EnerSys alpha LPS36 Quick start guide

LPS36

Line Power System

Technical Guide: 0120011-J0

Effective: 07/2020

Cordex HP LPS36/Compact

-48Vdc to +/-190Vdc Line Power System

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photo-

graphs may not match your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe operation of this powering

system, contact Alpha and Outback Energy GmbH or your nearest AOE representative.

NOTE:

AOE shall not be held liable for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware if used or operated in any manner or

subject to any condition inconsistent with its intended purpose, or if installed or oper-

ated in an unapproved manner, or improperly maintained.

For technical support, contact Alpha and Outback Energy GmbH:

Tel: +49 9122 79889 0

Mail: [email protected]

Copyright

Copyright © 2019 Alpha Technologies Ltd. All rights reserved. Alpha is a registered trademark of Alpha Technolo-

gies.

No part of this documentation shall be reproduced, stored in a retrieval system, translated, transcribed, or transmit-

ted in any form or by any means manual, electric, electronic, electromechanical, chemical, optical, or otherwise

without prior explicit written permission from Alpha Technologies.

This document, the software it describes, and the information and know-how they contain constitute the proprietary,

confidential and valuable trade secret information of Alpha Technologies, and may not be used for any unauthorized

purpose, or disclosed toothers without the prior written permission ofAlpha Technologies.

The material contained in this document is for information only and is subject to change without notice. While

reasonable efforts have been made in the preparation of this document to assure its accuracy, Alpha Technologies

assumes no liability resulting from errors or omissions in this document, or from the use of the information contained

herein. Alpha Technologies reserves the right to make changes in the product design without reservation and with-

out notification to its users.

3

0120011-J0 Rev M

Table of Contents

1. Safety �����������������������������������������������������������������������������������������������������������������������������������7

1.1 Safety Symbols .......................................................................................................................... 7

1.2 General Warning and Cautions.................................................................................................. 7

1.3 Mechanical Safety...................................................................................................................... 7

1.4 Electrical Safety ......................................................................................................................... 8

2. Product Overview................................................................................................................10

2.1 Product Part Numbers ..............................................................................................................11

2.2 Block Diagram—Three Shelves and a Fan Tray (19" and 23")................................................ 12

3. Product Specications ........................................................................................................13

4. Features..............................................................................................................................15

4.1 Converter Modules................................................................................................................... 15

4.2 LPS36 System Features (19"/23") ........................................................................................... 16

4.3 LPS Compact System Features (6") ........................................................................................ 20

5. Site Evaluation and Pre-Installation....................................................................................22

5.1 Pre-Installation Requirements.................................................................................................. 22

5.2 Packing Materials..................................................................................................................... 23

6. LPS36 System Installation..................................................................................................24

6.1 General Instructions................................................................................................................. 24

6.2 Safety Precautions................................................................................................................... 24

6.3 Tools Required ......................................................................................................................... 25

6.4 Thermal Management.............................................................................................................. 26

6.5 LPS36 Set Up: 19" and 23" Systems....................................................................................... 29

6.6 LPS Compact Set Up: 6" Systems........................................................................................... 34

6.7 Making Load Connections ....................................................................................................... 42

6.8 System Startup with CXCI+ Controller..................................................................................... 44

6.9 System Startup with the CXCI HP Controller........................................................................... 54

0120011-J0 Rev M

4

7. Maintenance and Troubleshooting......................................................................................61

7.1 Troubleshooting Converter Status LEDs.................................................................................. 61

7.2 Fan Filter Maintenance and Installation (19/23" only).............................................................. 63

7.3 Replacing the Fan Tray............................................................................................................ 65

7.4 Replacing a Converter (19"/23") .............................................................................................. 66

7.5 Replacing the Controller (19"/23" only).................................................................................... 66

7.6 Replacing an Alarm Relay Module (19"/23" only) .................................................................... 67

7.7 Spare Parts .............................................................................................................................. 69

8. Warranty Statement and Service Information .....................................................................70

8.1 Technical Support .................................................................................................................... 70

8.2 Warranty Statement ................................................................................................................. 70

8.3 Product Warranty ..................................................................................................................... 70

8.4 Battery Warranty ...................................................................................................................... 70

8.5 Warranty Claims....................................................................................................................... 70

8.6 Service Information .................................................................................................................. 70

9. Acronyms and Denitions ...................................................................................................71

10. Certication.......................................................................................................................72

5

0120011-J0 Rev M

List of Figures

Figure 1 — LPS36 shelf (19" shown).............................................................................................. 10

Figure 2 — LPS36 Compact (6" shown), cable length not to scale ................................................ 10

Figure 3 — LPS36 shelf (19" shown).............................................................................................. 16

Figure 4 — CXCI HP controller front panel..................................................................................... 16

Figure 5 — Cordex CXCI+ controller front panel ............................................................................ 17

Figure 6 — Shelf Connections ........................................................................................................ 18

Figure 7 — Shelf Alarm LEDs ......................................................................................................... 18

Figure 8 — Fan and Bae Tray Rack, mounted (19" shown)......................................................... 19

Figure 9 — Shelf Connections ........................................................................................................ 20

Figure 10 — DC input cable kit accessory (ordered separately, PN 8700870-001) ....................... 21

Figure 11 — Fan tray ...................................................................................................................... 21

Figure 12 — Natural Convection 19"/23" Systems ......................................................................... 26

Figure 13 — Output Power Derating Curve .................................................................................... 27

Figure 14 — Multi-shelf System Mounting ...................................................................................... 27

Figure 15 — LPS36 Compact Shelf with Fan Tray ......................................................................... 28

Figure 16 — Minimum Air Flow....................................................................................................... 28

Figure 17 — Locations for protective earthing terminals for chassis ground (LPS36 side view) .... 30

Figure 18 — DC input connections (19") ........................................................................................ 30

Figure 19 — DC input wiring connections....................................................................................... 31

Figure 20 — CAN and fan connections on the shelf interface panel (for reference only)............... 31

Figure 21 — CAN OUT terminator.................................................................................................. 32

Figure 22 — CAN Bus cabling ........................................................................................................ 32

Figure 23 — Fan tray connections.................................................................................................. 32

Figure 24 — Converter shelf alarm relays ...................................................................................... 33

Figure 25 — Fan Tray Alarm Relay................................................................................................. 33

Figure 26 — Rack Mount Bracket Assembly (either side, based on installation)............................ 34

Figure 27 — Rack Mount (left side shown)..................................................................................... 35

Figure 28 — Rack Mount, Left side with Fan Tray.......................................................................... 35

Figure 29 — Right Side Mount, with Fan Tray ................................................................................ 36

0120011-J0 Rev M

6

Figure 30 — Rack Mount Left Side, LPS modules upside down .................................................... 36

Figure 31 — Mounted Sideways (front of unit) ............................................................................... 37

Figure 32 — Mounted Sideways (back of unit) ............................................................................... 37

Figure 33 — Locations for Chassis Ground (LPS36 Compact, side view) ..................................... 39

Figure 34 — DC Input Connections ............................................................................................... 40

Figure 35 — DC Input Cable Kit Accessory .................................................................................... 40

Figure 36 — PIN Assignment Table ................................................................................................ 41

Figure 37 — CAN Connection ........................................................................................................ 41

Figure 38 — Connector Pinouts ..................................................................................................... 42

Figure 39 — Live Graphical View ................................................................................................... 45

Figure 40 — Live Table View .......................................................................................................... 45

Figure 41 — Channel Information for Position 6............................................................................. 46

Figure 42 — Grouping LPS Channels ............................................................................................ 47

Figure 43 — LPS Channel Custom Text ......................................................................................... 48

Figure 44 — LPS Alarm Highlighting .............................................................................................. 49

Figure 45 — Viewing LPS Alarms................................................................................................... 49

Figure 46 — Conguring LPS Alarms ............................................................................................. 50

Figure 47 — Fan Tray Live Status .................................................................................................. 50

Figure 48 — Conguring a Custom Alarm ...................................................................................... 51

Figure 49 — Equation Editor for Conguring a Fan Fail Alarm....................................................... 51

Figure 50 — Fan Fail Alarm ............................................................................................................ 51

Figure 51 — Manage Editable Text Files ........................................................................................ 52

Figure 52 — Custom Name Change............................................................................................... 52

Figure 53 — Line Power System Wizard ........................................................................................ 55

Figure 54 — Quick Reference: Congure a Line Power System.................................................... 55

7

0120011-J0 Rev M

1� Safety

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions that must be followed

during the installation, servicing, and maintenance of the product. Keep it in a safe place. Review the drawings

and illustrations contained in this manual before proceeding. If there are any questions regarding the safe

installation or operation of this product, contact Alpha Technologies or the nearest Alpha representative.

1.1 Safety Symbols

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and attention.

NOTE:

A NOTE provides additional information to help complete a specific task or procedure.

Notes are designated with a checkmark, the word NOTE, and a rule beneath which the

information appears

CAUTION!

CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment. Cautions are designated with a yellow warning triangle, the word CAUTION,

and a rule beneath which the information appears.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to personnel.

Warnings are indicated by a shock hazard icon, the word WARNING, and a rule beneath

which the information appears.

HOT!

The use of HOT presents safety information to PREVENT BURNS to the technician or

user.

1.2 General Warning and Cautions

WARNING!

This system is designed to be installed in a restricted access location that is

inaccessible to the general public.

1.3 Mechanical Safety

CAUTION!

Do not disassemble the product – call our qualified service centers for servicing.

Incorrect reassembling may result in a risk of electrical shock or fire.

Do not operate the product if it has received a sharp blow, it has been dropped, or

otherwise damaged in any way – return it to a qualified service center for repair.

0120011-J0 Rev M

8

LPR48-150

LPS36

Channel 1

T1

R1

≤75W

≤75W

LPS36

Channel 2

CONVERTER #1

CONVERTER #2

RADIO 100W

Load

T2

R2

+190V

-190V

+190V

-190V

Input A

Input B

LPR48-150

LPS36

Channel 1

T1

R1

≤75W

≤75W

LPS36

Channel 2

CONVERTER #1

CONVERTER #2

RADIO 100W

Load

T2

R2

+190V

-190V

+190V

-190V

Input A

Input B

Bridging circuits

1�4 Electrical Safety

Before working with any live battery or power system, follow these precautions:

a. Remove all metallic jewelry, such as watches, rings, metal rimmed glasses, or necklaces.

b. Wear safety glasses with side shields at all times during the installation.

c. Use OSHA approved insulated hand tools. Do not rest tools on top of batteries.

WARNING!

The DC input to the modules (and the converter system) – though not dangerous in volt-

age – has a high short circuit current capacity that may cause severe burns and electri-

cal arcing.

The DC output is a potentially dangerous voltage. Do not touch the output connections

when under power. Ensure that power has been removed from the outputs before work-

ing on them.

NOTE:

RFT-V output circuit configuration – bridged operation (not permitted)

The DC output is classified as an RFT-V circuit with a maximum rated power of

100W per channel. Paralleling of RFT-V circuits over multiple telecommunications

wires for the purpose of delivering power in excess of 100VA to a single load circuit

is not permitted. Refer to UL/CSA 60950-1 Section 6.2.1 for details.

RFT-V output circuit configuration – normal operation (permitted)

9

0120011-J0 Rev M

WARNING!

Lethal voltages are present within the power system. Always assume that an electrical

connection or conductor is energized. Check the circuit with a voltmeter with respect to

the grounded portion of the enclosure (both AC and DC) before performing any installa-

tion or removal procedure.

• Do not work alone under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment. Hazardous voltages are present at

the input of power systems. Ensure that the utility power is disconnected and locked out before performing

any installation or removal procedure.

• Ensure that no liquids or wet clothes come into contact with internal components.

• Hazardous electrically live parts inside this unit are energized from the batteries even when the AC input

power is disconnected.

• The enclosure which contains the DC or AC power system along with customer installed radios must remain

locked at all times, except when authorized service personnel are present.

• Always assume electrical connections or conductors are live. Turn off all circuit breakers and double-check

with a voltmeter before performing installation or maintenance.

• Place a warning label on the utility panel to warn emergency personnel that a reserve battery source is pres-

ent which will power the loads in a power outage condition or if the AC disconnect breaker is turned off.

• At high ambient temperature conditions, the internal temperature can be hot so use caution when touching

the equipment.

0120011-J0 Rev M

10

2� Product Overview

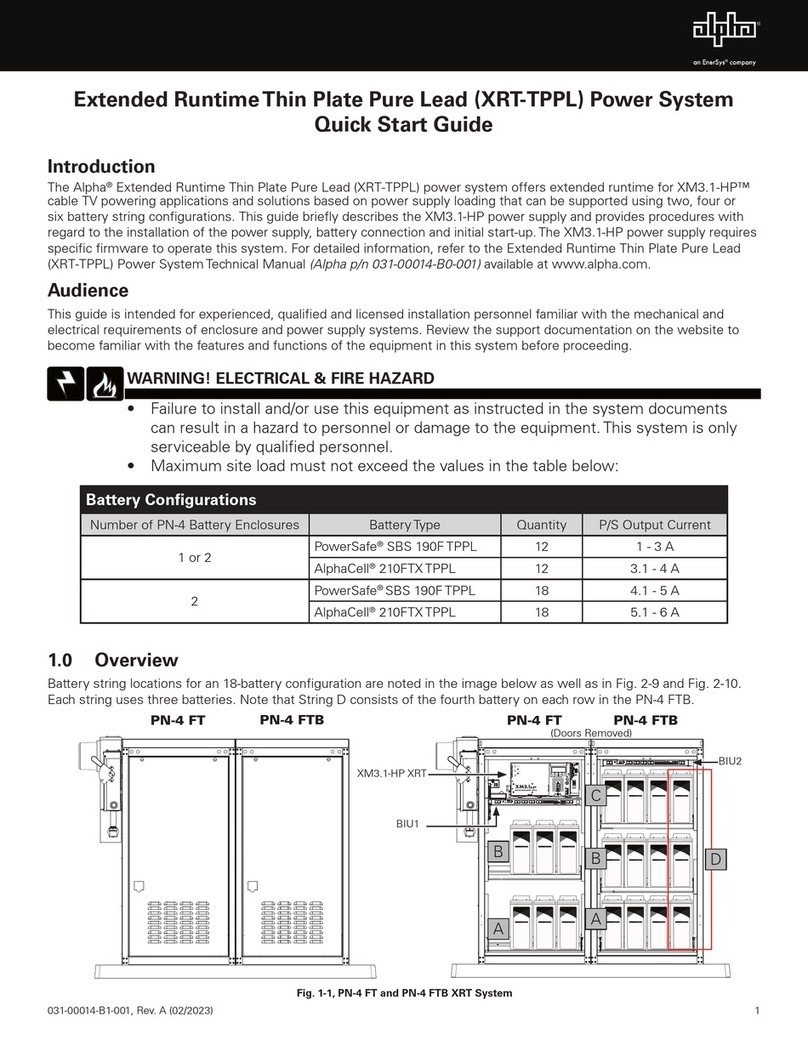

The LPS36 is a modular DC to DC up-converter system designed for distributed power communications applica-

tions using +/- 190Vdc (RFT-V circuit) over existing copper network.

Using switched mode technology, the LPS36 quad output converter module provides outstanding efficiency in a

compact design. Applications include powering sealed DSLAM’s, Distribution Point Units (DPU) as well as Optical

Network Terminals (ONT) in Fiber to the Home Networks (FTTH). Each LPS36 converter module contains four iso-

lated DC-DC converters, up to 100 Watt maximum. Converter modules are ordered separately at time of ordering or

later after the converter system has been installed. Blank plates can be ordered separately for empty slots.

• High efficiency >92% for increased operating expenses (OPEX) savings and reduced carbon footprint

• High temperature tolerance for installation in Central Office (CO) or harsh outside plant (OSP) cabinet environ-

ments

• Industry leading power density enabling up to 48 channels in a compact 2RU footprint

• High reliability convection-cooled design with optional fan tray

• Cordex CXCI series of system controllers provide advanced remote web based monitoring and control features

Figure 1 — LPS36 shelf (19" shown)

CXCI+ Converter slots #1-9

Mid mount

brackets

Load connectors

Front input

connections

Shelf

interface

panel

Rear input connections

(not shown)

#9

#1

Figure 2 — LPS36 Compact (6" shown), cable length not to scale

11

0120011-J0 Rev M

The 19" and 23"LPS36 systems consist of one or more converter modules and a CXCI+ controller installed in a

common shelf. A 19" shelf can have up to 9 modules, and a 23" shelf up to 12. All connections are front access. In-

put connections can be made at the rear of the unit as well. External connections are available at the shelf interface

panel for alarm interfaces.

The LPS36 Compact packs maximum power into minimum space, but doesn’t compromise on features. The shelf

provides up to 16 line powering channels in the compact 2RU x 6” x 12” form. Standard system features include

major and minor alarms for monitoring, connectorized cable output and one side mounting. This product is particu-

larly suitable for remote OSP power cabinets where free rack space is tight or non-existent. With a six inch width

and a single side bracket, it can be easily mounted to the side of a rack support post without using up valuable rack

space.

Alpha’s LPS36 modular DC to DC converter systems incorporate a full range of standard features, including cur-

rent limiting and individual ground fault interrupt for each circuit. Particular emphasis is placed on recognizing a

fault condition and shutting down the circuit as quickly as possible to ensure the highest level of personnel safety.

Compliance with GR-1089-CORE - Class A2 provides the ability to work on the equipment while powered, which

significantly reduces the administrative and labeling requirements and overheads for the high voltage wiring.

2�1 Product Part Numbers

Product Part number

19" Shelf - 9 modules 0300055-001

19" Fan Tray 0300055-002

19" Bae 0300055-003

23" Shelf - 12 modules 0300090-001

23" Fan Tray 0300090-002

23" Bae 0300090-003

Input Cover Kit (19/23") 0380249-001

Alarm Cable Kit (19/23") 8700649-001

6" Shelf - 4 modules 0300189-004

6" Fan Tray 0300189-002

6" Input Lug Kit (18") 8700870-001

CXCI+ Controller 7400232-001

CXCI HP Controller 0180053-001

Converter Modules 0120011-001

Blanking Plate Kit (quantity 2) 0380070-001

0120011-J0 Rev M

12

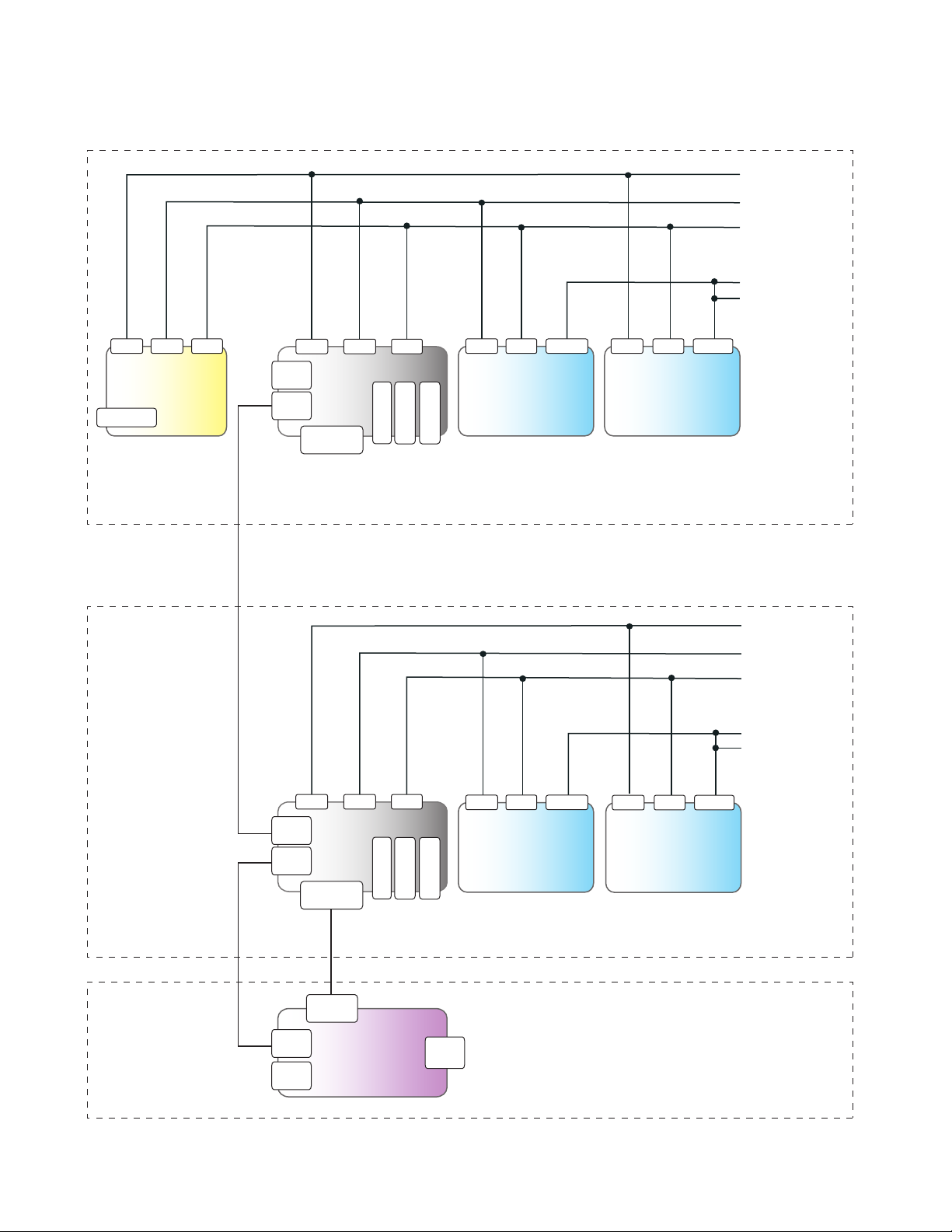

2�2 Block Diagram—Three Shelves and a Fan Tray (19" and 23")

CXCI+ Controller

Form C

contacts

SHELF 1 with CONTROLLER

Common RTN

OSP cable +/-190V lines

RJ21-J2

RJ21-J1

-48V Input A

-48V Input B

Common RTN

-48V Input A

-48V Input B

RTN

-48B -48A

CAN

out FAN

ALM

Fan tray

Fan

PWR in

SHELF 2 (not shown for clarity)

SHELF 3

FAN TRAY

Ethernet

Form C

contacts

Form C

contacts

CAN

in

-48A VOUT

DC-DC

power modules

slots 1- 5 (19")

slots 1 - 6 (23")

RTN

VOUT

-48B

DC-DC

power modules

slots 6-9 (19")

slots 7-12 (23")

RTN

VOUT

-48B

DC-DC

power modules

slots 6-9 (19")

slots 7-12 (23")

RTN

-48A VOUT

DC-DC

power modules

slots 1- 5 (19")

slots 1 - 6 (23")

RTN

OSP cable +/-190V lines

RJ21-J2

RJ21-J1

Interface Board

Shelf ID

-48B -48A

MAJOR

MINOR

CAN

out

CAN

in

RTN

Fan

PWR out

Interface Board

Shelf ID

-48B -48A

MAJOR

MINOR

CAN

out

CAN

in

RTN

Fan

PWR out

13

0120011-J0 Rev M

3� Product Specifications

Electrical

Input Voltage: -40 to -60Vdc

Recommended Breaker:

6" Shelf: 50A per feed

19" Shelf: 70A per feed

23" Shelf: 80A per feed

Recommended Cable Size: As per NEC 2014, Minimum #6 AWG (16mm2) copper rated for 90˚C or #4 (25mm2) rated

for 75˚C

Output Voltage: ±190Vdc (RFT-V)

Power: 96W nominal per output, >92W for worst case conditions (4 outputs per module)

>92%

Regulation: <2% no load to full load

<1% line

Output Noise:

Wide Band: <500mVRMS (10kHz to 10MHz)

<2.5V p-p (10kHz to 100MHz)

Acoustic: <60dBa @ 1m (3ft), 55˚C

Connections (19/23"):

Input: HOT: 2x sets, 1/4" holes on 5/8" centers

RTN: 2x sets, 1/4" holes on 5/8" centers

Output: Two 50-pin amp-champ style connector

Alarm Two 5-OIN terminal bloacks

Connections (6"):

Input: Anderson style connector

Output: One 50-pin amp-champ style connector

Alarm TE style connector

Quad Output Power Module (#0120011-001)

Dimensions (HxWxD): 386mm x 35mm x 283mm (3.4in x 1.4in x 11.1in)

Weight: 0.61kg (1.4lbs)

19" Shelf - 9 Modules (#0300055-001)

Dimensions (HxWxD): 88mm x 435mm x 311mm (3.5in x 17.1in x 12.25in)

Weight: 5.45kg (12lbs)

23" Shelf - 12 Modules (#0300090-001)

Dimensions (HxWxD): 88mm x 536mm x 311mm (3.5in x 21.1in x 12.25in)

Weight: 7.28kg (16lbs)

6” Shelf - 4 Modules (P/N 0300189-001)

Dimensions (HxWxD): 88mm x 149mm x 305mm (3.6in x 5.9in x 12in)

Weight: 1.5kg (3.3lbs)

Cable Length Output: 1372mm (54.00in)

Alarm: 1372mm (54.00in)

Efficiency:

0120011-J0 Rev M

14

Environmental

Temperature Operating:

Forced Air Cooling:

Convection Cooling:

-40 to 65˚C (-40 to 149˚F) with minimum OSP cabinet air ow @200LFM or fan tray

(used with two and three shelves)

-40 to 45˚C (-40 to 122˚F) single shelf operation only separated by 1RU bae

Temperature Storage: - 40 to 85˚C (-40 to 185˚F)

Humidity 0 to 95% RH non-condensing

Altitude: -500 to 2000m (-1640 to 6562ft)

Heat Dissipation: <118 BTU per hour/module

Performance/ Features

Communication Ports:

CAN: Smart peripherals

Ethernet: 10/100 Base-T for TCIP/SNMP features (19"/23" systems only)

Alarm relays:

Shelf: 1x Form C Major

1x Form C Minor

Fan Tray: 1x Form C fan tray alarm

Alarm indicating LEDs:

Module: One tri color LED per converter—see Table A

(19" or 23" only) Shelf: System OK (o)

Minor alarm (yellow)

Major alarm (red)

Fan Tray: Major alarm (red)

MTBF: > 400,000 @30°C (86°F) ambient; test model Telcordia SR-332, Issue 2 (2006)

Agency Compliance

Safety: CSA/UL/IEC/EN No 60950-1

CSA/UL/IEC/EN 60950-21 (RFT-V circuit)

CE marked

EMC: ETSI 300 386

Emissions: CFR47 (FCC) Part 15 - Class A Device

ICES-003 - Class A Device

Immunity: EN 61000-4-2, EN 61000-4-3

EN 61000-4-4, EN 61000-4-5

EN 61000-4-6

EN 61000-4-8

NEBS/Telcordia (19"/23"

systems only):

GR-1089-CORE - Class A2

GR-63-CORE

GR-3108-CORE

15

0120011-J0 Rev M

4� Features

4�1 Converter Modules

A module contains four isolated DC to DC converters with a common control and supervisory circuit. Each module

output operates independently. An internal micro controller monitors both the inputs and outputs of the converters,

turns the converters on and off, and generates a converter fail alarm if required.

4�1�1 Status Indicators

The converter module has four LED indicators – one per converter. The LEDs are color-coded to indicate converter

status as follows:

Table A — Converter Status LEDs

LED State Converter Status

Green Normal

Blinking Green Remote shutdown enabled on individual

channel/converter

Blinking Green

(All 4 LEDs) Shelf is not compatible with the module

Module not seated properly

Yellow (All 4 LEDs) Recoverable:

• Ambient temperature high

Blinking Yellow (All 4

LEDs) Input qualify not OK

Blinking Yellow Recoverable:

• OCP/Overload

Non-recoverable:

• Converter Input Fuse fail

Red Locked-State:

• OVP

Non-recoverable:

• Converter Output Fuse fail

Blinking Red Recoverable:

•GFI

OFF (All 4 LEDs) Recoverable:

• No power

Non-recoverable:

•Main Input Fuse cut-o

Chasing Red/Green

Pattern (All 4 LEDs) Locate feature enabled

4�1� 2 Converter Alarms

Two converter fail outputs are present at the card edge connector. Alarms are activated after a one second delay for

the following conditions:

• Internal regulation fails

• Output voltage <±140V

• Over Voltage Protection (OVP) operation

• Ground Fault Interrupt (GFI) trip

• Input fuse or output fuse fail

• Output short circuit (±30V ± 20%)

•Input voltage out of range

• Heatsink/ ambient temperature out of range (Over Temperature Protection - OTP)

4 Status LEDs–one per converter

0120011-J0 Rev M

16

4�1�3 Blanks

Blanks are available for blank slots. Order blanking plate kit (contains 2 blanks) #0380070-001.

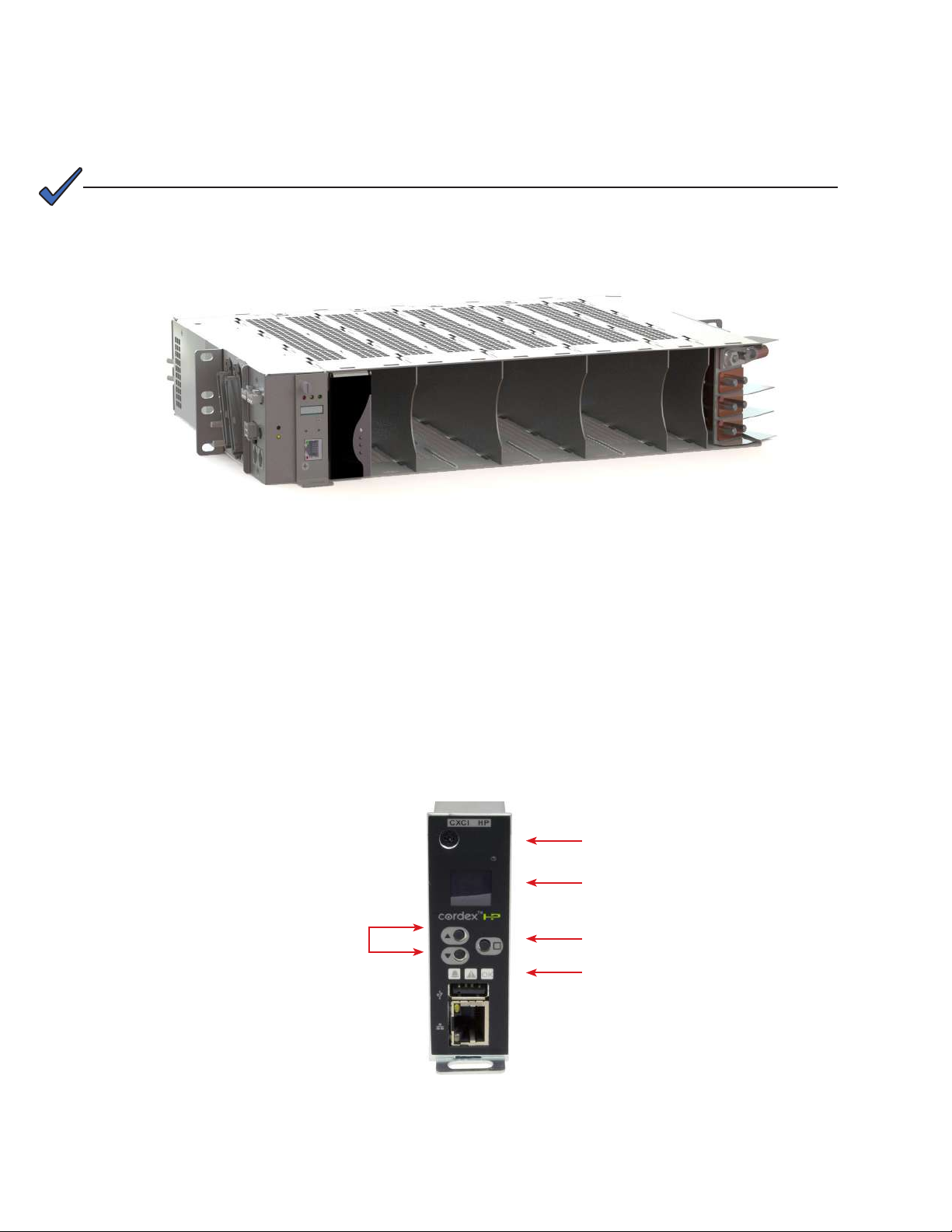

Figure 3 — LPS36 shelf (19" shown)

NOTE:

Figure 4 — CXCI HP controller front panel

4� 2 �1 Controllers

Both the CXCI HP and the CXCI+ controllers (Figure 4 and Figure 5) can be used in the shelves. For details on

using either controller go to the Alpha website to download the relevant software manual.

CXCI HP

CXCI HP in-shelf controllers have a small organic LED (OLED) display. This displays 30 characters total (six char-

acters wide, five lines high) and the controller has three navigation buttons and one reset button. The display has

three main operating modes: dashboard, menu and screen saver.

After 20 minutes with no activity, the controller goes into screen saver mode and the display shuts off. From

screen saver mode, press any of the three navigation buttons to re-activate the screen and enter dashboard

mode.

Forward and Back Buttons

to Scroll through menus

LED Status Indicators

•Green - Ok

• Yellow - Minor alarm

• Red - Major alarm

LED Display

Select Button to Enter Menus

and Execute Commands

Reset Button

Blanks must be installed when using fan trays to allow proper air flow to the

modules, see sections 6.4.2.

4.2 LPS36 System Features (19"/23")

17

0120011-J0 Rev M

LEDs

Each controller has three LEDs located on the front panel. These are used to display the alarm status of the power

system, controller progress and status during startup, as well as file transfers.

Alarm Conditions

The controller illuminates the LED that corresponds to the system alarm status. Only one LED is illuminated at a time

during alarm conditions. The following show the corresponding alarm status for each LED color:

Green:OK, no alarms

Yellow:Minor alarm, no major alarms

Red:Major alarm

Progress and Status Indication

The LEDs are also used in the following situations:

• Base unit validation – all three LEDs are on at the same time.

• File transfer – when recovering from invalid firmware application – the red LED is illuminated.

Reset

Refer to Section "Controller Reset" on page 53 for reset options.

Figure 5 — Cordex CXCI+ controller front panel

Ethernet port

Soft reset: push once

Reset IP address: hold

for 3 seconds

LCD screen (displays

Voltage or Current)

Display pushbutton toggle

switch for Voltage or Current

Hard reset: push once

System status LEDs

Locking screw

CXCI+ Controller

The controller brings advanced monitoring technology to the Cordex series of converters. A single controller man-

ages up to 9 converter modules. This compact system controller is equipped with the complete range of Cordex

software features, including the following:

• Ethernet port for local and remote communications

• User definable alarms

• Daily logging of power system events and system statistics

0120011-J0 Rev M

18

Figure 6 — Shelf Connections

4�2�2 Shelf Connections and Indicators (19" and 23" only)

Connections to the load and local alarm-sending unit are conveniently located on the side of each shelf.

Fan power connector

Major alarm relay

Minor alarm relay

50-pin load

connectors

CAN connectors

Shelf ID rotary switch

J1 J2

4�2�3 Alarm Relays (Form C Contacts)

The converter shelf has an interface panel with terminal blocks for Major and Minor alarm outputs (Form C contacts),

which are controlled by the controller. The Major alarm relay is designed to “fail safe” to ensure the alarm is regis-

tered when power is removed

Figure 7 — Shelf Alarm LEDs

OFF: Ok, no alarms

Red: Major alarm

Yellow: Minor alarm

Major Alarm

The Major alarm relay de-energizes under any one of the following conditions:

• When two or more outputs have failed within a shelf

• When the DC input feed is below the normal operating voltage

• When the DC input feed is above the normal operating voltage

Minor Alarm

The Minor alarm relay is de-energized under any one of the following conditions:

• Single output has failed within a shelf

• Internal ambient temperature is out of range

Alarm LEDs

On the front of the interface panel, are two LEDs—one red and one yellow, which indicate the shelf alarm status

(Figure 7).

If a Major alarm is activated, it "resets" the Minor

alarm relay to an energized state.

NOTE:

Table of contents

Other EnerSys Power Supply manuals

EnerSys

EnerSys alpha APX3 Series User manual

EnerSys

EnerSys alpha Cordex CXRF 48-3.6kW Quick start guide

EnerSys

EnerSys alpha APX3-G Series User manual

EnerSys

EnerSys Alpha Broadband UPS User manual

EnerSys

EnerSys Alpha XRT-TPPL User manual

EnerSys

EnerSys Alpha FMPS FTTP User manual

EnerSys

EnerSys alpha CXPS-E3 User manual