Trikdis SP231 Assembly instructions

©1997-2015 Trikdis 2 www.trikdis.com

Control Panel SP231

General properties

8 zones (possibility to expand to 32);

9 zone functions;

Exclusive zone for two-wire smoke

detector;

8 partitions;

Internal clock;

Control of temperature sensors;

Tamper tracking;

Anti-Masking tracking;

Convenient default settings for fast

installation of the security system.

Alarm control

44 alarm control codes;

Remote control: by phone call or SMS

message;

Control devices: “Trikdis” keyboard

Protegus SK130LED, SK232LED, “Paradox”

keyboard K32+, K32LED, K636, K10LED,

iButton keys, coded or other switches;

“Bypass”, “Door Chime”, “Tamper”,

“Shutdown”, “Anti-Masking”, “Force Arm”

“Bellsquawk” “Re-Arm” etc. functions.

Power supply:

Main supply from 16-18 V AC or 16-24 V DC

source

Back-up supply from 12 V battery

PGM outputs:

5 PGM outputs (3 PGM, 1 Bell, 1 LED);

9 PGM output functions;

PGM output remote control.

Setting of control panel operation

parameters

Software “TrikdisConfig” via USB;

In remote mode –via GPRS using

“TrikdisConfig” or “IPcom Control”

software.

Transmission of reports:

Two slots for SIM cards;

Transmission of encrypted reports to the

main or back-up CMS IP address via GPRS.

If GPRS connection is lost, the reports shall

be sent by SMS messages;

Continuous control of communication

channel;

Sending of reports when the temperature

comes outside the allowable set range;

Event reports shall be transmitted by

Contact ID codes;

Sending of SMS messages with the user

defined event text to 5 mobile phones;

Sending of temperature values by SMS

messages;

Warning calls to 2 phones about the

occurred event;

Event memory shall store at least 2000 last

events.

Control panel SP231 –intrusion (to premises) and fire alarming system (alarm system’s) processor part with

integrated GSM/GPRS communicator. The control panel allows the user to switch on the alarm conveniently to

protect the premises in the preferred mode and thus control the signals of different sensors and react to them.

Upon occurrence of any system event, its report via GSM connection shall be transmitted to the Centralised

Monitoring Station (CMS) and/or mobile phones of users.

©1997-2015 Trikdis 3 www.trikdis.com

Control Panel SP231

Warranty and liability limitations

The control panel is provided with a 24 months warranty to become effective from the purchase-sales date.

The warranty period shall ensure free of charge repair of troubles occurred due to the manufacturer fault.

The warranty shall be applied, if the control panel is installed by qualified specialists according to this

document.

The control panel for repair shall be provided in the manufacturer package together with a defect report

with the indicated nature of trouble.

Upon expiry of the warranty period the maintenance and repair of the control panel shall be performed at

the buyer's expense.

The warranty may be terminated prematurely in the following cases:

The control panel was repaired or was attempted to repair by an unauthorized person;

The control panel was used not for its intended purpose;

The control panel was stored and/or installed in an inappropriate premises with inappropriate climate

conditions, aggressive chemical environment;

The control panel was mechanically broken and/or intentionally damaged;

The control panel was damaged due to force-majeure (lightning discharge etc.) circumstances.

The manufacturer shall not be liable for the following:

control panel malfunctions, if the control panel was installed or used not according to its operation

manual;

control panel malfunctions, if they occurred upon malfunctioning, lost GSM/GPRS/Internet connection

or upon occurrence of troubles in the network operator networks;

termination or restriction of GSM/GPRS/Internet communication services to the control panel buyer or

to the control panel user, and shall not reimburse the control panel buyer or the control panel user for

the occurred property or non-property losses;

termination or restriction of electrical power supply to the control panel buyer or to the control panel

user, and shall not reimburse the control panel buyer or the control panel user for the occurred property

or non-property losses;

robbery, fire of premises or other incurred losses to the control panel buyer or to the control panel user,

and shall not reimburse the control panel buyer or the control panel user for the occurred property or

non-property losses as a result of these events.

©1997-2015 Trikdis 4 www.trikdis.com

Control Panel SP231

Safety requirements

Prior to using the control panel, you must get familiar with this manual.

Control panel SP231 –electrical facility, thus it shall be installed and serviced only by qualified specialists

following this document.

During installation of the control panel its power supply must be switched off!

In the premises the control panel shall be installed in the restricted access zones and at a safe distance from

sensitive electronic equipment. The control panel is not resistant to vibration, other mechanical impact, moisture

and aggressive chemical environment. Control panel shall comply with the requirements of Standard EN 50131

applied to environmental impact resistance Class II.

The used housings, transformers, batteries and programming devices shall comply with the

safety requirements established in the Standard EN 60950.

The device shall be connected to 230 V voltage 50 Hz frequency mains power through the Class

II transformer reducing voltage down to 16 –18 V or to 16 –24 V direct current source. To

ensure back-up supply a battery of 12 V and at least 7 Ah capacity shall be used. The current

consumption depends on the power of the connected external devices.

Protection of the power supply circuit shall be ensured with the installed two-pole automatic

safety switch. The dividing gap between the switch off contacts shall be at least 3 mm. The safety

switch shall be installed in the place known to the specialists servicing the control panel.

Cut-off of the control panel from the electricity network:

- from alternating current network –upon switching off the automatic safety switch;

- from the battery –by disconnecting the terminals.

©1997-2015 Trikdis 5 www.trikdis.com

Control Panel SP231

Content

1TECHNICAL PARAMETERS .................................... 6

2ALARM SYSTEM POWER SUPPLY ......................... 7

2.1 MAIN SUPPLY .....................................................7

2.2 BACK-UP SUPPLY .................................................7

2.3 BATTERY SUPPLY..................................................7

3CONTROL PANEL ASSEMBLIES ............................. 8

3.1 CONTROL PANEL SP231 .......................................8

3.2 CONTROL PANEL SP231 KIT .................................8

3.3 CONTROL PANEL SP231 KITI.................................8

4CONTROL PANEL STRUCTURE .............................. 9

4.1 PURPOSE OF TERMINALS .....................................10

4.2 LIGHT INDICATION..............................................10

5SYSTEM INSTALLATION.......................................11

5.1 RECOMMENDED INSTALLATION PROCEDURE............11

5.1.1 Control panel fastening in the mounting

housing 11

5.1.2 Equipment connection sequence............. 12

5.1.3 Recommendations for setting the control

panel operation parameters................................. 12

5.1.4 Alarm system operation testing .............. 14

5.2 COMPATIBLE MODULES.......................................15

5.3 CONNECTION OF SENSORS ...................................15

5.4 CONNECTION OF SMOKE DETECTORS......................16

5.5 CONNECTION OF EQUIPMENT TERMINALS TO PGM

OUTPUTS 16

5.6 CONNECTION OF REPORT TRANSMISSION DEVICES ....17

5.7 CONNECTION OF TEMPERATURE SENSORS,IBUTTON KEY

READERS 17

5.8 CONNECTION OF KEYBOARDS,INPUT EXPANDERS .....18

5.9 CONNECTION OF WIRELESS SENSORS......................18

6CONFIGURATION OF CONTROL PANEL OPERATION

19

6.1 CONNECT TO CONTROL PANEL ..............................19

6.1.1 Connect with USB cable........................... 19

6.1.2 Connect in remote mode ......................... 19

6.1.3 Changing of settings by SMS messages... 20

6.2 DESCRIPTION OF TRIKDISCONFIG PROGRAM............21

6.3 USER ACCESS ....................................................22

6.3.1 Control panel configuration .................... 22

6.3.2 Control panel control............................... 23

6.4 SYSTEM USER INITIAL LOGIN CODES .......................23

6.5 SYSTEM PARAMETERS.........................................24

6.5.1 General system parameters .................... 24

6.5.2 Resetting of initial parameters................ 24

6.5.3 Setting of control panel clock .................. 25

6.5.4 Regular connectivity checks .................... 25

6.5.5 Keyboard parameters.............................. 25

6.6 SYSTEM TROUBLES .............................................26

6.6.1 Tamper recognition ................................. 27

6.6.2 Control panel watch-dog......................... 28

6.7 ZONE PARAMETERS ............................................28

6.7.1 Main zone parameters ............................ 28

6.7.2 Parameters of zone event reports ........... 29

6.7.3 Zone function description ........................ 30

6.8 PARTITION PARAMETERS .....................................30

6.9 USER ACCESS PARAMETERS..................................32

6.9.1 iButton key code registering.................... 32

6.10 SIM CARD PARAMETERS .....................................33

6.11 REPORT TRANSMISSION TO CMS..........................33

6.12 REPORT TRANSMISSION TO USER...........................35

6.12.1 Message texts to User......................... 37

6.13 PGM OUTPUT CONFIGURATION ...........................38

6.13.1 PGM output operation descriptions.... 39

6.13.2 PGM output remote control................ 41

6.14 CONTROL BY CALL ..............................................41

6.14.1 Partition control .................................. 41

6.14.2 PGM Output control............................ 41

6.15 TRANSMISSION MODULE REGISTRATION .................42

6.16 KEYPADS AND EXPANDERS REGISTRATION ...............43

6.17 WIRELESS SENSORS REGISTRATION ........................44

6.17.1 Detectors............................................. 44

6.17.2 Sirens................................................... 46

6.17.3 Pendants ............................................. 47

6.17.4 Keypad ................................................ 48

6.18 SETTING OF TEMPERATURE METERING REPORT

CHARACTERISTICS............................................................49

6.19 SETTING OF EVENT REPORTS.................................50

6.20 EVENT LOG.......................................................50

6.21 CONTROL PANEL FIRMWARE UPGRADING................51

7PROGRAMMING AND CONTROL BY SMS

MESSAGES ..................................................................52

Control panel SP231 Technical parameters

©1997-2015 Trikdis 6 www.trikdis.com

1Technical parameters

Name

Description

Value

Units

Supply voltage

From alternating current source

16-18

V

From direct current source

16-24

V

Current

consumption

In standby mode

80

mA

When sending data

Up to 150

mA

Between [AUX+]

and [C]

terminals

Output DC voltage (level of impulses shall not exceed 200 mV).

13.6

(10-14)

V

1

A

Maximum allowable current consumption

Note: If the supply limits via “AUX” outputs are exceeded, the supply

to the connected devices shall be switched off automatically

2

A

Between [+5V]

and [C]

terminals

Output DC voltage (level of impulses shall not exceed 100 mV).

Note: If the supply limits via “+5V” output are exceeded, the supply

to the connected devices shall be switched off automatically

5

(4.9-5.1)

V

0.2

A

Surge protection

All the control panel terminal block terminals shall be protected

against static voltage jumps

2000

V

PGM1-PGM3

Programmable OC (open collector) type output terminals for

switching on/off of various devices automatically or by remote

control command (create “minus”)

30

V

0.5

A

BELL- (PGM4)

Programmable OC (open collector) type output terminal for

automatic switching on of the outdoor or indoor sirens (create

“minus”)

30

V

1

A

LED (PGM5)

Programmable OC (open collector) type output terminal with 5.1 kΩ

resistor for connecting the LED cathode (-) (create “minus”).

30

V

0.1

A

Operating

environment

At relative humidity below 80% at +20C, without condensation

From -25

up to +50

C

Control panel

dimensions

-

117x74x2

5

mm

Weight

-

0.1

kg

Report transmission technology

Name

Description

Report transmission to CMS

Complies with criteria of operating properties ATS5 established in

Standards EN 50131 and EN 50136 and applied to Grade III class

equipment

GSM/GPRS modem

Integrated quad-band SIM800H

850 / 900 / 1800 / 1900 MHz

Communication with CMS

technologies

TCP/IP or UDP/IP via GPRS, SMS messages

Report transmission protocols

TRK_TCP or TRK_UDP

Report encoding

Protocol Contact ID codes

Report encryption

Yes, using 6 symbol encryption key

Control panel SP231 Alarm system power supply

©1997-2015 Trikdis 7 www.trikdis.com

2Alarm system power supply

2.1 Main supply

The control panel and all alarm system can be fed from the alternating or direct current source. In both cases,

to ensure an uninterrupted supply to the system, the control panel shall be additionally connected to a back-up

supply source –12 V battery. To ensure the requirements of Standard EN50131, in case of cut-off from the

main supply source, the back-up supply battery shall be of sufficient capacity to provide power from the back-

up source to the system for 12 hours to comply with Grade II requirements or for 60 hours to comply with

Grade III requirements. Assess the current consumption of auxiliary devices, which is provided in chapter 5.2

„Compatible modules“.

2.2 Back-up supply

Upon interruption of power supply to the system from the main supply source, the event AC Failure report shall

be formed and the control panel shall automatically switch over the system for its feeding from the back-up

supply –12 V battery. When the battery voltage decreases down to 11.5 V, the event Low Battery report shall

be formed. When the battery discharges below 9.5 V, the event Battery Missing/Dead report shall be formed

and the battery shall be disconnected. Upon restoration of the AC mains voltage, the AC Restore report shall be

formed and the battery charging process shall start automatically. The desired charging current from 0.1 to 2.0

A can be set during programming the control panel, see 6.5.1 „General system parameters“. When the battery

voltage restores to 12.6 V, the event Battery Restore report shall be formed.

2.3 Battery supply

In individual case, e.g., for testing, the control panel and all the alarm system can be supplied not through the

main supply port, but only through a back-up supply port, e.g., only from 12 V battery. In this case, in order to

start the control panel (system) it is necessary to connect the battery to the control panel –BAT+ port and click

the circuit board button BAT_ON (see 4 “Control panel structure”).

Control panel SP231 Control panel assemblies

©1997-2015 Trikdis 8 www.trikdis.com

3Control panel assemblies

3.1 Control panel SP231

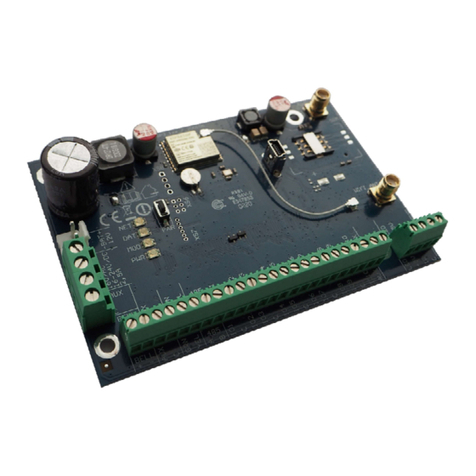

Control panel SP231 circuit board

1 pc.

Battery connection wire

1 pc.

Resistors 2.2 kΩ

16 pcs.

Plastic holder (fasteners)

4 pcs.

3.2 Control panel SP231 KIT

Control panel SP231 circuit board embedded in the metal housing

1 pc.

Metal housing K01 with 40 VA transformer

1 pcs.

Resistors 2.2 kΩ

16 pcs.

Stick-on GSM antenna ANT04 with 2.5 m length cable

1 pc.

Battery connection wire

1 pc.

Tamper sensor

1 pc.

Terminal block with 0,5 A fuse

1 pc.

3.3 Control panel SP231 KITi

Control panel SP231 circuit board embedded in the metal housing

1 pc.

Metal housing K02 with Mean Well impulse supply source

1 pc.

Resistors 2.2 kΩ

16 pcs.

Stick-on GSM antenna ANT04 with 2.5 m length cable

1 pc.

Battery connection wire

1 pc.

Tamper sensor

1 pc.

Terminal block with 3,15 A fuse

1 pc.

Note: USB wire (Mini-B type), which is designed for control panel programming, is not included.

Control panel SP231 Control panel structure

©1997-2015 Trikdis 9 www.trikdis.com

4Control panel structure

1.

RESET button

7.

GSM antenna port

2.

Communication and operation light indication

8.

SIM1 card holder

3.

Back-up supply port

9.

SIM2 card holder

4.

Main supply terminal block

10.

USB port for configuration of the control panel

operation parameters

5.

BAT_ON button is designed for starting the

control panel, when the DC voltage source is

connected to the back-up supply terminal block

11.

1-wire bus terminal block

6.

Terminal block for peripherals

Control panel SP231 Control panel structure

©1997-2015 Trikdis 10 www.trikdis.com

4.1 Purpose of terminals

Main supply terminal block

Terminal

Description

16V AC

16-24V DC

Main supply contacts shall be connected either to 16 –18 V AC or 16 –24 V DC

source.

Back-up supply port

Terminal

Description

-BAT+

Port for connecting the 12 V back-up battery.

Terminal block for peripherals

Terminal

Description

PGM1-PGM3

Programmable operation output terminals for connecting the indicators and

remotely controlled equipment.

BELL+, BELL-

Contacts for connecting the siren.

AUX+

Positive 13.6 V DC supply terminal for keyboard(s), indicators and sensors.

C

Negative supply terminal for keyboard(s), indicators and sensors.

YEL

Peripherals (e.g., keyboard) YEL circuit contact (yellow wire).

GRN

Peripherals (e.g., keyboard) GRN circuit contact (green wire).

MCI

Data bus contact for iButton key code reader and/or other report transmission

devices (e.g., radio transmitter).

ZN1-ZN8

Contacts for connecting the sensor control circuits. The contact ZN8 can be used for

connecting the 2-wire smoke detectors.

1-wire bus terminal block

Terminal

Description

LED

The contact for connecting the premises protection mode indicator, e.g., iButton

key reader LED cathode (-) (PGM5).

+5V

Positive 1-wire devices 5V DC supply contact.

1W

1-wire devices data circuit contact (iButton keys, temperature sensors)

C

Negative 1-wire devices supply contact.

4.2 Light indication

LED indicator

Operation

Value

“NET2”

shows log on

to GSM network

statuses using card

SIM2

Off

Not available or impossible to read SIM2 card.

Flashing green

SIM2 card registration in GSM network in progress.

Solid green

SIM2 card is registered in GSM network.

Frequently flashing green

SIM2 card PIN code error.

Flashing red

Number of flashes (below 10) show GSM field strength.

“NET1”

shows log on

to GSM network

statuses using card

SIM1

Off

Not available or impossible to read SIM1 card.

Flashing green

SIM1 card registration in GSM network in progress.

Solid green

SIM1 card is registered in GSM network.

Frequently flashing green

SIM1 card PIN code error.

Flashing red

Number of flashes (below 10) show GSM field strength.

“Data”

shows broadcasting

Solid green

The control panel memory contains unsent reports.

Flashing green

Transmission of reports to indicated addresses.

“PWR”

shows power

supply status,

programming

mode.

All are off

Power is off or battery voltage is lower than 9.5 V.

Flashing green

Supply voltage is sufficient.

Flashing red

Low supply voltage (< 11.5 V).

Flashes green and red in

turns

Start-up of the control panel operation software

(duration approx. 7 sec.).

Control panel SP231 System installation

©1997-2015 Trikdis 11 www.trikdis.com

5System installation

5.1 Recommended installation procedure

System planning:

Draw the plan of premises and indicate the zones for installation of the mounting housing with a

control panel, keyboard(s), indicators, equipment to be remotely controlled through the control panel

or controlled automatically by the control panel.

Upon assessment of the premises, requirements set to their protection and properties of possible

sensors, select the types of sensors, their number and places, where they should be fastened.

5.1.1 Control panel fastening in the mounting housing

The control panel circuit board shall be installed into

the mounting housing equipped with the reducing

transformer with 500 mA fuse and provided place

for a back-up supply battery.

Reinforce the control panel into the selected plastic

or metal mounting housing using plastic distance

holders of the control panel circuit board. Upon

choosing the metal housing, ensure its grounding

during installation. The used housing must comply

with the requirements of Standard EN 60950 and EN

50131.

5.1.1.1 SP231 circuit board dimensions

The figure shows the dimensions (in mm) of the control panel and its fastening holes and their locations.

Plastic distance holders

Control panel SP231 System installation

©1997-2015 Trikdis 12 www.trikdis.com

5.1.2 Equipment connection sequence

1) Connect the GSM antenna to the antenna port.

2) Insert the SIM card(s), which are already registered in the GSM network, into the SIM card holders. Card

holder SIM1 is the main card holder. The card inserted into SIM1 shall have a priority in operation, and

SIM2 shall be operated only upon malfunction of SIM1.

3) Following the provided diagrams and connection diagrams of every product intended for connection,

connect the magnetic contacts of windows and doors, motion, fire and other sensors, indicators,

keyboards, controlled devices. Connect the housing door tamper sensors and wall mounted tamper

sensors to the control panel terminals.

4) Connect the main supply source wires to the control panel AC/DC terminals. Switch the main supply on.

SP231 shall automatically recognise the correctly connected keyboards, expanders, interfaces, sensors

to the 1-wire and YEL/GRN buses and shall register them in the system.

5) Install a back-up supply battery into the mounting housing. Connect its wires to the control panel back-

up supply source terminals BAT+ / BAT–. Verify the battery charging current to ensure it is charged in

due time.

5.1.3 Recommendations for setting the control panel operation parameters

1) The first log on to the control panel shall be via USB cable (see 6.1.1 “Connect with USB cable”).

2) System settings:

a. Partitions

If the premises have several areas, the protection of which is preferred to be switched on

separately, the alarm system can be divided into partitions. Regarding dividing the system and

setting the necessary partition attributes see 6.8 “Partition parameters".

b. Zones

Parameters regarding setting of every zone according to sensor properties and preferred alarm

operation after an event takes place in this zone. If the alarm system is divided into partitions,

every zone can be assigned to the preferred partition. See 6.7 “Zone parameters”.

Note

The battery shall be fully charged no longer than within 72 hours so the alarm system complies with Grade

II class or within 24 hours to comply with Grade III class.

Control panel SP231 System installation

©1997-2015 Trikdis 13 www.trikdis.com

c. Users

In order to control the alarm system by means of a keyboard, iButton key or phone call (SMS

message), the “User” level users shall be created. Regarding creating “User” and assigning the

rights to them see 6.9 “User access parameters”.

3) Sending of reports:

a. Time setting

In order to receive the reports with a precise event timestamp, it is necessary to set clock time

in the control panel, see 6.5.3 “Setting of control panel clock”.

b. Enabling report sending

In the control panel with manufacturer set primary configuration the sending function of all

event reports is enabled. Regarding enabling or again disabling sending of the desired event

report, see 6.19 “Setting of event reports”.

c. SIM card parameters

If report sending is provided via GSM/GPRS, it is necessary to set the parameters of used SIM

card(s), see 6.10 “SIM card parameters”.

d. Reports to the Central Monitoring Station

Report s to the Central Monitoring Station shall be transmitted only via specified communication

channels. Regarding setting of parameters for report transmission to the Central Monitoring

Station see 6.11 “Report transmission to CMS ”.

e. Reports to user

Event reports to the user can be sent by SMS messages, and by calling the system shall warn on

occurrence of an event. Regarding correct setting of parameters for report transmission to the

user mobile phone see 6.12 “Report transmission to user”.

4) System remote control:

a. User access

In remote mode (by phone call and/or SMS message) the alarm system can be controlled only

by those users, whose phone numbers are entered into the user list. Regarding correct entering

of the phone numbers see 6.9 “User access parameters”.

b. Control by phone call

By a phone call it is possible not only to switch on/off the protection of all or part of premises,

but also control (start or stop) the equipment connected to PGM terminals. Regarding setting

procedure so it was possible by a phone call to change the status of the preferred PGM terminal,

which is connected to the equipment control circuit, see 6.14 “Control by call”.

c. Control by SMS messages

Using SMS messages it is possible to change some control panel operation parameters, switch

on/off the protection of all or part of premises, also control (start or stop) the equipment

connected to PGM terminals. The list of programming commands sent by SMS messages is as

follows: 7 “Programming and control by SMS messages”, and regarding setting procedure so it

was possible by SMS message to change the status of the preferred PGM terminal, which is

connected to the equipment control circuit, see 6.13.2 “PGM output remote control”.

5) Extra:

a. Changing of control codes

It is recommended to change the manufacturer set default values of alarm control and control

panel configuration codes that are known only to You.

Master user code shall be changed in the software menu branch Users.

Remote SMS control code shall be changed in the software menu branch Reporting

column User reporting field SMS reporting.

Log on to TrikdisConfig shall be changed in the software menu branch System options

column System administration.

Control panel SP231 System installation

©1997-2015 Trikdis 14 www.trikdis.com

b. Registration of MCI modules

If compatible equipment is connected to the control panel MCI data bus to be recognised by the

control panel and made a communication with it, this equipment shall be registered manually.

Regarding registering, see 6.15 “Transmission module registration”.

5.1.4 Alarm system operation testing

Upon completion of the alarm system installation, it shall be tested for correct operation.

5.1.4.1 Walk-test function

Operation of sensors and siren can be tested by carrying out a Walk-test function by using Trikdis Protegus

SK130 or SK232 keyboards. The following shall be done:

1. Press the button [OK].

2. Enter installer (Installer) code.

3. Press the button [TRB].

a. The buttons STAY and ARM shall start flashing and the alarm shall switch over to the testing

mode.

b. Due to change of the zone statuses, the sirens and keyboard buzzer shall beep by informing

about the zone operation.

c. If during testing the sensor fuse has been tampered or the protection mode is on, the testing

mode shall terminate automatically.

To switch off the mode, repeat the procedure as switching it on.

5.1.4.2 Testing of report transmission system

If GRPS network parameters are correctly set with the Central Monitoring Station addresses, upon switching on

the power supply to the system the following shall take place:

a) A report E305 System Reset shall be sent.

b) If compatible, but unregistered, modules are connected to the control panel YEL/GRN data bus, there

shall be sent as many reports R333 Expansion Module Restore as there are to be newly registered

modules.

c) If in the control panel, communication control parameters the communication verification signal PING is

on, a report E760 (Control panel PING signal) shall be sent. When the IP receiver gets the report, it shall

start automatic control of the communication channel with the control panel.

Also, it is possible to manually formulate the communication testing report E602 (Periodical Test). It is

recommended to inform in advance the security service about the testing.

Testing of the report transmission by using Trikdis Protegus SK130 or SK232 keyboards shall be as follows:

1. Press the button [OK].

2. Enter installer (Installer) code.

3. Press the button [MEM].

Control panel SP231 System installation

©1997-2015 Trikdis 15 www.trikdis.com

5.2 Compatible modules

Product code

Bus

Purpose

Current

consumption

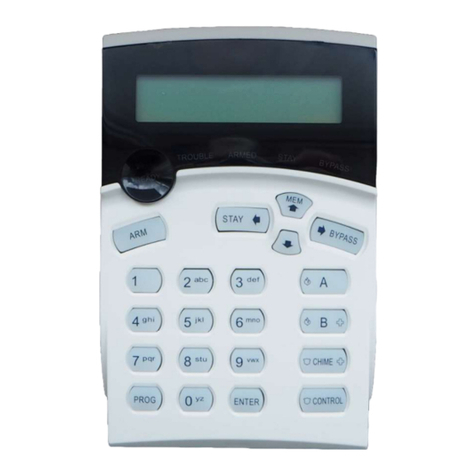

Trikdis PROTEGUS

SK232LED W/B

Y/G

2 partitions, 32 zone LED keyboard with touch-

sensitive keys, white or black glass surface

up to 150 mA

Trikdis PROTEGUS

SK130LED W/B

Y/G

16 zone LED keyboard with touch-sensitive keys,

white or black glass surface

up to 150 mA

Paradox K32+

Y/G

32 zone LED keyboard

up to 150 mA

Paradox K32LED

Y/G

32 zone LED keyboard

up to 150 mA

Paradox K10LEDV

Y/G

10 zone LED vertical keyboard

up to 100 mA

Paradox K10LEDH

Y/G

10 zone LED horizontal keyboard

up to 100 mA

Paradox K636

Y/G

10 zone LED keyboard

up to 100 mA

CZ8

Y/G

8 zone input expansion module

50 mA

W131

MCI

Interface with iButton key code reader

30 mA

T10R

MCI

Radio transmitter able to send control panel event

reports at VHF range radio frequencies

standby - 50 mA

sending - up to 1 A

E10C

MCI

Ethernet communicator able to send control panel

event reports via internet networks

standby - 60 mA

sending –up to

100 mA

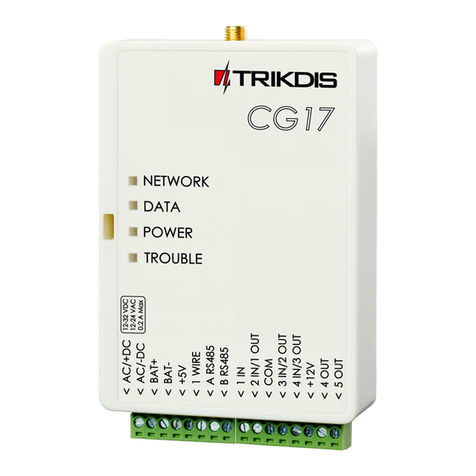

G10D

MCI

GSM&GPRS communicator able to send control

panel event reports via GPRS and/or SMS.

standby - 60 mA

sending –up to

250 mA

CZ-DALLAS

1-wire

iButton key reader

up to 25 mA

DS18B20

DS18S20

1-wire

Temperature sensor Dallas. Measuring range from -

55°C to +125°C

1 µA

5.3 Connection of sensors

The control panel circuit board has eight terminals ZN1–ZN8 (inputs) for connection of sensor control circuits.

When using input expanders CZ8, the number of outputs can be increased up to 32. Regarding setting of every

input as a zone, i.e. assigning the zone attributes: circuit type (EOL, NC...), sensitivity to short-term circuit

events, zone function (“Delay”, “Instant”...) see 6.7 “Zone parameters”.

Normally closed

circuit (NC).

Normally open

circuit (NO).

Normally open circuit

with end of line resistor

(EOL, End of Line).

Normally closed circuit with end

of line resistor (EOL, End of

Line).

Normally closed circuit with end of line

resistor and tamper recognition (NC with

EOL & tamper recognition).

Normally closed circuit with tamper anti-masking

recognition (NC with tamper & anti-masking recognition).

Control panel SP231 System installation

©1997-2015 Trikdis 16 www.trikdis.com

5.4 Connection of smoke detectors

In order to connect the control circuit of the smoke detector to the selected input, it is necessary that this input

was “Fire” zone, i.e. this input must be with the set “Fire” zone function (see 6.7.1 “Main zone ”).

When connecting the four-wire smoke detector circuit to the selected PGM output, this output shall be with the

set Fire reset function (see 6.13 “

PGM output configuration”).

ZN8 input can be dedicated namely for connecting the two-wire smoke detectors (see 6.7.1.2 “Setting of Fire

zones”).

Four-wire smoke detectors

Two-wire smoke detectors

5.5 Connection of equipment terminals to PGM outputs

PGM1-PGM3 - three terminals of open

collector,

BELL-(PGM4) - open collector terminal for

connecting the siren,

LED (PGM5) - collector terminal with 5K1

resistor.

Regarding all possible operation modes of

PGM outputs see 6.13.1 “

PGM output operation descriptions”.

Regarding changing of initial output values

see 6.13 “

PGM output configuration”.

Connection of sirens

PGM initial settings

1. Remote Control

2. Remote Control

3. Remote Control

4. Bell

5. System State

Connection of alarm (controlled) devices

Control panel SP231 System installation

©1997-2015 Trikdis 17 www.trikdis.com

Connection of remotely controlled terminals

5.6 Connection of report transmission devices

Report transmission devices

(T10R, E10C, G10D etc.) shall be

connected to a 1-wire data bus

MCI. The maximum length of the

bus shall be up to 100 m, with a

possibility to connect up to 4

devices. The control panel shall

not automatically register the

connected devices. Registration

shall be done manually (see 6.15

“

Transmission module

registration”).

5.7 Connection of temperature sensors, iButton key readers

It is possible to connect iButton key

readers and/or DS18B20 or DS18S20

temperature sensors to a 1-wire data

bus. The total length of the bus shall not

exceed 30 m, with a possibility to

connect up to 10 devices.

Circuit board terminal +5V is designed

for supply of 5 V DC to devices

connected to 1-wire bus. Allowable

output current shall not exceed 0.2 A.

The output shall be protected against

overload. Upon exceeding the allowable

current, the supply shall be cut-off

automatically. The control panel shall

automatically recognise and register the

connected devices.

When connecting more than one sensor with longer than 0.5 m wires,

for connections it is recommended to use twisted pair cable (UTP, STP).

Control panel SP231 System installation

©1997-2015 Trikdis 18 www.trikdis.com

Connection of iButton key readers

A –iButton key readers can be connected directly to 1-wire data bus. In addition, schematic shows the colour code

of wires for LED connection.

B –iButton key readers, when connecting at distances exceeding 30 m to the control panel, can be connected

using W131 expansion module.

5.8 Connection of keyboards, input expanders

The 2-wire data bus Y/G (a.k.a.

YEL/GRN) can be connected to

“Trikdis” Protegus SK232 LED B/W,

Protegus SK130LED B/W, “Paradox”

K32+, K32LED, K636, K10LED

keyboards and/or input ZN number

expanders CZ8. The total length of

the bus shall not exceed 300 m, with

a possibility to connect in parallel up

to 16 devices. The control panel shall

automatically recognise and register

the connected devices. Regarding

device unregistering see “

Keypads and expanders registration”.

5.9 Connection of wireless sensors

In order to connect the wireless

sensors, it is necessary to connect RF-

MOD module to control panel`s serial

port (the newest SP231 already have

soldered 4 pins plug to connect RF-

MOD. For older version –solder 4

pins plug in the marked “SERIAL”

holes).

To register wireless sensors in the

system refer to 6.17 Wireless sensor

registration

Control panel SP231 Configuration of control panel operation

©1997-2015 Trikdis 19 www.trikdis.com

6Configuration of control panel operation

The control panel operation parameters shall be set by software TrikdisConfig, which operates in OS MS

Windows environment. It is possible to connect to the control panel by using a USB cable or remotely, by

communicating with the control panel via GPRS communication. The software is available on the website

www.trikdis.com. Some control panel parameters can also be changed remotely by SMS messages.

6.1 Connect to control panel

6.1.1 Connect with USB cable

1) The computer shall have installed the following: parameter setting software TrikdisConfig and

software Microsoft.NET Framework 4.

2) After the software is in place, connect the control panel and the computer with the USB cable. Power

supply via USB port is sufficient to set the control panel operation parameters, so additional supply

is not necessary. Start the parameter setting software TrikdisConfig. The software shall automatically

recognise the connected device and open the window for its programming.

3) In order to read the parameters entered in the control panel, click the button Read and in the pop-

up table enter your (Admin or Installer) code (if the administrator initial code exists, the code shall

not be prompted).

4) After the first time reading of the control panel operation parameters, the software shall show the

manufacturer set default control panel operation parameters. After changing the parameters, click

the software button Write to enter the changes in the control panel memory. When configuration is

complete, shut down the software TrikdisConfig and unplug the USB cable from the control panel

USB port.

6.1.2 Connect in remote mode

Configuration of the control panel settings in remote mode shall be carried out via GPRS communication. For

both softwares TrikdisConfig and IPcom the appropriate GPRS communication settings shall be set. The manual

of the control panel shows how to do it and how to connect by using TrikdisConfig software. The description

how to connect with IPcom software is provided in the supporting documentation to this software.

6.1.2.1 GPRS communication settings

1) Ensure that SIM card has a disabled PIN code protection.

2) Insert SIM card with enabled GPRS communication service into the control panel SIM 1 slot. For

information how to enable this service please contact Your GSM service provider.

3) Add phone number the user, because only from listed numbers it is available to use all SMS commands.

SMS commands must be sent to the inserted SIM card’s number.

Command to add new phone number:

CFG [SMS password] ˽ 01 ˽ [USER Code] # [User Phone No.] #

CFG –beginning of SMS command, [SMS password] –six digit SMS password, 01 –command code,

[User code] –user code, [User phone No.] –user phone number, # - symbol to end value, “˽ “– marks the

space symbol in SMS message.

An example adding a phone number to Master user, while using default password values:

“CFG123456 01 1234#+37061111111#”

Note. When the Grade 2/3 protection class setting function is enabled, the remote control and

configuration function of the control panel shall be disabled automatically.

Control panel SP231 Configuration of control panel operation

©1997-2015 Trikdis 20 www.trikdis.com

4) Setup an inserted SIM1 card GSM network parameters. Command to set operator parameters:

PSW XXXXXX ˽ 12 ˽ APN# LOGIN# PSW###

PSW XXXXXX –beginning of SMS command and its password, 12 –changing network parameters

command, APN –gateway name (up to 50 symbols), LOGIN –user name (up to 29 symbols), PSW –

user password (up to 29 symbols), # - symbol to end value.

Example: “PSW123456 12 gprs.net#web#web###”

If network does not have user name nor password, fields must be left empty.

Example: “PSW123456 12 gprs.net#####”

5) Connection to the remote server must be enabled in a control panel. Command to enable connection:

PSW XXXXXX ˽ 94 ˽ 1

PSW XXXXXX –beginning of SMS command and its password, 94 –connection to the remote server

command, 1 –connection enabling value (0 –to disable).

Example: “PSW123456 94 1”

6) It is required to know IMEI address of Control Panel. IMEI address can be found on product package or

it can be requested by SMS command:

PSWXXXXX ˽ 97 ˽ 5

PSW XXXXXX –beginning of SMS command and its password, 97 ˽ 5 – request about GSM field

strength, modem IMEI number and control panel software version.

Example: „PSW123465 97 5“

6.1.2.2 Remote log on through TrikdisConfig

1) Make sure that the control panel is connected to supply source and in operation.

2) Start TrikdisConfig software.

3) At the field Remote access, in the field Unique ID enter the control panel GSM/GPRS modem IMEI address.

IMEI address is provided on the product package.

4) In the adjacent field System Name enter the desired name to the module.

5) Press Configure. After successful connection the settings shall be saved.

6.1.3 Changing of settings by SMS messages

Communication by SMS messages is designed for monitoring and control of the alarm system. The list of

commands sent by SMS messages see 7 “Programming and control by SMS messages”.

To activate this function, perform the following actions:

1) Insert the SIM cards, which are already registered with the GSM network provider, into the SIM card

holders.

2) Complete adding phone number to user command as instructed in 6.1.2.1 GPRS communication

settings the third point in a list. Because only from listed numbers it is available to use all SMS

commands.

Other manuals for SP231

1

Table of contents

Other Trikdis Control Panel manuals

Popular Control Panel manuals by other brands

Integrated Technical Vision

Integrated Technical Vision U-PROX HUB LAN user manual

Honeywell

Honeywell PL-1000 Installation and user manual

Edwards

Edwards 2010-2-PAK-900 Registration Guide

Nakanishi

Nakanishi E4000-PB Operation manual

Zamel

Zamel VO-803B manual

Bentel Security

Bentel Security K-NET installation manual

Cooper Menvier

Cooper Menvier Scantronic 9751 Installation and programming guide

Festo

Festo CP-E16-M8 manual

Pyronix

Pyronix OCTAGON II installation instructions

Kasco

Kasco C-25 Installation & operation manual

Groupe Atlantic

Groupe Atlantic NAVISTEM B1000 Instructions for installation, use and maintenance

NAPCO

NAPCO MA3000 Basic operating instructions