Energie Combi 6 Use and care manual

www.energie.pt 1

Assembly and User Manual

Thermodynamic Solar System

Combi [6 | 12 | 16]

Combi 12 HT

Directives

2006/95/CE

Review: 1

Version: 0

Date: 06/01/2015

CENTRAL HEATING +DOMESTIC HOT WATER

EN

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

2www.energie.pt

INDEX

1. Introduction ..............................................................................................................................4

2. General....................................................................................................................................4

2.1. Symbology.............................................................................................................................4

2.2. Manufacturer’s Liability............................................................................................................4

2.3. Installer’s Liability ...................................................................................................................4

2.4. Safety Information ..................................................................................................................5

3. Indications................................................................................................................................5

3.1. Unit inspection ........................................................................................................................5

3.2. Lodging a complaint ................................................................................................................5

3.3. Packaging ..............................................................................................................................5

3.4. Transporting the unit................................................................................................................6

3.5. Unit storage ...........................................................................................................................6

4. Comby Sistem..........................................................................................................................6

4.1. Operation ...............................................................................................................................6

4.2. Technical Specifications..........................................................................................................7

4.3. Components ..........................................................................................................................8

4.3.1. Combi Block ..............................................................................................................................8

4.3.2. Thermodynamic solar panels ....................................................................................................9

5. Installation................................................................................................................................9

5.1. Installation Tools required........................................................................................................9

5.2. Thermodynamic Solar Panel....................................................................................................9

5.2.1. Panel orientation .......................................................................................................................9

5.2.2. Inclination ................................................................................................................................10

5.2.3. Distance ..................................................................................................................................10

5.2.4. Unevenness ............................................................................................................................11

5.2.5. Standard Gap of the Panels ....................................................................................................11

5.2.6. Direction of the Panels ............................................................................................................12

5.2.7. Relative position of the panels.................................................................................................13

5.2.8. Fixation....................................................................................................................................14

5.2.9. Liquid Distributor and Collector, placement and connection....................................................14

5.3. Combi Block.........................................................................................................................16

5.3.1. Installation site.........................................................................................................................16

5.3.2. Connections at the Combi Block..............................................................................................17

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 3

5.3.3. Removing the covers...............................................................................................................18

5.3.4. Electrical connections..............................................................................................................19

5.3.5. Implementation of piping connections (Welds) ........................................................................20

5.3.6. Leak test..................................................................................................................................21

5.3.7. Vacuum ...................................................................................................................................21

5.3.8. Refrigerant R-407C (except Combi 12 HT) .............................................................................22

5.3.9. Fluid Charge............................................................................................................................22

5.4. Hydraulic Connections ..........................................................................................................23

5.5. Temperature Probe...............................................................................................................25

6. Control Panel..........................................................................................................................25

7. Error Messages ......................................................................................................................27

8. Annexes A (Wiring Diagram)....................................................................................................28

8.1. Combi System 220-240 Vac / 1+N / 50 Hz ..............................................................................28

8.2. Combi System 400-420 Vac / 3+N / 50 Hz ..............................................................................29

8.3. Glossary ..............................................................................................................................30

9. Annexes B - Installation...........................................................................................................31

9.1. Plan.................................................................................................................................................31

9.2. Glossary..........................................................................................................................................32

10. Warranty ................................................................................................................................33

Revisão 1

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

4www.energie.pt

1. INTRODUCTION

Esteemed Client,

Thank you and congratulations for buying an ENERGIE product, the upshot of several years of experience in the

sector.

We have built products based on specific studies, top quality materials and highly advanced technologies.

Our company’s serious approach ensures you all the support you’ll need from the sizing stage, to installation and

assistance.

For the best use of this product we would ask you to read this instructions manual carefully in which you will find all

the indications, information and tips you need to enjoy all the advantages that this appliance has to offer and by

following its indications and regulations in force you will be assured of optimum operation and a perfect performance.

The information contained in this document is subject to any modifications deemed necessary to enhance the

product without any prior notice.

2. GENERAL

2.1. Symbology

The notes/symbols shown can be found throughout the manual. They are intended to indicate and draw attention

to certain situations/indications. In this way we seek to ensure any possible problems for the installer or user and

assure smooth equipment performance.

Warning / Important Information.

Indicates any potentially dangerous situation which may result in physical injury or material damage.

2.2. Manufacturer’s Liability

Our products are manufactured in line with the requirements of the various European directives.

With a constant concern for the quality and performance of our products, we make a continuous effort to improve

them. This is why we reserve the right to modify the information described in this document at any time.

As the manufacturers we cease to be liable for the malfunctioning or even breakdown of the equipment whenever:

✓The usage instructions are not respected.

✓The installation instructions are not respected.

✓Lack of maintenance (where required).

2.3. Installer’s Liability

The installer is liable for proper equipment installation and for putting into operation.

The installer must bear in mind the following notes:

✓Read and closely follow the instructions of the manuals supplied with the appliance.

✓Carry out installation in accordance with standards in force and required by the manufacturer.

✓Carry out the initial start-up of the equipment and verify all the checkpoints.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 5

✓Explain the installation to the user as well as how he/she should use the equipment.

✓Notify the user of its obligation, where required, as regards equipment maintenance and inspection

operations.

✓Obligation to provide the user with all the documentation supplied with the equipment (manuals and

warranty certificate).

2.4. Safety Information

With a view to protecting the physical integrity of the operator as well as of the equipment, it is vital that all the safety

information noted in this manual should be taken into account.

This appliance is not envisaged for use by people (including children) whose physical, sensorial or mental

capabilities are reduced or by people without any experience or knowledge, unless they have been given

supervision or instructions about use of the appliance by someone responsible for its safety.

Children must be supervised to ensure that they do not play with the appliance.

3. INDICATIONS

This manual accompanies all the “Combi Systems”and contains important instructions which must be followed

during installation.

3.1. Unit inspection

The unit was tested and inspected for quality assurance before its dispatch. Carefully inspect the equipment

components (Combi, Solar Panels etc.) as soon as you receive it in order to check that all the equipment is intact.

Confirm whether all the parts requested have been received in accordance with that which has been specified and

whether the type, size and voltage of the unit are correct.

3.2. Lodging a complaint

If damage is identified in the inspection carried out at the time of reception of the unit, describe the damage in the

transport reception document. Any transport complaint must be submitted at the act of delivery.

If you are in any doubt, get in touch with ENERGIE to obtain information about how to lodge a complaint with the

haulage company.

Should damage occur during transport, do not install the unit. Keep all packaging for inspection of the

hauler.

3.3. Packaging

The Combi System is packed in a bottomless cardboard box and is secured to a treated pinewood pallet using

plastic tape.

The thermodynamic solar panels are packed in cardboard boxes unless otherwise provided for.

The dimensions of the boxes, pallets and respective weights for the Combi System are shown in table below.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

6www.energie.pt

Model

Box (H*L*P mm)

Pallet (H*L*P mm)

Weight (Kg)

Combi 6

2020x750x1000

140x750x1000

215

Combi 12

227

Combi 16

232

Combi HT 12

232

3.4. Transporting the unit

The tools recommended for transporting the unit whilst it is still in the pallet may be: forklift truck or pallet rack.

Where possible, the latter must move/transport the unit to the final destination (point of installation).

pallets truck lift truck

When transporting the unit, make sure that you only lift it by its lower part and always with the unit placed on the

pallet. Do not try to move the unit without help.

Transportation and handling must always be done on vertical.

It is vital to follow all the warnings and recommendations stated on the packaging boxes.

3.5. Unit storage

If the unit is not installed immediately, keep it in a safe place protected from the weather in such a way that it does

not suffer any kind of damage which may hinder its correct operation. Poor installation of the unit may give rise to

the cancellation of the manufacturer’s warranty.

4. COMBY SISTEM

4.1. Operation

Combi Systems are items of equipment intended for heating and domestic hot water.

The thermodynamic panel is placed on the exterior and it ensures the capturing of energy as regards:

✓Direct and diffuse radiation

✓Outside air by natural convection.

✓Wind effect (almost always to be found).

✓Rainwater

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 7

The temperature difference brought about by the previous factors ensures that the fluid will change to vapour state

inside the panel.

The compressor aspirates the refrigerant fluid (vapour) of the panel, raising the pressure and temperature thereof,

which is transmitted to the water circuit by way of a heat exchanger.

The Exchanger is located inside the cabinet (Combi Block), providing heat to the water which is inside.

When the refrigerant fluid reaches the expansion valve it is at its liquid phase and the load loss owing to

strangulation reduces the pressure and the fluid is re-prepared for entry into the panels.

4.2. Technical Specifications

The ENERGIE Combi Systems are presented on the market in a range of 4 models in accordance with the table

below:

Un.

Combi 6

Combi 12

Combi 16

Combi 12HT

Thermodynamic

Solar Panels

Quantity

6

12

16

12

Weight

kg

48

96

128

96

Exposed Capture Surface

m²

9,6

19,2

26,6

19,2

Refrigerant

Type

R 407C

R 407C

R 407C

R 134a

Amount (pre charge)

kg

1,6

2

2,5

2

Test Pressure

bar

30

LP Switch Open Value

bar

1

0,3

LP Switch Close Value

bar

2

1,7

HP Switch Open Value

bar

28

21

HP Switch Close Value

bar

23

16,0

Electrical Data

Single Phase / Three Phase

1P+N

3P+N

1P+N

3P+N

1P+N

3P+N

Power Supply

220-240V~

50Hz

380-420V~

50Hz

220-240V~

50Hz

380-420V~

50Hz

220-240V~

50Hz

380-420V~

50Hz

Rated Power Consumption*

kw

1,2 - 2,2

1,9 - 3,1

3,2 - 5,2

1,7 - 3,0

Auxiliary Heater 1

kw

4,5

4,5

6

6

Auxiliary Heater 2 (DHW)

kw

1,5

1,5

1,5

1,5

Output Capacity

kw

4,9 - 9,7

9,2 - 16,7

14,2 - 24,2

7,8 - 15,8

Domestic Hot Water

Material

Stainless Steel

Capacity

l

200

Safety Thermostat Activ.

°C

80

Cathodic Protection

Magnesium Anode

Maximum Running

Pressure

bar

7

Maximum Running

Temperature

°C

80 (safety thermostat)

Expansion Vessel

l

5

Inlet / Outlet Connections

inch

3/4"

Heating

Heating Pipe Diameter

mm

28

Pressure Safety Valve

bar

7

Expansion Vessel

l

10 (installations<120l)

Nominal Flow

m³/h

0,7

1,1

1,5

1

*Rated Power Consumption Without Auxiliary Heater 1 and 2

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

8www.energie.pt

4.3. Components

4.3.1. Combi Block

IMPORTANT

* The Combi Block has one 10 l expansion vessel sized for heating line with ≤ 120 l (7 bar safety valve and

pre-charge circuit of 1,5bar). If the heating installation has more than 120 l, a new expansion vessel

should be sized.

** It’s mandatory to install the filter (supplied with the system) on the heating line.

*** It’s mandatory to install the safety valve (supplied with the system) on the heating line.

Symbol

Meaning

[A]

Aspiration Line

[B]

Liquid Line

[C]

DHW Outlet

[D]

DHW Inlet

[E]

Heating Inlet

[F]

Heating Outlet

[G]

Tank electric

heater

[H]

Coil Outlet

[I]

Coil Inlet

[J]

Mg anode

Compressor

Symbol

Meaning

Thermostatic

expansion valve

Dry filter

Liquid receiver

Plate heat exchanger

Drain valve

Circulator pump

Symbol

Meaning

Flow switch

Expansion vessel 5 l

Expansion vessel 10 l*

Cut-off valve

Air vent

Three way valve

Safety valve ***

Line electric heater

“y” filter**

G

D

C

G

Cut of upper

view from tank

J

H

S4

J

I

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 9

4.3.2. Thermodynamic solar panels

The solar panel is a plate made of twin-channel pressed aluminium with post-pressing anodic oxidation. The panel

has the dimensions 2000 mm x 800 mm x 5 mm and it has a fluid flow entry and exit in a copper-aluminium pipe

with an interior diameter of ¼’’

5. INSTALLATION

5.1. Installation Tools required

To ensure correct assembly of the equipment, the installing technician must be endowed with the following tools:

✓Manometers (low and high pressure).

✓Vacuum Pump.

✓Refrigerant gas loading station or scales.

✓Pipe cutter.

✓Adjustable spanner.

✓Screwdriver.

✓Measuring tape.

✓Tube bender.

✓Tube expander.

✓Refrigerant gas cylinder.

✓Rotoblock wrench.

✓Set of hydrant keys or ratchet.

✓Blowpipe (welding).

✓Copper rods with 40% of Silver.

✓Descaler.

To verify the operationality of the equipment the installing technician must have at its disposal:

✓Multimeter.

✓Appliance for measuring temperature.

5.2. Thermodynamic Solar Panel

5.2.1. Panel orientation

The panels must be at ventilated places and preferably not be exposed to any kind of shade.

ENERGIE panels must preferably be oriented in a southerly direction (at north hemisphere), but they may also

have an orientation towards Northeast and Northwest.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

10 www.energie.pt

5.2.2. Inclination

The inclination angle of the sun rays with regard to the horizontal varies in accordance with the seasons of the year.

In Winter, at the Zenith, the solar rays form an angle of 20º to 40º with regard to the horizon. In Summer the angle

is between 60º and 80º.

To get the most out of the solar rays on the panel, it’s best to choose an inclination between 45º and 90º.

The panels inclination should never be less then 10°.

However, you may install the panels with another inclination in certain situations.

5.2.3. Distance

The maximum distance between the panels and the Combi Block depends on certain factors such as the

equipment model, the no. of curves, the piping diameter etc.

However, we would recommend that the distance should not exceed the 20m.

For Installations with a distance greater than those indicated must contact the Technical Dept.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 11

5.2.4. Unevenness

Under normal circumstances the total maximum gradient must always be less than 15 mts. However, there are

situations where it is not possible to respect these distances, in these cases you must consult our technical

department.

The aspiration piping must rise above the level of the panels, in the same way as the distribution shaft in order to

avoid the rapid siphon effect of the liquid at the time of the stoppage of the compressor.

5.2.5. Standard Gap of the Panels

The position of the panels and the choice of the sides of the connections must be carried out so as to limit the length

of the piping and simplify the connections.

The panel gap is determined so as to facilitate its placement and the implementation of the connections between

piping, though due consideration must be given to:

✓Minimum space between the panels on the connections’ side: 200mm (ideal space: 500mm).

✓Space between the panels on the side opposite the connections: they should preferably not be

completely stuck together (preferably> 20mm)

Key:

A

Solar Panels

B

Distributor

C

Combi Block

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

12 www.energie.pt

5.2.6. Direction of the Panels

The direction of the panels is defined by the outlets of the tubes pointing downwards and by the view of the front

part of the panel. They must always be placed with the largest length horizontally and the connections pointing

downwards. In this context two panel models are manufactured:

- Left-hand panel

A –Liquid Line (Inlet)

B –Vapour Line (Outlet)

Left: A left-hand panel is installed on the right (front view). To this end, it has connections on the left side.

The Solar panel must not be installed on the vertical in accordance with the representation indicated

above with a red cross.

- Right-hand Panel

A - Liquid Line (Inlet)

B - Vapour Line (Outlet)

Right: A right-hand panel is installed on the left-hand side (front view). To this end, it has connections on right-

hand side.

The Solar panel must not be installed on the vertical in accordance with the representation indicated

above with a red cross.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 13

5.2.7. Relative position of the panels

The relative Position of the panels depends on the system to be installed, the availability of the installation area, the

architectonic integration etc.

In the diagrams below some of the possible positioning layouts of the panels are represented. However, you may

consult in the annex complementary information about the position of the panels in the installation.

Combi 6

Combi 12

In the event of some other positioning of the panels, you must contact our Technical Department.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

14 www.energie.pt

5.2.8. Fixation

The affixation of panels depends on the installation site and the method and type of affixation is the installer’s

decision. However, you must bear various factors in mind (described above such as, for example, distance,

orientation…).

For a correct affixation of the panels, as regards the physical part of the affixation supports they must have a sturdy

structure in line with the circumstances of the site. Each panel must be secured at 6 points (as a minimum).

The image below illustrates an example of the affixation used:

The affixation of the panels is ensured by aluminium supports*. The support is bent in “L” form with two M8 through

holes. The support base is secured to the roof (where applicable) using an M6 screw and a plastic plug or a female

thread (depending on the situation).

The other support rib is secured to the panel by way of galvanised M6 screws to prevent corrosion situations.

*The aluminium supports are not supplied with this product.

The Panels must have a minimum gap of 50cm (from the previous and/or subsequent panel)

5.2.9. Liquid Distributor and Collector, placement and connection

To ensure that the fluid reach the panels in homogeneous fashion, a liquid distributor must be installed. This

same distributor includes as many distribution tubes as there are panels in the installation.

The distributor is placed between the panels. The connection tubes to the panels must have strictly the same length

and their ends connect directly to the panels.

The distributor and the collector may be placed before the installation of the panels for the sake of convenience

(obstruction, passage of distribution tubes behind the panels).

Only remove the pipe protection cover at the time of connection to the power and aspiration shafts with a view to

avoiding the penetration of impurities.

Install the distributor (s) vertically, face downwards (never horizontally!), thereby ensuring that the fluid reaches

the panels in homogeneous fashion.

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 15

If a shaft is too long for the length required, it must be rolled up and never cut.

If it is wished to shorten or elongate, this operation must be carried out on all the shafts with the same diameter.

All ø ¼” shafts must be welded to the lower connections of the panels (liquid inlet). The shafts of the main distributor

must be welded to the secondary distributors.

✓A –Main Liquid Line

✓B –Main Liquid Line viewed from above.

It is vital that the power shafts (Ø 1/4’’) should have the same length and the same is true of the main

distributor shafts.

Depending on the Thermodynamic Block model and the position of the panels, one or more aspiration collectors

must be carried out.

The aspiration which allows the collection of the refrigerant fluid in its gaseous state must regroup all the panel

aspiration outlets (∅3/8’’) as far as the collector. This is shown in the figure below.

✓B –Main Aspiration Line.

All the shafts must be welded to the upper panel outlets.

It is important for the connections at the collectors to be as simple as possible, respecting the instructions in the

event of any unevenness.

It is essential for the copper tubes used to be refrigerant type CUDHP according to the ISO1337 and/or according

to EN12735, both on the aspiration line and on the liquid line (power).

It is also recommended for all the piping to have good quality thermal insulation in order to avoid any possible

condensation.

The piping diameters vary with the system model as can be seen in the table below.

Model

Aspiration Line

Liquid Line

Combi 6

3/4’’

1/2’’

Combi 12

7/8’’

1/2’’

Combi 16

7/8’’

3/4’’

Combi 12 HT

7/8’’

1/2’’

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

16 www.energie.pt

5.3. Combi Block

5.3.1. Installation site

The choice of site where the Combi Block is placed is very important and must be carried out bearing mind a

certain number of criteria such as:

✓Easy access and sufficient space to move the equipment as far as the installation site

✓Load capacity of the ground (check the weight of the equipment)

✓Equipment placed on a even base

✓Point for hydraulic and electrical connections

✓Avoid the possibility of vibration transmission

✓Place anti-vibration supports between the appliance and the ground

✓Position of the piping from the panels

✓Protected from bad weather such as garages, cellars, attics etc

✓Allow any possible assistance intervention

To install the Combi Block, is recommended that the site of installation allow the distances shown on the next

scheme:

The installation of the Combi Block near bedrooms should be avoided owing to the possible

transmission of vibrations and noise.

If the Combi Block is placed in the attic special care must be taken as regards the vibrations produced

under the wooden construction. Also provide for the placement of a tray under the appliance in

accordance with legislation to collect any water in the event of an installation rupture.

Never grab nor handle the Combi Block by the refrigerant or hydraulic connections.

300 mm

300 mm

300 mm

600 mm

150 mm

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 17

5.3.2. Connections at the Combi Block

The back of the Combi Block has the various connections in accordance with the designation set out below.

The Combi Block connections to the panels are supplied with two hermetic valves valves to avoid the penetration

of impurities and humidity in the refrigerant circuit wich are already installed according the picture bellow.

Key:

1

Inlet from panels

2

Outlet to panels

3

DHW Inlet

4

DHW Outlet

5

Heating inlet (to the block)

6

Heating outlet (from the block)

7

Electrical Connections

2

3

5

4

6

7

1

Location of two

hermetic valves

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

18 www.energie.pt

5.3.3. Removing the covers

1. Unscrew M6 screws on the top of the unit;

2. Move up and pull the front panel;

3. Unscrew M6 screws on the lateral as promenor X as picture bellow;

4. Pull the lateral panel.

X

X

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

www.energie.pt 19

5.3.4. Electrical connections

After the placement of the Combi Block it’s is necessary to connect the power supply cable and the two

thermostats (ambiente and external) to the elctric box of the Combi Block.

The power supply cable and the two thermostats should pass on the three electric gland placed on the back of the

Combi Block.

The power supply cable, the ambiente thermostat (TA) and the external thermostat (TEXT), should enter in the

bottom of electric switchboard.

Ambient Thermostat

External Thermostat

Electric Gland

ASSEMBLY AND USER MANUAL

Combi [6 | 12 | 16] & Combi 12 HT

20 www.energie.pt

5.3.5. Implementation of piping connections (Welds)

Once the Panels are installed and the Combi Block has been finally placed at the site, now the following types of

piping must be placed:

✓Liquid (Outward to panels).

✓Aspiration (Return from panels).

Before making the aforementioned connections, it is best to carry out the connections of the panel tubes to the:

✓Liquid distributor (s).

✓Aspiration collector (s)

The implementation of the connections is one of the most delicate points of the whole installation and it is extremely

important that the welds are carried out in line with all the basic criteria of a quality welding process.

The recommended welding type for implementing the piping connection is oxy-acetylene welding

(oxygen/acetylene). Other types of gas may also be used such as propane, for example.

The most delicate welds and which require the greatest care are carried out at the panels. It is necessary to place

a damp fabric strip which must envelop the “Thermoretractable Joint” so that it is fuly protected from high

temperatures caused by the blowlamp flame as shown in the figure below.

The copper is heated until it goes dark red at which point welding must begin. Bring the slightly inclined welding rod

closer without exposing it to the flame. As a general rule, the quantity to be applied is the same as one and a half

times the tube diameter. As soon as the alloy expands, stop heating and let it cool.

As soon as the weld is in a solid state, you must cool the whole area around the weld immediately with a damp

cloth.

Welds alongside the Combi Block must also be carried out with due care so as not to burn any component of the

Combi Block.

You should weld the aspiration and the liquid pipe to the corresponding pipping, at the back of the Combi Block. Be

carefull with the welding process.

Key:

A

Thermoretractable Joint

B

Connection and Weld

C

Aspiration Line (panel outlet)

D

Liquid Line (panel inlet)

This manual suits for next models

3

Table of contents

Other Energie Water System manuals

Popular Water System manuals by other brands

PondMAX

PondMAX PM2600 instruction manual

3M

3M Aqua-Pure AP510 Installation and operating instructions

DAB

DAB EVOSTA2 OEM Series Instruction for installation and maintenance

Graf

Graf one2clean Service instructions

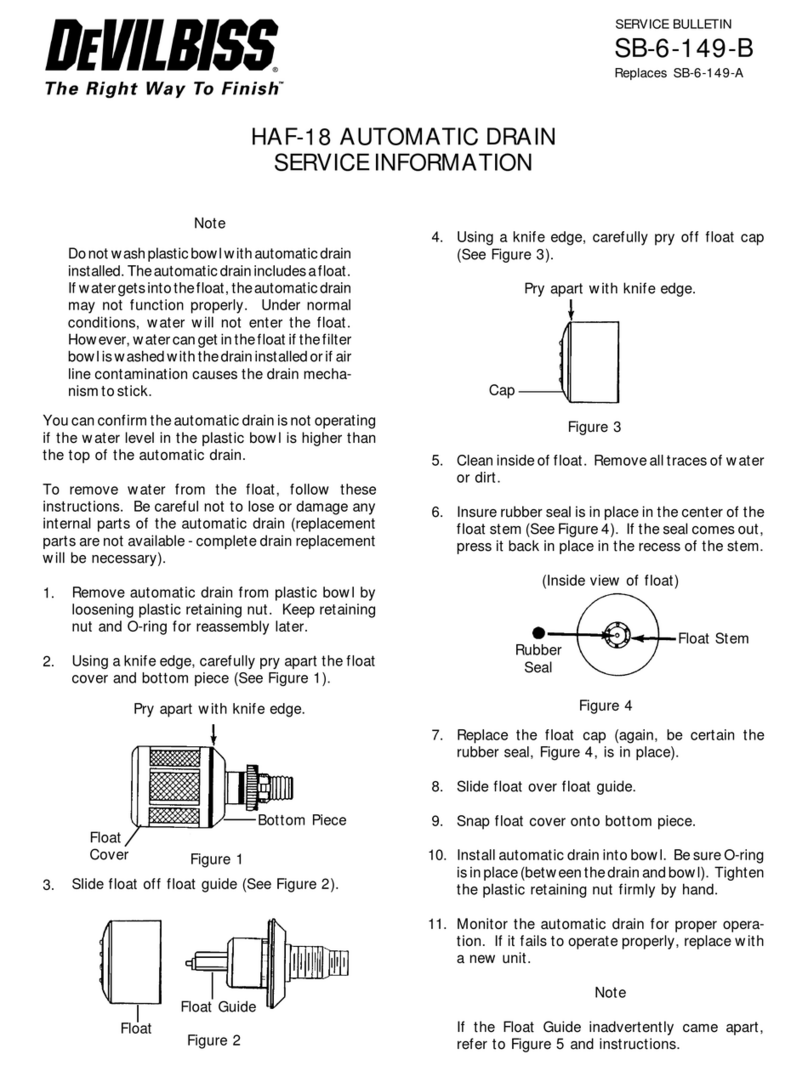

DeVilbiss

DeVilbiss HAF-18 Service information

Everpure

Everpure ENVI-RO Installation and operation guide