EnerSys Alpha XRT-TPPL User manual

1031-00014-B1-001, Rev. A (02/2023)

Introduction

The Alpha®Extended Runtime Thin Plate Pure Lead (XRT-TPPL) power system offers extended runtime for XM3.1-HP™

cable TV powering applications and solutions based on power supply loading that can be supported using two, four or

six battery string configurations. This guide briefly describes the XM3.1-HP power supply and provides procedures with

regard to the installation of the power supply, battery connection and initial start-up. The XM3.1-HP power supply requires

specific firmware to operate this system. For detailed information, refer to the Extended Runtime Thin Plate Pure Lead

(XRT-TPPL) Power System Technical Manual (Alpha p/n 031-00014-B0-001) available at www.alpha.com.

Audience

This guide is intended for experienced, qualified and licensed installation personnel familiar with the mechanical and

electrical requirements of enclosure and power supply systems. Review the support documentation on the website to

become familiar with the features and functions of the equipment in this system before proceeding.

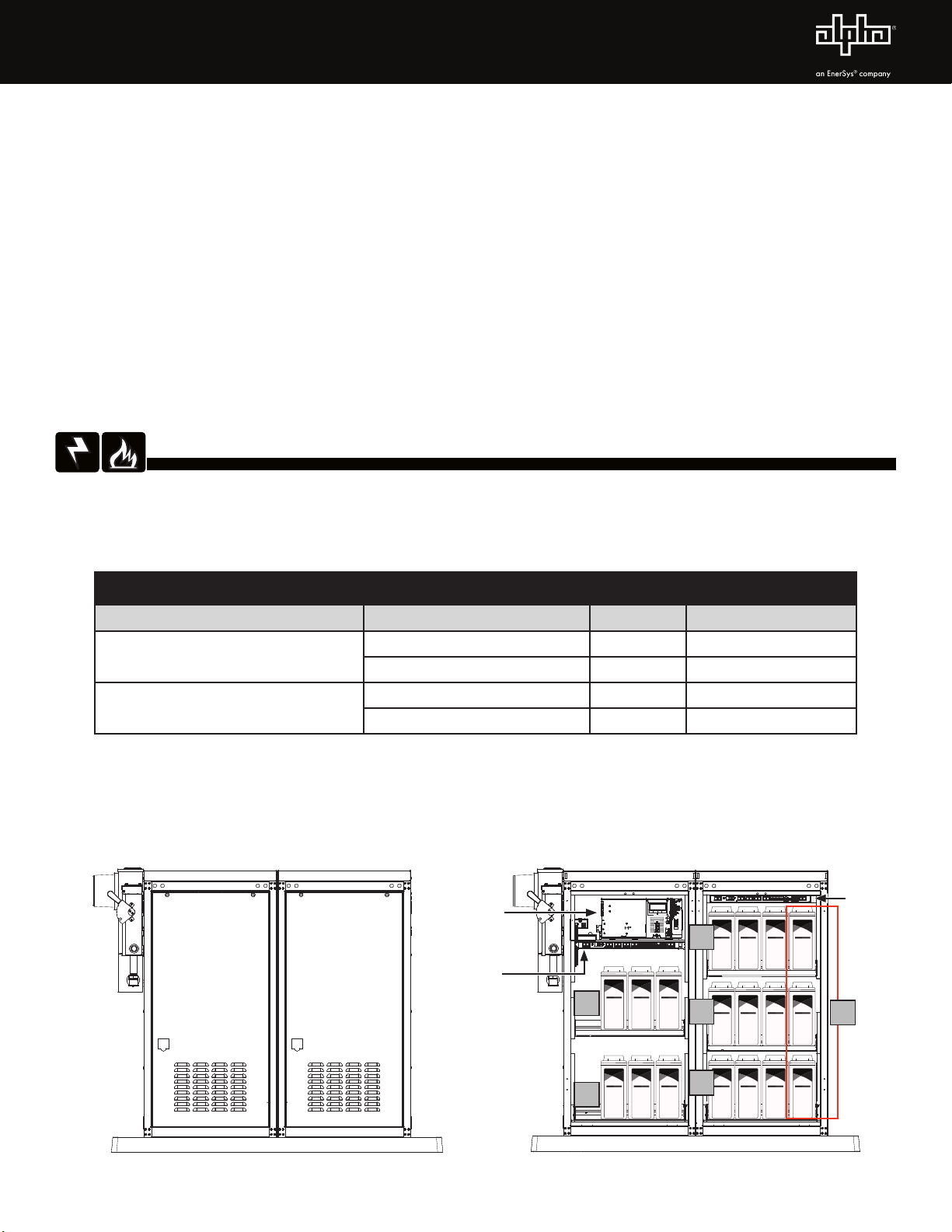

1.0 Overview

Battery string locations for an 18-battery configuration are noted in the image below as well as in Fig. 2-9 and Fig. 2-10.

Each string uses three batteries. Note that String D consists of the fourth battery on each row in the PN-4 FTB.

Extended Runtime Thin Plate Pure Lead (XRT-TPPL) Power System

Quick Start Guide

Fig. 1-1, PN-4 FT and PN-4 FTB XRT System

XM3.1

BROADBAND UPS

]

]

]

OUTPUT1

OUTPUT2

N+ 1

N

N

N

~

~

~

IntelligentInverter Module-IM3.1TM

BATTERY

TEMP

TORQUE

10.0 IN-LB

11.5kgf.cm

LRI

OUTPUT

ALARM

TEST

DS

OL

US

SFP

LNK

ALM/

RDY

E

T

H

GRN=OK

BLU=WARN

RED

=OUT

RST

RX/TX

PWR

TPR

A

STRGB

STRGC

STRGD

SMART

ALPHA

GUARD

E

N

V

BATTERYINPUT

BATTERY

BREAKER

RF

ACTIVE

PWR

COM

+

_

BIU

PN-4 FT PN-4 FT

PN-4 FTB PN-4 FTB

(Doors Removed)

XM3.1-HP XRT

BIU2

BIU1

AA

BB

C

WARNING! ELECTRICAL & FIRE HAZARD

• Failure to install and/or use this equipment as instructed in the system documents

can result in a hazard to personnel or damage to the equipment. This system is only

serviceable by qualified personnel.

• Maximum site load must not exceed the values in the table below:

Battery Configurations

Number of PN-4 Battery Enclosures Battery Type Quantity P/S Output Current

1 or 2 PowerSafe®SBS 190F TPPL 12 1 - 3 A

AlphaCell®210FTX TPPL 12 3.1 - 4 A

2PowerSafe® SBS 190F TPPL 18 4.1 - 5 A

AlphaCell®210FTX TPPL 18 5.1 - 6 A

D

2031-00014-B1-001, Rev. A (02/2023)

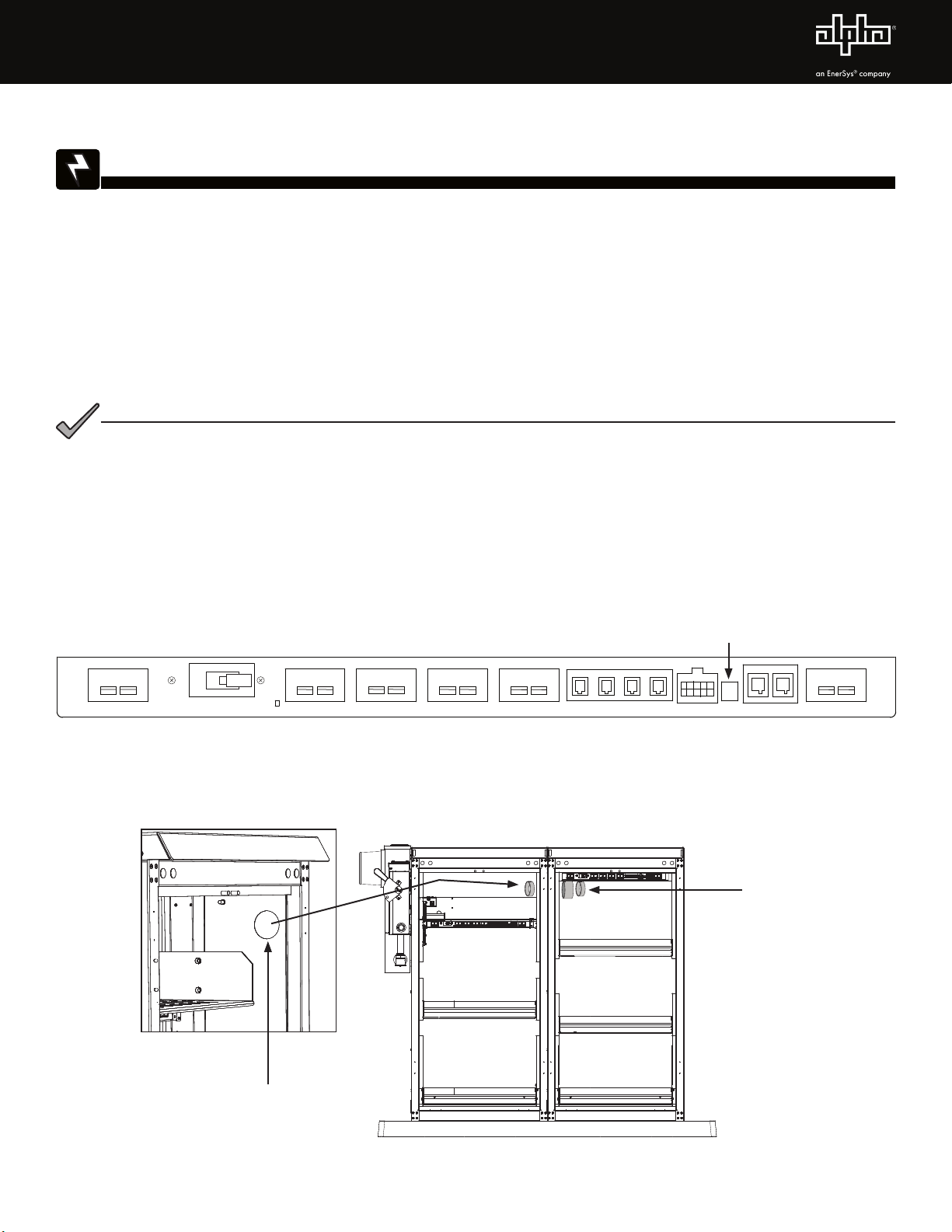

Procedure

1. Before installing the batteries, ensure the enclosure(s) are set and bolted to pad. Remove bottom battery tray if

necessary.

2. Ensure enclosure grounding is in place.

3. Ensure BIU (Battery Interface Unit) is installed (see Fig. 1-1 for mounting locations) and verify the tamper switch (TPR)

is plugged in.

Fig. 2-2, Conduit PassThrough

Fig. 2-1, BIU Tamper Switch Location

2" Knockout

(Located on both enclosures)

Connect enclosures with

conduit pass through

2.0 Battery Installation And Start-Up Procedure

Required Tools

• Insulated tools (size and setting based on battery manufacturer torque specification)

• Safety glasses or face shield

• Rubber gloves

• Chest shield

• Box or bag for storing cables and hardware while out in the field

• True RMS voltmeter

Installer must wear the correct PPE when installing batteries. Failure to do so may result in

injury or death.

WARNING! ELECTRICAL HAZARD

Review Fig. 2-9 and Fig. 2-10 for hardware stack-up and wiring diagram to see the

recommended layout and set up, then proceed with the installation procedure below.

NOTICE:

4. Install conduit pass-through if side by side PN-4 enclosures are used. Use 2" conduit knockout on the side top front of

enclosure.

STRING B

STRING A

STRING C STRING D

PTS A

BATTERY TEMP SENSE

PTS B PTS C PTS D

80A CB

DC OUTPUT

BAT SNS

TPR COM 1 COM 2

DC INPUT

+

-+

-+

-+

-+

-+

-

PWR

A DCB

Tamper Switch (TPR)

3031-00014-B1-001, Rev. A (02/2023)

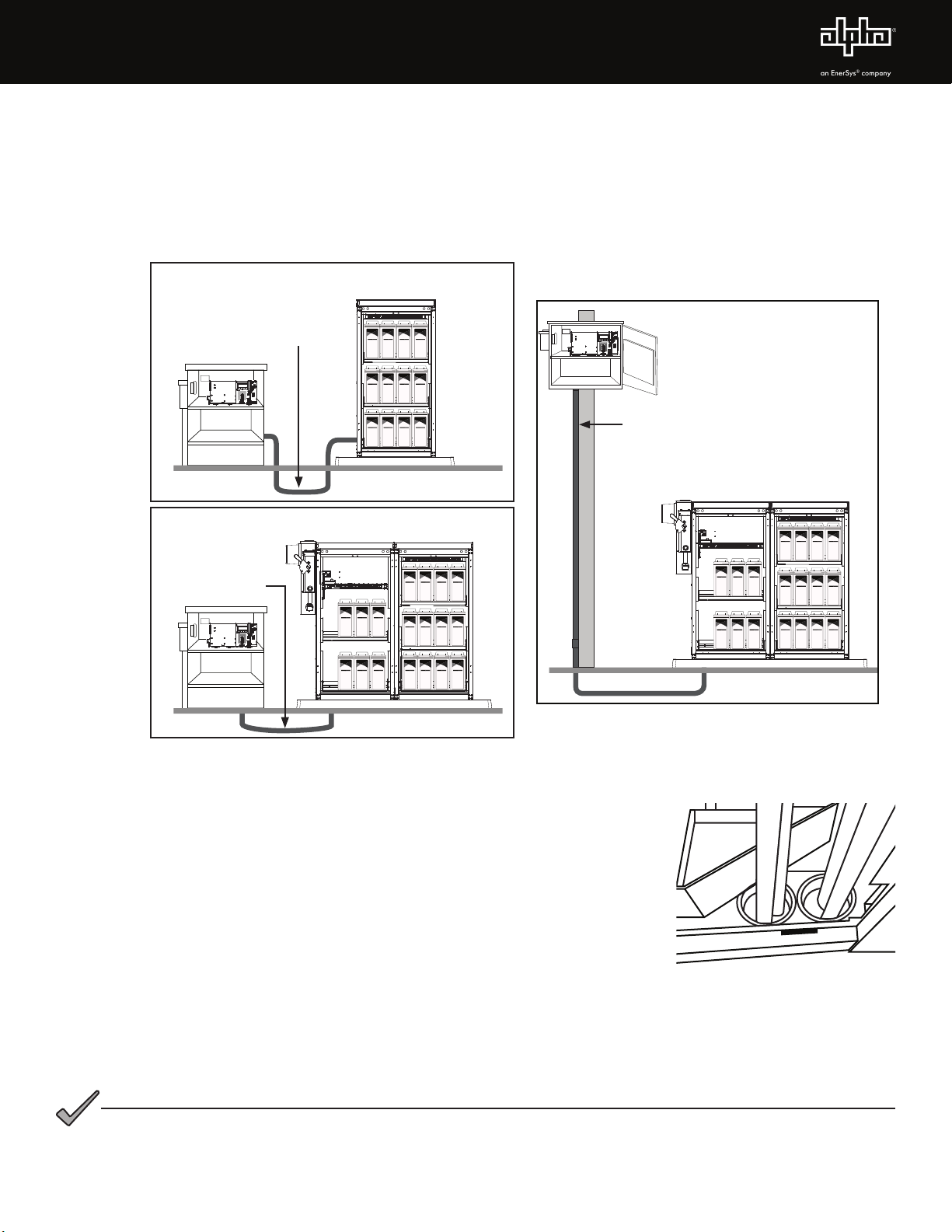

5. If integrating an existing ground mounted UPE or PWE cabinet, install metallic conduit run from the PN-4 FT to

existing enclosure (see figure below). Remove PN-4 bottom battery tray if necessary. Use 2" conduit knockout on

front side bottom of PN-4 or 2" knockout in bottom under battery tray to go under the pad. (Metallic conduit must be

used above ground to prevent radiated emissions. Metallic conduit must be ground bonded.)

6. If integrating a pole mounted enclosure, remove existing PWE batteries and slide trays so conduit can enter the

bottom of the enclosure. BIU Integration wires should be long enough to route to XM3.1-HP™ power supply battery

and RS485 COM connectors. Excess wire can be looped in the bottom of the PWE.

When installing PowerSafe®SBS 190F batteries, leave approximately 1½" of space behind the

batteries on the shelf. Always install batteries with the rear door removed to avoid slamming the

batteries into the rear door and causing damage.

NOTICE:

Fig. 2-3, Routing Conduit Underground Examples

Existing underground enclosure

5.5 Amp Draw

Add 1/2 or 2-inch metallic conduit

for battery cables and comms cable

PWR

COM

+

_

Existing underground enclosure

2 Amp Draw

Add 1 1/2 or 2-inch metallic conduit

for battery cables and comms cable

PWR

COM

+

_

Existing underground enclosure

5.5 Amp Draw

Add 1 1/2 or 2-inch metallic conduit

for battery cables and comms cable

PWR

COM

+

_

Existing Aerial Enclosure

5.5 Amp Draw

Existing Underground Enclosure

2 Amp Draw

Existing Underground Enclosure

5.5 Amp Draw

Add 1 ½" or 2" metallic conduit for

battery cables and COM cables

Add 1 ½" or 2"

metallic conduit for

battery cables and

COM cables

Add 1 ½" or 2" metallic

conduit for battery cables and

COM cables

Fig. 2-4, PN-4 FT Conduit Location

(Back of Enclosure)

7. Install grouped BIU extension, #6 AWG battery and COM cables in conduit run.

Remove 75A Anderson™ connector housing on the end to be pulled through

the conduit. Use appropriate wire pulling grip techniques to protect Anderson

terminals and RS485 COM connector. When in place, BIU extension wires must

be long enough to route from XM3.1-HP power supply to BIU1 connectors after

batteries are installed. Re-install 75A Anderson connector housing on battery

cables.

8. Ensure all PN-4 battery trays are installed correctly.

9. Verify XM3.1-HP power supply battery breaker and BIU circuit breakers are off.

10. With battery covers on, place batteries on shelves using proper lifting procedure.

This is a two-person operation. When installing AlphaCell®210FTX batteries leave

the rear handle flipped forward to aid in future removal. Use approximately ½"

spacing between batteries. On PN-4 FTB leave more space (approximately ¾")

between last battery in the first three string and the D string battery. This will

help with wiring the D string batteries.

4031-00014-B1-001, Rev. A (02/2023)

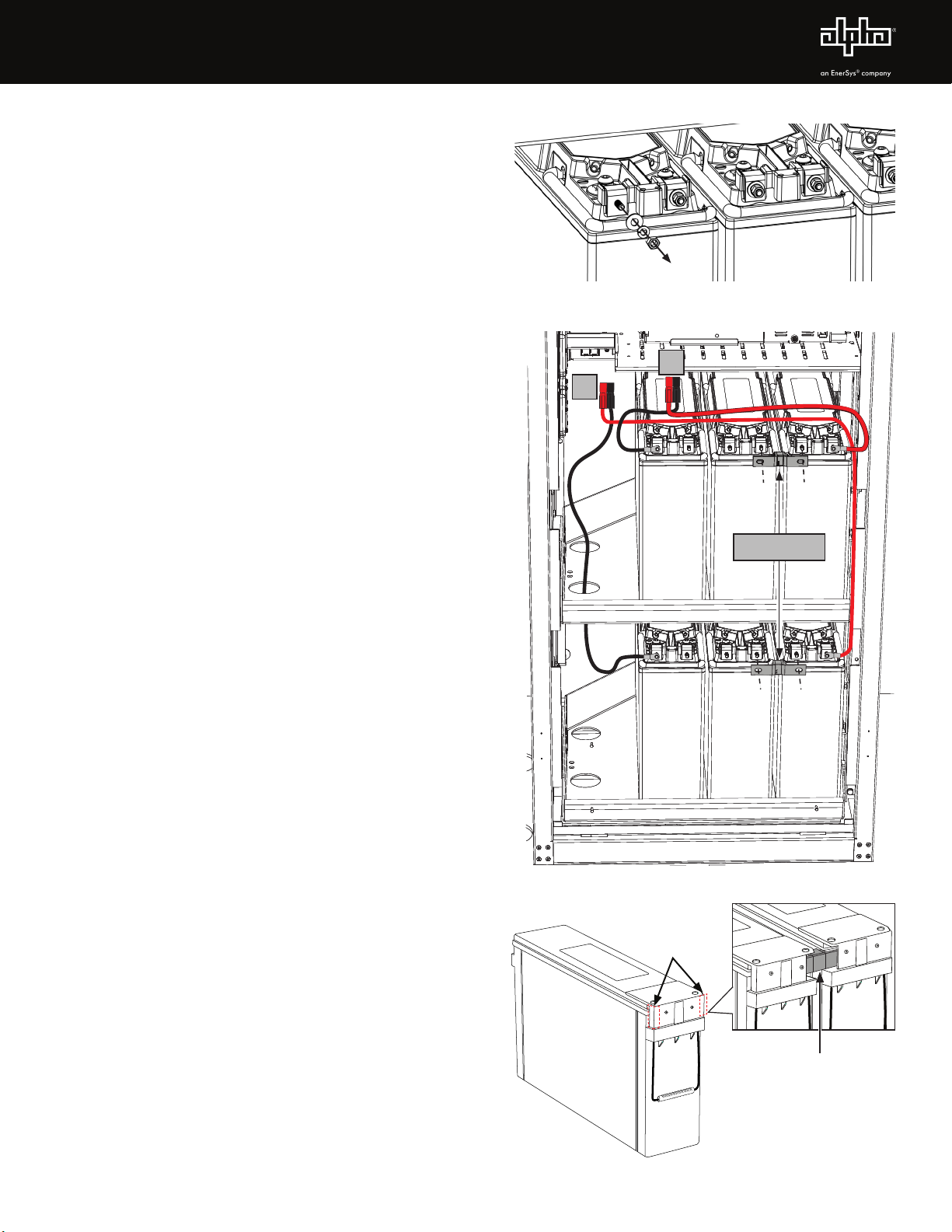

11. Remove all battery covers.

12. Remove all hardware from battery terminals and store in

a bag or convenient place. (Fig. 2-5)

13. Install 876-00059-20 BAT,INTG,36VDC,2STRG,PN4FT,W/

BIU,PTS,BS in the PN-4 FT with two battery trays. (See

Fig. 1-1, Fig. 2-9 and p/n 031-00014-08 System Wire

Diagram available on Alpha's website for reference.)

A. Start with A string battery cables on the bottom

tray of the PN-4 FT. Route the black wire through

the hole in left side of the top tray as seen in Fig.

2-6. Route the red wire along the right side of the

enclosure.

B. Install B string battery cables on middle tray.

C. Install intercell fuses on batteries 2A and 3A, and 2B

and 3B. (On AlphaCell® 210FTX batteries, the fuse

can be offset to the back. On PowerSafe® SBS 190F

batteries, the fuse must be offset to the front.)

D. Install interconnect bus bars on batteries 1A and 2A,

and 1B and 2B.

E. Install Precision Temperature Sensors (PTS). Plug in

to appropriate BIU1 port (ex: PTS A cable into the

PTS A BIU1 port) in turn so they don’t get mixed up.

Route wires down the right side. Use wire label A

& B provided by installer to mark both ends of PTS.

Note: The PTS are 4ft long.

F. Install battery voltage sense wires. Route wires

down the right side.

G. Torque battery terminals to battery manufacturer's

specifications.

H. Check battery cable connectors for correct polarity

and voltage. Verify connector color, orientation and

wire labels, then fully insert into BIU1.

Note: The BIU will power up as soon as the

batteries are connected, regardless of circuit

breaker position.

I. Before installing covers, use a corrosion inhibitor

such as NO-OX®electrical contact grease on battery

terminals. Install battery covers. (On PowerSafe SBS

190F batteries, the covers must be trimmed with

side cutters to fit around the intercell fuses. See Fig.

2-7. Trim side needed.)

14. Plug in battery voltage sense connector into BIU1.

15. Connect BIU1 extension cable from BIU DC Output to

XM3.1-HP™ power supply Battery Input.

16. Connect RS485 COM cable from BIU1 COM1 to

XM3.1-HP power supply BIU connection.

Fig. 2-5, Remove Battery Hardware

Fig. 2-6, Installing Battery Cables and Intercell Fuses

Fig. 2-7,Trimming Battery Cover on PowerSafe®SBS 190F

A

B

Intercell Fuses

1A

1B

2A

2B

3A

3B

Intercell Fuse

Trim the

side needed

5031-00014-B1-001, Rev. A (02/2023)

OUTPUT

ALARM

TEST

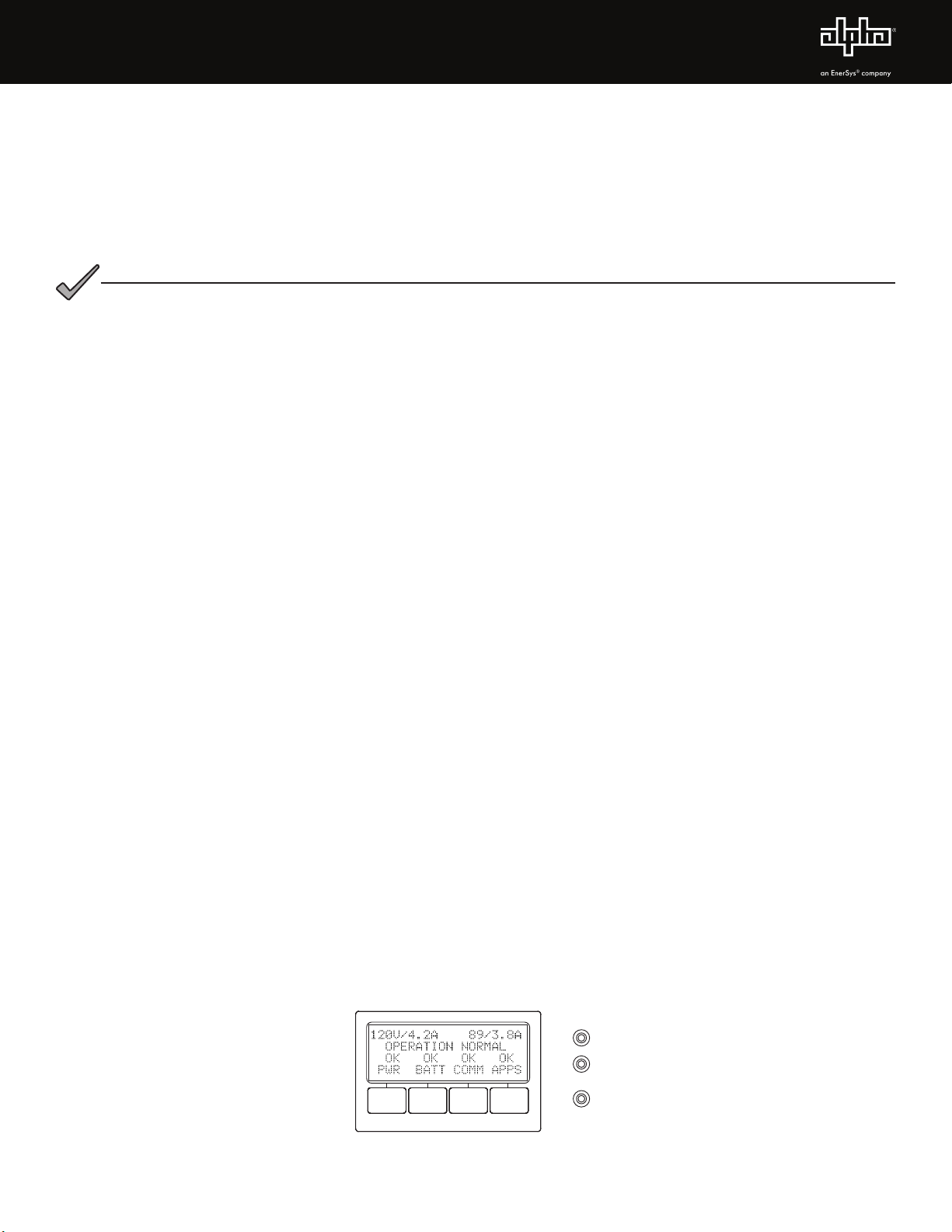

Fig. 2-8, XM3.1-HP™ Power Supply

Smart Display

1 7. Install 876-00059-22 BAT,INTG,36VDC,4STRG,PN4FT,W/BIU,PTS,BS in PN-4 FTB with 3 battery trays. (See Fig. 1-1,

Fig. 2-10 and p/n 031-00014-08 System Wire Diagram available on Alpha's website for reference.)

A. Start with A string battery cables on the bottom tray.

B. Install B string battery cables on middle tray.

C. Install C string battery cables on top tray.

D. Install D string battery cables.

E. Install intercell fuses on batteries 2A and 3A, 2B and 3B, and 2C and 3C. (On AlphaCell® 210FTX batteries the

fuse can offset to the back. On Powersafe®SBS 190F batteries the fuse must offset to the front.) If installing D

string batteries, use the F4 fuse wire kit between batteries 2D and 3D.

F. Install interconnect bus bars on batteries 1A and 2A, 1B and 2B and 1C and 2C. If installing D string batteries,

install an intercell jumper between batteries 1D and 2D.

G. Install Precision Temperature Sensors (PTS). Plug in to appropriate BIU2 port (ex: PTS A cable into the PTS A BIU2

port) in turn so they don’t get mixed up. Route wires down the right side. Use wire label A, B, C & D provided by

installer to mark both ends of PTS. Note: PTS A is 12ft. The rest are 4ft.

H. Install battery voltage sense wires. Route wires down the right side.

I. Torque battery terminals to battery manufacturer's specifications.

J. Check battery cable connectors for correct polarity and voltage. Verify connector color, orientation and wire labels

then fully insert into BIU2.

K. Before installing covers, use a corrosion inhibitor such as NO-OX®electrical contact grease on battery terminals.

Install battery covers. (On PowerSafe SBS 190F batteries the covers must be trimmed with side cutters to fit

around the intercell fuses. See Fig. 2-7.)

18. Plug in Battery Voltage Sense connector to BIU2.

19. Connect BIU2 extension cable from BIU2 DC Output to BIU1 DC Input.

20. Connect RS485 COM cable from BIU2 COM1 to BIU1 COM2.

21. Verify communication termination is installed in BIU2 COM2.

22. Turn on BIU breakers one at a time, then turn on XM3.1-HP™ power supply battery breaker.

23. On the XM3.1-HP power supply Smart Display, select B AT T and choose the battery model that corresponds with the

configuration. Check individual battery voltage via the Smart Display.

24. Verify BIU is configured correctly by selecting BIU INFO and all menus are "OK". Another way to access this is by

pressing the left three buttons on the Smart Display at the same time. If any menus have ALM flashing, identify the

alarm and fix the problem.

25. Verify proper operation. Site must be alarm-free after running self-test.This can be accomplished manually or

by using Alpha XM360™ software.

If only three battery strings are required, don’t install the D string wires, F4 fuse wire kit or PTS.

D string battery voltage sense wires GRY and WHT ring lugs must be taped up and wires coiled

with wire tie to prevent shorting.

NOTICE:

6031-00014-B1-001, Rev. A (02/2023)

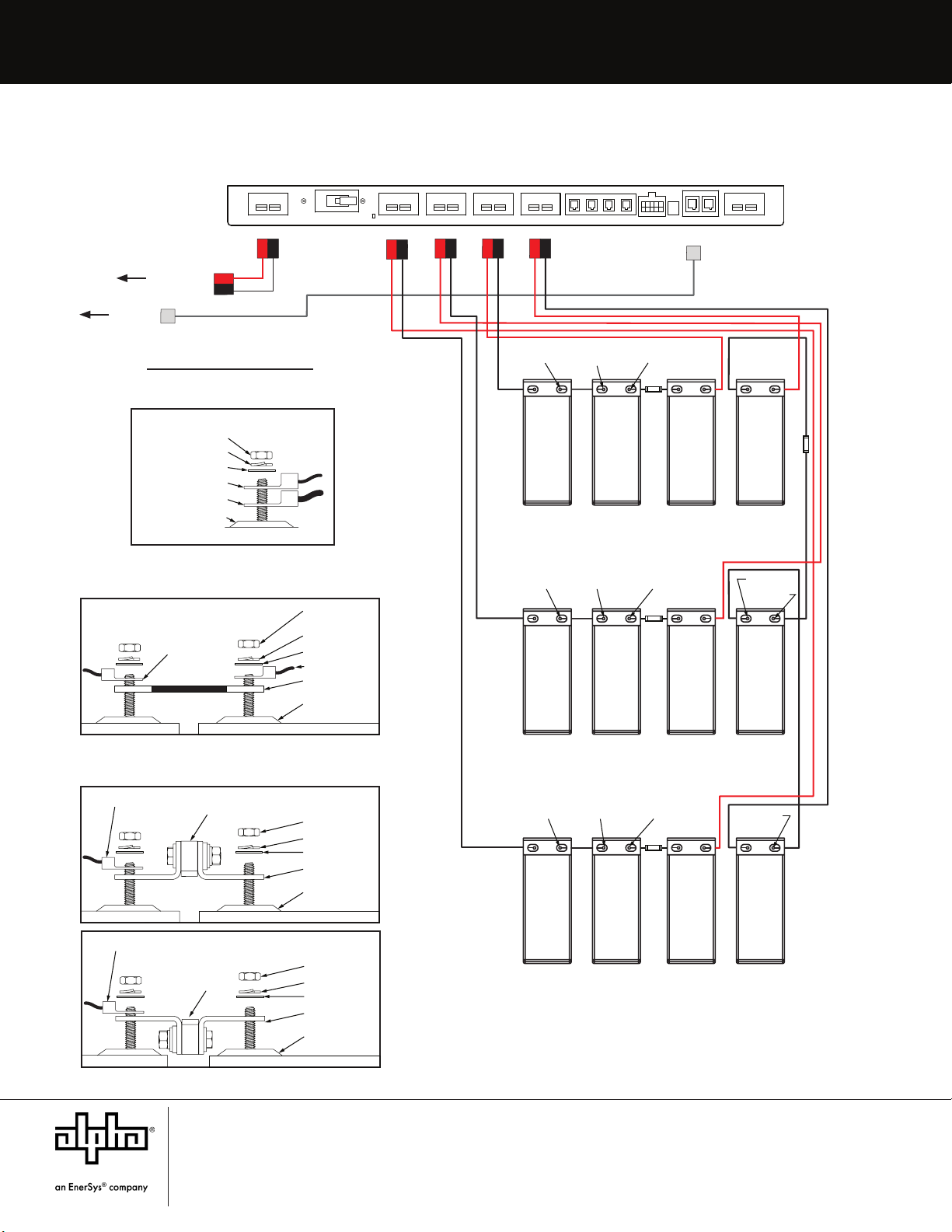

2.1 Battery Installation Layout

Fig. 2-9, PN-4 FT XRT Battery Installation Arrangement and Wiring Diagram

BOTTOM TRAY

BATTERY INTERFACE UNIT (BIU)

BAT 1B

BAT 3B

BAT 2B

BAT 1A

BAT 3A

BAT 2A

PTS B

PTS A

MIDDLE TRAY

100A

100A

BAT SNS

BAT SNS

BAT SNS

PowerSafe®

SBS 190F battery

AlphaCell®

210FTX battery

BAT SNS

- + - +- +

- + - + - +

TO POWER

SUPPLY

DC INPUT

TO POWER SUPPLY

BIU RS485

COMMUNICATION

CONNECTION

TO DC OUTPUT

ON BIU2

TO COM1

ON BIU2

STRING B

STRING A

STRING C STRING D

PTS A

BATTERY TEMP SENSE

PTS B PTS C PTS D

80A CB

DC OUTPUT

BAT SNS

TPR COM 1 COM 2

DC INPUT

+

-

+

-

+

-

+

-

+

-

+

-

PWR

A DCB

Precision

Temp

Sense (PTS)

Battery

Voltage

Sense

{

Battery String

Input

{

{

Circuit Breaker

{

COM

Tamper Switch

{

{

PN-4FT EXTENDED RUNTIME (XRT) SYSTEMS BATTERY ENCLOSURE

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

Fused Interconnect

+-

Battery Sense

CONNECTIONS

Interconnect

+

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

-

PTS

Battery Sense

Battery

M6 NUT

Split Washer

Flat Washer

(PTS or Battery Sense)

Battery Terminal

Battery Cable

100A Fuse

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

+

-

Battery Sense

100A Fuse

12V BRN

12V YEL 24V GRN

24V ORG

PN-4 FT EXTENDED RUNTIME (XRT) SYSTEMS BATTERY ENCLOSURE

BATTERY INTERFACE UNIT (BIU1)

7

Alpha Technologies Services, Inc. | 3767 Alpha Way, Bellingham, WA 98226, USA

Tel.: Toll Free North America: +1 800 322 5742 | Outside US: +1 360 647 2360 | Technical Support: +1 800 863 3364

For more information visit our website at: www.alpha.com

© 2022 Alpha Technologies Services, Inc. All Rights Reserved. Trademarks and logos are the property of Alpha

Technologies Services, Inc. and its aliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E.

NO-OX®is a registered trademark of Mind Head LLC.

031-00014-B1-001, Rev. A (02/2023)

Alpha Technologies Services, Inc. | 3767 Alpha Way, Bellingham, WA 98226, USA

Tel.: Toll Free North America: +1 800-322-5742 | Outside US: +1 360-647-2360 | Technical Support: +1 800-863-3364

For more information visit www.alpha.com

© 2022 Alpha Technologies Services, Inc. All Rights Reserved. Trademarks and logos are the property of EnerSys and its afliates unless otherwise

noted. The following trademarks are not the property of EnerSys: NO-OX®, Anderson™. Subject to revisions without prior notice. E.&O.E.

Fig. 2-10, PN-4 FTB XRT Wiring Diagram

BAT 1C

BAT 3D

BAT 3C

BAT 2C

BOTTOM TRAY

BATTERY INTERFACE UNIT (BIU)

BAT 1B

BAT 2D

BAT 3B

BAT 2B

BAT 1A

BAT 1D

BAT 3A

BAT 2A

PTS B PTS D

PTS C

PTS A

BAT SNS BAT SNS

MIDDLE TRAY

TOP TRAY

100A

100A

100A

100A

BAT SNS

BAT SNS

BAT SNS

BAT SNS BAT SNS BAT SNS

- +- + - + - +

- + - +- +- +

- + - + - + - +

TO DC INPUT

ON BIU1

TO COM2

ON BIU1

STRING B

STRING A

STRING C STRING D

PTS A

BATTERY TEMP SENSE

PTS B PTS C PTS D

80A CB

DC OUTPUT

BAT SNS

TPR COM 1 COM 2

DC INPUT

+

-

+

-

+

-

+

-

+

-

+

-

PWR

A DCB

Precision

Temp

Sense (PTS)

Battery String Input

Battery

Voltage

Sense

{

{

{

COM

Tamper Switch

{

{

Circuit Breaker

{

PN-4FTB EXTENDED RUNTIME (XRT) SYSTEMS BATTERY ENCLOSURE

PowerSafe

®

SBS 190F battery

AlphaCell

®

210FTX battery

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

Fused Interconnect

+-

Battery Sense

CONNECTIONS

Interconnect

+

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

-

PTS

Battery Sense

Battery

M6 NUT

Split Washer

Flat Washer

(PTS or Battery Sense)

Battery Terminal

Battery Cable

100A Fuse

Interconnect

Bus Bar

M6 Nut

Flat Washer

Split Washer

Battery Terminal

+-

Battery Sense

100A Fuse

24V WHT

24V GRN

24V VIO12V BLU

12V GRY

24V ORG12V BRN

12V YEL

PN-4 FTB EXTENDED RUNTIME (XRT) SYSTEMS BATTERY ENCLOSURE

BATTERY INTERFACE UNIT (BIU2)

Other EnerSys Power Supply manuals

EnerSys

EnerSys alpha APX3 Series User manual

EnerSys

EnerSys alpha LPS36 Quick start guide

EnerSys

EnerSys alpha APX3-G Series User manual

EnerSys

EnerSys Alpha Broadband UPS User manual

EnerSys

EnerSys alpha CXPS-E3 User manual

EnerSys

EnerSys alpha Cordex CXRF 48-3.6kW Quick start guide

EnerSys

EnerSys Alpha FMPS FTTP User manual