2

• Never attempt to pry the puller by inserting tools or other

objects between the jaws. This may cause spindle damage.

• Use hydraulic pressure gauges to verify proper operating

pressure in the hydraulic system. Do not exceed maximum

pressure limits of the lowest rated component in your

system. Always use high pressure hoses and fittings.

• It is impossible to predict the exact force needed for every

pulling situation. The amount of press fit and force of removal

can vary greatly between jobs. Set-up requirements along

with the size, shape and condition of the parts being pulled

are variables which must be considered. Study each pulling

application before you select your puller.

• Do not overload equipment. Use the correct size puller for

your application. If you have applied maximum force, and the

part still will not move, then use a larger capacity puller. Use

of a sledge hammer to loosen parts is not recommended.

• Do not use puller if threads on spindle, threaded collar or

hydraulic cylinder are damaged or worn. Do not use puller if

spindle is bent.

• Do not over-extend the hydraulic cylinder. Do not operate

the cylinder beyond the limits of its rated stroke.

• Align puller grip jaws as required. Be sure the setup is rigid

and that puller is square with the work. Apply force gradually.

• Never use a puller that is damaged, altered or in need of

repair.

• Always be sure that the spindle is loosened and hydraulic

pressure is completely relieved before performing any puller

adjustment or repair procedures. Never service the puller

while it is installed and under tension.

• Always read, understand and follow all safety precautions

and instructions, including those that are contained within

the procedures of this manual.

2.3 Additional Hydraulic Safety Precautions

WARNING

Failure to observe and comply with the following

precautions could result in death or serious personal

injury. Property damage could also occur.

• Do not remove or disable the pump relief valve. Never set

the relief valve to a higher pressure than the maximum rated

pressure of the pump.

• The puller hydraulic cylinder is designed for a maximum

pressure of 10,150 psi [700 bar]. Do not connect a pump

with a higher pressure rating to the cylinder.

• To avoid personal injury and equipment damage, make sure

all hydraulic components are rated for at least 10,150 psi

[700 bar] working pressure.

• The system operating pressure must not exceed the

pressure rating of the lowest rated component in the system.

Install pressure gauge(s) in the system to monitor operating

pressure. It is your window to see what is happening in the

system.

• Make sure that all system components are protected from

external sources of damage, such as excessive heat,

flame, moving machine parts, sharp edges and corrosive

chemicals.

• Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin. If oil is injected under the

skin, seek medical attention immediately.

• Always visually inspect the puller and puller hydraulic

system before placing it into operation. If any problems are

found, do not use the puller. Have the equipment repaired

and tested before it is returned to service.

• Never use a hydraulic cylinder that is leaking oil. Do not use

a cylinder that is damaged, altered or in need of repair.

• Do not loosen plugs, relief valves or any other hydraulic

components unless hydraulic pressure is completely

relieved.

• Avoid damaging hydraulic hose. Avoid sharp bends and

kinks when routing hydraulic hoses. Using a bent or kinked

hose will cause severe back-pressure. Sharp bends and

kinks will internally damage the hose, leading to premature

hose failure.

• Do not drop heavy objects on hose. A sharp impact may

cause internal damage to hose wire strands. Applying

pressure to a damaged hose may cause it to rupture.

• Always read, understand and follow all safety precautions

and instructions, including those that are contained within

the procedures of this manual.

CAUTION

Failure to observe and comply with the following

precautions could result in minor or moderate personal

injury. Property damage could also occur.

• Do not lift hydraulic equipment by the hoses or swivel

couplers. Use the carrying handle or strap.

• Keep hydraulic equipment away from flames and heat.

Excessive heat will soften packings and seals, resulting in

fluid leaks. Heat also weakens hose materials and packings.

For optimum performance, do not expose equipment to

temperatures of 150˚F [65˚C] or higher. Protect all hydraulic

equipment from weld spatter.

• Immediately replace worn or damaged parts with genuine

Enerpac parts. Enerpac parts are designed to fit properly

and to withstand high loads. Non-Enerpac parts may break

or cause the product to malfunction.

• Hydraulic equipment must only be serviced by a qualified

hydraulic technician. For repair service, contact the Enerpac

Authorized Service Center in your area.

• To help ensure proper operation and best performance, use

of Enerpac oil is strongly recommended.

3.0 CONFORMANCE TO NATIONAL AND

INTERNATIONAL STANDARDS

Enerpac declares that this product has been tested

and conforms to applicable standards and is

compatible with all CE Requirements. A copy of an

EU Declaration is enclosed with each shipment of this product.

2

3

4

5

7

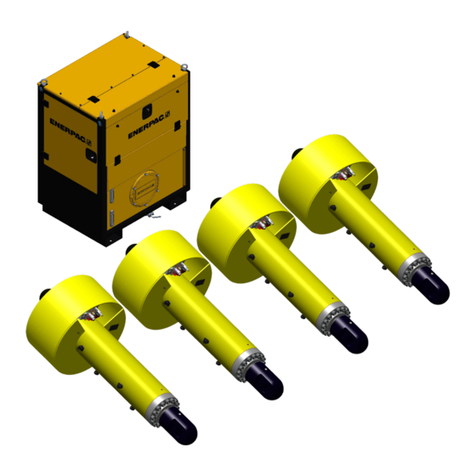

Figure 1, Features and Major Components

Key:

1. Spindle

2. Handle

3. Upper Body

4. Lower Body

5. Jaw

6. Cylinder

7. Point Protector