Energie Aquapura 14 HT Operating manual

USER AND INSTALLATION MANUAL

1

USER AND INSTALLATION MANUAL

EN

Aquapura HT

AQUAPURA 14HT (INVERTER P 6-16)

AQUAPURA 8HT (INVERTER P 3-10)

Directives:

2014/35/UE

2014/30/UE

Regulation nº 814/2013

Regulation nº 812/2013

Revision:6

Versão 2

Date: 11/07/2023

USER AND INSTALLATION MANUAL

2

Esteemed Client,

We would like to thank you for your choice when you acquired an equipment for sanitary

water heating.

AQUAPURA INVERTER HT14 aero-thermal system will surely meet all your expectations

and provide many years of comfort with maximum power saving.

Our organization dedicates much time, energy and economic resources in order to

develop innovations that will promote power saving in our products.

Your choice has demonstrated your good sense and concern with power consumption, a

matter that affects the environment.

We have taken on a permanent commitment to conceive innovative and efficient

products so that this rational use of energy can actively contribute to the preservation of

the environment and natural resources of the planet.

Keep this manual whose objective is to inform, alert and advise about the use and

maintenance of this equipment.

Our services are always at your disposal. Feel free to call upon us!

USER AND INSTALLATION MANUAL

3

INDEX

1. INFO....................................................................................................................................... 5

2. SAFETY INFORMATION ......................................................................................................... 5

2.1 Danger Info.................................................................................................................... 6

2.2 Warnning Info................................................................................................................ 7

3. GENERAL INFO ...................................................................................................................... 7

3.1 Manufacturer Responsibility......................................................................................... 7

3.2 Installer responsibility ................................................................................................... 7

4. TRANSPORT........................................................................................................................... 8

5. PRINCIPLE OF OPERATION.................................................................................................... 9

6. UNIT OVERVIEW ................................................................................................................... 9

7. UNIT DIMENSIONS.............................................................................................................. 10

7.1. Aquapura 8HT................................................................................................................... 10

7.2. Aquapura 14HT ................................................................................................................ 11

................................................................................................................................................. 11

8. PERFORMANCE ................................................................................................................... 12

8.1 AQUAPURA 8HT .......................................................................................................... 14

8.2 AQUAPURA 14HT ........................................................................................................ 15

9. ETCHNICA INFO................................................................................................................... 12

10. INSTALLATION................................................................................................................. 16

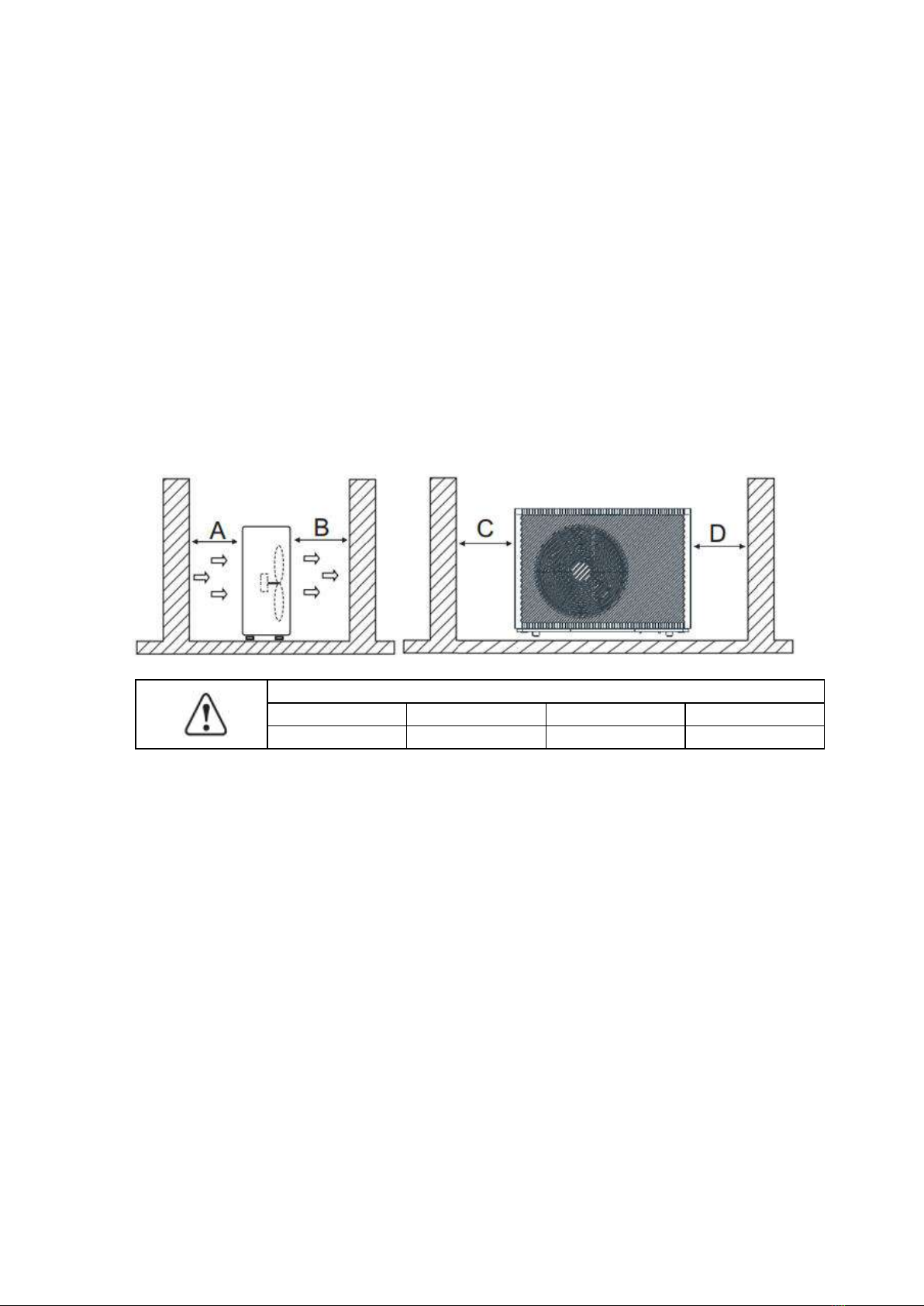

10.1 Installation place ......................................................................................................... 16

10.2 Condensate drainage .................................................................................................. 16

10.3 Hydraulic installation................................................................................................... 17

10.4 Water filter.................................................................................................................. 17

10.5 Circuit water quality.................................................................................................... 18

10.6 Glycol (%)..................................................................................................................... 18

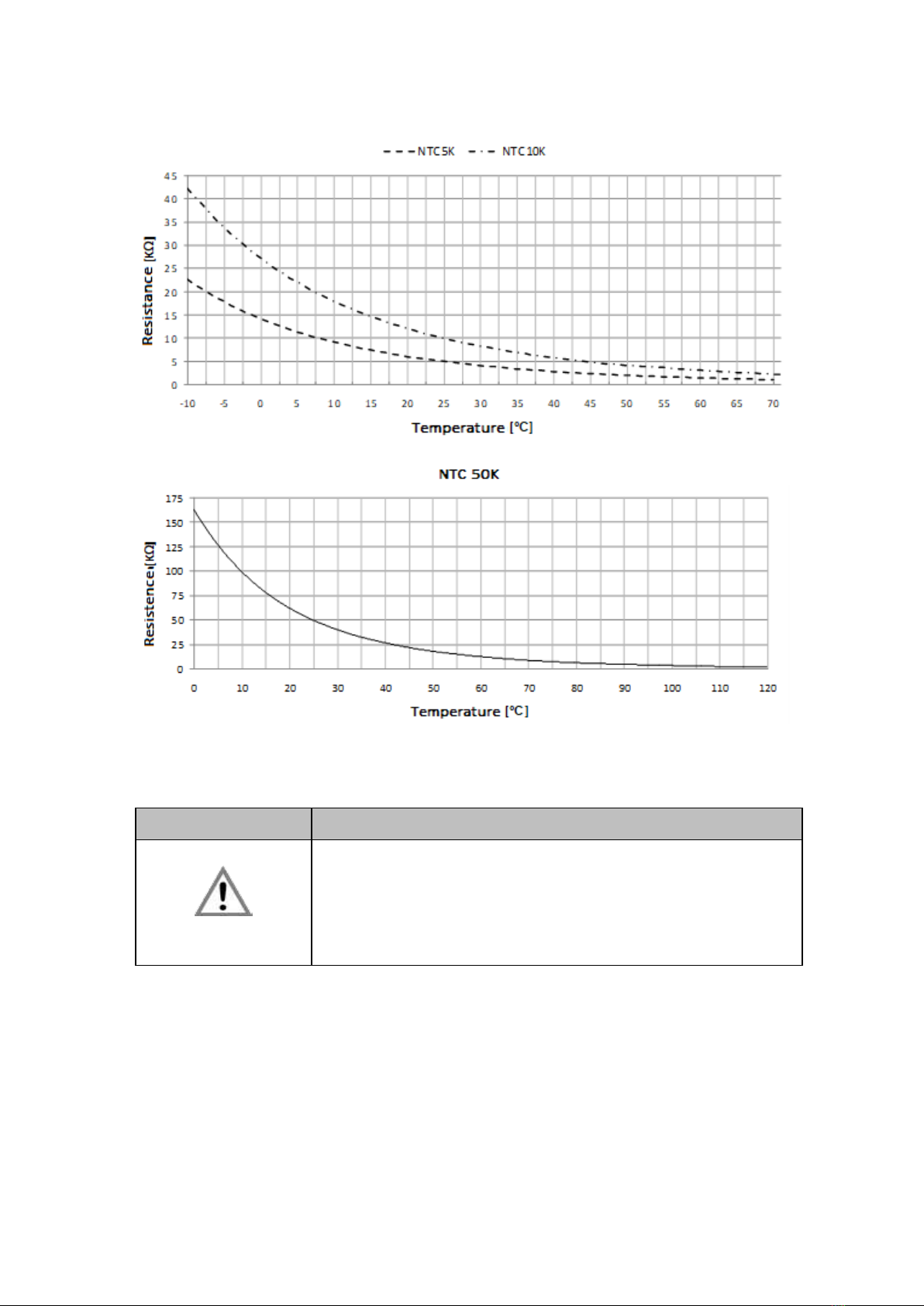

10.7 Temperature probes info ............................................................................................ 19

11. ELECTRICAL REQUIREMENTS .......................................................................................... 19

10.1 Main specifications...................................................................................................... 19

10.2 Electrical main spcifications/ protection devices........................................................ 20

10.3 Connection between external unit and display (user interface) ................................ 20

10.4 Connection terminals - Inputs..................................................................................... 21

10.5 Digital input configuration .......................................................................................... 22

10.6 Connections terminals –Outputs................................................................................ 23

12. ROOM THERMOSTAT INSTALLATION............................................................................. 23

13. MAIN CONTROLLER --- USER INTERFACE ....................................................................... 24

12.1 User interface description........................................................................................... 24

12.2 Unlock screen.............................................................................................................. 25

USER AND INSTALLATION MANUAL

4

12.3 Operation mode switch............................................................................................... 26

12.4 Setting target temperature ......................................................................................... 26

12.5 Setting interface display and function ........................................................................ 27

12.6 Time setting................................................................................................................. 28

12.6.1 System time setting................................................................................................. 28

12.6.2 Mute timer setting .................................................................................................. 29

12.6.3 Power timer setting................................................................................................. 29

12.7 Temperature curve...................................................................................................... 29

12.8 Color display calibration.............................................................................................. 30

12.9 Electric Heating ........................................................................................................... 30

12.10 Status interface display ........................................................................................... 31

12.11 Fault list ................................................................................................................... 32

14. MAIN CONTROLLER –INSTALLER INTERFACE................................................................. 32

13.1 Installer parameters.................................................................................................... 33

13.2 Compensation curve - Outdoor temperature Vs setpoint .......................................... 35

13.3 Output/ input state of digital / analogic contacts....................................................... 35

13.4 Info of software version .............................................................................................. 36

15. ALARM ............................................................................................................................ 36

13.1 Alarm –Electronic control fault table ......................................................................... 36

13.2 Alarm –Frequency conversion board fault table........................................................ 38

16. TROUBLESHOOTING ....................................................................................................... 39

17. APPENDIX 1 –HYDRAULIC SCHEMES ............................................................................. 41

15.1 Hydraulic schemes glossary ........................................................................................ 41

15.2 Central Heating and Cooling ....................................................................................... 41

15.3 Central Heating and Cooling with buffer tank ............................................................ 43

15.4 Central Heating and Cooling with buffer tank + DHW ................................................ 43

15.5 Central Heating and Cooling + DHW ........................................................................... 44

15.6 Domestic hot water..................................................................................................... 45

18. WARRANTY ..................................................................................................................... 45

USER AND INSTALLATION MANUAL

5

1 INFO

This manual is intended as an aid to qualified service personnel for proper installation, operation

and maintenance of the Heat Pump.

Read this manual carefully before attempting to install or operate the Heat Pump. Failure to

follow these instructions may cause a fault of the Heat Pump, resulting in electrical shock, scald

injury and/or property damage.

Installer:

Before leaving the premises, review this manual to be sure the Heat Pump has been installed

correctly.

Start or operate the unit and check that the parameters are within the normal operating range.

2 SAFETY INFORMATION

To prevent the users and others from the harm of this unit, and avoid damage on the unit or

other property, and use the heat pump properly, please read this manual carefully and

understand the following information correctly.

The piping connection and wiring should be installed according to the local legal laws and

regulations as well as the qualified professional.

DANGER

Any process that the supplier believes may pose a danger of personal injury

and/or material damage must be marked with a DANGER SIGN.

As a means of further classifying the hazard, the symbol will be accompanied

by one of the following words:

• DANGER: when the operator and/or people in the vicinity of the equipment

are subject to personal injury.

• ATTENTION: when nearby equipment and/or materials are subject to

material damage.

INFO

All information that the supplier believes can contribute to the best

performance and conservation of the equipment must be marked with the

information sign.

WARNNING

Children must not play with the device.

Cleaning and maintenance must not be carried out by children without

supervision.

This appliance can be used by children aged 8 years and over and by people

with limited physical, sensory or mental capabilities or lack of experience and

knowledge if they are supervised or have received instructions concerning the

use of the appliance in a safe way and understand the risks involved;

USER AND INSTALLATION MANUAL

6

2.1 Danger Info

INSTALLATION:

Description

DANGER

The heat pump must be installed by qualified personals, to avoid improper

installation which can lead to water leakage, electrical shock or fire.

Please make sure that the unit and power connection have good earthing, otherwise

may cause electrical shock.

Unit refrigerant is flammable.

•Carry out brazing or welding only on empty pipes, free from any residual

lubricating oil;

•Do not place flames or other heat sources near pipes that contain

refrigerant;

•Do not operate with an open flame near the unit;

HP RUNNING:

Description

It is prohibited to place fingers, hands or other objects on the fans. Failure to do so

can cause serious injury or equipment destruction.

DANGER

When there is something wrong or strange smell, the power supply needs to be

shut off to stop the unit. Continue to run may cause electrical short or fire.

MAINTENANCE:

Description

DANGER

When the heat pump need to be moved or installed again, please entrust dealer or

qualified person to carry it out. Improper installation will lead to water leakage,

electrical shock, injury or fire.

DANGER

Maintenance or repairs must be carried out by the seller or qualified technician.

Improper intervention could cause water leakage, electric shock, injury or fire.

The user is prohibited from carrying out any intervention at HP. Failure to do so

can cause water leakage, electric shock, serious injury or fire.

USER AND INSTALLATION MANUAL

7

2.2 Warnning Info

INSTALLATION:

Description

DANGER

The unit CANNOT be installed near the flammable gas. Once there is any

leakage of the gas, fire can occur.

Make sure that the basement of the heat pump is strong enough, to avoid

any decline or fall down of the unit.

Make sure that there is circuit breaker for the unit, lack of circuit breaker

can lead to electrical shock or fire.

MAINTENANCE:

Description

PERIGO

Please switch off the power for clean or maintenance.

It is expressly prohibited to make any type of chamfering in the

protection fuses.

Fuses must be replaced by a qualified person.

Do not spray BC with flammable liquids, it may cause fire.

Do not use any cleaning agents containing sand, soda, acid or chloride as

these may damage the surface.

3 GENERAL INFO

3.1 Manufacturer Responsibility

Our products are produced according to the requirements of various European Standards.

Always concerned with the quality and performance of our products, we strive continuously to

improve them. Therefore, we reserve to the right to modify at any time the information described

herein.

As manufacturers we are no longer responsible for the malfunction or even damage of the

equipment when:

•The instructions for use are not respected.

•The installation instructions are not respected.

•Lack of maintenance (if required).

3.2 Installer responsibility

The installer is responsible for proper installation of the equipment and start with its operation.

The installer should note the following notes:

USER AND INSTALLATION MANUAL

8

•Carefully read and follow the instructions of the manuals supplied with the equipment;

•Do the installation in accordance with the standards and requirements given by the

manufacturer;

•Do the initial startup of the equipment and check all control points:

•Explain to the user how to do the installation and how to use the equipment;

•Warn the user of the obligation to make the checking and maintenance of the

equipment when necessary;

•Supply to the user all the documents provided with the equipment (manual and

warranty datasheet).

4 TRANSPORT

The Heat Pump is packed in a cardboard box without a bottom, and is secured to a wood pallet

with plastic strapping.

When the heat pump is transported, please keep the unit stand up, otherwise the inner parts of

the device may be damaged.

The unit should be transported to the final installation site on a wooden pallet, during transport

the heat pump must not be tilted more than 45 (in either direction).

The recommended tools to transport the equipment while it is still on the pallet can be: forklift

or pallet.

When transporting the unit make sure that you lift it only from the bottom and always with the

unit placed on the pallet. Do not move the unit without assistance.

USER AND INSTALLATION MANUAL

9

Description

WARNNING

The unit has been tested and inspected prior to shipment from the

manufacturer for quality assurance. Carefully inspect the equipment

components upon receipt to ensure that the equipment has not been

damaged in transit.

Confirm that all ordered parts have been received as specified and that unit

type, size, and voltage are correct.

5 PRINCIPLE OF OPERATION

Ambient air is drawn in by the fan and passed over the evaporator. The evaporator cools the air,

i.e. it extracts the heat it contains. In the evaporator, the heat removed is transferred to the

working fluid (refrigerant).

With the aid of an electrically driven compressor, the absorbed heat is "pumped" to a higher

temperature level through an increase in pressure and given off to the heating water via the

condenser (heat exchanger).

In so doing, the electrical energy is used to raise the heat of the environment to a higher

temperature level.

Due to the fact that the heat energy extracted from the air is transferred to the heating water,

this type of appliance is referred to as an air to water heat pump.

The air to water heat pump consists of the following main components: Evaporator, fan,

expansion valve, low-noise scroll compressor, condenser and the control unit.

In the case of low ambient temperatures, air humidity may accumulate on the evaporator in the

form of frost, impairing the heat transfer. The evaporator is automatically defrosted by the heat

pump, as required, with the possibility of vapor plumes forming at the air outlet.

6 UNIT OVERVIEW

Display (user interface)

Air outlet (horizontal)

USER AND INSTALLATION MANUAL

10

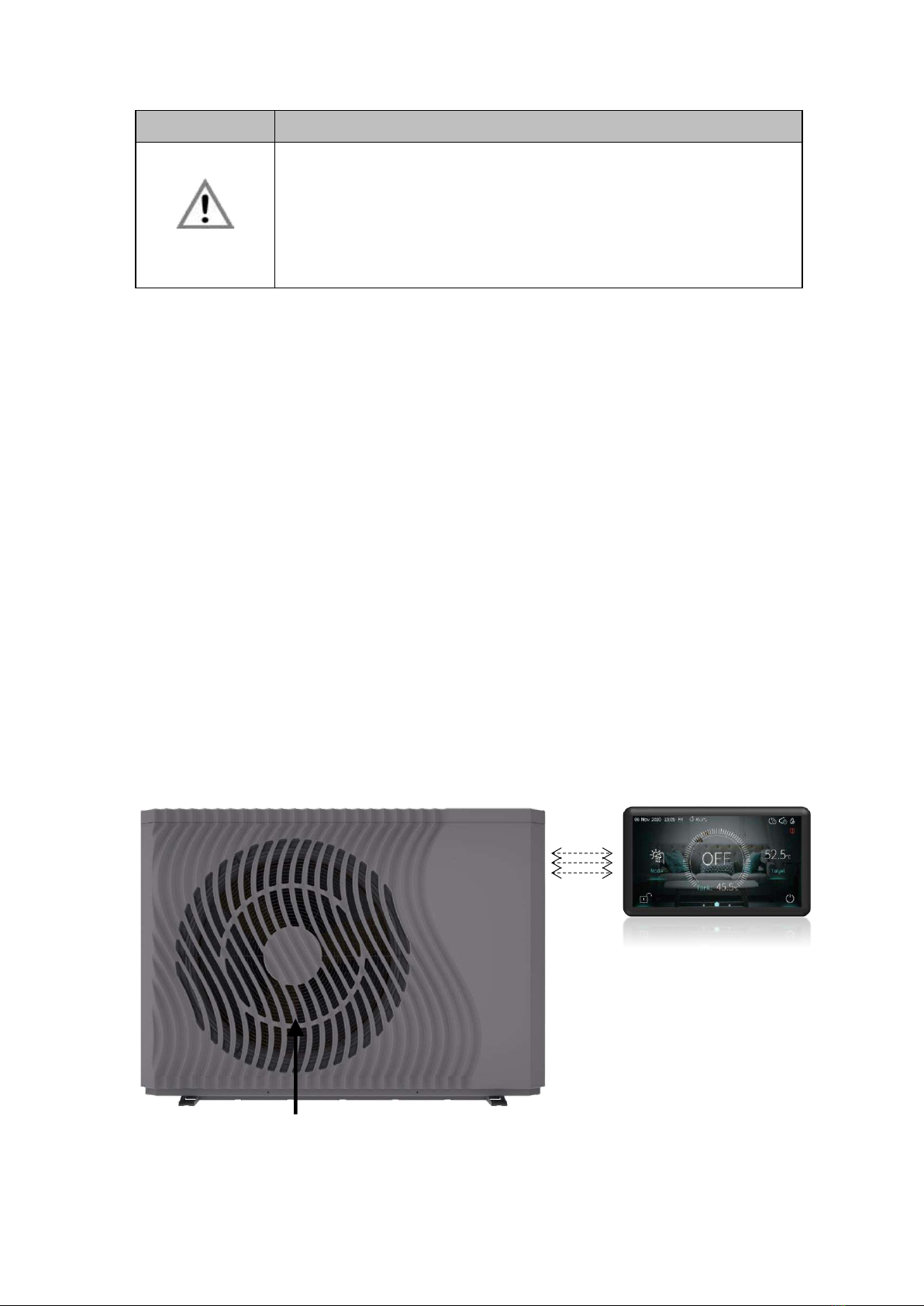

7 UNIT DIMENSIONS

7.1 Aquapura 8HT

~

A

B

C

D

E

F

G

H

Dimension

(mm)

830

1167

445

428

795

166

339

229

I

(Inlet Water)

J

(Outlet Water)

Dimension

(Inches)

1”

1”

J

I

E

USER AND INSTALLATION MANUAL

11

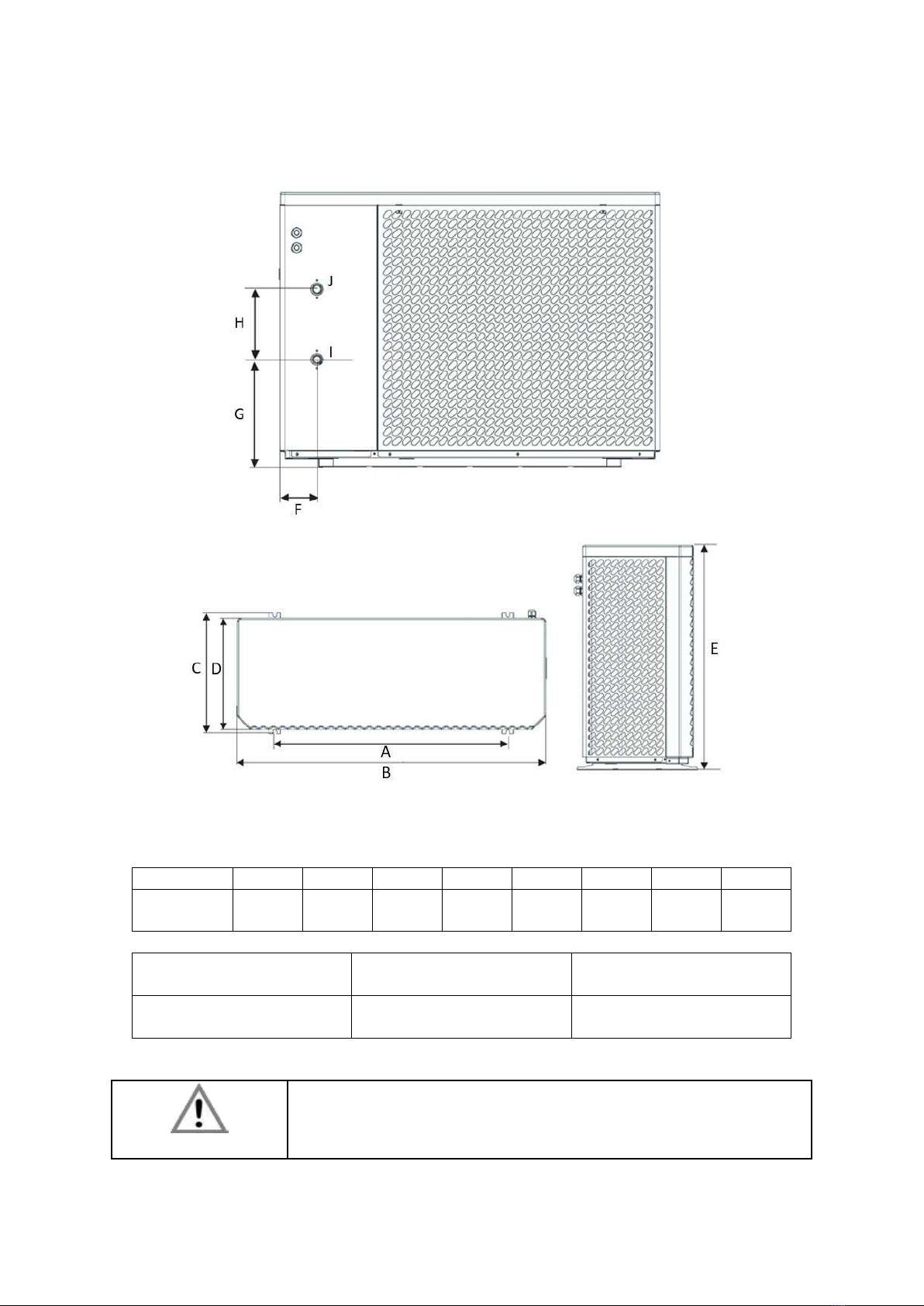

7.2 Aquapura 14HT

A

B

C

D

E

F

G

H

Dimension

(mm)

975

1287

500

458

928

125

363

238

I

(Inlet Water)

J

(Outlet Water)

Dimension

(Inches)

1”

1”

INFO

All the units are represented in millimeters

USER AND INSTALLATION MANUAL

12

8 TECHNICAL INFO

1) Air temperature (DB/WB) 7°C/6°C; Water temperature (inlet/outlet) 30°C/35°C

2) Air temperature (DB/WB) 35°C/ 24°C; Water temperature (inlet/outlet) 12°C/ 7°C

Aquapura 8HT (Inverter P3-10)

Powe supply

/

240V~/50Hz

Refrigerant / Charge

/ Kg

R290 / 0,500 / 0,0015

Heating

Heating capacity range (min/ max)

kW

3,0 ~ 10,3

Electrical power range

kW

0,71 ~ 2,9

Rated thermal power supplied ¹

kW

7,2

Rated electrical power consumption¹

kW

1,5

COP¹

/

4,8

Cooling

Cooling capacity range (min / max)

kW

1,6 ~ 8,51

Electrical power range

kW

0, 78 ~ 2,95

Rated thermal power supplied 2

kW

5,7

Rated electrical power consumption 2

kW

1,64

EER²

/

3,47

Technical specifications

Maximum temperature –heating

ºC

70

Backup electrical heater

/

Não integrado

Maximum operating current

A

13,5

Maximum power consumed

kW

3,0

Number of compressors

/

1

Compressor typology

/

DC Inverter

Water pump

/

Integrada/ 5

Minimum water flow

m3/h

1,0

Internal water pressure drop

kPa

20

Number of fans

/

1

Hydraulic connections (inlet/outlet)

Pol.

1’’ / 1’’

Sound pressure at 1m

dB(A)

43

Sound Power

dB

57

Net weight

Kg

80

Net dimensions (L/ A/ P)

mm

795/ 1167/ 455

Erp / Performance in accordance with EN 14825 –Average climate

Energy efficiency class (35°C)

%

A+++

SCOP

/

5,02

Energy efficiency class (55°C)

A++

SCOP

3,73

USER AND INSTALLATION MANUAL

13

Aquapura 14HT

Aquapura 14HT-T

Powe supply

/

240V~/50Hz

400V~/3P+N/50Hz

Refrigerant / Charge/CO2 Eq.

/ Kg/ton

R290 / 0,850/0,0025

Heating

Heating capacity range (min/ max)

kW

6,18~ 15,75

6,18~ 15,75

Electrical power range

kW

1,45 ~ 4,67

1,45 ~ 4,67

Rated thermal power supplied ¹

kW

11,85

11,85

Rated electrical power consumption¹

kW

2,36

2,36

COP¹

/

5,02

5,02

Cooling

Cooling capacity range (min / max)

kW

3,35 ~ 11,61

3,35 ~ 11,61

Electrical power range

kW

1,52 ~ 4,98

1,52 ~ 4,98

Rated thermal power supplied 2

kW

7,85

7,85

Rated electrical power consumption 2

kW

1,98

1,98

EER²

/

3,96

3,96

Technical specifications

Maximum temperature –heating

ºC

70

70

Backup electrical heater

/

Not provided

Not provided

Maximum operating current

A

24,5

10,5

Maximum power consumed

kW

5,3

5,3

Number of compressors

/

1

1

Compressor typology

/

DC Inverter

DC Inverter

Water pump

/

Integrated

Integrated

Minimum water flow

m3/h

1,6

1,6

Internal water pressure drop

kPa

30

30

Number of fans

/

1

1

Hydraulic connections (inlet/outlet)

Pol.

1’’ / 1’’

1’’ / 1’’

Sound pressure at 1m

dB(A)

42

42

Sound Power

dB

58

58

Net weight

Kg

160

160

Net dimensions (L/ A/ P)

mm

1287/ 928/ 485

1287/ 928/ 485

Erp / Performance in accordance with EN 14825 –Average climate

Energy efficiency class (35°C)

%

A+++

A+++

SCOP

/

5,13

5,13

Energy efficiency class (55°C)

A+++

A+++

SCOP

3,97

3,97

1) Air temperature (DB/WB) 7°C/6°C; Water temperature (inlet/outlet) 30°C/35°C

2) Air temperature (DB/WB) 35°C/ 24°C; Water temperature (inlet/outlet) 12°C/ 7°C

USER AND INSTALLATION MANUAL

14

9 PERFORMANCE

9.1 AQUAPURA 8HT

Heating Capacity

Water temperature (inlet/outlet) 30°C/35°C

COP

Water temperature (inlet/outlet) 30°C/35°C

0

2

4

6

8

10

12

14

-15 -10 -7 -5 0 2 7 10 15 20 25

Heating Capacity kW

Ambient temperature °C

0,00

1,00

2,00

3,00

4,00

5,00

6,00

7,00

-15 -10 -7 -5 02710 15 20 25

COP

Ambient temperature °C

USER AND INSTALLATION MANUAL

15

9.2 AQUAPURA 14HT

Heating capacity

Average climate (DB/WB) 7°C/6°C; Water temperature (inlet/outlet) 30°C/35°C

COP

Average climate (DB/WB) 7°C/6°C; Water temperature (inlet/outlet) 30°C/35°C

0

2

4

6

8

10

12

14

16

18

-15 -12 -8 -5 -2 0 2 5 7 12 15 18 21 25

Heating Capacity kW

Ambient Temperature °C

0

1

2

3

4

5

6

7

8

-15 -12 -8 -5 -2 0 2 5 7 12 15 18 21 25

COP

Ambient Temperature °C

USER AND INSTALLATION MANUAL

16

10 INSTALLATION

10.1 Installation place

Before starting any installation procedure, check that the base of the place where the equipment

will be placed is perfectly level. This prevents the compressor lubricating oil from working outside

the indicated levels.

Look for a place with an even, safe and resistant floor, preferably in concrete, taking into account

the weight of the machine. At a minimum, the concrete base should have a thickness of 150mm

and if possible above ground level (100mm)

During its operation, the heat pump can create water originated by the condensation of the

evaporator, being necessary to prepare the installation site with a drain point to facilitate its

drainage.

Another important point is the minimum distances that the equipment must comply with in

relation to walls, ceilings or any type of obstacles that may impair its performance and make

access difficult, both during installation and in any maintenance operations.

Requirements

A

B

C

D

>500mm

>1500mm

>1000mm

>500mm

The walls and roof of the technical room can be insulated with sound absorption panels if the

noise level of the heat pump is too high.

The feet of the HP must be fixed to the base, preventing the equipment from moving with the

vibrations caused by its normal operation.

10.2 Condensate drainage

In normal operation, water is produced as a result of condensation in the evaporator and defrost

cycles. Prepare a good drainage system to prevent the formation of ice on the floor, thus avoiding

possible falls. The drain tube must have a diameter of min. 50mm, the water discharge must be

carried out to the sewer and must not be exposed in places with frost formation.

USER AND INSTALLATION MANUAL

17

10.3 Hydraulic installation

Take the following points into account when executing the hydraulic circuit:

•Reduce as much as possible the number of bends in the pipes to reduce pressure drops

in the installation;

•Ensure system fittings, dowels, water pumps and valves are designed for full flow through

the facility. Obstructions can impact the unit's performance and the effectiveness of the

central heating system;

•The piping must be free from dirt, if possible, clean the installation;

•Load the installation to check for possible leaks and then isolate the entire installation;

•Place an expansion vessel in the installation, the pressure in the expansion vessel must

be 0.5 bar higher than that of the installation;

•Check if the equipment's flow switch is working properly. Simulate a flow failure by

closing a strainer and check if the controller stops the BC operation and issues an alarm

message;

•The hydraulic connections between the BC and the central heating circuit must be made

with a flexible tube to avoid the transmission of vibrations;

•Before putting the BC into operation, check that the hydraulic circuit is full and properly

bled. If the hydraulic circuits are sectioned, each circuit must be bled, ensuring that it

eliminates all air pockets in the installation;

•Place a thermometer and a pressure gauge at the water inlet and outlet to facilitate

inspection;

•The pressure placed on the hydraulic circuit must be between the following values: Min.

1.5 bar and Max. 2 bar.

warnning

The hydraulic connection should be installed according to the local legal

laws and regulations as well as the qualified professional

10.4 Water filter

The filter allows block any impurities present in the hydraulic circuits. Residue left in the heater

pipes will damage the heat exchangers and cause the heat pumps to malfunction. It is

recommended install the filter in the heater return line, especially if no buffer storage is present.

It is indispensable in order to prevent serious damage to the heat exchanger.

Note 1: The filter must contain a filtering mesh with holes that do not exceed one millimeter.

Note 2; The filter should be kept cleaned and inspected periodically to maintain your condition,

cleanliness and ensuring the proper functioning of Heat pump

USER AND INSTALLATION MANUAL

18

10.5 Circuit water quality

The composition and quality of the water in the system has a direct effect on the performance of

the entire system and the lifetime of the heat pump.

For the initial charging and backfill of the system, usually normal tap water with a pH value of 7-

8 can be used as long as the water is not highly corrosive (chloride content > 150 mg/l) or hard

(>14°dH; degree of hardness IV). A drinking water analysis can be requested from the local water

supply company.

If the specific system volume is greater than 25 liters/kW heating output (e.g. through the

installation of a hot water buffer storage), then the maximum permissible calcium carbonate

input from the charging and backfilling water should be calculated in accordance with the VDI

guideline 2035. In some cases the charging water has to be softened.

Criteria

Max. value

Effects of non-compliance

PH - Wert

7-8

Danger of corrosion in boiler parts and heating

system

Degree of

hardness

< 14dH

- Increased lime deposits

- Reduced lifetime of boiler

Chloride content

< 150mg/l

Corrosion of alloyed materials

10.6 Glycol (%)

Glycol is used as an effective antifreeze in cooling and heating applications.

The percentage of glycol to be added to the hydraulic circuit is calculated as a function of the

ambient air temperature, considering for this purpose -5 °C. Using this value as a reference, the

installer must add 20% Ethylene Glycol to the hydraulic circuit.

USER AND INSTALLATION MANUAL

19

10.7 Temperature probes info

11 ELECTRICAL REQUIREMENTS

11.1 Main specifications

Description

WARNNING

•The installation of the electrical network must be carried out in

accordance with local regulations in force and by a qualified

professional.

•The installer must not make any kind of electrical changes to

the equipment.

Before making any type of connection, check that the supply voltage matches the characteristics

of the appliance.

The equipment must be connected directly to the general electrical distribution board. Dedicated

protection systems must be installed for the BC (circuit breaker and differential), connecting the

equipment together with others can cause voltage drops, impairing the equipment's operation.

Pay attention to the losses caused by the device's power cables, the smaller the cable section

area, the smaller the recommended maximum length. Make a note of the reference values for

the electrical consumption of the equipment and the distance from it to the power supply and

consult an electrician for advice on the diameter and type of cable to be used.

USER AND INSTALLATION MANUAL

20

To make the electrical connection, open the side panel and connect the general power cable in

the indicated places.

Description

WARNNING

•The equipment must be earthed in accordance with the

relevant regulations.

•The manufacturer is not responsible for any damage caused by

the equipment's lack of earth connection or by an anomaly in

the electrical supply.

11.2 Electrical main spcifications/ protection devices

Model

Power source

Max. current

* cable section

Aquapura 8HT

240V/50Hz

14A

2,5mm2

Aquapura HT 14

240V~ /50Hz

25 A

4 mm²

Aquapura HT 14 T

400V~/ 50Hz

11 A

2,5 mm2

The section of the wires above was selected in accordance with current regulations, considering

a cable distance of 10 meters.

NOTE: Follow local regulations when selecting ground wires and circuit breakers.

Select protection systems according to the following table:

Model

Power source

Max. current

CB

ELB

(nº pólos/A/mA)

Auapura 8HT

240V~/50Hz

14A

20A

1F+N/20/30

Aquapura HT 14

240V~/50Hz

25 A

32 A

1F+N/ 32/ 30

Aquapura HT 14 T

400V~/ 50Hz

11A

16 A

3F+N / 16/ 30

CB - Circuit Breaker; ELB –Differential

11.3 Connection between external unit and display (user interface)

The equipment is supplied with a 12 meter cable to interconnect the outdoor unit with the

display.

If the supplied cable is not long enough and the distance between the outdoor unit and the

display is less than 50 meters, we recommend installing a straight-through cable.

The cable must have at least 4 conductors with a section of 0,5mm and protected with a mesh

to avoid interference.

This manual suits for next models

1

Table of contents

Other Energie Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual