FireClass Panels and Repeaters Contents

Installation Guide Doc. version 2.0 3

Contents

1 Introduction ............................................................................................................................4

1.1 Keywords and symbols ........................................................................................................................ 4

1.2 Who this manual is for .......................................................................................................................... 4

1.3 What this manual does not cover........................................................................................................ 4

2 Installation notes ...................................................................................................................5

3 Safety warnings .....................................................................................................................5

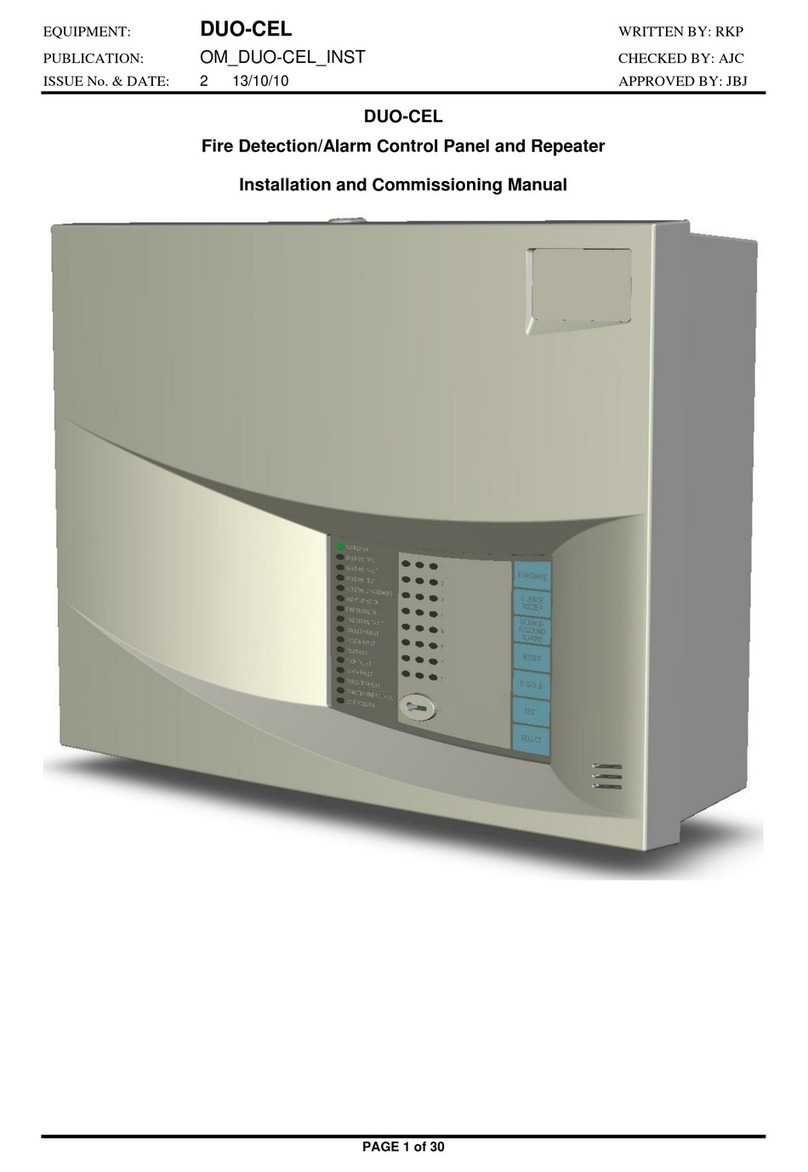

4 FireClass FC600 series panels ..............................................................................................5

4.1 Optional mounting plate ....................................................................................................................... 6

4.2 Mounting a FC600 series panel to the wall without a mounting plate............................................ 6

5 Inter-unit cabling ................................................................................................................. 11

5.1 Connecting the mains cable and protective earths in FC600 series panels and AC repeaters ..11

6 Loops installation................................................................................................................ 14

6.1 Running and temporarily connecting the loops ..............................................................................14

6.1.1 Interface conventional detectors .............................................................................................................15

6.2 Making insulation checks ..................................................................................................................15

6.3 Wiring the remaining modules ..........................................................................................................15

6.4 Measuring loop resistance .................................................................................................................15

6.5 Connecting the loops fully .................................................................................................................15

7 Installing the batteries .......................................................................................................16

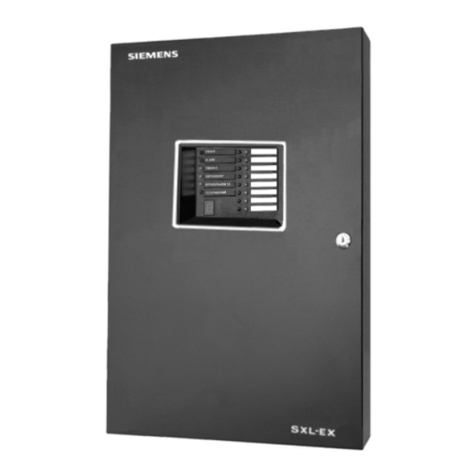

8 Mounting CUI repeater panels........................................................................................... 17

8.1 Connecting the CUI repeater DC supply cabling .............................................................................17

8.2 Connecting the CUI repeater RBus wires .........................................................................................17

9 Provide installation records............................................................................................... 21

10 Make final checks ............................................................................................................... 21

11 Install the FC-FI/FC-FI-1 - field interface board................................................................. 22

11.1 Local FC-FI/FC-FI-1board connections ..............................................................................................23

11.2 Connecting local sounders.................................................................................................................23

11.3 Connecting supervised inputs ...........................................................................................................24

11.4 Checking the FC-FI/FC-FI-1 connections...........................................................................................25

11.5 FC-FI/FC-FI-1 switches and jumper positions ...................................................................................26

11.6 Jumper and DIP switch settings........................................................................................................26

11.6.1 Configuration of a FC600 series panel RBus interface ............................................................................27

11.7 Changing a fuse on the FC-FI/FC-FI-1 ................................................................................................30

12 Installing optional boards, cards and modules................................................................ 31

12.1 Obtaining card addresses...................................................................................................................32

12.2 Card arrangement planning ...............................................................................................................32

12.3 Mounting cards and boards on a FC600 series panel......................................................................32

13 Installing the PNI800 - Panel Net Interface ...................................................................... 32

13.1 Changing a fuse on the PNI800..........................................................................................................35

14 Mounting a FB800 15WAY fuse board on a FC600 series panel.................................... 36

14.1 FB800 15WAY fused 24V outputs board details..............................................................................36

15 Binary DIP switch lookup table ......................................................................................... 37