10

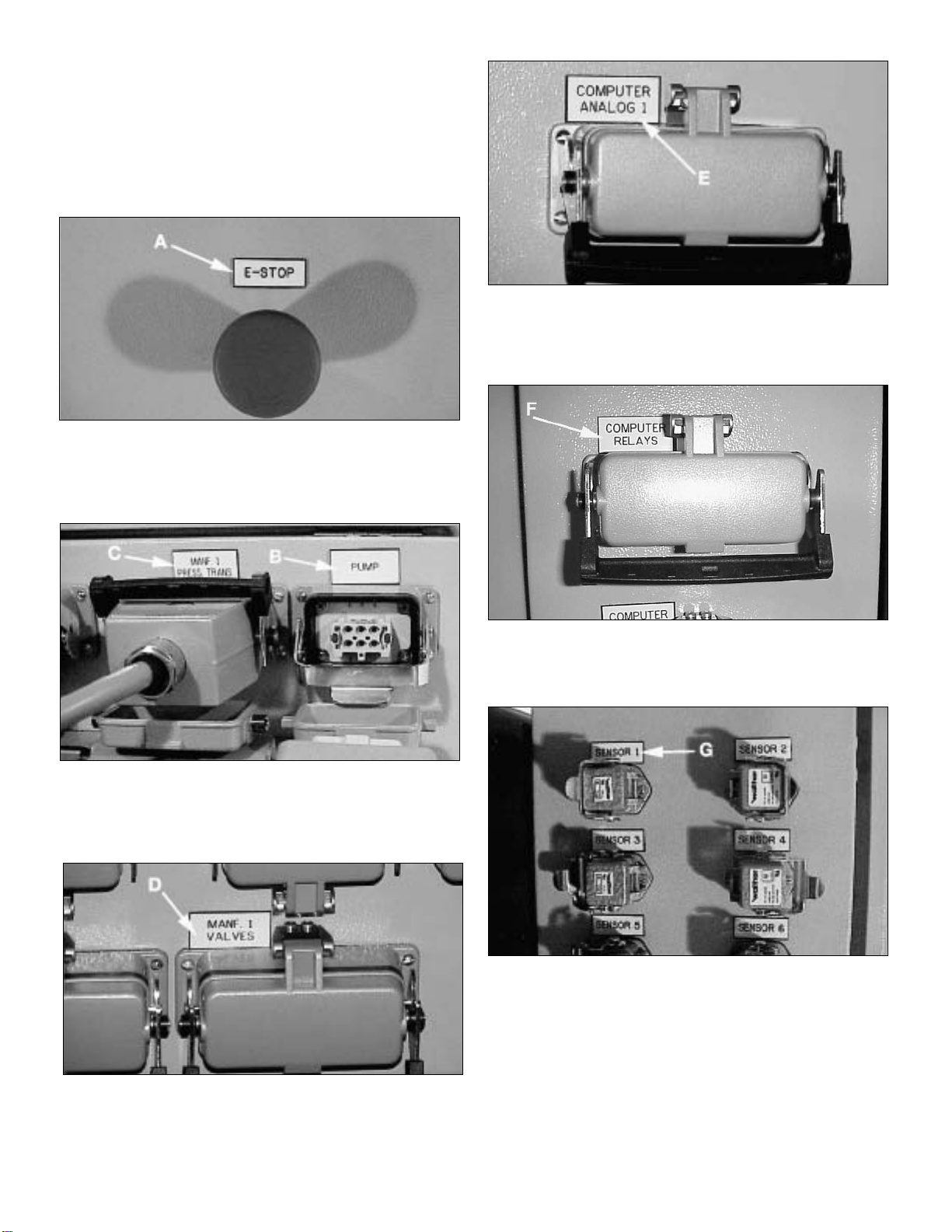

5. Click on the ALL UP button.Verify that the selected cylinder is

moving. If no movement is observed at the selected cylinder,

check to see if movement has occurred at another cylinder.

Movement of a cylinder other than the one selected indicates

incorrect electrical or hydraulic connections. NOTE: When a

system is assembled, for the first time, some cylinder

movement may occur when the manifold valve is not actuated.

This indicates that there is air present in the line, See No. 7.

Check all electrical and hydraulic circuits to make sure cables

and hoses are plumbed correctly. If the cylinder operation is

opposite from the direction selected, check for reversed hose

plumbing from the manifolds to the cylinder and from the

pump to the manifolds.

6. When proper cylinder control has been achieved, deselect the

cylinder by clicking onto the box. Continue testing all

remaining cylinders.

7. The hydraulic system must be bled of air to ensure smooth

load movement. Use the pump mounted valve to prefill all of

the hoses at the same time. Using the manual mode, bleed

each cylinder by extending and retracting the cylinder full

stroke several times. If possible, cylinders should be laying

down with the couplers pointing upward. The preferred

method of bleeding is with the hydraulic pump on a level

higher than the cylinders, allowing the air to rise to the pump

reservoir. Avoid building pressure in the cylinder during this

procedure to prevent cylinder damage.

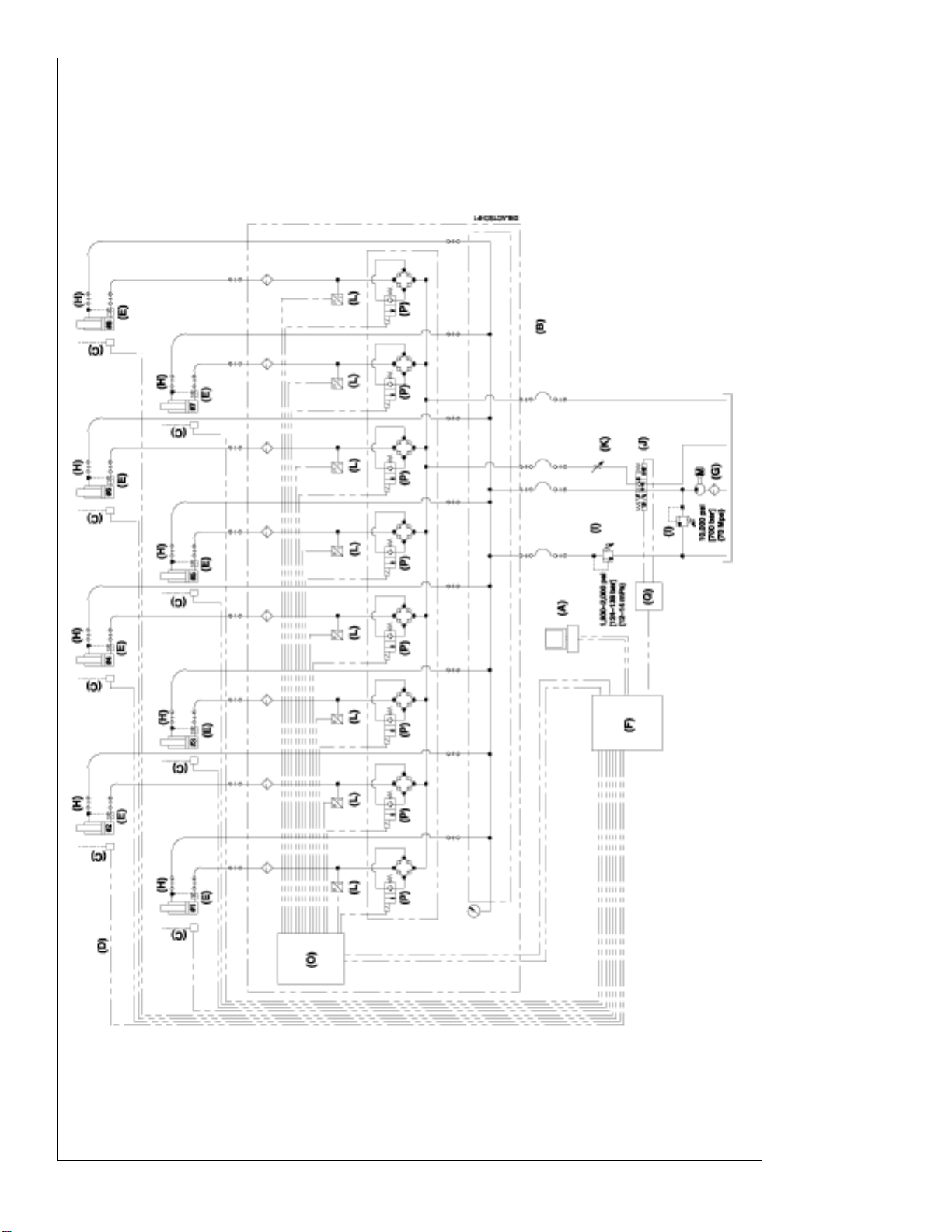

8. After the system has been completely purged of air, set the

system relief valves. Rotate the PRESSURE RELIEF VALVE

handles counterclockwise until minimum spring resistance is

encountered to reduce the initial pressure setting. Manually

advance any cylinder to full stroke and continue while

adjusting the V-152 pressure relief valve in the advance circuit

to the desired pressure by rotating the handle clockwise. DO

NOT EXCEED THE RECOMMENDED LIMITS 8,800–9,200

psi (607-634 bar). Manually retract the cylinder to full stroke

and continue while adjusting the V-152 pressure relief valve in

the retract circuit to the desired pressure by rotating the

handle clockwise. DO NOT EXCEED THE RECOMMENDED

LIMITS 1,800-2,000 psi (124 - 138 bar).

9. Position all cylinders under the load. Cylinders must be placed

on firm foundations and plunger saddles must have full

contact with the load.

CAUTION:

The system components are designed to 10,000 psi

(700 bar). Exceeding this pressure could cause system

failure and damage to system components.

Retract pressure must be limited to 1,800-2,000 psi (124 – 138

bar). Failure to do so may cause system failure and/or

damage to system components.

Route cables and hoses in a safe manner. Do not step on

cables. Keep cables dry and protected from abrasion and

direct exposure to moisture.

9.5 Cylinder/Sensor Interface Check

1. Sensors from each lift point should be placed near the cylinder

to ensure precise measurement of load displacement.

2. Manually extend the sensor cable to verify that the sensor

readout change corresponds to the lift point being tested. If

the cylinder and sensor operation do not correspond, the

situation must be corrected prior to operating the system.

CAUTION: Inaccurate load displacement data may be

the result of SENSORS that are not placed on solid

foundations. The display may indicate that the

sensors are seeing load movement, however, the load may

not have moved. What may occur is that the cylinder base had

settled or compressed and the sensor positions have changed

as a result.

9.6 Flow Control Valve Setting

A V-8F FLOW CONTROL VALVE is located on the advance side of

the CYLINDER CONTROL VALVE. This valve is to be used to

affect the rate of flow in the extend and retract directions.This valve

is used to control the flow rate to the cylinders and can be adjusted

to increase the accuracy of the system. (Refer to "Troubleshooting

Response Errors".) For best accuracy in the lifting mode, the flow

rate must be restricted to 91 in 3/min [1,5 liter/min]) or less. The

higher the flow rate, during lifting, the lower the accuracy in

positioning.

NOTE: In the MANUAL mode, individually extend each cylinder

until the load is contacted. If the system is equipped with pressure

transducer, the pressure of each cylinder can be read on the

pressure display.When readout begins changing, the cylinder is in

contact with the load. Be sure only one cylinder is extended at a

time. Visually inspect each lift point to ensure that each cylinder

has made load contact.

10.0 LIFTING SEQUENCE

10.1 Manual Mode

To commence the cylinder movement the measuring has to be

started first by clicking the command button START.After that either

single circuits or all circuits which are switched on can be extended

or retracted. When all cylinders are driven together in the manual

mode synchronized movement is not controlled. Movement can be

stopped either by clicking the command button STOP or by hitting

any key on the keyboard (except the return or space bar key).

The info-label in the upper part of the program window shows

which function is currently used.

The display STROKE VALUE shows the movement of each lifting

point. The display DIVERGENCE shows the difference between

maximum and minimum stroke value of all circuits which are

switched on.

The system is also equipped with pressure transducers. The

pressure of each circuit can be read on the pressure display.When

readout begins changing the load is contacted. Be sure only one

cylinder is extended at a time. Visually inspect each lift point to

ensure that each cylinder has made load contact.

By clicking the command button RESET, stroke values are set to

zero. The display of the absolute sensor extension will not be

changed.

10.2 Automatic Mode - Stroke Sensing (Standard)

By choosing the AUTOMATIC option in the MODE area, automatic

mode is activated. The automatic mode allows controlled

synchronized lifting and lowering within a preset tolerance of all

lifting points which are switched on. This mode also allows for

presetting a stroke limit when lifting or lowering is stopped.

Before lifting or lowering is started all stroke values should be set

to zero by clicking the command button RESET.

The desired tolerance can be entered in the textbox TOLERANCE

after activating it by clicking on it. The minimum tolerance which

can be achieved depends on the cylinder speed which results from

the cylinder size and the output volume of the pump unit.