Engineering Solutions OMNIGUARD 5 User manual

Owner's Manual V1.60

OMNIGUARD™CELLULAR

Manometer / Differential Pressure Recorder

with Cellular and WiFi Communication

ENGINEERING

SOLUTIONS INC

Serial #:

Dealer:

The serial number is located inside the case, by the USB ports.

OMNIGUARD™CELLULAR

Manometer / Differential Pressure Recorder

with Cellular and WiFi Communication

1201 Monster Rd SW, Suite 240

Renton, Washington USA 98057

(206) 241-9395 • (206) 241-9411 fax

www.omniguard.com

ENGINEERING

SOLUTIONS INC

Purchase Date:

Registered To:

Name

Address

Telephone

© 1995-2018 Engineering Solutions Inc. Omniguard™ is a trademark of

Engineering Solutions Inc. Product specifi cations subject to change without

notice. First Printing 6/2018. Printed in the USA.

P/N OG-MAN.160

Page 1

Engineering Solutions Inc

P/N OG-MAN.160

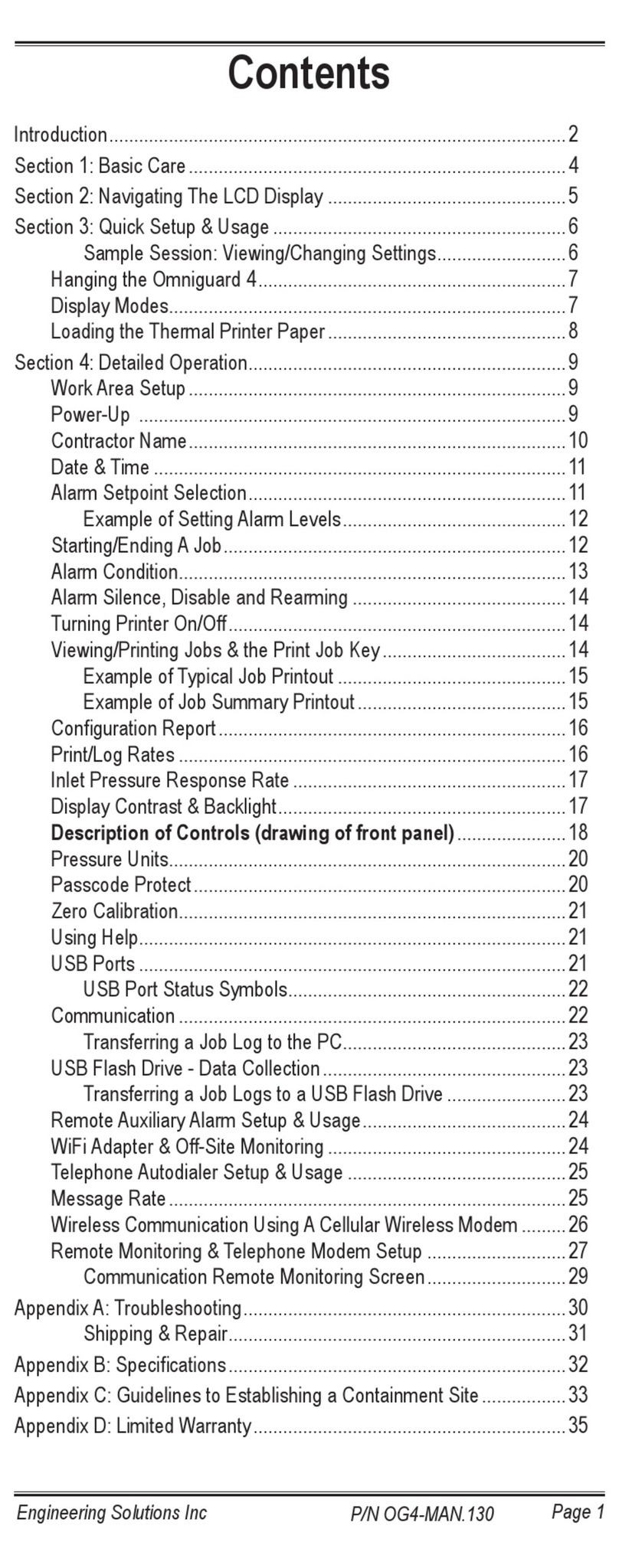

Contents

I

ntroduction ............................................................................................2

Section 1: Basic Care ............................................................................4

Section 2: Navigating the LCD Touchscreen .........................................5

Tutorial Screens .............................................................................5

Screen Icons, Front Panel Icons, USB Port Status Icons ..............6

Section 3: Quick Setup & Usage ...........................................................7

Hanging the Omniguard .................................................................8

Loading the Thermal Printer Paper ................................................8

Section 4: Detailed Operation ................................................................9

Work Area Setup ............................................................................ 9

Power-Up .......................................................................................9

Starting/Ending a Job .....................................................................11

Example of Job Summary Report .......................................11

Alarm Settings Screen ...................................................................11

Alarm 1 & Alarm 2 Settings ...................................................... 11

Alarm Settings & Operating Window ...................................12

Pressure Units .........................................................................12

Response Rate ........................................................................12

Alarm Condition..............................................................................12

Audible Alarm Mute, Disable & Re-arming .....................................13

Printer Settings & Reports Screen .................................................14

Example of Typical Job Log Printout ...................................14

General Settings Screen ................................................................15

Contractor Name .....................................................................15

Time & Date .............................................................................15

Log Rates ................................................................................16

Screen Settings ..............................................................................16

Touchscreen Calibration ..........................................................16

Zero Calibration..............................................................................17

Passcode Protection ......................................................................17

Erase Job Logs ..............................................................................18

Restore Factory Defaults ...............................................................18

Using Help......................................................................................19

USB Ports ......................................................................................19

Communication ..............................................................................19

Transferring a Job Log to a PC ................................................20

USB Flash Drive - Data Collection .................................................20

Transferring the Job Logs to a USB Flash Drive ..................... 20

Message Rate ................................................................................21

Cellular Communication Set up and Operation ..............................21

WiFi Communication Set up and Operation ...................................22

Section 5: Accessories ..........................................................................25

Remote Auxiliary Alarm ..................................................................25

Telephone Autodialer......................................................................25

Cellular Wireless Modem for non-Verizon Wireless Networks .......25

Appendix A : Troubleshooting ................................................................28

Shipping & Repair ..........................................................................29

Appendix B: Specifi cations ....................................................................30

Appendix C: Establishing a Containment Site .......................................31

Appendix D: Limited Warranty ...............................................................33

Battery Disposal Information................................................................. 34

FCC Certifi cation information.................................................................35

Page 2 Omniguard Cellular™ Owner’s Manual Page 3

Engineering Solutions Inc

pressure level.

• Extremely simple to setup and use, with on screen help.

• Log and track by Jobs. Stores multiple jobs, each with unique Job

Name and starting/ending dates.

• Remote communication of Alarms and Job Logs to off site

personell

Contractor name appears in all Job Logs.•

• Programmable high and low alarm settings.

• Large window in the case lid allows viewing pressure reading and

monitoring status with lid closed to prevent damage to unit.

• Touchscreen controls, extremely easy to use & set up.

• Internal memory stores pressure readings and alarm occurrences

with a date/time-stamp for up to 6 months, complete record of

operation available for printing and transfer to computer.

• Built-in hanging clip keeps the Omniguard away from possible

damage while allowing easy viewing of the screen.

• Totally self-contained unit, all necessary parts store securely inside

the lid.

• Temperature compensation circuitry ensure accuracy of measured

pressure readings under all job site conditions.

• Pressure readings displayed in Inches WC, Millimeters WC or

Pascals.

• USB Type A port supports multiple peripherals and accessories

including USB flash drive, cellular wireless modem, remote

auxiliary alarm and telephone autodialer.

• USB Type B port supports PC communication for transferring job

logs to a computer.

• Audible and visual alarm systems with Alarm Mute function.

• Operating temperature range 30°- 130°F.

• 85 - 240VAC, 50-60 Hz, power supply operation (10W max).

• Internal rechargeable 3.7 volts Li-ion type battery provides 4-6

hours of portable operation.

• 1 Year Limited Warranty.

Accessories

• Remote auxiliary alarm with high intensity strobe light and 95db

alarm & 25 ft. cable (requires USB Port Adapter).

• Cellular Wireless Modem for non-Verizon Wireless networks

alerts off-site personnel via e-mail or text message during alarm

conditions. It can also send daily status reports (requires USB

Port Adapter).

Introduction

The Omniguard Cellular is the latest version in the Omniguard™ series

of differential pressure recorders (manometers) first introduced over

20 years ago by Engineering Solutions Inc.

The Omniguard’s newest enhancements and features:

• Built-in Cellular Wireless Modem and WiFi Module

automatically sends Status reports & Job Logs to off-site

personnel via email and text messaging using the Verizon

Wireless network.

• Advanced pressure measurement technology with NIST

Certificate of Accuracy.

• 4.3” Color LCD with touchscreen, easy to read and even

easier to use.

• Multilingual - English, French and Spanish language

operation (French and Spanish Owner’s Manuals

available at www.omniguard.com).

• 4MB of secure log space.

• Internal rechargeable 3.7 volts Li-ion type battery provides

4-6 hours of portable operation.

• International power supply, 85-240 VAC 50-60Hz 10W

max.

Unpacking

The Omniguard is shipped complete and ready to use. When

unpacking the unit, please check for the following items:

• Roll of thermal paper (installed)

• USB Cable 6 ft A-B Male-Male

• 10 ft. inlet pressure tubing

• Owner’s Manual

• NIST Certificate of Accuracy

Save the shipping box and packing material, in the event the unit

must be shipped to another location or for service. If you are missing

any items shown on the packing list, or if you have any questions

regarding your Omniguard, please call your dealer or Engineering

Solutions at (206) 241-9395.

The Registration Card must be filled out and returned to activate the

12 month limited warranty.

Features

• Real-time differential monitoring of containment vacuum or

Omniguard Cellular™

Manometer / Differential Pressure Recorder

with Cellular and WiFi Communication

Page 4 Omniguard Cellular™ Owner’s Manual Page 5

Engineering Solutions Inc

Tutorial Screens

The Omniguard display is now a touchscreen! Touch the screen where

indicated to view and change settings, or to see Help.

Section 1: Basic Care

The Omniguard is built and engineered to provide you with dependable

performance for years to come. Following these basic guidelines will

insure that you get maximum use from your Omniguard. Once the

unit is set up, field operation is easy. Complete reports are virtually

automatic, providing the most accurate records of your job site

conditions available.

• This unit is designed to measure differential pressure only from

+0.250” to -0.250” WC (optional pressure ranges are available).

Caution: Never apply pressure to the inlet port by

mouth or with any other strong pressure device.

High pressure will permanently damage the sensor!!

• Use only Omniguard thermal printer paper (other thermal paper

will not work).

• Always store the unit away from sources of excessive temperature,

dust and moisture.

* When in use, close the lid to protect the Omniguard from damage.

Route the pressure tubing & power cord through the slot on the

side of the case.

• Never attempt to repair or modify any of the internal components

of the unit.

• Protect the unit from strong shocks or vibrations. Be sure the lid

is securely closed whenever transporting or hanging the unit.

• Be sure to plug your Omniguard into a power supply that complies

with the National Electrical Code. Keep all connections dry. As

with any electrical device, this unit has the potential to cause an

electrical shock hazard.

• If your unit must be shipped at any time to another location or for

service, use the original packing material and shipping box for

optimum protection during shipping.

Section 2: Navigating the LCD Touchscreen

Home Screen

-Indicates monitoring

status.

-Touch the icons to

access or change the

individual settings.

Main Menu

-Touch the menu item to

access system settings.

-Start or End a Job.

-View Tutorial screens &

enable/disable showing

tutorial when turned On.

Page 6 Omniguard Cellular™ Owner’s Manual Page 7

Engineering Solutions Inc

Section 3: Quick Setup & Usage

This section is a quick reference for using your Omniguard.

1. Find a safe place for the Omniguard outside the containment area.

Plug the power cord into an AC power outlet.

2. Connect one end of tubin

g to

the nozzle.

Secure the other end

of pressure tubing inside the containment area

.

3. Press the button to turn on the Omniguard.

4. A quick start tutorial will explain how to use the touchscreen. Touch

anywhere on the screen to go to tutorial screen 2. Touch the

icon to exit the tutorial and go to the Home screen.

5. To get a printed copy of the Job Log, touch the icon.

6. Touch START JOB at the bottom of the screen to begin a new

job. On the next screen, confirm Start New Job and enter a job

name, then touch the icon.

7. Check Alarm 1 & 2 settings by touching the Alarm settings

displayed on the Home screen. Adjust as needed by touching the

arrows to change the value up or down.

8. On any screen touch to get help about that screen. Touch

again to go to the general Help menu.

Once a job has been started, the status will indicate WAITING FOR

PRESSURE until containment pressure reaches the normal operating

window (a pressure reading that is between the Alarm settings). When

reached, the status will change to NORMAL and a green border will

appear indicating that the Omniguard is now in its normal operation

mode. The logging & printing pressure readings begins when the

NORMAL status is achieved.

During normal operation, the highest and lowest pressure readings

will be logged into memory and printed with a time/date stamp every

15 minutes (the default Normal Operation Log Rate).

If the monitored pressure then goes outside the operating window,

the unit will go into alarm mode. The alarm will sound, the status will

change to >>ALARM<< and a red border will appear on the screen.

The log and print rate of the pressure readings will increase to every

15 seconds (the default Alarm Condition Log rate).

To mute the alarm during an alarm condition, touch the icon once.

The icon will change to and the alarm will remain muted until the

alarm condition is over.

Power On/Off

Inlet Nozzles

Ambient (Reference)

Containment

Front Panel Icons

USB Port Status Icons

Analyzing

device.

USB Flash Drive

connected.

USB Flash Drive error -

full or write protected.

Connected to PC

USB Port Adapter

connected.

Screen Icons

Touch for item specific

Help. Touch again for

Help menu.

Touch to arm or disarm the

audible alarm - mutes during

an Alarm condition.

Touch to exit or return

to previous screen.

Touch for

Alarm settings.

Touch for Main Menu.

Touch to scroll thru menu,

Job Logs, reports or Help.

Indicates the battery

life remaining &

charging status.

Monitoring Status:

Printer On

Printer Off

Printer Off

(battery powered)

Touch for Printer settings.

Paper Jam

START JOB

WAITING FOR PRESSURE

NORMAL

APPROACHING ALARM

ALARM

Network Communication Settings Icons

Cellular Modem connected.

Cellular Modem error - not

activated or network not

detected.

Cellular Modem off.

WiFi connected

with full signal

WiFi error - can not

connect to wifi network

WiFi ON - No Wifi

log in informaiton, or

no signal in range

Page 8 Omniguard Cellular™ Owner’s Manual Page 9

Engineering Solutions Inc

Hanging the Omniguard

The Omniguard can be hung on a wall for easy viewing and to keep it

off of the floor, away from possible damage. Hanging the Omniguard

by the clip allows the cover to close, protecting the unit from water

damage while allowing the monitoring screen to be viewed through

the window on the cover. The pressure tubing and AC cord should exit

the case thru the foam slot, then the cover should be latched closed

to protect the unit from damage.

Caution: Only hang the Omniguard from a sturdy hook. A

fall could damage the unit and disrupt accurate pressure

measurements.

Loading the Thermal Printer Paper

Caution : Only use Omniguard thermal printer paper!

Thermal paper prints on one side only. If the paper roll

is installed incorrectly, the printer will be able to advance

the paper but will not be able to print on it.

1. Remove the paper lid and

thumbscrew. Cut the end of the

paper to a tapered point.

2. Place the paper roll, marked A,

into the paper lid so the paper

unrolls from the bottom.

3. Insert the tapered point of the

paper into the front panel slot

marked B, feed through the

printer until tapered point can be

pulled from the top of the front

panel at slot marked C.

Do not use the Paper Feed

function to advance the

paper.

4. From C, gently pull the paper until

the tapered portion is completely

exposed.

5. Replace the paper lid onto the

front panel and secure with the

thumbscrew.

A

B

C

C

BA

Section 4: Detailed Operation

The Omniguard monitors and records (logs) the differential pressure

between the nozzle and the nozzle (Reference).

In abatement applications, the Omniguard should be located outside

the containment area and not in any antechambers (i.e. shower or

changing room). This allows a supervisor or hygienist to monitor

pressure readings without entering the containment area.

Work Area Setup (see Appendix C for more details)

The Omniguard should be placed on a solid (non-vibrating) surface,

excessive vibrations disrupt accurate pressure measurement.

1. The intake end of the pressure tubing must be located a minimum

of 5 feet away from any openings or HEPA fan/filter units. Choose

a location away from excessive dust or moisture.

2. Cut a 1/2” slit in the polyethylene barrier and feed approximately

1 ft. of pressure tubing through it. Tape the tubing securely to the

polyethylene.

3. Connect the free end of the tubing securely over the nozzle.

Be careful not to turn the nozzle.

4. Route the tubing and AC cord through the foam notch area on

the upper right corner of the case. Close the lid to protect the

Omniguard from damage, (be careful to not pinch the tubing or

AC cord).

5. The maximum hose length is limited to 70 ft (for 3/16”ID hose).

Lengths beyond 70 ft can degrade reading accuracy.

Caution: It is important that there be no kinks or

sharp bends in any part of the tubing. Any blockage

could inhibit accurate recording of the pressure in the

containment area.

Power-Up

To use the Omniguard, plug the power cord into a standard wall outlet

providing 115-230 VAC, 50-60 Hz and press the power button.

The first time that a new Omniguard is turned on, the settings will be

at default values.

Initial Power-Up

Note: The first time the Omniguard is turned on, the

touchscreen will need to calibrated. The screen will

display a small box with an X in the middle of it. Touch

the X and continue until the calibration is completed.

Touchscreen calibration will need to be done if the

Omniguard is reset to factory default settings.

Page 10 Omniguard Cellular™ Owner’s Manual Page 11

Engineering Solutions Inc

A quick start tutorial will explain how to use the touchscreen.

Touch anywhere on the screen to go to tutorial screen 2. Touch

the icon to exit the tutorial and go to the Home Screen.

Set the Time & Date and Alarm 1 & Alarm 2 settings because

they are set at the factory defaults. The Time & Date will only

need to be set once. The Alarm 1 & Alarm 2 settings may need

to be adjusted for each Job’s requirements. For asbestos

removal, the Alarm 1 & Alarm 2 settings should be in negative

units when used to monitor a negative (vacuum) containment

area. For positive pressure applications, use positive units for

the Alarm settings.

Note: The Alarm 1 & 2 settings and the Time & Date

are displayed in yellow on the Home screen until

they have been changed from factory defaults.

Normal Power-Up Sequence

A diagnostic test will automatically run and the Omniguard will then

immediately begin to monitor containment pressure. The status will

indicate START JOB. Touch START JOB to begin actively monitoring

a new job.

Note: If the Omniguard was actively monitoring a Job when

it was turned off, it will automatically resume monitoring the

current Job. POWER OFF followed by the time-stamp will

print. Otherwise AC MODE or POWER FAIL will print,

indicating that an AC power failure occurred. Either message

will be followed by the time-stamp.

Once the Omniguard is actively monitoring a Job, the status will

indicate WAITING FOR PRESSURE until the containment pressure

has reached the operating window. The Job Name, time-stamp and

Alarm settings will be printed.

Note: Logging and printing of monitored pressure readings

does not begin until the containment pressure has reached the

operating window and the status indicates NORMAL.

Reminder: Be sure the Alarm 1 and Alarm 2 settings are

correct for your job site requirements!

Once the containment pressure reaches the operating window (the

area between the Alarm 1 and Alarm 2 settings) the status changes

from WAITING FOR PRESSURE to NORMAL and a green border

will appear around the screen. NORMAL OP is then printed along

with a time-stamp.

The screen border will change from green to yellow and the status

changes to APPROACHING ALARM to warn of an impending

Alarm condition when the pressure is within 0.005”WC of the Alarm

settings.

Starting/Ending A Job

Pressing START JOB will not erase any previous job logs, nor will it

alter any other settings (such as the Alarm settings). The log for the

previous job can be printed at any time.

Note: It is a good idea to print a report of the previous

job before starting a new job. A report for the previous

job may be printed at a later time by touching on

the Home screen, choose the report you want and touch

Print.

To start a new job --

1. If the Omniguard is not currently monitoring a job, the status will

indicate START JOB at the bottom of the Home screen. Touch

START JOB, then confirm you want to start a new job.

2. Enter the new Job Name, then touch to save it and start

monitoring. The Job Name, time-stamp and current alarm settings

will be logged and printed.

To end the current job --

1. From the Home screen, touch in the upper left-hand corner

to go to the Main menu.

2. From the Main Menu, touch End Job, then confirm you want to

end the job by touching End Job again.

Example of Job Summary Report,

after End Job is pressed --

Alarm Settings Screen

Alarm 1 & Alarm 2 Settings: The operating window is the area between

the Alarm 1 and Alarm 2 settings. These settings can be set anywhere

within the operating range of the unit; +/- 0.250” WC in increments

of 0.005”WC. The Omniguard can also operate in units of mmWC or

Pascals. (See Pressure Units.)

Job Summary Report

Page 12 Omniguard Cellular™ Owner’s Manual Page 13

Engineering Solutions Inc

armed. If the containment pressure rises or falls outside the operating

window, the following will occur:

1. Internal alarm and the Remote Auxiliary Alarm (if present) will

sound and will remain active until the alarm is muted by touching

the icon on the Home screen. The icon will change to to

indicate it is muted. Once the alarm condition is over and the

Omniguard returns to Normal operation the alarm will automatically

re-arm.

2. Any other accessory devices (Telephone Autodialer or Cellular

Wireless Modem) will also activate and will remain active until

the containment pressure is restored and the Omniguard returns

to Normal operation.

3. As the containment pressure nears the alarm settings, the

Omniguard will indicate that it is nearing an alarm condition. The

border around the screen will change from green to yellow, and

the status will change to APPROACHING ALARM.

4. As the pressure continues to move outside the operating window

(Alarm settings), the alarm will sound and a red border will appear

around the screen and the status will change to >>ALARM<<.

5. The Omniguard will log & print which Alarm, 1 or 2 was exceeded.

The Log Rate will increase to the Alarm Condition rate. Pressure

readings will be time-stamped as they are saved and printed.

When the containment pressure returns to within the normal operating

window, the Omniguard will log and print NORMAL OP with a time-

stamp. The alarm and accessories (if present) will turn off (or re-arm

if they have been muted), also a Normal Operation status message

will be sent to off-site personnel if the Cellular Wireless Modem is

present. The screen border will change back to green and the status

will indicate NORMAL.

Audible Alarm Mute, Disable & Re-arming

The speaker icon on the Home screen indicates if the internal audible

alarm (and optional Remote Auxiliary Alarm if present) is armed,

disabled or muted. The audible alarm is automatically armed when the

Omniguard is turned On. Touch the speaker icon to change between

armed and disabled, and to mute during an ALARM condition.

Audible Alarm Armed (and Remote Auxiliary Alarm)

Armed, speaker sounds during an ALARM condition.

Audible Alarm Disabled (and Remote Auxiliary Alarm)

Disabled, speaker will not sound during an ALARM condition.

Audible Alarm Muted (and Remote Auxiliary Alarm)

Muted during the ALARM condition, automatically re-arms

when containment pressure returns to operating window, status

NORMAL.

Alarm 1: Upper limit of operating window. (default is -0.025” WC)

Alarm 2: Lower limit of operating window. (default is -0.050” WC)

The Omniguard can be used in both positive and negative pressure

monitoring applications.

Negative Pressure Application -- Asbestos or lead abatement

Example settings: Alarm 1 @ -0.020” WC

Alarm 2 @ -0.050” WC

Positive Pressure Application -- Clean room or HVAC system

Example settings: Alarm 1 @ +0.050” WC

Alarm 2 @ +0.025” WC

Alarm Settings & Operating Window

This is an example of a setting for negative containment with an

operating window of -0.020” to -0.050” WC (Alarm 1 & 2 settings).

-0.050"

Alarm 2

-0.020"

0.000"

NORMAL OPERATING WINDOW

Alarm 1

INCREASING

VACUUM LEVEL

Negative Pressure

(containment)

Application

Pressure Units: (default is Inches WC)

• Choices are Inches WC (“ WC), millimeters WC (mmWC) or

Pascals (Pa).

Response Rate: (default is Medium)

• Choices are Slow, Medium, Fast.

• Determines how quickly the Omniguard will react to pressure

changes. Reduce this setting if the job site conditions are

fluctuating rapidly and can cause false alarms, such as high

wind.

To change the settings --

1. To change the Pressure Units or the Response Rate, tap the

current setting to scroll through the choices until the desired setting

is shown.

2. To change the Alarm 1 or Alarm 2 settings, touch the arrows

beneath the appropriate setting. Hold the arrow to go faster. New

values are automatically saved.

Touch to return to the Main Menu.

Once the containment pressure reaches the operating window, the

status will indicate NORMAL and logging will begin.

Alarm Condition

Once the containment pressure reaches the operating window, the

Omniguard status will indicate NORMAL and the alarms will be

Page 14 Omniguard Cellular™ Owner’s Manual Page 15

Engineering Solutions Inc

Printer Settings & Reports Screen

The Omniguard maintains a log of all recorded data, alarm messages

and changes in operational settings. The current Job or any previous

Job (or portions of those jobs) and the Omniguard’s Configuration

Report can be viewed or printed at any time.

Touch the printer icon at the Home screen to go to the Printer

Settings & Reports screen.

Note: If a printer error is detected, the printer

stops automatically and the printer Jammed

icon appears. Touch the Jammed icon to view

instructions on how to remove jammed paper.

Once the jam is cleared, you will need to go to the

printer settings screen to turn on the printer. Printer

jams are logged with a time-stamp.

Note: The icon indicates that the printer is disabled

while it is powered by the battery. Plug the AC

cord of the Omniguard into an electrical outlet to

re-enable the printer.

To view or print the current Job Log --

1. Touch the icon at the Home screen.

2. Touch the Job Name & Duration (white text) to change the report’s

duration, then touch Print or View.

3. Scroll thru the report using the arrows (if viewing).

4. Touch to return to the Home screen.

To view or print a previous Job Log or the Confi guration Report --

1. From the Printer Settings screen, touch Other Report/Log. Use

the arrows to scroll through the available reports & logs. Tap the

Name of the report to view it or print it.

2. The selected item will appear on the screen to view, use the arrows

to scroll thru the report. Touch Print at any time to print it.

Cancel printing by touching anywhere on the screen.

General Settings Screen

In the General Settings screen the following can be set:

- Contractor Name

- Time & Date

- Log Rates

To go to the General Settings screen touch the icon in the upper

left-hand corner of the Home screen, then touch General Settings.

Contractor Name: The Omniguard can store the name of the Contractor

that is using the unit. The Contractor Name is shown in all Job logs

and printed reports. Only one name can be stored.

To set the Contractor Name --

1. Go to the General Settings screen from the Home screen as

described above.

2. To the right of Contractor Name will be “Your Name” or the

previously entered contractor name in white text.

3. Touch “Your Name” and the Keyboard screen will appear.

4. Use the alpha-numeric keyboard to enter the contractor name.

5. When the entire name has been entered, touch to return to

the previous screen. The new contractor name will be shown.

Touch to return to the Main Menu.

Time & Date: The time and date are used as a reference time-stamp

for all logged events.

To change the Time & Date --

1. Go to the General Settings screen by touching the icon in

the Home screen, then touch General Settings.

2. Touch the arrows to adjust the time minute by minute. Hold the

arrow to increase the speed of adjustment.

3. To set the date, simply touch the white text indicating the month,

Example of Typical Job Log Printout

Typical startup sequence

Setting changes print for verification

Containment pressure reached

operating window... status is NORMAL

Alarm Condition (Alarm 1 tripped)

Back into NORMAL operation

New Date prints at midnight

Sign-off header

Page 16 Omniguard Cellular™ Owner’s Manual Page 17

Engineering Solutions Inc

day, or year. The value will change each time you tap. Once the

desired value is shown, the change is automatically saved.

Touch to return to the Main Menu.

Log Rates: The logging and printing of pressure readings begins once

the pressure reaches the normal operating window (status indicates

NORMAL). There are two rates at which logging occurs

Normal Operation: (default is 15 min.)

• Setting choices are 5, 15, 30 minutes of Off.

• When set to Off, Omniguard will only log & print pressure

readings during an Alarm Condition.

Alarm Condition: (default is 15 sec.)

• Setting choices are 15 sec, 30 sec, 1 min or 2 min.

To change the Log Rates --

1. Go to the General Settings screen by touching the icon in

the Home screen, then touch General Settings.

2. Touch the current Log Rate setting (white text) to change value.

3. The value will change each time you tap. Once the desired value

is shown, the change is automatically saved.

Touch to return to the Main Menu.

Screen Settings (including Touchscreen Calibration)

To adjust the Screen Brightness --

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Screen Settings.

3. Touch the current Screen Brightness setting to adjust to the

desired brightness level.

To Calibrate the Touchscreen --

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Screen Settings.

3. Touch Calibrate Touchscreen to begin the calibration process.

4. A white box with an X in the middle of it will appear. With the tip

of the finger or by pressing gently with a stylus, touch the X. The

get closer to touching the center of X, the better.

5. Repeat this process 3 more times, until the Omniguard shows the

calibration is completed.

Zero Calibration

The Omniguard does not require calibration between jobs. Internal

temperature compensation and other circuitry provides unsurpassed

accuracy over a 30°- 130° Fahrenheit range.

Note: A soft clicking sound is made by the

Omniguard as it is constantly compensating for

zero offset drift due to changes in barometric

(atmospheric) pressure. Annual NIST calibration

verification is recommended.

To manually reset the zero point --

1. Disconnect the pressure tubing from both inlet nozzles.

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Zero Calibration.

4. Touch Calibrate Now. (If Passcode Protection is On, Omniguard

will prompt for the Passcode.)

5. When the calibration is complete the screen will read Calibrate

Zero Done.

6. Touch to return to the Main menu.

Note: Allow the Omniguard to warm up for 15

minutes prior to zero calibrating. This permits the

pressure sensor to stabilize its readings. Zero

calibration can only be done when the pressure

tubing is not attached to the unit.

Passcode Protection

The passcode protection feature allows the site manager to assign

a passcode that prevents unauthorized changes to the Omniguard’s

settings. Once enabled, the passcode must be entered to change any

setting. Settings may be viewed without the passcode.

Passcode Protection : (default is Off)

Passcode : (default is 0 0 0 0)

• A passcode is always required to Erase Job Logs and

Restore Factory Defaults.

• Master passcode is 5 5 5 5

To set and activate Passcode Protection --

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Passcode Protection.

3. Touch Off to enable or On to disable Passcode Protection.

Note : Disabling Passcode Protection requires

knowing and entering the Passcode.

Page 18 Omniguard Cellular™ Owner’s Manual Page 19

Engineering Solutions Inc

To change the Passcode --

1. From the Passcode Protection screen, touch the **** to go to

the passcode entry screen.

2. Type in the current passcode followed by , to be allowed to

create a new passcode.

3. Type in the new passcode using the alpha-numeric keypad an

press when done.

4. Re-enter the passcode and press to confirm it.

Note : In case the passcode is lost or forgotten, it can be changed

using the Master passcode.

Erase Job Logs

This function will completely erase all Job Logs, the Passcode is

required to use this function.

To Erase Job Logs --

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Erase Job Logs.

3. Touch Clear Log Now and enter the Passcode (required).

4. Screen shows Clearing job logs..., then Done when completed.

5. Touch to return to the Main menu.

Restore Factory Defaults

This function will completely erase all Job Logs and restore all settings

to the factory defaults (except Time & Date), including the Passcode.

The Passcode is required to use this function.

To Restore Factory Defaults --

1. From the Home screen, touch to go to the Main menu.

2. From the Main menu, touch Restore Factory Defaults.

3. Touch Factory Default and enter the Passcode (required).

4. Screen goes blank, then shows Omniguard and Initializing (the

power on screen).

5. Touchscreen calibration is required. A white box with an X in the

middle of it will appear. With the tip of the finger or by pressing

gently with a stylus, touch the X. The closer to touching the center

of X, the better.

6. Repeat this process 3 more times, until the Omniguard shows the

calibration is completed.

Note: The Alarm 1 & 2 settings are displayed in

yellow on the Home screen until they have been

changed from factory defaults.

Using Help

To obtain help for a specifi c screen --

1. If the screen has an icon in the corner, the touch the icon to

see Help about the current screen.

2. Touch to return to the previous screen.

To go to the general Help menu --

1. If the screen has an icon in the corner, the touch the icon to

see Help about the current screen. Touch the icon again to go

to the general Help menu.

3. Use the arrows to scroll thru the Help topics.

4. Touch the topic title to view detailed Help about it.

5. Touch to return to the previous screen.

USB Ports

The Omniguard has two USB ports located by the icon. A chart

showing all of the USB device icons is on page 6.

The top port supports the following devices:

• USB Flash Drive

• Remote Auxiliary Alarm (requires USB Port Adapter)

• Telephone Autodialer (requires USB Port Adapter)

• Cellular Wireless Modem (requires a USB Port Adapter)

The bottom port, is used to communicate between a PC and the

Omniguard.

Communication

The Omniguard has a built-in USB port to connect to a PC. Before a

PC can communicate with an Omniguard, download and install the

Windows® compatible Omniguard Communication software from our

web site at www.Omniguard.com. Detailed instructions for installation

and operation of the software are included with the download.

Plug the flat rectangular end of the USB cable into a PC and the

square end into the bottom USB port of the Omniguard.

Once connected, you can --

• Transfer the current Job Log or all Job Logs to the PC.

• Configure and set up multiple Omniguards, using the software to

upload configuration settings

Transferring a Job Log to a PC

The Job Logs stored in the Omniguard’s memory can be transferred

to a PC for permanent storage, statistical analysis and summary

report generation. Job Logs transferred to a PC can be reviewed and

reprinted any number of times.

Page 20 Omniguard Cellular™ Owner’s Manual Page 21

Engineering Solutions Inc

To transfer a Job Log --

1. Install the Communication program on your computer.

2. Plug the USB cable (included with your Omniguard ) into the lower

USB port on the Omniguard

3. Plug the other end of the cable into the appropriate USB port on

your PC.

4. Follow the instructions in the Communication program to transfer

the Job Log.

5. Once transferred to the PC, Job Logs can be exported in a tab

separated format so they can be imported into Microsoft Excel for

charting and analysis.

USB Flash Drive – Data Collection

The upper USB port on the Omniguard allows a Supervisor to gather

Job Logs at the job site using a USB Flash Drive. The logs can be

viewed later on a PC using the Omniguard Communication software

available free @ www.Omniguard.com.

Transferring the Job Logs to a USB Flash Drive

The Job Logs stored in the Omniguard’s memory are copied as a

single Log file to a USB Flash Drive. The Omniguard Communication

software can read the Log file and separate it back into individual Job

Logs for storage on your PC. Each time a USB Flash Drive is inserted

into an Omniguard, all Job Logs are copied to the drive.

To transfer Job Logs --

1. The Omniguard must be turned on and displaying the current

pressure (at Home screen).

2. Plug the USB Flash Drive into the upper USB port on the

Omniguard. The flash drive icon should appear and the Omniguard

will automatically begin to download all job logs. This could take

several minutes before completing.

3. When the transfer is complete the screen will show the name of the

new Log file created on the flash drive. The file name will consist

of the last 6 digits of the Omniguard serial number followed by a

letter. Each file also has the time & date it was copied onto the

flash drive.

Example: If the Omniguard 5 serial number is

G506932, the fi rst Log fi le will be 506932.OGL. The

second fi le will be 506932A.OGL, the third fi le will be

506932B.OGL, etcetera. The Log fi les are stored in

the folder OMNIGUARD in the sub-folder LOGS.

To complete the transfer to the PC, insert the USB Flash Drive into

an open USB port on the PC. Using the Omniguard Communication

software, select “Open Log...” from the “File” menu. Navigate to the

USB Flash Drive, select the “OMNIGUAR\LOGS” folder and open

the appropriate Log file.

Message Rate

The Message Rate setting is the minimum amount of time the

Telephone Autodialer or Cellular Wireless Modem must wait between

multiple alarms before dialing or sending an new alert message in

response to a new alarm condition. This setting is to prevent multiple

alert messages from being when the job site is experiencing rapid

alarm occurrences due to windy (or other) conditions.

The setting can only be viewed and changed when a USB Port Adapter

is connected to an Omniguard.

Message Rate: (default is 10 min.)

• Choices are 5 min, 10 min or 15 min.

To change the Message Rate --

1. Plug the Autodialer into the USB Port Adapter, then connect the

USB Port Adapter to the Omniguard with the USB cable provided.

The screen should display the USB Port Adapter icon on the

Home Screen.

2. Press to go to the Message Rate screen.

3. Touch the current rate (white text) to toggle through the Message

Rate choices.

4. Touch to save the setting return to the Home screen.

Cellular Communication Set Up and Operation

The Omniguard Cellular has a built-in Cellular Wireless Modem that

will automatically send status report updates (including Power, Alarm,

Normal Operation and Job Logs) to off-site personnel via cell phone

text messaging and email. 24 Hour Job Logs are sent on a daily

basis, eliminating the need to visit the job site to manually download

logs. Job Logs are received via email as an attachment and can be

viewed with any text editor.

2 years of cellular connectivity on the Verizon network is included

with the purchase of a new Omniguard Cellular. After the initial 2

year subscription period, there is an annual subscription available to

continue the service.

To activate your cellular communication service, or renew your

annual service, log in to www.engsolinc.com and fill out and submit

the Cellular Activation Form, or call 206-241-9395 and contact the

sales department. Please allow 24-48 hours for activation or renewal

to take effect.

After the Omniguard Cellular is activated with Verizon, the cell modem

will automatically connect to the Verizon network when the Omniguard

is turned on. If the Omniguard has never connected with the network,

a prompt will be displayed during the initial start up. At the prompt,

Page 22 Omniguard Cellular™ Owner’s Manual Page 23

Engineering Solutions Inc

4) Press Option to choose which type of Status Updates

will be emailed. Touch the box to select. Status

Update emails have the Status Message + Job Name

+ Omniguard Serial Number in the email Subject. This

allows receiving personnel to easily automatically sort

incoming emails into appropriate inboxes.

a. Power Status

b. Waiting for pressure (every 60 min)

c. Alarms and Alarm Updates (every 15 min)

d. Normal Operation Updates (every 60 min)

5) Touch to choose when the 24 Hour Job Log will be

sent.

6) Touch to return to the Cellular Communication screen.

Touch again to return to Home Screen.

press Connect to connect your Omniguard’s cell modem to the

network, or you can press to skip connecting to the cellular

network.

To set up Cellular Communication

1) From the Home Screen, touch to go to the Network

Communication screen.

2) The network status is in the top left corner of the screen.

Touch Off to toggle through the Network options untill you

reach Cellular.

3) On the top right corner of the screen, Initializing... is

displayed while attempting to connect to the Verizon

cellular network. When connected the Signal strength

percentage will display.

5) Touch to return to the Cellular Communication screen.

Touch again to return to Home Screen.

WiFi Communication Set Up and Operation

The Omniguard Cellular has a built in Wifi Module that will that will

automatically send status report updates (including Power, Alarm,

Normal Operation and Job Logs) to off-site personnel via cell phone

text messaging and email. 24 Hour Job Logs are sent on a daily

basis, eliminating the need to visit the job site to manually download

logs. Job Logs are received via email as an attachment and can be

viewed with any text editor.

To set up WiFi Communication

1) From the Home Screen, touch to g o to t h e Network

Communication screen.

2) The network status is in the top left corner of the screen. Touch

Off to toggle through the Network options untill you reach WiFi

or WiFi+

3) To enter the Wifi Network information, press the WiFi button in the

lower left hand corner. You will need to enter the Network Name

and Password to connect to the local Wifi network.

4) On the top right corner of the screen, Initializing... is

displayed while attempting to connect to the WiFi network.

When connected the Signal strength percentage will

display.

5) Touch to return to the Cellular Communication screen.

Touch again to return to Home Screen.

Entering Contact information for Remote Communication Recipients

To send text messages to Cell Phones, use the 10

digit wireless number without dashes combined

with the domain for the phones’s network to create

an email address as shown below.

Domains for major wireless network providers are listed

below. Domains for networks not shown can be found online.

Alltel Wireless @sms.alltelwireless.com

AT&T Wireless @txt.att.net

Boost Mobile @myboostmobile.com

Consumer Cellular @txt.att.net

Cricket @sms.mycricket.com

Metro PCS @mymetropcs.com

Sprint (PCS) @messaging.sprintpcs.com

@pm.sprintpcs.com

Sprint (Nextel) @page.nextel.com

Straight Talk @vtext.com

T-Mobile @tmomail.net

US Cellular @email.uscc.net

Verizon @vtext.com

Verizon @vtext.com

Virgin Mobile @vmobl.com

1) From the Network Communication Screen, enter an

E-mail Address (or Cell Phone Number texting address)

plus an optional Name for up to 4 personnel to be

remotely notified.

2) Check the boxes to the left of the Email Address for each

email address to receive Status Updates or Job Logs or

both.

3) Press Test to send emails, confirm emails were received

by all personnel listed. Test emails have the Subject:

‘Testing

Page 24 Omniguard Cellular™ Owner’s Manual Page 25

Engineering Solutions Inc

Section 5: Accessories

Remote Auxiliary Alarm

The Remote Auxiliary Alarm is a combination high-intensity strobe

light and 95db audible alarm on a 25 foot cable that connects to the

Omniguard USB connector using the optional USB Port Adapter. The

Remote Auxiliary Alarm plugs into the Aux Alarm port on the USB

Port Adapter which in turn is connected to the USB port using the

USB cable (included with the Omniguard).

In an alarm condition, the Remote Auxiliary Alarm will activate. It may

be muted by touching the icon. The Remote Auxiliary Alarm will

only re-arm once the unit has returned to normal operation.

Telephone Autodialer

The Telephone Autodialer is supplied with a 25 foot cable that connects

to the Omniguard USB port using the optional USB Port Adapter. The

Telephone Autodialer plugs into the Autodialer port on the USB Port

Adapter which in turn is connected to the USB port using the USB

cable (included with the Omniguard). The Autodialer also requires a

working land line telephone connection box with an RJ11 jack.

In an alarm condition, the Autodialer will call the pre-programmed

phone numbers (up to 4) and play a pre-recorded message alerting

the off-site personnel of an alarm condition at the job site.

The Autodialer only activates once in a given time period (5, 10 or 15

minutes – the Message Rate setting). This prevents the Autodialer

from calling more than once if there are multiple alarms occurring

within a short period of time. After the 5, 10 or 15 minute period has

elapsed, the Autodialer will dial out again if the unit is still in an alarm

condition or when the next alarm condition occurs.

Cellular Wireless Modem for non-Verizon Wireless

NetworksBy using the optional Cellular Wireless Modem and USB

Port Adapter, the Omniguard Cellular can access cellular wireless

networks other than Verizon to automatically send alarm and job

reports to cell phones and email accounts. In addition, the Omniguard

can respond to requests for information from wireless cell phones

and via e-mail.

Wireless communication requires a specially configured MultiTech

MultiModem cellular wireless modem. This modem is similar to a

cell phone. It has a phone number and requires an active cell phone

account with SMS texting support, using either a traditional plan with

monthly payments or a prepaid plan. Contact Engineering Solutions

for more information on acquiring a cellular wireless modem.

JOB: Job A

20:38 0.000 0.000

Omniguard: # C501234

Normal

Job A

BATTERY POWERED

BATTERY 97%

Omniguard: #

C501234

JOB: Job A

AC POWERED

BATTERY 10%

Omniguard: #

C501234

Power Change

Waiting for Pressure

JOB: Job A

STATUS: Waiting Pressure

PRESSURE: 0.079" WC

Omniguard # C501234

** ALARM **

JOB: Job A

ALARM 1: 0.040" WC 15:19:11

0.045" WC Omniguard: # C501234

Alarm

You will be receiving Logs Messages

for job “Job A.”

Omniguard # C501234

Status Messages:

Job Log Test

Test Messages:

Status Message Test

You will be receiving Status

Messages from this Omniguard.

Omniguard # C501234

E-mail Message Examples

Page 26 Omniguard Cellular™ Owner’s Manual Page 27

Engineering Solutions Inc

To confi gure and test the Cellular Wireless Modem setup --

1. Connect the modem’s serial cable to the SERIAL port on the USB

Port Adapter and to the modem.

2. Connect the USB Port Adapter to the Omniguard USB port using

the USB cable (included with the Omniguard ).

3. Plug in the modem power adapter to turn the modem on. The

Wireless Modem icon should appear on the screen of the

Omniguard (it may take 2 minutes to connect).

4. Touch to access the Wireless Modem set up menu.

5. Use the keyboard to enter in the Master Cell Phone Numbers.

6. If a Notify List has been uploaded to the Omniguard by the

Omniguard Communication Software, choose which Notify List

to use by touching the List Name to toggle though the available

Lists (if a Notify List has not been uploaded, the Text/Email list

will say “None”).

7. Set the Text/Email Notification Rate by touching the current

rate.

The Default is set to 10 minutes. (The choices are 5, 10,

and15 minute intervals).

8. After the setting have been entered, touch Test Modem to ensure

the Wireless Cellular Modem is communicating properly with the

Master cell phone numbers and personnel on the Notify List. After

confirmation of receiving the Test text message, touch anywhere

on the screen to exit to the Home Screen.

Master Cell Phone Numbers –

Two cell phone numbers can be programmed directly into the

Omniguard. A text message will be sent to each phone number when

the Omniguard enters Normal operation and when an Alarm condition

occurs. The Message Rate setting determines the minimum time

between Alarm notification messages, this is to prevent frequent

messages if the unit is going in and out of the Alarm condition.

Phone numbers programmed directly into the Omniguard will also

receive a Daily Summary report, indicating how long the Omniguard

was in Normal operation, the number of alarms and the total time the

unit was in the Alarm condition. The Daily Summary is sent at 5:30pm

each day unless a Notify List has been selected (see below).

Notify Lists –

In addition to the two Master Cell Phone Numbers, the Omniguard can

also send alerts to personnel contained in a Notify List. The Omniguard

can store up to four Notify Lists, only one can be active at a time.

A Notify List contains a list of wireless phone numbers and e-mail

addresses for a specific group of off-site personnel. Each Notify List

allows different phone numbers and/or e-mail addresses for Alarm

and Normal Operation notification and for Reports. The Lists also

allow the report notification time to be changed.

Notify Lists can only be created and programmed into

the Omniguard using the Omniguard Communications

PC software. See the Help that comes with the

software for more information on setting up Notify

Lists.

Request Job Site Status via Cell Phone or E-mail –

It is possible to request status information from an Omniguard

connected to a cellular wireless modem. A text message or e-mail is

sent to the Omniguard which replies with the report type requested.

The available reports include a Daily Summary, overall Job Summary,

Current Status and Settings.

To get a complete list of reports the Omniguard can provide send a text

message or e-mail with a “0” (zero) in the body of the message.

Text messages sent to the Omniguard must be in

the “short message” (SMS) format and are sent to

the phone number of the wireless modem. E-mail

messages sent to the Omniguard must be in plain

text format and should be sent to the e-mail address

provided by the wireless service provider. The

message format is shown below, where “nnnnnnnnnn”

is the 10-digit phone number of the cellular modem,

with area code first (no hypens or spaces).

Page 28 Omniguard Cellular™ Owner’s Manual Page 29

Engineering Solutions Inc

Problem: OMNIGUARD status does not indicate NORMAL

operation when turned on, and does not print.

Solution: For normal operation, the monitored pressure must be

between the Alarm 1 and Alarm 2 settings. When the Omniguard is

first turned on, the containment pressure will not likely be between

the Alarm 1 & 2 settings, and the Omniguard will not log or print the

pressure readings. The Omniguard will begin logging and printing

the pressure readings only after the containment pressure has

reached the Normal operating window.

Shipping & Repair

Please call the Engineering Solutions technical support department

for a return authorization. A Return Material Authorization number

(RMA #) will be assigned to aid in tracking your unit.

You may also e-mail [email protected].

Send the entire unit, enclosing a brief explanation of the problem

along with your company name, address, phone number and

name of the individual responsible for the unit. The RMA# must

be clearly marked on the outside of the box. No COD’s will

be accepted. If the original packing materials are not available,

package the unit securely in a sturdy container with enough

padding to surround the unit on all sides. The unit should not be

able to be shift after packing. Engineering Solutions will not be

responsible for any damage which may occur.

Ship To: Engineering Solutions, Inc.

1201 Monster Rd SW, Suite 240

Renton WA, 98057 USA

(206) 241-9395

Appendix A : Troubleshooting

If you experience problems with your Omniguard, use this section

to try to resolve the problem. For additional information consult with

your dealer or call Engineering Solutions at (206) 241-9395 (8:00

a.m.-12:00 noon, 12:30-4:30 p.m. Pacific Time) and ask for Technical

Support, or e-mail [email protected].

Problem: The unit does not display the proper pressure.

Solution: Check to see that the tubing is connected properly to the

top nozzle. The bottom nozzle should not be connected.

Solution: Make sure that the tubing does not have a kink or a sharp

bend.

Solution: Make sure that you are using the correct 3/16” ID tubing

size, and the end of the tubing on the inlet nozzle is not worn. If

it is worn or loose, cut off 1” of the tube using a sharp knife and

reinsert on the inlet nozzle.

Solution: Make sure that the tubing connection into the containment

area is properly placed and secured as described in Section 4:

Work Area Setup.

Problem: Excessive momentary alarms.

Solution: Adjust Alarm 1 &2 settings to allow for normal air pressure

fluctuations caused by entries into work area or other equipment.

Make sure that you are within the minimum negative air pressure

requirements.

Remedy: If you suspect that wind may be causing rapid pressure

fluctuations, reduce the setting for Response Rate (see Section

4: Detailed Operation).

Problem: Printer is not working properly or a paper jam occurs.

Solution: The icon indicates printer is disabled. Turn On the printer

by touching the icon and then touching Off.

Solution: The icon indicates printer is disabled because Omniguard

is unplugged and powered by battery. Plug the Omniguard power

cord into an AC outlet, printer will activate automatically.

Solution: Icon indicates paper jam. After the paper jam is removed,

turn On the printer by touching the icon and then touching

Off.

Caution: Do not apply oil or grease to the printer, as this will attract

dirt and debris and could damage the printer mechanism.

Solution: Thermal paper allows printing on only one side. If incorrectly

installed, the printer will be able to advance paper but cannot

print on it. Make sure that paper is loaded properly as described

in Section 3: Loading the Thermal Printer Paper.

Page 30 Omniguard Cellular™ Owner’s Manual Page 31

Engineering Solutions Inc

Appendix C: Establishing a Containment Site

The Omniguard monitors and records the differential pressure

between the top inlet nozzle and the bottom inlet nozzle

(Reference).

In abatement applications the Omniguard should be located outside

the containment area and not in any antechambers (i.e. shower or

changing room). This allows a supervisor or hygienist to monitor

pressure readings without entering the containment area.

This section of general guidelines to establishing a containment

site is provided by Engineering Solutions Inc for informational

purposes only. Engineering Solutions Inc is not responsible for

its accuracy nor conformance with specific regulations for your

area. Engineering Solutions Inc specifically advises all users

to obtain the advice of qualified professionals for each use and

application of the Omniguard. Engineering Solutions Inc makes

no claims as to the proper usage or interpretation of the data

provided by the Omniguard.

General Guidelines to Establishing a Containment Site

1. The contractor and hygienist are to be certified prior to qualifying

to bid on an abatement job.

2. All workers are to have undergone specific training in abatement

procedures.

3. Typical abatement requirements:

a. Containment area to be sealed within a double layer of

8 mil plastic or equivalent.

b. Before beginning work within the containment area and at

the beginning of each shift, the containment area must be

inspected for breaches and smoke-tested for leaks, and

any leaks sealed.

c. Air volume within containment must be changed 4 times

per hour, i.e. the entire air volume must be evacuated

every 15 minutes.

d. Minimum pressure in containment is -0.020”WC, i.e. the

differential pressure between containment pressure and

ambient/outside pressure must be at least -0.020”WC as

measured by a manometer.

e. The containment area must be kept under negative pressure

throughout the period of its use.

f. Air movement must be directed away from employees within

containment and toward a HEPA filtration unit.

g. Fiber levels within the containment area must be sampled

at a specific interval and be less than a proscribed level,

i.e. sampled 1 time a day or more and fiber levels below

“5 fibers/100 fields”.

Appendix B: Specifi cations

Differential Pressure Range: +/-0.250”WC (+/-6.35 mmWC,+/-62.5

Pascals)

Accuracy: +/-0.003” WC or +/-1 % of reading, whichever is greater

Resolution: +/-0.001” WC, (+/-0.05mm WC, 0.5 Pascals)

Burst Pressure: 3 psi (20 kPa) on either inlet nozzle

Pressure Units: “ WC (inches Water Column), mmWC (millimeters

Water Column), or Pa (Pascals)

Date (Log) Storage: 4 MB non-volatile memory

Display: 4.3” Color Touchscreen LCD (480 x 272 pixels)

Internal Clock: The internal clock is powered by a self-charging

lithium-ion battery that provides clock operation when AC power

is not present

Printer: 20 character wide thermal printer (uses 2.2” wide thermal

printer paper)

Pressure Reading Log Rates (Log Rate):

Normal Operation -- Highest and lowest pressure readings are

logged & printed at intervals of 5, 15, 30 minutes or OFF

Alarm Condition -- Highest and lowest pressure readings are

logged & printed at intervals of 15, 30, 60 or 120 seconds for first

10 minutes of alarm condition, increasing to 15 minute intervals

thereafter

Alarms: Two programmable alarm settings, 95db audible alarm and

red bordered on-screen warning indicate alarm condition

Pressure Inlet Nozzles: Two 3/16” OD barbed hose connectors, 10

ft of pressure hose provided

USB Port: USB V1.1 Type-A

USB Port: USB V1.1 Type-B

AC Power: 85-240 VAC 50-60Hz 10W (with 6 ft power cord)

Battery Power: Internal rechargeable 3.7 Volt Li-ion type battery

internal provides 4-6 hours of portable operation, recharges

in 4 hours when AC power is available (printer is disabled

when powered by battery)

Case: Dimensions 9.25” x 7.5” x 4.5”, Shipping Weight 8 lbs., case &

handle is copolymer polypropylene with polycarbonate window in

the lid, and stainless steel hanging hook

Warranty: One Year Limited Warranty

Page 32 Omniguard Cellular™ Owner’s Manual Page 33

Engineering Solutions Inc

Appendix D: Limited Warranty

Engineering Solutions warrants that all products, component parts

and accessories will, for a period of twelve (12) months from date of

purchase, be free from defects in material and workmanship under

normal use and service.

PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS

WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS F.O.B., ENGINEERING SOLUTIONS, INC., 1201

MONSTER RD SW, SUITE 240, RENTON, WA 98057 USA.

To keep this warranty valid, the purchaser must (a) have promptly

informed Engineering Solutions’ customer service department of any

defects in writing, (b) properly used, maintained and repaired the

Product, and (c) have proof of purchase.

This warranty does not cover normal wear and tear or defects due to

(a) improper or negligent handling or unauthorized modifications, (b)

defective or improper premises, chemical, electrochemical or electrical

influences, (c) weather or other influences of nature.

LIMITATIONS OF WARRANTY - THIS WARRANTY IS EXPRESSLY IN

LIEU OF ANY AND ALL OTHER WARRANTIES AND OBLIGATIONS

OF ENGINEERING SOLUTIONS OR ITS SUPPLIERS, EXPRESS

OR IMPLIED. ENGINEERING SOLUTIONS INC EXPRESSLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF REMEDY- Under no circumstances shall Engineering

Solutions or any of its suppliers be liable for any loss or damage,

including, but not limited to, loss or damage arising out of failure of

the Product to operate for any period of time, inconvenience, use of

rental or replacement equipment, loss of profit or other economic

loss, or general, direct, special, indirect, incidental or consequential

damages or property damages.

PRODUCT SUITABILITY - Many states and localities have codes

and regulations governing sales, construction, installation, and/or

use of products for certain purposes, which may vary from those in

neighboring areas. While Engineering Solutions attempts to assure

that its Products comply with such codes, it cannot guarantee

compliance, and cannot be responsible for how the Products are

installed or used. Engineering Solutions recommends that, before

purchasing and using a Product, purchasers review the Product

application, and federal, state and local regulations, to be sure that

the Product, installation, and use will comply with them.

4. Calculating site airflow requirements:

A typical heavy duty HEPA fan/filter unit has a 1000 CFM (cubic

feet per minute) capacity with a new filter. Units are typically

derated by 25%, so a 1000 CFM unit is derated to 750 CFM by

the hygienists when calculating actual site airflow requirements.

Example #1: A room measuring 20 x 20 ft with a 10 ft ceiling

encloses 4000 CF of air. To meet the 4X per hour change

rate the fan/filter unit must be capable of pulling 267 CFM

of air (4000 x 4/60) from the containment area and maintain

a minimum negative pressure of -0.020”WC.

Example #2: Room size is 20 x 50 with 12 ft ceiling. Requires

(20 x 50 x 12) CF x 4 / 60 = 800 CFM or 2 units (of a 1000

CFM fan/filter unit... remember the fan/filter unit is derated

to 750 CFM).

Example #3: Room size is 100 x 100 with 16 ft ceiling.

Requires (100 x 100 x 16) CF x 4 / 60 = 10667 CFM or

15 fan/filter units (of a 1000 CFM unit).

5. The containment area pressure should be monitored at various

points to confirm adherence to abatement requirements.

Remember that air is a medium, and air pressure is not identical

throughout the containment area. The pressures at specific

locations within the containment area vary due to distance, room

temperature, proximity to openings, room geometry, etc. Typically

one manometer is used for every two “rooms” that have a doorway

and attached hallway, up to 1000 square ft.

5. Using a manometer that provides highly accurate pressure

readings, time stamped logging of all readings, and audible alarm

and printouts of all logged readings protects workers and the

public from accidental exposure to airborne hazards and provides

proof of containment to protect employers from environmental

contamination lawsuits

NOTE: It is important that there be no kinks or sharp

bends in any part of the tubing. Any blockage could

inhibit accurate recording of the pressure in the

containment area.

Page 34 Omniguard Cellular™ Owner’s Manual Page 35

Engineering Solutions Inc

FCC Certifi cation Information

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own

expense.

Contains FCC ID:RI7ME910C1NV and FCC ID:2AHMR-

ESP12F.”

Batteries containing heavy metals may contaminate the environment

if improperly discarded. When incinerated, certain chemicals are

released into the air or concentrated in the ash residue from the

combustion process; this may lead to a health risk to humans,

animals and the environment in general.

Batteries marked with the symbol of a ‘crossed-out wheeled bin’ are

strictly prohibited from being discarded with household waste.

Batteries must be disposed of by separate collection and recycling

means.

End users are obligated by law to comply with the discarding procedure

for waste batteries.

Battery Disposal Information

The battery included with this product contains

heavy metals that may contaminate the environment

if improperly discarded. Please follow the battery

recycling guidelines as directed by the E.P.A.

(http://www.epa.gov/osw/conserve/materials/battery.htm)

To fi nd your local recycling location please visit:

http://www.call2recycle.org/

This product contains a

Lithium-ion Battery

-Please Recycle-

EU Battery Disposal

Table of contents

Other Engineering Solutions Measuring Instrument manuals