EnerSys Alpha FMPS FTTP User manual

FMPS FTTP

Multipurpose Power Supply

Installation & Operation Manual: 010-592-B2

Effective: 09/2020

i

SAFETY NOTES

SAVE THESE INSTRUCTIONS

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or your nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

notations/symbols have been placed throughout this manual. Where these notations/symbols appear, use extra

care and attention.

ATTENTION:

The use of ATTENTION indicates specific regulatory/code requirements that may affect the

placement of equipment and installation procedures.

NOTE: A NOTE provides additional information to help complete a specific task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

A WARNING presents safety information to PREVENT INJURY OR DEATH to the technician or

user.

ii

General Safety Precautions

To avoid injury:

•Read and follow all installation, equipment grounding, usage, and service instructions included in this manual.

•Disconnect power before servicing.

•This enclosure and its associated hardware must be serviced only by authorized personnel.

•Enclosure must remain locked at all times, except when authorized service personnel are present.

•Remove all conductive jewelry or personal equipment prior to servicing equipment, parts, connectors, wiring,

or batteries.

•Use proper lifting techniques whenever handling enclosure, equipment, parts, or batteries.

•Batteries contain dangerous voltages, currents and corrosive material. Battery installation, maintenance,

service and replacement must be performed by authorized personnel only.

•Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or replacing

batteries.

•Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable or

an unconnected battery cable can result in arcing, a fire, or possible explosion.

•A battery that shows signs of cracking, leaking or swelling must be replaced immediately by authorized

personnel using a battery of identical type and rating.

•Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery. Emissions

contain dilute sulfuric acid which is harmful to the skin and eyes. Emissions are electrolytic, which are

electrically conductive and are corrosive. Follow the Chemical Hazards notes if contact occurs.

•Do not smoke or introduce sparks in the vicinity of a battery.

•Under certain overcharging conditions, lead-acid batteries can vent a mixture of hydrogen gas that is

explosive. Proper venting of the enclosure is required.

•Follow the battery manufacturer’s approved transportation and storage instructions.

CAUTION!

Enclosure, equipment, or parts may be damaged (or cause damage) if installed or used improperly.

To avoid damage:

•Prior to installation, verify that the AC input voltage to the enclosure and its equipment match with respect to

voltage and frequency.

•Prior to installation, verify that the output voltage from the enclosure or its equipment match the voltage

requirements of the connected equipment (load).

•Prior to installation, verify that the enclosure’s utility service panel is equipped with a properly rated circuit

breaker for use with the equipment inside. Refer to manufacturer’s recommendations.

•Review and upgrade utility service panel circuit breaker requirements whenever the equipment within the

enclosure is changed.

•Prior to installation, contact local utilities, local building maintenance departments, and cable/piping locator

services to ensure that installation does not interfere with existing utility or building cables/piping.

•Do not exceed the output rating of equipment. Verify load requirements prior and during connection process.

•Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed in your body.

•For continued protection against risk of fire, replace only with same type and rating of fuse.

iii

Battery Safety Notes

WARNING!

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed only by authorized

personnel.

Chemical Hazards

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contain dilute sulfuric acid, which

is harmful to the skin and eyes. Emissions are electrolytic, and are electrically conductive and corrosive.

To avoid injury:

•Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

•Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all

metallic objects from hands and neck.

•Batteries produce explosive gases. Keep all open flames and sparks away from batteries.

•Use tools with insulated handles; do not rest any tools on top of batteries.

•Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Battery post terminals and related accessories contain lead and lead compounds. Wash

hands after handling (California Proposition 65).

•Wear protective clothing (insulated gloves, eye protection, etc.) whenever installing, maintaining, servicing, or

replacing batteries.

•If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

company’s approved chemical exposure procedures.

•Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with a

solution of 2.2 kg (one pound) bicarbonate of soda to 3.8 liters (one gallon) of water. Report chemical spill

using your company’s spill reporting structure and seek medical attention if necessary.

•Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or replacing

batteries.

•Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable or

an unconnected battery cable can make contact with an unintended surface that can result in arcing, fire, or

possible explosion.

•A battery showing signs of cracking, leaking, or swelling should be replaced immediately by authorized

personnel using a battery of identical type and rating.

iv

Battery Maintenance Guidelines

The battery maintenance instructions listed below are for reference only. Battery manufacturer’s instructions for

transportation, installation, storage or maintenance take precedence over these instructions.

•To prevent damage, inspect batteries every three months for:

Signs of battery cracking, leaking or swelling. The battery should be replaced immediately by authorized

personnel using a battery of the identical type and rating.

Signs of battery cable damage. Battery cable should be replaced immediately by authorized personnel

using replacement parts specified by vendor.

Loose battery connection hardware. Refer to battery manufacturer’s documentation for the correct torque

and connection hardware for the application.

•Apply battery manufacturer’s specified antioxidant compound on all exposed connections.

•Verify battery terminals or exposed connection hardware is not within close proximity of a conductive surface.

Reposition batteries as necessary to maintain adequate clearance.

•Clean up any electrolyte (battery emission) in accordance with all federal, provincial (or state), and local

regulations or codes.

•Proper venting of the enclosure is recommended. Follow the battery manufacturer’s approved transportation

and storage instructions.

•Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

•Do not charge batteries in a sealed container. Each individual battery should have at least 12.7mm (0.5”) of

space between it and all surrounding surfaces to allow for convection cooling.

•All battery compartments must have adequate ventilation to prevent an accumulation of potentially dangerous

gas.

Recycling and Disposal Instructions

Spent or damaged batteries are considered environmentally unsafe. Always recycle used batteries or dispose of

the batteries in accordance with all federal, provincial (or state) and local regulations.

Electrical Safety

•Lethal voltages are present within the power system. Never assume that an electrical connection or conductor

is not energized. Check the circuit with a voltmeter with respect to the grounded portion of the enclosure (both

AC and DC) prior to any installation or removal procedure.

•Always use the buddy system when working under hazardous conditions.

•A licensed electrician is required to install permanently wired equipment.

•Ensure no liquids or wet clothes contact internal components.

•Hazardous electrically live parts inside this unit are energized from batteries even when the AC input power is

disconnected.

•For cord connected model, the plug is the disconnect device. A socket outlet shall be installed near the

equipment. For hardwired model, a breaker shall be used for a disconnect device. For IEC line cord option,

the inlet on the cord is the disconnect device for such systems.

CAUTION!

DOUBLE POLE/NEUTRAL FUSING:

For continued protection against risk of fire, replace only with the same type and rating of fuse.

v

Grounding Connection Notes

In order to provide a ready, reliable source of backup power it is necessary to establish a grounding system that

not only provides for the safety of the service personnel responsible for its operation and maintenance, but also

facilitates the proper operation and protection of the equipment within the network. Such a grounding system will

provide protection with respect to operator safety, system communication, and equipment protection.

Safety Ground

The safety ground is a two-part system. The first part is a return path for stray current back to the input breaker,

and the second is a return path from the enclosure to a second ground rod.

Typically, the safety, or utility ground, provides a return path to the input breaker or fuse panel by means of a

connection to an appropriate driven ground rod at the base of the power pole. This path must meet National

Electrical Code (NEC) as well as local codes to ensure the breaker will open, preventing unwanted current flow

from posing a hazard to service personnel.

Strike (Lightning) Ground

Lightning strikes, grid switching, or other aberrations on the power line all have the potential to cause “fast rise-

time currents” which can cause damage to the powering system. Without a low-impedance path to ground, the

current, while travelling through wires of varying impedance, can produce high voltages that will damage the

powering equipment. The most viable method available to protect the system from damage is to divert these

unwanted “fast rise-time currents” along a low-impedance path to ground. A low-impedance path to ground will

prevent these currents from reaching high voltage levels and posing a threat to equipment. The single-point

grounding system provides a low-impedance path to ground, and the key to its success is the proper bonding of

the ground rods, so the components of the grounding system appear as a single point of uniform impedance.

NOTE: Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with its

intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

vii

TABLE OF CONTENTS

SECTION PAGE

1INTRODUCTION.............................................................................................................................................................1

1.1 Scope of the Manual.....................................................................................................................................1

1.2 Product Overview..........................................................................................................................................1

2THEORY OF OPERATION ...............................................................................................................................................3

2.1 Operating States...........................................................................................................................................3

2.2 Exception States...........................................................................................................................................4

2.3 Status Signals...............................................................................................................................................4

3TRANSPORTATION AND STORAGE .................................................................................................................................5

4INSTALLATION ..............................................................................................................................................................6

4.1 Enclosure Preparation...................................................................................................................................6

4.2 Lifting Preparation.........................................................................................................................................6

4.3 Removing the FMPS Cover..........................................................................................................................7

4.4 Wall-mounting the FMPS..............................................................................................................................7

4.5 Recessed/Stud-mounting the FMPS.............................................................................................................8

4.6 Grounding Connection Notes........................................................................................................................8

4.7 Safety Ground...............................................................................................................................................9

4.8 Strike (Lightning) Ground..............................................................................................................................9

4.9 AC Wiring, Optional Power Cords.................................................................................................................9

4.10 AC Wiring, Permanent Connection.............................................................................................................10

4.11 DC Output And Alarm Wiring......................................................................................................................11

5BATTERY INSTALLATION.............................................................................................................................................12

5.1 Preparation/Mounting..................................................................................................................................12

5.2 Installation of Batteries in Alpha Power Systems .......................................................................................12

6OPERATION................................................................................................................................................................15

6.1 Start-up .......................................................................................................................................................15

6.2 Normal Operation........................................................................................................................................15

6.3 Status LEDs................................................................................................................................................15

6.4 Battery String LEDs.....................................................................................................................................15

6.5 AC Fail Alarm..............................................................................................................................................15

6.6 Audible Alarm..............................................................................................................................................16

6.7 Battery Backup Mode..................................................................................................................................16

6.8 Charging Mode............................................................................................................................................16

6.9 Battery Management...................................................................................................................................16

6.10 Battery Self-test...........................................................................................................................................17

7TEST AND COMMISSIONING (OVERVIEW)......................................................................................................................18

7.1 System ........................................................................................................................................................18

7.2 Battery.........................................................................................................................................................18

7.3 Documentation............................................................................................................................................18

8MAINTENANCE ...........................................................................................................................................................19

8.1 Using the Enclosure Security Bypass.........................................................................................................19

8.2 Replacing the FMPS...................................................................................................................................20

viii

9APPENDIX A...............................................................................................................................................................21

9.1 Installing the FMPS Power Module as a Stand-alone Unit.........................................................................21

10 APPENDIX B...............................................................................................................................................................22

10.1 Installing the FMPS Power Module in a 19” or 23” Rack Mount Chassis...................................................22

11 WARRANTY................................................................................................................................................................23

11.1 Technical Support.......................................................................................................................................23

11.2 Warranty Statement....................................................................................................................................23

11.3 Product Warranty........................................................................................................................................23

11.4 Battery Warranty.........................................................................................................................................23

11.5 Warranty Claims..........................................................................................................................................23

11.6 Service Information.....................................................................................................................................23

12 ACRONYMS AND DEFINITIONS .....................................................................................................................................24

FIGURE PAGE

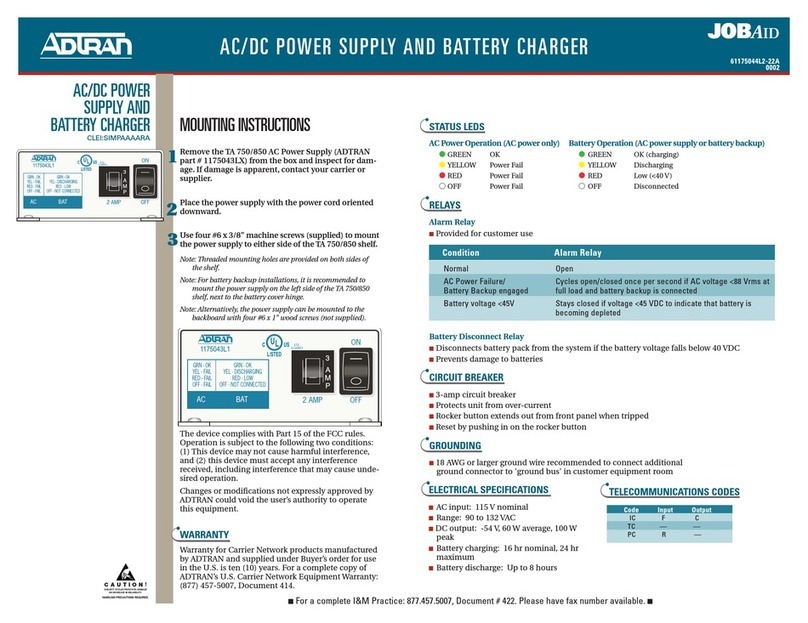

Figure 1–Front perspective view of FMPS-150W.............................................................................................................1

Figure 2–FMPS features overview with cover removed...................................................................................................2

Figure 3–Lifting the FMPS cover......................................................................................................................................7

Figure 4–Sliding the FMPS cover out...............................................................................................................................7

Figure 5–FMPS wall-mounting .........................................................................................................................................7

Figure 6–Stud-mounting the FMPS..................................................................................................................................8

Figure 7–Power cord options............................................................................................................................................9

Figure 8–AC mains connection ......................................................................................................................................10

Figure 9–DCoutput connections....................................................................................................................................11

Figure 10–Connecting the battery pigtails......................................................................................................................12

Figure 11–Installing the batteries ...................................................................................................................................13

Figure 12–Battery capacity characteristics.....................................................................................................................16

Figure 13–Battery self-test .............................................................................................................................................17

Figure 14–Security bypass.............................................................................................................................................19

Figure 15–FMPS power module connection details.......................................................................................................21

Figure 16–Location of FMPS mounting bracket screws.................................................................................................22

Figure 17–Location of mounting bracket captive screw.................................................................................................22

Figure 18–Six rack mounted FMPS power modules......................................................................................................22

010-592-B2 Rev E Page 1

1 Introduction

1.1 Scope of the Manual

This instruction manual explains the features, installation, startup and maintenance of the FMPS FTTP

Multipurpose Power Supply.

NOTE: Images contained in this document are for illustrative purposes only and may not exactly match your installation.

1.2 Product Overview

The FMPS, model number FMPS-150W, is an intelligent microprocessor-controlled 48Vdc UPS system.

The input is powered by either a customer-owned 120 to 240Vac power outlet or a hardwired AC connection.

The system includes two parallel outputs with alarm connections.

The FMPS supports distances of up to 100-feet using unshielded cable between the FMPS and ONT, allowing the

FMPS to be located close to existing power outlets.

Individually monitored 48Vdc strings of standard 7.2 AH maintenance free, sealed lead-acid batteries provide

standby power.

Model FMPS-150CWK features a factory installed cold weather kit that includes a battery heater, and supports

extended runtimes at –40°C.

LED indicators and audible alarm provide local status indication, and PacketCable-compliant telemetry

connections to the ONT provide remote status reporting.

System includes:

•Local and remote status indicators

•Universal AC input

•Two DC outputs and alarm connections

•Microprocessor controlled battery management

•Low voltage battery disconnect

•LED status indicators for each battery string

•Indoor or outdoor installation

•Up to two FMPS units may be installed on a single dedicated

15A circuit

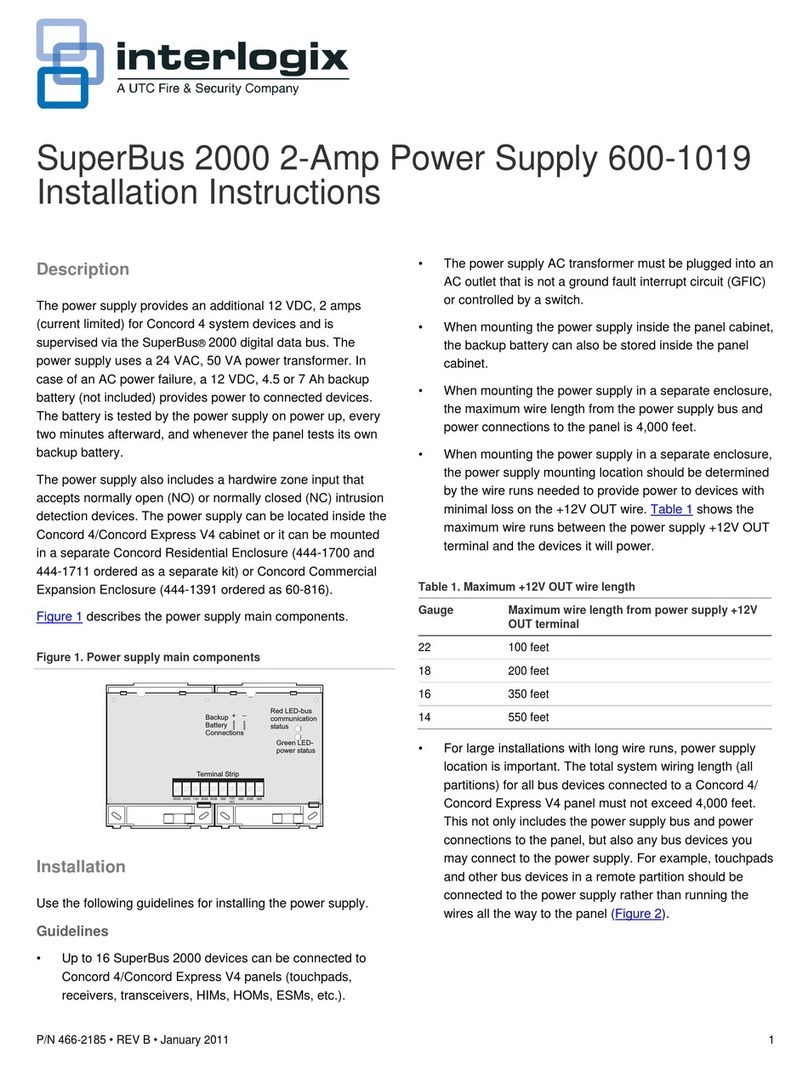

Figure 1–Front perspective view of FMPS-150W

010-592-B2 Rev E Page 2

Figure 2–FMPS features overview with cover removed

Battery string (A, B) status LEDs

#10 ONT ground reference stud (2 PL)

8’ Power cord (List 85)

Safety ground stud and

AC input block

LED indicators

Silence alarm button

Audible alarm ON/OFF

Output (1, 2) and alarm connections

Battery string A connections (4 PL)

Factory installed heater option

Battery string B connections (4 PL)

010-592-B2 Rev E Page 3

2 Theory of Operation

2.1 Operating States

The FMPS has two operating states, Normal Operation and Battery Backup.

2.1.1 Normal Operation

The FMPS supplies power to the ONT, while being powered by the AC mains outlet. It may also be charging the

batteries or performing a battery test. While in the Normal Operation state, the FMPS operates in one of three

sub-modes and switches between these sub-modes as necessary. The sub-modes are:

2.1.1.1 Battery Standby

The Battery Standby mode is the normal mode of operation. The battery in the UPS is fully

charged and in good condition.

2.1.1.2 Battery Charging

The Battery Charging mode is initiated by a drop in battery voltage, due either to battery self-

discharge or powering the ONT(s) after an AC outage. In either case, the FMPS initiates battery

charging. Temperature compensated charging is used to maintain battery capacity at the

suitable voltage for the temperature range.

2.1.1.3 Battery Self-test

In order to determine when a battery needs replacement, a battery test program is initiated by

the microprocessor. Battery testing occurs only when AC power is present. See Section 6.10 for

a battery test overview.

From the Normal Operation state, the FMPS can switch to the Battery Backup state. This occurs without DC

interruption when AC power fails.

2.1.2 Battery Backup

The FMPS supplies power to the ONT via the backup batteries. The FMPS backup batteries consist of one or two

strings of 7.2 AH batteries. Each battery string consists of four batteries wired in series (Figure 10). Projected

battery run times are listed in the Specifications (010-592-B1). While in the Battery Backup state, there are two

sub-modes:

2.1.2.1 Battery Low

The FMPS sends a “Low Battery” alarm to the ONT(s) when either battery string has discharged

to 46.8Vdc. The FMPS also sounds an audible alarm once a Low Battery condition has been

detected (unless the alarm has been disabled).

2.1.2.2 Low Voltage Disconnect

If AC power is not restored after an extended time, and both battery strings have discharged to

42.0Vdc, the FMPS disconnects the batteries to protect them from over-discharge.

If the depleted batteries are removed from the FMPS, and other (charged) batteries are installed

before restoration of AC power, the LVD circuit automatically resets and provides battery

backup power to the ONT(s).

The FMPS switches from the Battery Backup state to the Normal Operation state on resumption of reliable AC

power. The FMPS initiates the Battery Charging sub-mode until battery capacity is fully restored.

010-592-B2 Rev E Page 4

2.2 Exception States

While in Normal Operation or Battery Backup, there are three exception states that may occur.

2.2.1 Replace Battery

The FMPS enters the Replace Battery state when the charge control circuit determines the battery is not holding

a charge, or is incapable of being charged. The Replace Battery alarm initiates when the battery capacity is less

than 70% of the battery capacity stated by the battery manufacturer. The battery replacement criteria are based

on the battery test results described in Section 6.10.

2.2.2 Battery Missing

The Battery Missing condition is a critical condition because the FMPS is unable to supply the expected amount

of backup power should AC power fail. A Battery Missing alarm is sent to the ONT if one or more batteries are

missing from the FMPS; i.e., there are less than eight batteries in the unit.

2.2.3 Over-current

Over-current is a serious condition that could damage the FMPS. The state becomes active if the FMPS detects

the external load current draw exceeds the FMPS capacity; e.g., this condition could be caused by an inadvertent

short across the power leads.

The FMPS automatically determines the proper operating state and resumes operation when the Battery Missing

or Over-current conditions are removed. Replacing the battery (batteries) clears the Replace Battery alarm.

2.3 Status Signals

The status connections communicate FMPS status to the ONT(s). Status signals sent to the ONT are assertive

high; i.e., when active, the signal line is disconnected from float with respect to the “Telemetry Return” pin. Status

signals are open collector (open circuit = alarm, and low impedance = no alarm).

010-592-B2 Rev E Page 5

3 Transportation and Storage

3.1.1 Packaging

The enclosure and components are shipped on individual pallets and shrink wrapped. The pallet is approximately

0.15m H x 1.22m W x 1.52m D (6” H x 48” W x 60” D) and the overall height including pallet and enclosure is

approximately 0.46m (18”). The enclosures and components cannot be stacked.

Batteries may or may not be installed; if they are not, they will be on a separate pallet and packaged per the

manufacturers guidelines.

NOTE: Packaging assemblies and methods are tested to International Safe Transit Association standards.

3.1.2 Storage

The weight of the enclosure is listed in the specifications. The equipment pallet can be moved using a forklift.

Do not hoist/lift enclosure with batteries installed.

If the batteries are installed, the warehouse facility may have to be certified for handling such goods. Typically, the

batteries will be on a separate pallet; the same requirements for certification will apply.

3.1.3 Site Considerations

It is assumed that the site will be ready for enclosure installation upon arrival.

The supporting structure must be designed to support a fully configured enclosure. In addition, the mounting site

must be designed and installed in accordance with local building practices and codes.

Site considerations should include the following:

•Areas that may receive hot air exhaust from neighboring buildings or structures should be avoided.

•Any areas with architectural controls or environmental restrictions should be known.

•Areas prone to flooding should be avoided.

•A proper grounding system.

3.1.4 Inspection

Prior to unpacking the equipment, perform a visual inspection and note any damage. Unpack the equipment and

inspect the exterior for damage. If any damage is observed contact the carrier immediately.

Continue the inspection for any internal damage. In the unlikely event of internal damage, please inform the

carrier and contact Alpha Technologies for advice on the consequence of any damage.

Verify that you have all the necessary parts per your order for proper assembly.

Call Alpha Technologies if you have any questions before you proceed: 1 (888) 462-7487

010-592-B2 Rev E Page 6

4 Installation

The information in this section is intended as a guideline only; there may be site-specific

requirements and other factors that will require individual attention, such as jurisdictional codes

and construction covenants.

The FMPS can be installed by one technician during a single visit to the customer premises. The FMPS can be

mounted on an internal or external customer premises wall, or it can be recessed into a newly framed wall during

new construction.

Generous placement of 1/2" electrical metallic tubing (EMT) knockouts can accommodate flexible placement of

ONT(s) and AC service. Watertight fittings are supplied for strain relief, and to seal the ONT(s) cable transition

into the FMPS housing.

NOTE: The FMPS is factory equipped with an eight-foot power cord and safety ground stud. Placement of the FMPS

adjacent to a customer-owned AC outlet can minimize installation time.

When mounting the FMPS on an external wall, route the AC power lines to the FMPS in conduit. The FMPS

power cord is removable to allow installation of 1/2" EMT conduit to the FMPS using the same hole.

For “built-in” FMPS installations, a six-inch to eight-inch space below the FMPS should be provided. This will

allow access to EMT conduit and output fittings, in the event the FMPS requires service or replacement. This

opening should be free from drywall or other wall coverings.

ATTENTION:

The max/peak current draw for the FMPS power supply is 5.8Apk. Based on max/peak inrush

current, two FMPS units may be installed on a dedicated 15A, 120Vac circuit, and three FMPS

units may be installed on a dedicated 20A, 120Vac circuit.

4.1 Enclosure Preparation

Remove the protective covering from the enclosure.

NOTE: Inspect the packing slip to verify that all equipment is there.

If batteries are on a separate pallet, they should not be installed until after the enclosure has been secured. If the

batteries are going to be placed within the enclosure, the inter-unit connectors must be installed.

Inspect moving parts, hardware, connectors, and installed equipment.

NOTE: In case of damage, report it according to procedure.

Remove and properly dispose of all packaging.

4.2 Lifting Preparation

ATTENTION:

All local safety practices and guidelines must be followed while lifting the enclosure.

Do not lift enclosure with batteries installed.

All personnel involved with lifting and placing the enclosure should wear head and eye protection

and gloves when required.

010-592-B2 Rev E Page 7

4.3 Removing the FMPS Cover

1. Remove the Phillips screw securing the cover.

2. Grasp the cover by the sides and lift up slightly (see Figure 3).

3. Swing the bottom of the cover out and away from the unit (see Figure 4).

Figure 3–Lifting the FMPS cover

Figure 4–Sliding the FMPS cover out

4.4 Wall-mounting the FMPS

1. Select a suitable location for mounting the FMPS (within 8 feet of a power outlet if using the line cord: L85).

2.

Install a 3/4" plywood backing plate measuring 18” wide by 36” long on stud centers using four customer-supplied

5/16” x 4” lag bolts. Use one customer-supplied 5/16” flat washer and one 5/16” spring lock washer per lag bolt.

3. Attach the FMPS to the backing plate using four customer-supplied 5/16” x1” lag bolts, with one 5/16” flat

washer and one 5/16” spring lock washer per lag bolt. See Figure 5.

Figure 5–FMPS wall-mounting

010-592-B2 Rev E Page 8

4.5 Recessed/Stud-mounting the FMPS

1. Select a suitable location for mounting the FMPS.

2. After removing the cover, unscrew the battery retaining brackets.

3. Drill four 3/8” holes in the side of the enclosure using the pressed dimples in the side of the enclosure as a

guide. See Figure 6. Clean any shavings from the enclosure.

4. Using a hammer and punch, knock out the DC wiring knockout on the bottom of the enclosure. See Figure 6.

5. Mount one side of the FMPS to a stud using two user-supplied 5/16” x 1” lag bolts.

6. Insert a 1/2" (typical) plywood spacer on the other side of the FMPS and secure it using two more 5/16” x 1”

lag bolts.

Figure 6–Stud-mounting the FMPS

4.6 Grounding Connection Notes

In order to provide a ready, reliable source of backup power it is necessary to establish a grounding system that

not only provides for the safety of the service personnel responsible for its operation and maintenance, but also

facilitates the proper operation and protection of the equipment within the network. Such a grounding system will

provide protection with respect to operator safety, system communication, and equipment protection.

010-592-B2 Rev E Page 9

4.7 Safety Ground

The safety ground is a two-part system. The first part is a return path for stray current back to the input breaker,

and the second is a return path from the enclosure to a second ground rod.

Typically, the safety, or utility ground, provides a return path to the input breaker or fuse panel by means of a

connection to an appropriate driven ground rod at the base of the power pole. This path must meet National

Electrical Code (NEC) as well as local codes to ensure the breaker will open, preventing unwanted current flow

from posing a hazard to service personnel.

4.8 Strike (Lightning) Ground

Lightning strikes, grid switching, or other aberrations on the power line all have the potential to cause “fast rise-

time currents” which can cause damage to the powering system. Without a low-impedance path to ground, the

current, while travelling through wires of varying impedance, can produce high voltages that will damage the

powering equipment. The most viable method available to protect the system from damage is to divert these

unwanted “fast rise-time currents” along a low-impedance path to ground. A low-impedance path to ground will

prevent these currents from reaching high voltage levels and posing a threat to equipment. The single-point

grounding system provides a low-impedance path to ground, and the key to its success is the proper bonding of

the ground rods, so the components of the grounding system appear as a single point of uniform impedance.

4.9 AC Wiring, Optional Power Cords

1. The FMPS may be supplied with an optional power cord, up to eight feet in length, equipped with a 5-15P-

type plug (as shown in Figure 2 or List 85 below).

2. If hardwiring the FMPS, discard the AC line cord by removing it from the AC input terminal block.

3. The inlet on the line cord shown here (Figure 7, List 84) is the disconnect device for systems provided with

this option:

Figure 7–Power cord options

NOTE: For use with external line cords compatible with IEC 60320 type female connections. Verify local electrical codes

and installation requirements before connection.

4. The FMPS must be permanently connected, or provided with a IEC 60309 compliant power cord set, when

installed in the following countries: Austria, Belgium, Denmark, Finland, Germany, Norway, Sweden, UK.

List 84

List 85

010-592-B2 Rev E Page 10

4.10 AC Wiring, Permanent Connection

1. Run the AC wiring through the 1/2" EMT along the same path as the original AC line cord.

2. Connect the AC wiring as follows:

•Black wire = Line

•White wire = Neutral

3. Connect the ground wire (min. #14 AWG) to the safety ground stud on the chassis, and then to the AC input

block. The stud uses a 7mm nut.

4. Secure the EMT connector.

CAUTION!

Do not apply power at this time. Connection to the building utility may only be performed by a

licensed electrician in accordance with the NEC and all applicable local codes and regulations.

Figure 8–AC mains connection

#10 ONT ground reference stud (2 PL)

Accepts #10 solid ground wire

NOTE:

The #10 groun

d studs are used only

when there is no other way to ground

the ONT to earth

Connect to safety ground stud

and then to the AC input block

(green)

Line (black)

Neutral (white)

To AC mains

Table of contents

Other EnerSys Power Supply manuals

EnerSys

EnerSys alpha APX3 Series User manual

EnerSys

EnerSys alpha APX3-G Series User manual

EnerSys

EnerSys Alpha Broadband UPS User manual

EnerSys

EnerSys alpha Cordex CXRF 48-3.6kW Quick start guide

EnerSys

EnerSys alpha LPS36 Quick start guide

EnerSys

EnerSys alpha CXPS-E3 User manual

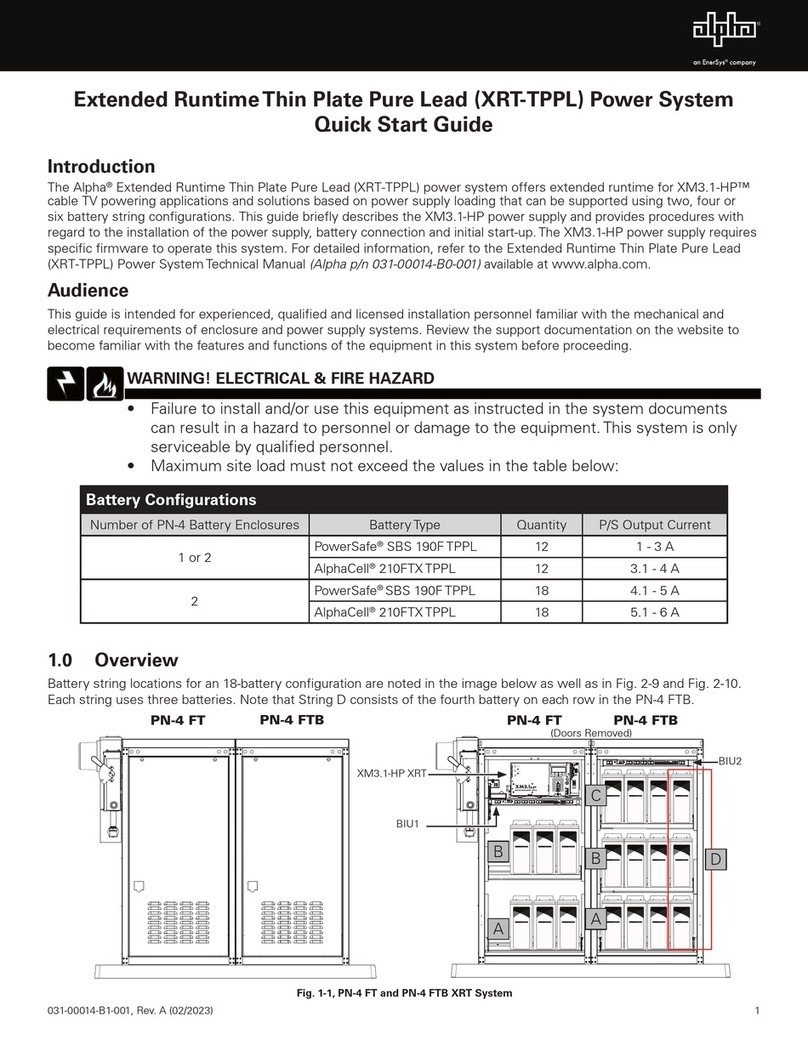

EnerSys

EnerSys Alpha XRT-TPPL User manual

Popular Power Supply manuals by other brands

Conductix-Wampfler

Conductix-Wampfler IPS 3.0 manual

Mercury

Mercury SMDC409UK user manual

ENERMAX

ENERMAX REVOLUTION85PLUS Brochure & specs

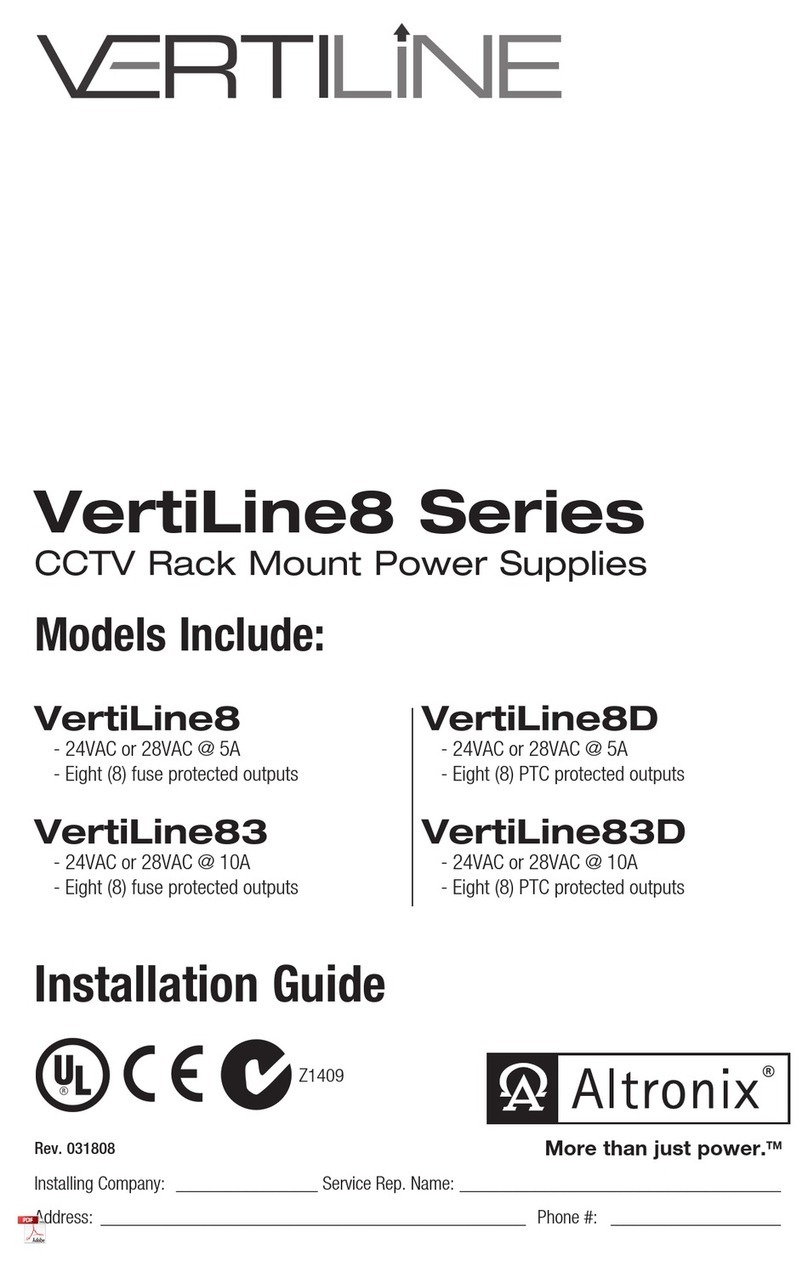

Altronix

Altronix VertiLine8 Series installation guide

Interlogix

Interlogix SuperBus 2000 installation instructions

Keysight Technologies

Keysight Technologies 66312A user guide