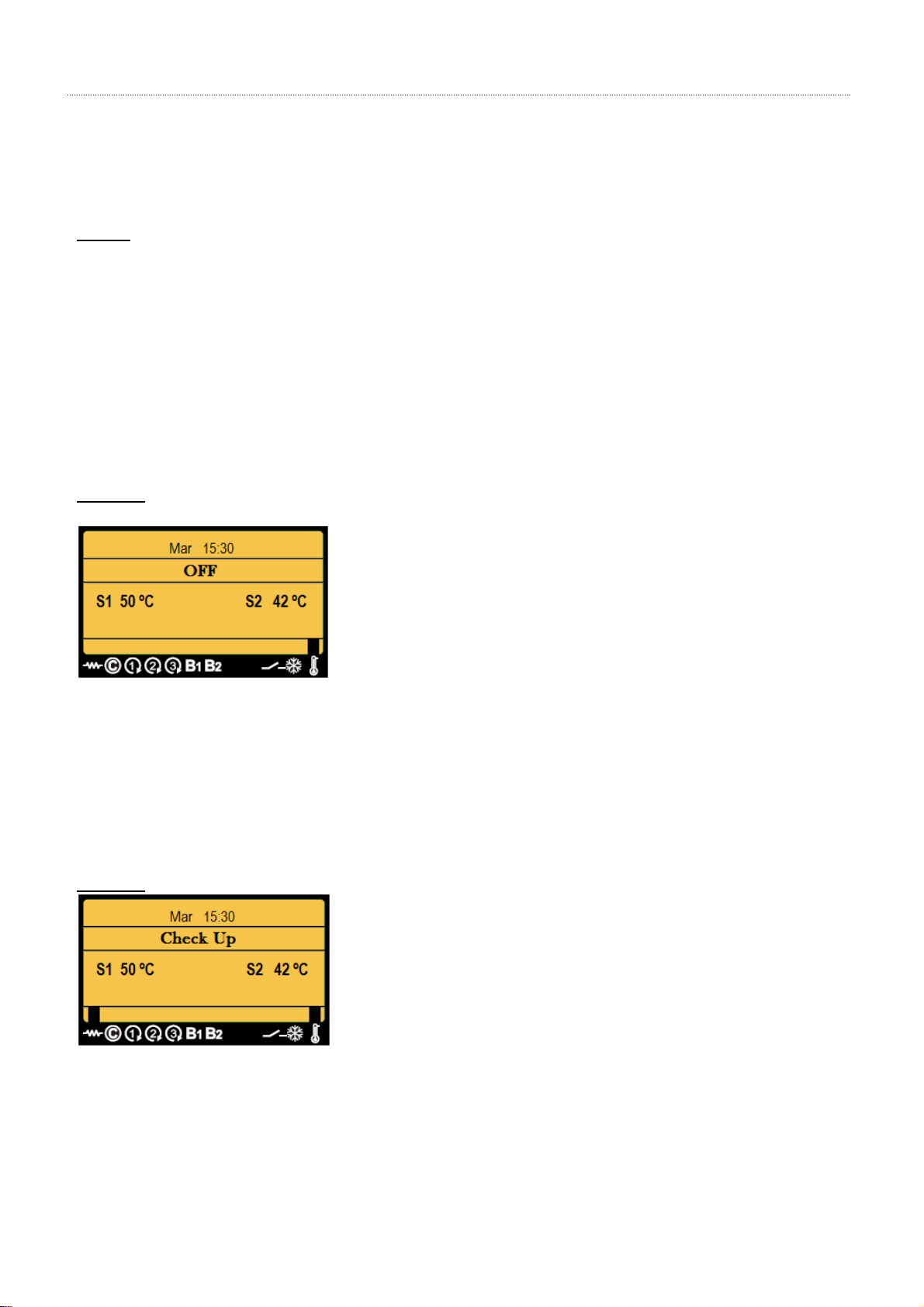

13.1. “OFF” Mode

In the off mode (OFF) the screen shows:

- Display OFF (only if you visualize the clock and the values for the probes)

- Compressor, Pump 1, Carter Resistance, Back Up –OFF (everything switched off).

Example:

13.2. “CHECK-UP” Mode

In the mode for time-setting (check-up), the electronic will review every connection, checking the connection of

the probes; the screen shows:

- Display Check Up.

- Carter Resistance and Environment Thermostat are “ON”.

- Compressor, Pump 1, etc., everything “OFF”.

- Etc.

Example:

13.3. “NORMAL” Mode

In the (normal) operating mode the control panel shows the following information, according to the typology of

installation employed:

- Compressor is “ON”

- Circulation Pump 1 is “ON”

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

16 www.energie.pt

- Environment Thermostat is “ON”

- Etc.

Example:

13.4. “SAFETY” MODE

In the safety mode, the electrónico will protect the equipment from potential malfunctions such as:

- Safety thermal (TH)

- Low pressure (LP)

- High Pressure (HP)

- Damaged Probe or not properly connected (TL)

- Etc.

Example:

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

www.energie.pt 17

14. APPLICATIONS OF THE BACKUP SYSTEM

The Backup System(s) can engage simultaneously with the ENERGIE System in the following situations:

ENERGIE System and BACKUP. To raise the water temperature above 55 °C.

ENERGIE System and (ENERGIE + BACKUP). Low external temperatures.

(ENERGIE + BACKUP)and ENERGIE System. Start with “Backup” support.

Note: In every situation described above the Backups 1 and 2 will not engage unless the external thermostat is

closed.

14.1. System: ENERGIE and BACKUP

The Parameters that should be adopted in the configuration of the Backup System are the following:

ENERGIE and BACKUP

ENERGIE and (ENERGIE + BACKUP)

(ENERGIE + BACKUP) and ENERGIE

Temperature > 55 °C

Low external temperatures

Start with Backup

Condition:

Back up only works if the outdoor

thermostat contact is closed

Condition:

Back up only works if the outdoor

thermostat contact is closed

Condition:

Back up only works if the outdoor

thermostat contact is closed

Timer

Timer

Timer

Temperature (0C)

Temperature (0C)

Temperature (0C)

Condition:

Back up only works if the outdoor

thermostat contact is closed

After reaching 65 0C, back up

only works at 43 0C (THS305-

HYS305) + Timer (T02)

Timer (T02)

HYS305=220C

430(650- 22 0)

THS305 = 65 0C

THS302 = 50 0C

THS304 = 48 0C

Probe temperature (0C)

Note: The diferential HYS305 should be higher than THS305 –THS304

ASSEMBLY AND USER MANUAL

ENERGIE CONTROL PANEL (SY250)

18 www.energie.pt

14.2. System: ENERGIE and (ENERGIE + BACKUP)

The Parameters that should be adopted in the configuration of the Backup System are the following:

14.3. System: (ENERGIE + BACKUP) and ENERGIE

The Parameters that should be adopted in the configuration of the Backup System are the following:

Condition:

Back up only works if the outdoor

thermostat contact is closed

HYS305=220C

Timer (T02)

280(450- 17 0)

After reaching 45 0C, back up

only works at 28 0C (THS305-

HYS305) + Timer (T02)

Note: The diferential HYS305 should be higher than THS305 –THS304

THS305 = 45 0C

THS302 = 45 0C

THS304 = 38 0C

Probe temperature (0C)

Timer (T02)

HYS305=50C

After reaching 45 0C, back up

only works at 25 0C (THS305-

HYS305) + Timer (T02)

Condition:

Back up only works if the outdoor

thermostat contact is closed

THS302 = 45 0C

THS305 = 30 0C

Probe temperature (0C)

Table of contents