Enotec AQUATEC 1000 User manual

Doc.-ID: AQUA_16012020_EN

Installation and Operation Manual

O

2

and water vapor analyzer system

AQUATEC

®

1000

Version 04

for Software Version: 4.10

ENOTEC GmbH

Process and Environmental

Measuring Technology

DIN EN ISO 9001

Höher Birken 6

D-51709 Marienheide

Germany

Tel.: +49 (0) 2264 - 45 78 0

Fax: +49 (0) 2264 - 45 78 31

Internet: www.enotec.com

Preface

Dear Customer,

For many years now, our AQUATEC

®

1000 oxygen and water vapor analyzer systems have been operating in numerous

applications with many thousand units being produced and shipped around the world. ENOTEC are committed to total quality

and performance and we have continuously enhanced our products to integrate various additional features and functions. In this

package, the electronic unit uses the very latest Microprocessor Technology permitting you to reduce your maintenance & fuel

costs, and to achieve increased measuring accuracy with more operational reliability using these monitoring functions.

In our oxygen measuring probes you will find that the Zirconium Oxide measuring cell is soldered in place using a special

process and technique developed by our company. This results in a considerably increased service life compared to "glued or

cemented" measuring cells, which have a tendency to leak or crack during operation. The Zirconium Oxide measuring cell has a

proven gas-tight design, providing greater measuring accuracy, durability and longer working life.

All ENOTEC instruments are thoroughly tested in the factory and are subject to a strict ISO 9001 Quality Assurance procedure.

Therefore, with the correct installation, the operation of the AQUATEC

®

1000 oxygen and water vapor analyzer system is very

easy and user friendly and will provide you with many years of operation with perfect measuring results.

Symbols used in this Manual

All symbols listed beneath, attached to the analyzer or noted in this manual show important information as well as safety

instructions for installation, operation and maintenance, to protect the personnel and the equipment.

Warning

Follow all instructions of this manual

Consider Information

Points out important information which must be

considered before execution

Warning hot Surface

Warns of danger of burns which could occur from

hot system parts

Note

Contains further detailed information

Caution

Warns of risks of destroying the system or its

components or its functionality

Ground earth electrical protection

The contents of this manual are protected by copyright. Alterations and errors reserved.

Safety Instructions

The System is operated with line voltage. After removal of terminal covers some parts of this system may be accessible which

are under high line voltage.

Only well trained and authorized personnel are allowed to work on this system. The personnel must know and understand all

precautions, safety instructions, installation and maintenance instructions of this manual. The trouble free and safe operation

of the system requires safe transportation, professional storage, installation, operation and maintenance.

Furthermore all local safety requirements at the point of installation and operation must be considered.

This analyzer may not be used to measure oxygen in combustible gases or in an environment with combustible gases. Parts of

this system may cause an explosion risk.

Installation and Operation Manual – AQUATEC 1000 Table of Contents

Doc.-ID: AQUA_16012020_EN 3

Table of Contents

1System Description 4

1.1System Overview ................................................4

1.2Measuring Principle.............................................6

1.3Measuring Principle Water Vapor........................6

1.4Intended use .......................................................6

1.5Safety Hazards....................................................6

1.6Disruption of the Process ....................................7

1.7Storage instructions ............................................7

1.8Name Plates .......................................................7

2Installation 8

2.1Installation Requirements for Electronic Unit ......8

2.2Installation of Probe Signal Cable FEP-0001 ......9

2.3Access to the Terminals....................................10

2.4Ferrite Sleeves (EMC).......................................10

2.5Wiring Diagram of the Electronic Unit ...............11

2.6AQUATEC® 1000 Wiring diagram ....................12

2.7Installation of the probe.....................................13

2.8Mounting of the Probe.......................................13

2.9Adjusting the V-shield / filter head.....................14

2.10Electrical Connections of the Probe ..................15

2.11Requirements for Pneumatic Tube FEP-0002 ..15

2.12Preparation of the pneumatic Tube ...................16

2.13Gas plans..........................................................16

2.14Pneumatic Connections of the Probe................16

2.15Pneumatic Connections of the Electronic Unit ..17

3Initial Operation 18

3.1Checklist before commissioning the system .....18

3.2System Power Up .............................................18

3.3Display - Probe Heating Phase .........................18

3.4Display - Measuring Mode ................................18

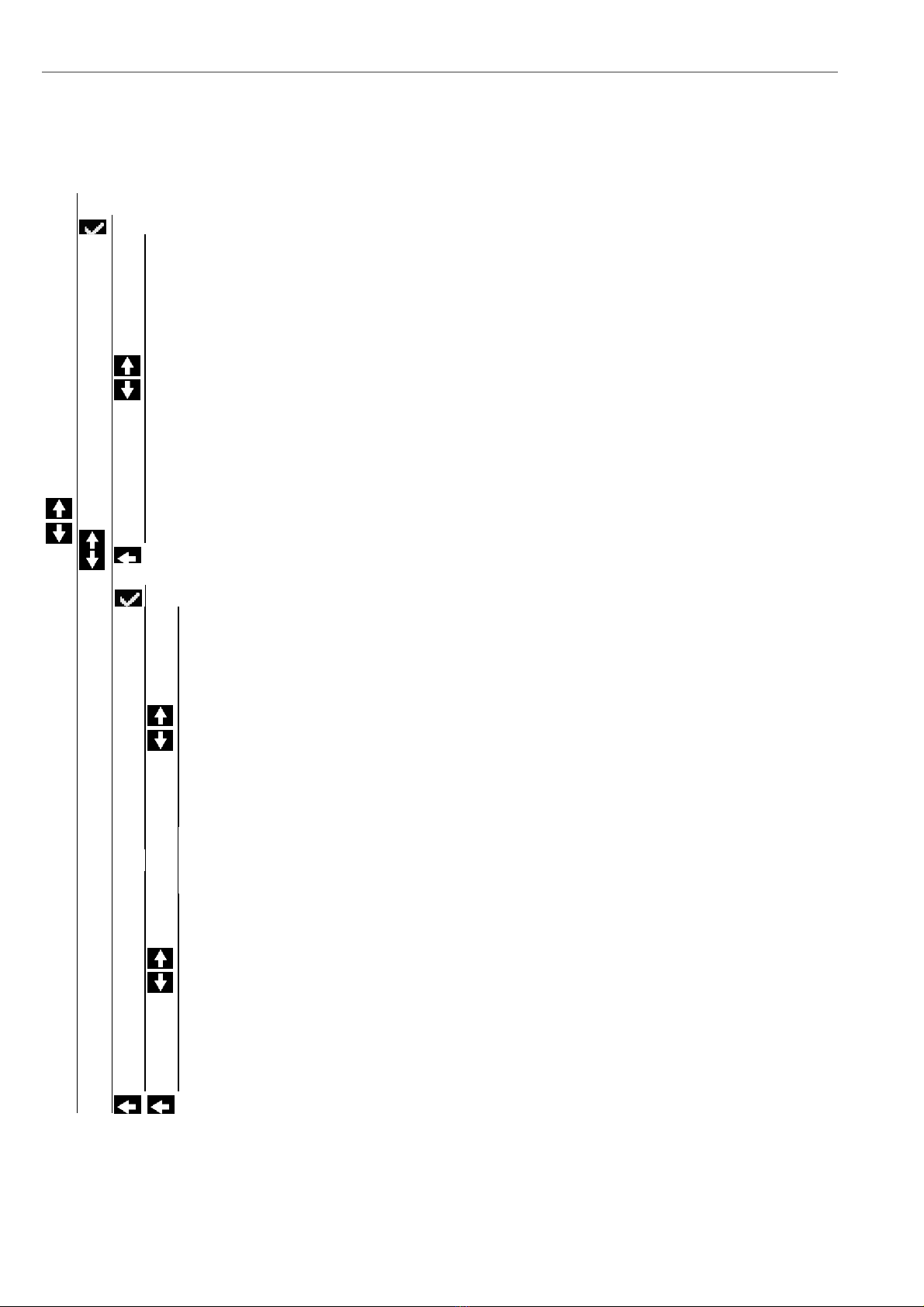

3.5Keypad and Display ..........................................19

3.6Status LEDs ......................................................19

3.7Softkey Symbols ...............................................19

3.8System Code.....................................................19

3.9Adjustment of the Analyzer to the Dryer............19

4Software Overview and Explanations 20

4.1Menu Overview - SYS-MENU ...........................20

4.2Software Explanations - SYS-MENU ................23

4.2.1O2Measuring Ranges (Scaling)........................23

4.2.2Measuring value averaging for .......................... 23

4.2.3mA output on system errors ..............................23

4.2.4O2limit alarm settings .......................................23

4.2.5O2Sensor calibration values ............................. 24

4.2.6Time per test gas apply.....................................24

4.2.7Delay time to process........................................24

4.2.8Automatic Calibration (ACAL) ...........................24

4.2.9Automatic Calibration Settings ..........................24

4.2.10Bluetooth...........................................................25

4.2.11Measuring units.................................................25

4.2.12Language ..........................................................25

4.2.13Change system code ........................................25

4.2.14Load factory settings .........................................25

4.2.15Service (Factory Service Settings) .................... 25

4.3Calibration Menu ............................................... 26

4.3.1Calibration Menu - Display Overview ................ 26

4.3.21-point calibration (manual) .............................. 27

4.3.32-point calibration (manual) .............................. 27

4.4System Checks................................................. 28

5Service and Maintenance 29

5.1Exchange fuses ................................................ 29

5.2Flow rates for Test Air and Reference Air ......... 29

5.3Adjusting Flow Rate (integrated Pneumatics) ... 30

5.4Position of the adjustment valves ..................... 31

5.5Replacing the Filter ........................................... 31

5.5.1Remove old Filter.............................................. 31

5.5.2Cement in new Filter ......................................... 32

5.6Replacing the probe.......................................... 32

5.7Replacing the O2Sensor .................................. 33

5.8Exchange of Probe Inner Parts......................... 34

5.9Exchange of Thermocouple Element................ 34

5.10Exchange of Heating Element .......................... 35

5.11Exchange of Signal Measuring Wire................. 35

5.12Exchange of 4-Hole Ceramic Rod .................... 35

5.13Relay Outputs / Functions and Correlation ....... 36

5.14Digital Inputs ..................................................... 37

5.15Stability Criteria for Calibration ......................... 37

5.16Reaction Time of the mA Output....................... 37

5.17Extension Modules............................................ 37

6Status Messages 38

6.1Error Messages ................................................ 38

6.2Alarm Messages ............................................... 39

6.3Maintenance Messages .................................... 39

7Troubleshooting 40

ATechnical Data 41

A.1Technical Specifications - Electronic Unit ......... 41

A.2Technical Specifications - Probe....................... 42

A.3Gas Supply - Systems with Instrument Air........ 43

BDimensional drawings 44

B.1Dimensions of Electronic Unit Housing versions44

B.2Probe Dimensions ............................................ 44

B.3Counter Flange Dimensions ............................. 45

B.4Dimensions of protection tube flanges .............. 46

CSpare Parts 47

C.1Probe Components - KES-132X ....................... 47

C.2Probe inner parts assembly .............................. 48

C.3Mounting Plates of the Electronic Unit .............. 49

C.4Display Board ................................................... 50

DWarranty 51

EDeclaration of Conformity 52

Index 53

System Description Installation and Operation Manual – AQUATEC 1000

4 Doc.-ID: AQUA_16012020_EN

1 System Description

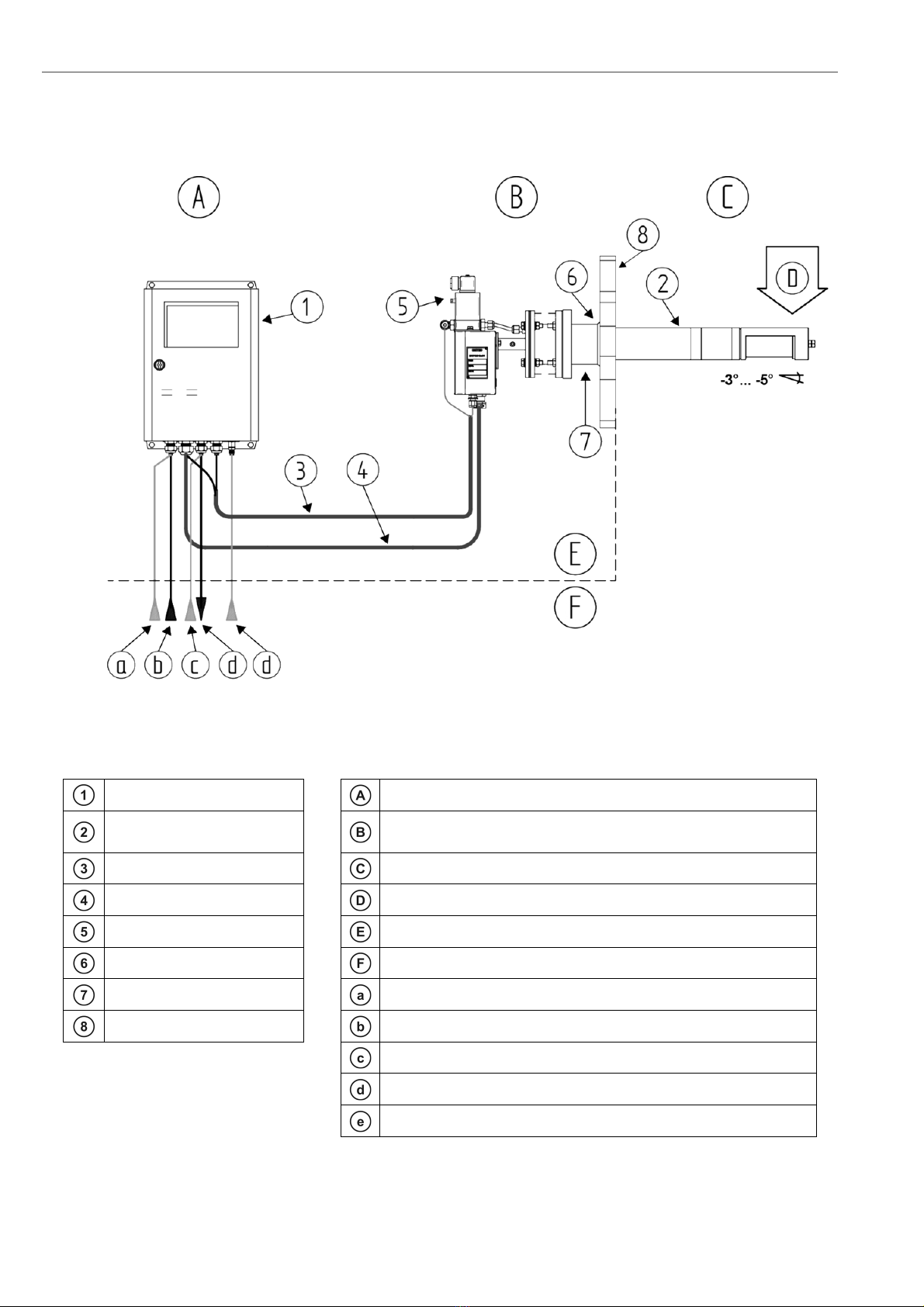

1.1 System Overview

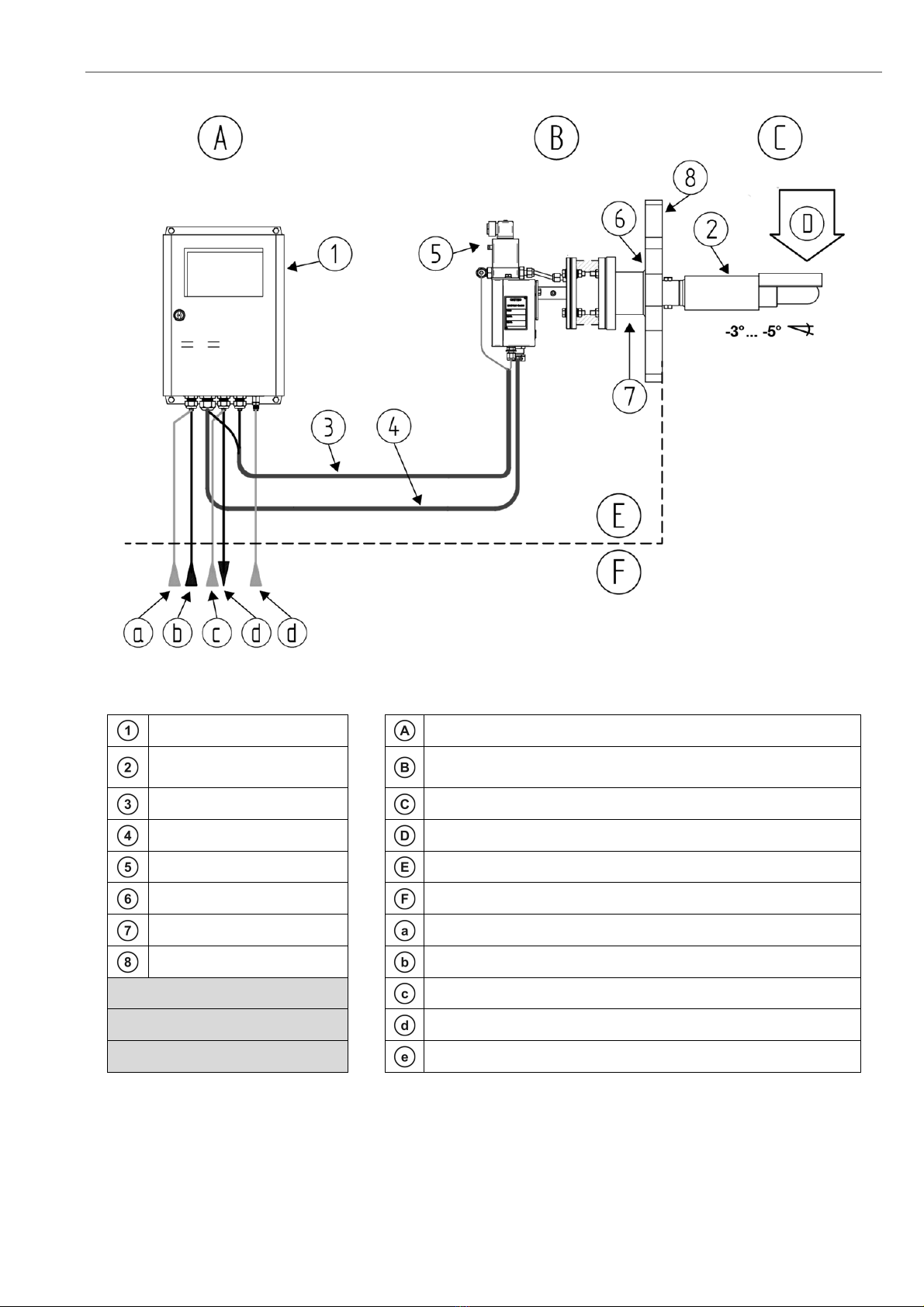

Figure 1 - AQUATEC 1000 analyzer system with active carbon filter

Electronic unit SME5 / IP66 Safe Area - Max. ambient temp.:-20°C to +55°C (-4°F to + 131°F)

In-situ measuring probe /

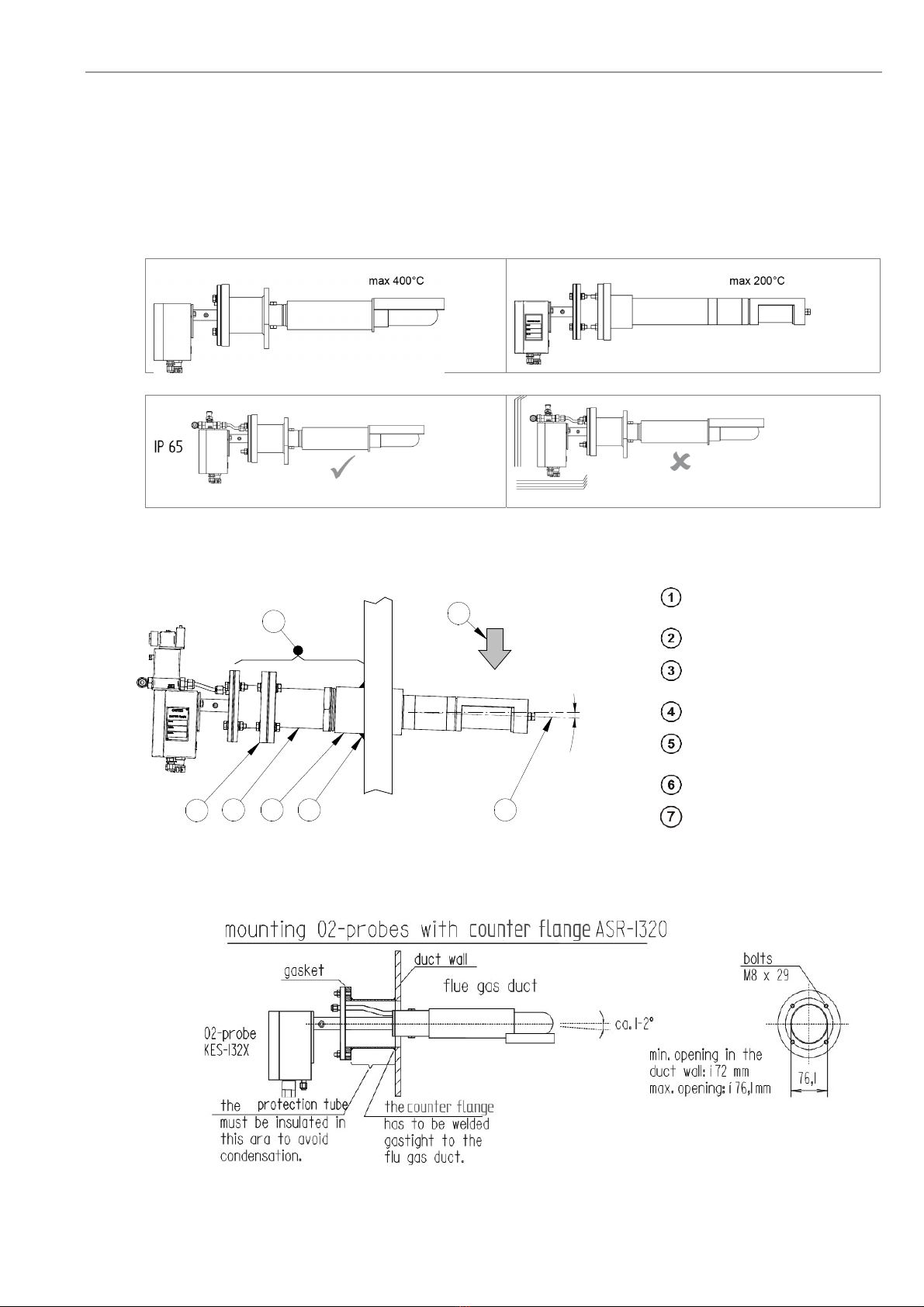

IP65

Safe Area - Max. ambient temp.:-20°C to +80°C (-4°F to + 167°F)

Pneumatic cable Process

O

2

probe signal cable Process gas direction – max. flue gas temp. 200 °C (392 °F)

Solenoid valve (Optional) Manufacturer supply

Counter flange (Optional) Customer supply

Isolation: Customer Test gas in

Duct wall Power supply

Instrument air in (Reference air in for pump systems)

Output signals (analog and digital)

Test air in (only for pump systems)

Installation and Operation Manual – AQUATEC 1000 System Description

Doc.-ID: AQUA_16012020_EN 5

Figure 2 - AQUATEC 1000 analyzer system with standard filter

Electronic unit SME5 / IP66 Safe Area - Max. ambient temp.:-20°C to +55°C (-4°F to + 131°F)

In-situ measuring probe /

IP65

Safe Area - Max. ambient temp.:-20°C to +80°C (-4°F to + 167°F)

Pneumatic cable Process

O

2

probe signal cable Process gas direction – max. flue gas temp. 400 °C (752 °F)

Solenoid valve (Optional) Manufacturer supply

Counter flange (Optional) Customer supply

Isolation: Customer Test gas in

Duct wall Power supply

Instrument air in (Reference air in for pump systems)

Output signals (analog and digital)

Test air in (only for pump systems)

System Description Installation and Operation Manual – AQUATEC 1000

6 Doc.-ID: AQUA_16012020_EN

1.2 Measuring Principle

The AQUATEC

®

1000 O

2

/ H

2

O analyzer system consists of an in-situ probe which is installed in a process to

measure non-combustible process gases and of an electronic unit for voltage and gas supply, as well as for signal

processing.

The oxygen sensor is at the tip of the probe and is regulated to 800 °C and works on the zirconium oxide principle of

measurement. Here, a mV signal between the reference gas side of the sensor (inside, instrument air 20.95% O2)

and the measured gas side is measured, which depends logarithmically on the ratio of oxygen partial pressures on

both sides of the sensor.

The mV signal is converted according to the Nernst equation into oxygen partial pressure within the process gas,

whereby the O

2

concentration is determined in the process gas. Gas-tight separation of reference air and process

gas is of particular importance.

1.3 Measuring Principle Water Vapor

The AQUATEC 1000 does not measure water vapor directly, but calculates it using the measured oxygen content.

The water vapor concentration is proportional to the quantity of the displaced oxygen.

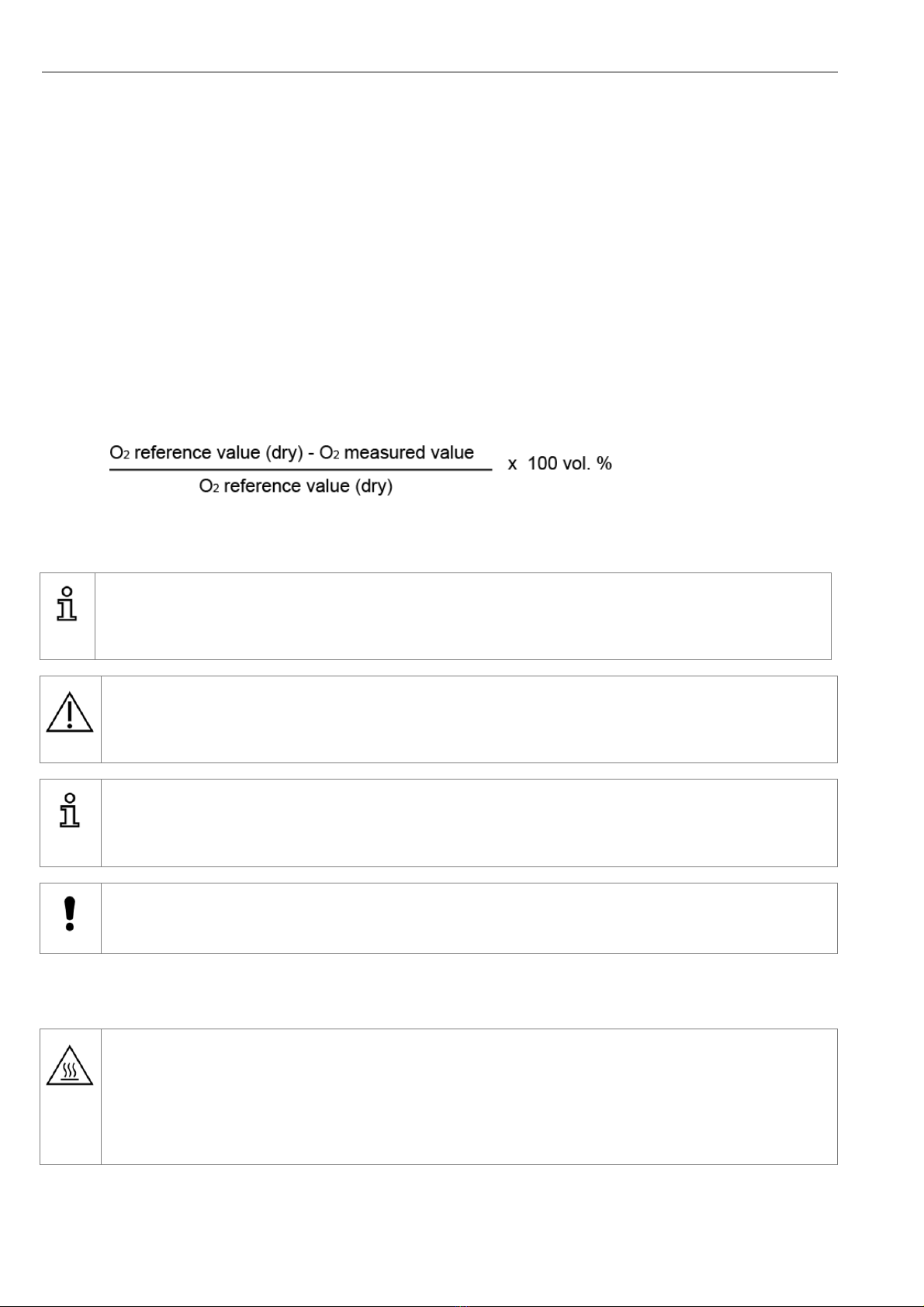

The formula for water vapor evaluation is represented as follows (see chapter 3.9 for details):

1.4 Intended use

Info

The AQUATEC

®

1000 analyzer system is a system for measuring the oxygen (O

2

) concentration in non-combustible

process gases and to calculate the water vapor content (H

2

O) using the oxygen concentration.

Warning

The system cannot be used to determine the oxygen concentration of combustible gases or in a location where

combustible gases are present as the measuring cell temperature of 800°C could present an explosion hazard!

Info

The minimum concentration of O

2

in flue gas should under normal process conditions, not be less than 0,5%.

If the O

2

concentration is regularly below 0,5%, we recommend the option of CSP (Cell Surface Protection) to

protect the O

2

sensor

.

Caution

Under no circumstance should the measuring probe be directly connected to the 230V main power supply, as this will

immediately destroy the probe heater element!

1.5 Safety Hazards

Warning hot surface

During operation, the temperature of the probe filter head and of other parts exposed to flue gas is 150°C - 800°C

(302°F - 1472°F). Direct contact with the hot parts when dismantling or maintenance will cause severe burns!

The probe may only be removed with heat-insulated gloves. Before removing the probe, always switch off the supply

voltage of the electronic system. After removal, store the probe in a safe, protected place and wait until it has cooled

down below 35°C (95°F).

Installation and Operation Manual – AQUATEC 1000 System Description

Doc.-ID: AQUA_16012020_EN 7

1.6 Disruption of the Process

The analyzer system has to be kept in operation also in the event of the process being disrupted or if the plant is

powered off temporarily (e.g. at night or during the weekend). Frequently cooling down and heating up of the probe

results in thermal stress of the hot probe parts (heater, thermocouple and sensor) and reduces their product life.

ENOTEC will not accept any responsibility for resultant damage.

1.7 Storage instructions

ENOTEC equipment is to be stored in a dry and ventilated environment. Paint fumes, silicone sprays, etc. must be

avoided in the storage environment.

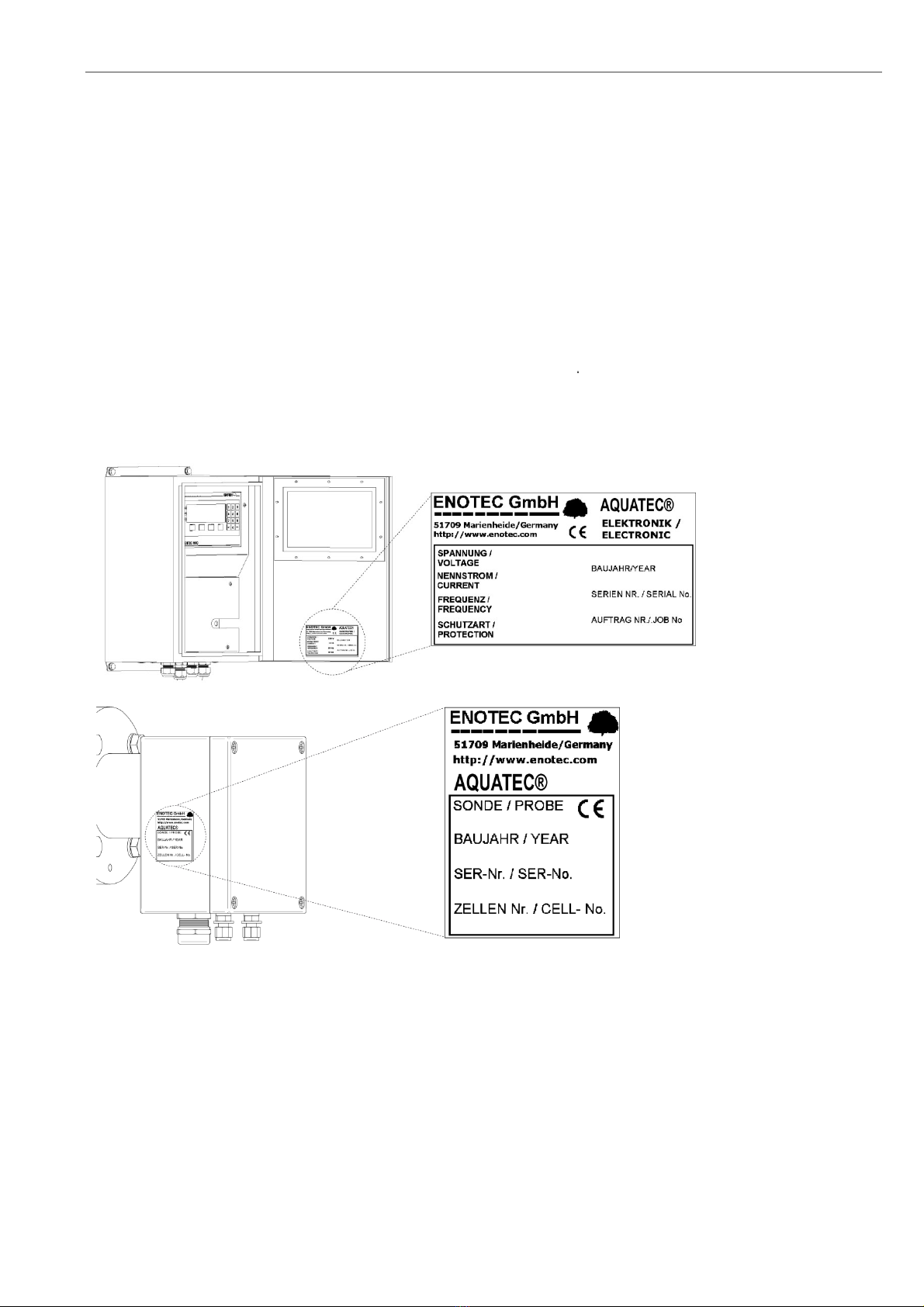

1.8 Name Plates

The name plate contains information about the line voltage, the nominated current, frequency, protection class, year

of manufacture, serial number, order number and system order code.

The system order code refers to information which is detailed in the system test report and supplied with the system.

SME-53 Electronic Unit

Probe Connection Box

Figure 3 - Position of the name plates

Installation Installation and Operation Manual – AQUATEC 1000

8 Doc.-ID: AQUA_16012020_EN

2 Installation

Warning

The system is not equipped with an external power-off switch. The line voltage switch/fuse/breaker must be installed

and be in accordance with local technical standards and should be near to the electronic unit and must be clearly

marked as such. The probe cable is suitable for an ambient temperature range from -40°C to +90°C. All other

installed cables must be suitable for the ambient temperature range at side and must have the required size. All

electronic unit terminals are specified from 0,08 mm² (AWG 26) to 2,5 mm² (AWG 14). If wire end ferrules are used

the next smaller size is required. Before removal of the electronic terminal cover the line voltage must be switched off.

The line voltage to the electronic unit must be switched on again after the cover is back in position. After installation

power conducting parts may not be accessible.

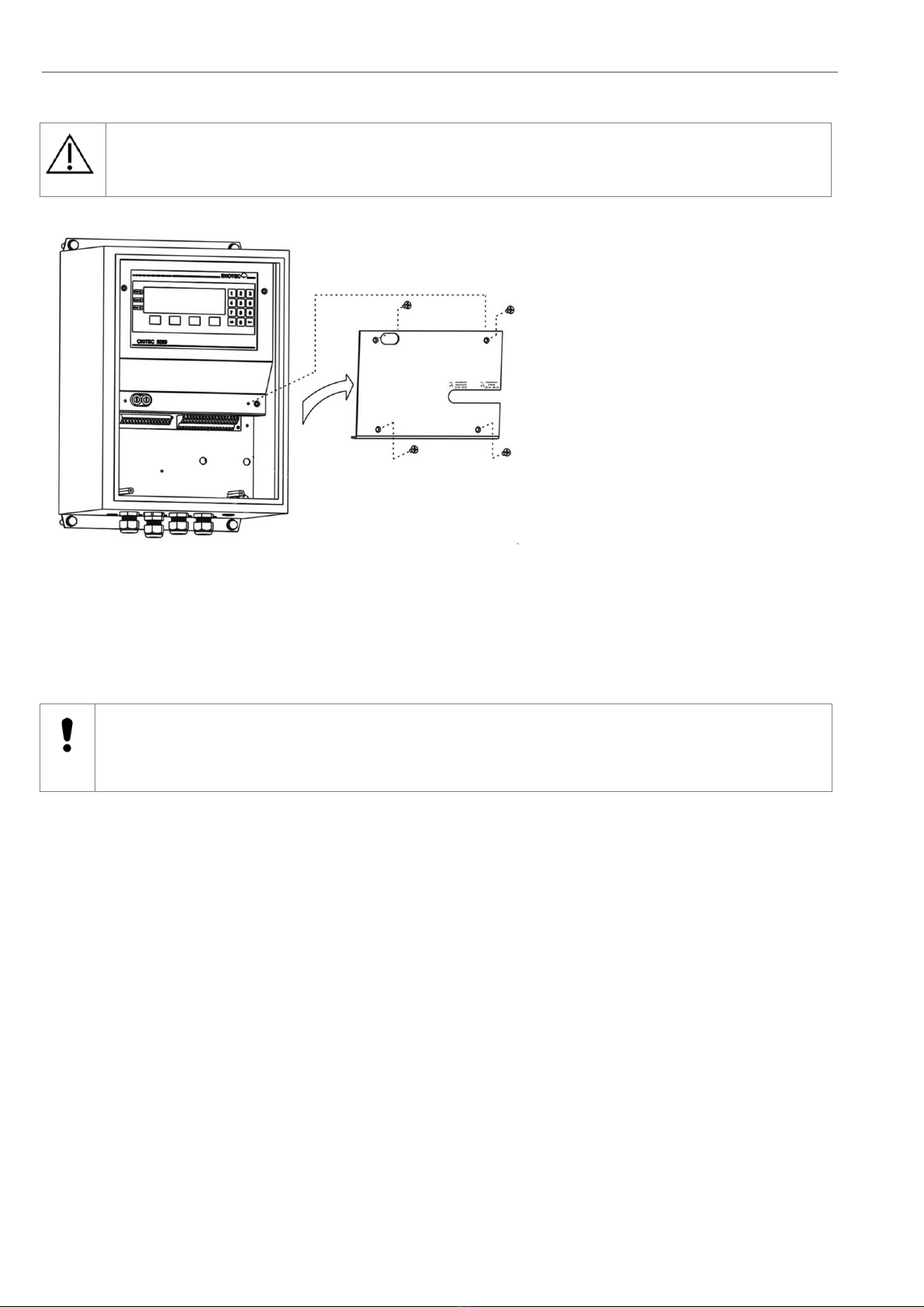

2.1 Installation Requirements for Electronic Unit

Keep the minimum distance to adjacent objects

Install at eye level

Avoid vibrations greater than 2g

Mind the IP code

Heavy equipment,

ensure proper lifting

and carrying

Ambient temperatures

Min.: -20 °C (-4 °F) / Max.: +55 °C (+131 °F) - (Pump version -20 °C to +50 °C)

Drill holes for the electronic unit

Use suitable screws

Electronic unit

Figure 4 - Installation of the Electronic unit

Installation and Operation Manual – AQUATEC 1000 Installation

Doc.-ID: AQUA_16012020_EN 9

2.2 Installation of Probe Signal Cable FEP-0001

Abide by the maximum cable length (max. 150m)

Note the minimum bending radius.

FEP-0001 R

min

= 96 mm

Temp. during installation

Temp. during operation

Cross the probe signal cable (FEP-0001) at right angle

to power supply cables

Figure 5 - Probe cable FEP-0001

Probe Cable FEP-0001 (FEP-0004 armored version)

No. Function Diameter Colors Additional info.

Measuring cell 2 x 0,75 mm

2

white-brown / brown With shield

Thermocouple 2 x 0,75 mm

2

green / white With shield

Probe heating 3 x 1,5 mm

2

black / blue / green-

yellow

Solenoid valve 2 x 0,75 mm

2

grey / grey-blue

Caution

The shield of the probe cable must only be connected at the electronic housing at the PE terminal. Under no

circumstance should the shield also be connected at the probe.

-

5 °C

Min.

+50 °C

Max.

-40 °C

Min.

+90 °C

Max.

Installation Installation and Operation Manual – AQUATEC 1000

10 Doc.-ID: AQUA_16012020_EN

2.3 Access to the Terminals

Warning

Before removing the terminal covers, switch off the mains voltage to the system. Switch the mains voltage on only

after attaching the terminal cover. After the installation has been completed, live parts may no longer be accessible.

Figure 6 - Access to the Terminals

2.4 Ferrite Sleeves (EMC)

Caution

In order to avoid cable related disturbances to the electronic unit, the supplied ferrite sleeves must be used.

CE-conformity is invalid if these ferrite sleeves are not fitted!

Installation and Operation Manual – AQUATEC 1000 Installation

Doc.-ID: AQUA_16012020_EN 11

2.5 Wiring Diagram of the Electronic Unit

Figure 7- Wiring diagram of the Electronic Unit

Ferrite sleeves (Enclosed)

A

nalogue output cable (customer)

Power supply cable (customer) Status signal cable (customer)

Probe signal cable Pressure transmitter analogue input cable

(customer)

Internal Power supply

1 L phase

Relay contacts for status signals -

Potential free

1

The output

voltage of these

contacts (4…6)

always have the

same voltage as

on the power

supply input on

contacts (1…3)

2 N neutral wire

3 PE grounding conductor 18 A/B Maintenance

Internal Power supply

1

19 A/B System Error

4 L phase 20 A/B Output A O

2

measuring range

5 N neutral wire 21 A/B O

2

Limit Alarm 1

6 PE grounding conductor 22 A/B O

2

Limit Alarm 2

Shielding Probe solenoid valve

Power supply probe heater (115V) 23 A

Internal Power supply for probe

solenoid valve (115VAC)

8 L black 23 B

9 N blue 24A L grey

10 PE green/yellow 24B N grey/blue

O

2

-sensor signal Measuring Range O

2

(12..24V DC- External supply)

12 + brown 25A +

13 - brown/white 25B -

Thermocouple (O

2

sensor) Calibration release (12..24V DC - External supply)

14 + green 27A +

15 - white 27B -

Analogue outputs (active 4-20mA) Input Process pressure (passive 4-20mA)

17A + O

2

29A +

17B - O

2

29B -

34A + H

2

O

34B - H

2

O

Installation Installation and Operation Manual – AQUATEC 1000

12 Doc.-ID: AQUA_16012020_EN

2.6 AQUATEC® 1000 Wiring diagram

Figure 8 - Wiring diagram of the AQUATEC 1000 Analyzer system

Installation and Operation Manual – AQUATEC 1000 Installation

Doc.-ID: AQUA_16012020_EN 13

2.7 Installation of the probe

The flue gas temperature, pressure and all other process conditions must be in accordance with the specification.

Leave enough space for insertion/removal of the probe and protection tube (if supplied) and ensure access to the

measuring probe and/or connecting box. Before cutting a hole in the flue gas duct, make sure that the inside of the

duct has enough space for probe installation and that no soot is blown out nearby or any obstacles are in the way.

For probe lengths exceeding 2000 mm, a support must be mounted inside the duct (every 2m) to prevent the probe

and mounting tube from flexing or bending. ENOTEC recommends installing the probe horizontally for the

fastest possible response time.

Maintain the protection class

Avoid vibrations greater 2g

2.8 Mounting of the Probe

The mating flange must be

welded at the specified angle

Process gas flow

The welded seam must be gas-

tight

A

dapter (supplied by customer)

Stainless steel adapter with

R2½”-thread

A

QUATEC – Probe

Insulation

Figure 9 - Mounting the KES 132x with filter head KES-132060AK and adapter plate ASR-1320-KN

Figure 10 - Mounting of the O

2

probe KES-132x with ASR-1320

1-3°

1345

6

2

7

A

Q

U

A

T

E

C

Installation Installation and Operation Manual – AQUATEC 1000

14 Doc.-ID: AQUA_16012020_EN

2.9 Adjusting the V-shield / filter head

Before installing the probe, the direction of flue gas flow must be determined and the filter head assembly turned

to such a position that the V-shield faces the oncoming flue gas. The filter head can be turned freely a full 360° for

this purpose, by loosening the counter nut, loosening the Allen screw and rotating the filter head / V-shield to the

required position, and then tightening the Allen screw and counter nut.

Flue gas direction

V-shield (KES-132X/KES-200X)

V-shield ( KES500X)

Screws to secure filter head

Filter head

Rotation of filter head

Probe

Figure 11 - Adjustment of the V-shield

Loosen the locknut

Loosen the locknut

Adjust the filter head. Adjust the position of the

shield against the flow direction

Tighten the locknut

Tighten the locknut

Figure 12 - Adjustment the fitter head

1

2

3

4

Installation and Operation Manual – AQUATEC 1000 Installation

Doc.-ID: AQUA_16012020_EN 15

2.10 Electrical Connections of the Probe

Info

The probe cable (FEP-0001) has to be connected to the terminal board in the probe terminal box. Please do not

attach the shield to the probe.

1 : - mV O

2

sensor (white-brown)

2 : + mV O

2

sensor (brown)

3 : + mV thermocouple 1 (green)

4 : - mV thermocouple 1 (white)

6 : L 115VAC heater (black)

7 : N 115VAC heater (blue)

8 : PE Protection earth (green yellow)

9 : L 115VAC solenoid valve (grey)

10: N115VAC solenoid valve (grey-blue)

Figure 13 - Electrical Connections of the Probe

connections box

2.11 Requirements for Pneumatic Cable FEP-0002

Note the minimum bending radius.

FEP-0002R

min

= 138 mm

Temp. during installation

Temp. during operation

-

5 °C

Min.

+50 °C

Max.

-40 °C

Min.

+90 °C

Max.

Installation Installation and Operation Manual – AQUATEC 1000

16 Doc.-ID: AQUA_16012020_EN

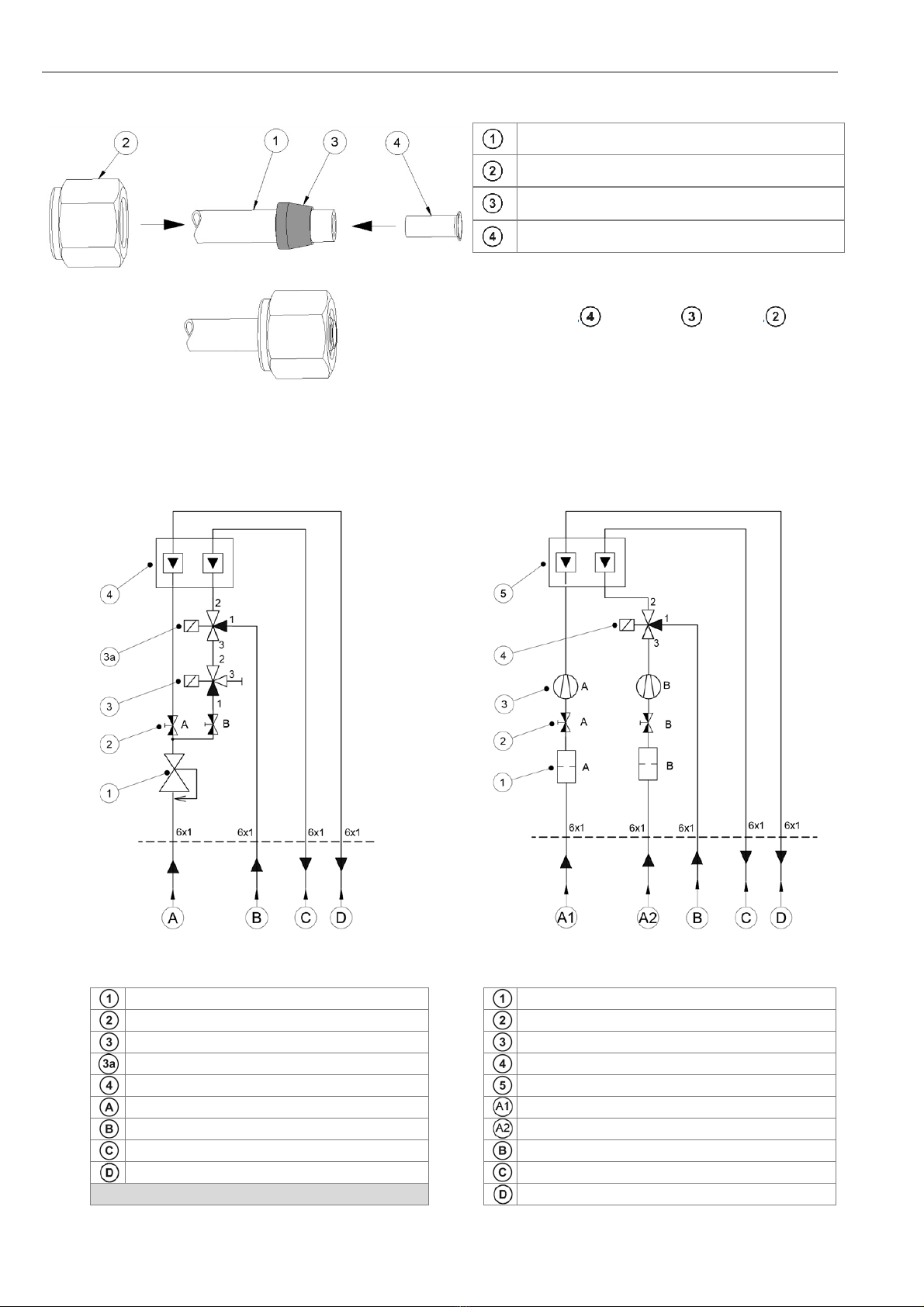

2.12 Preparation of the pneumatic Cable

Pneumatic tubing FEP-0002

Nut

Clamp ring

Support sleeve

Both, the pneumatic tubing for the reference air (blue)

and the test gas (green) have to be prepared with

support sleeves , clamp rings and nuts .

Figure 14 - Preparation of pneumatic tubes

2.13 Gas plans

Pneumatic version for Instrument air

SME-50000010 Pneumatic version with pumps

SME-50000020

Figure 15 - Gas plans

Pressure control valve Filter

Choke non return valve Choke non return valve

Solenoid valve 3/2 ways Reference air pump / Test air pump

Solenoid valve 3/2 ways Solenoid valve 3/2 ways

Flow meter Flow meter

Instrument air in, 4 – 10 Bar Reference air in

Test gas in, Max. 3 Bar Test air in

Test gas out, 150 - 180 l/h Test gas in

Reference air out, 30 – 40 l/h Test gas out, 150 - 180 l/h

Reference air out

Installation and Operation Manual – AQUATEC 1000 Installation

Doc.-ID: AQUA_16012020_EN 17

2.14 Pneumatic Connections of the Probe

Reference air in (FEP-0002: blue tube)

Test gas in ( FEP-0002: green tube)

Figure 16 - Pneumatic connections of the probe

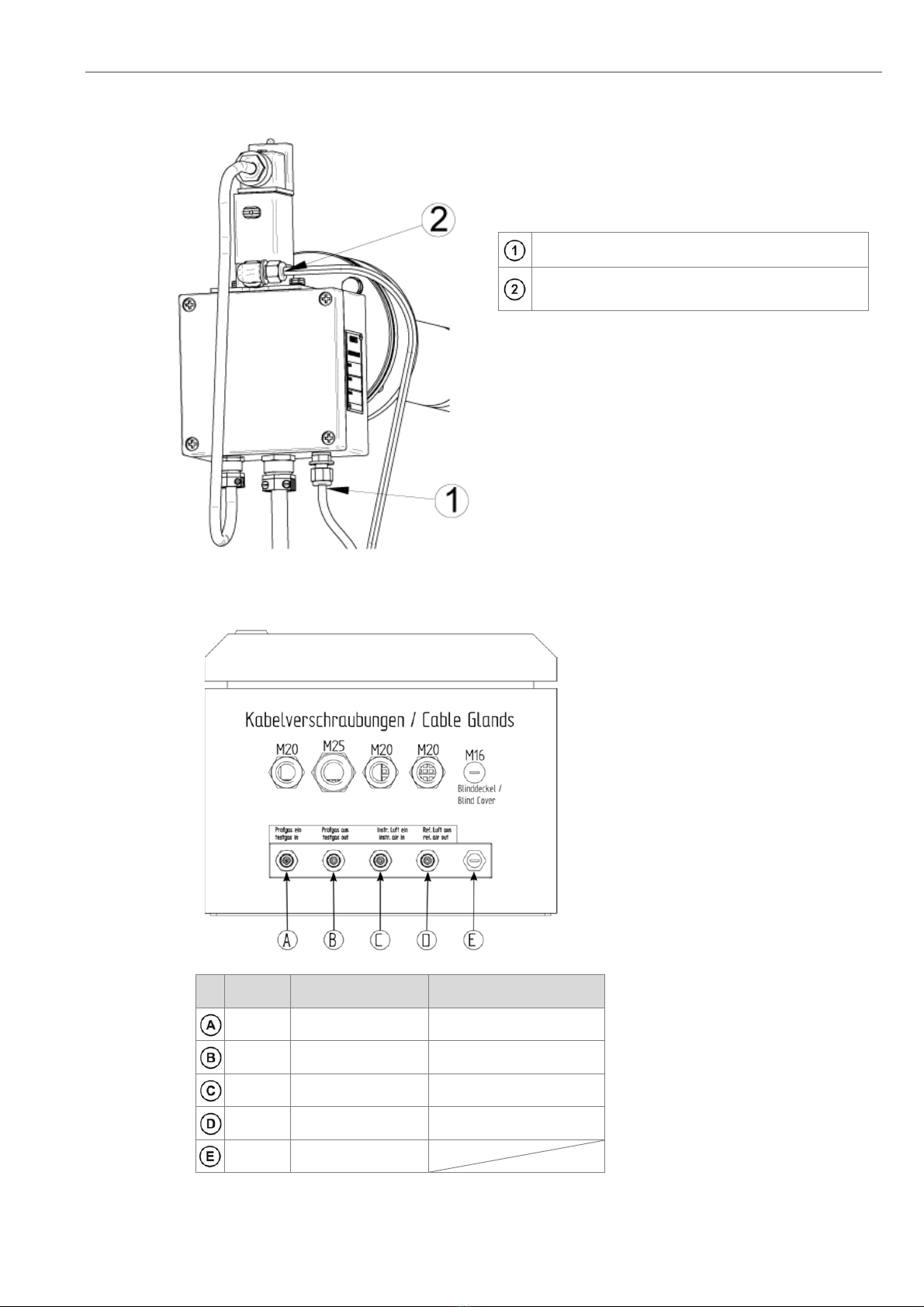

2.15 Pneumatic Connections of the Electronic Unit

Figure 17 - Bottom view of SME-53 with

integrated pneumatic unit

Nr. Tube Pump version Instrument air version

1/4“ Testgas in Testgas in

1/4“ Testgas out Testgas out

1/4“ Reference air input Instrument air in

1/4“ Reference air output Reference air out

1/4“ Test air input

Initial Operation Installation and Operation Manual – AQUATEC 1000

18 Doc.-ID: AQUA_16012020_EN

3 Initial Operation

3.1 Checklist before commissioning the system

Is the system number of the probe identical to the system number of the electronic unit? If not, change the

assignment.

Does the voltage specified on the name plate correspond to the line voltage? (See section 1.8 Name Plates)

If not, contact ENOTEC.

Is the electrical wiring connected correctly? (See section 2.6 AQUATEC 1000 Wiring Diagram)

Are the pneumatic connections correct and gas tight? (See sections 2.15 Pneumatic Connections)

Make sure that there are no leakages at the probe - e.g. is the counter flange welded gas tight to the duct and are the

flange bolts tightened sufficiently? Are gaskets in use? (See section 2.8 mounting of the Probe)

Do the conditions at site match the specification in the data sheets? (See section ATechnical Data)

Has the O2 reference value been entered into the system? (See section 3.9)

3.2 System Power Up

Switch on the line voltage to the system. After a short power up information, the user is prompted to

Select language, set the System date and System time.

The probe heating phase now begins which is followed by the measuring mode.

Figure 18 - System Power up. Note the software

version at the bottom right of the display.

3.3 Display - Probe Heating Phase

Figure 19 - O

2

sensor heating phase

The probe heating phase begins with the heating

up of the O

2

sensor.

Rising probe temperature

(or) waiting period

(or) heater error

Last access with corresponding date

Current temperature

A

nalogue temperature bar

Set point probe temperature

Softkey title: e.g. System menu

3.4 Display - Measuring Mode

Figure 20 - Measuring mode

Measured component

Measured value

A

ctive measuring range

Blinking indicators showing under or over

measuring range

A

nalogue bar showing measured value and

measuring range start and end

Softkey titles

Installation and Operation Manual – AQUATEC 1000 Initial Operation

Doc.-ID: AQUA_16012020_EN 19

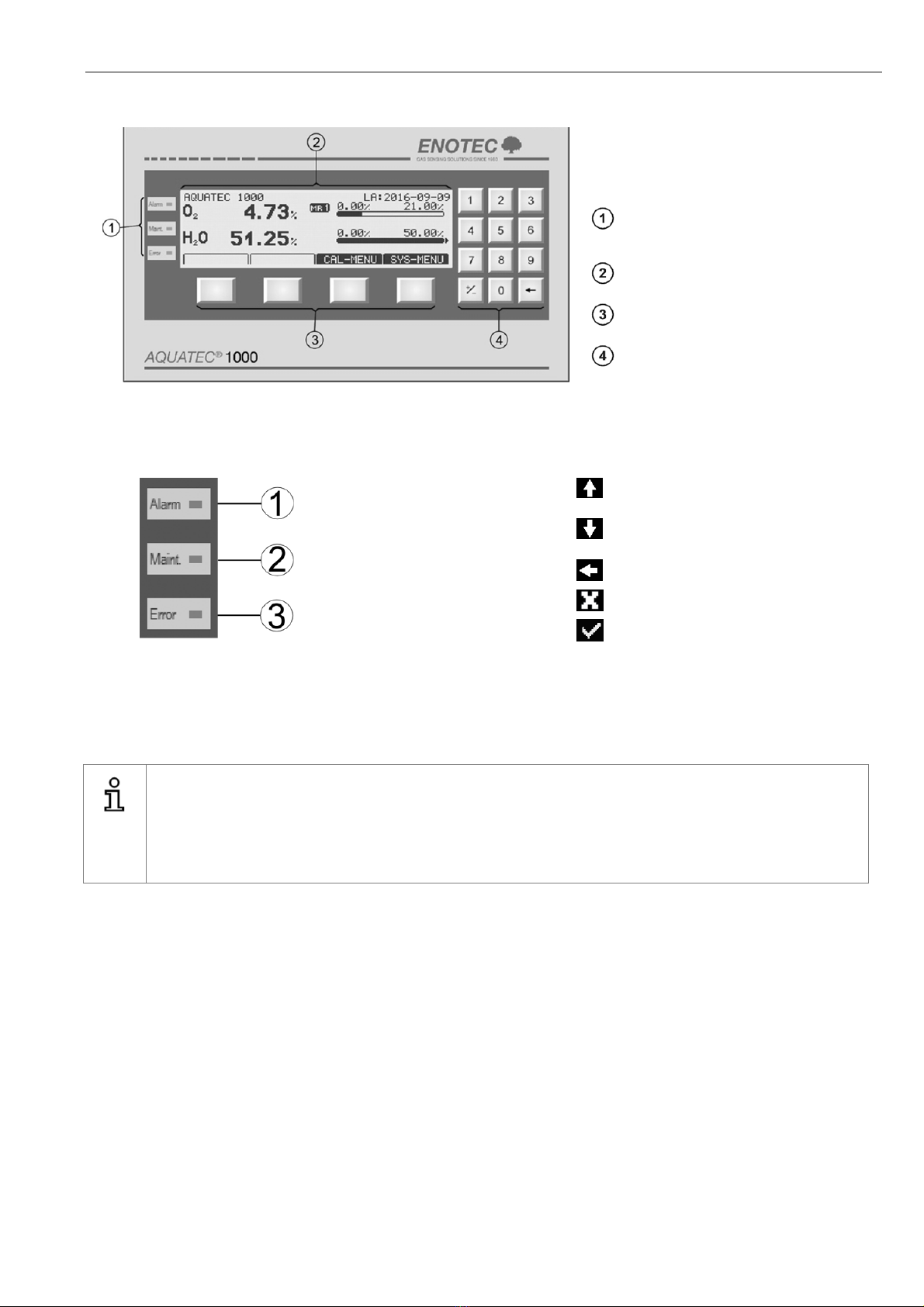

3.5 Keypad and Display

Figure 21 - Keypad and display

The controls and display of the AQUATEC

1000 are housed in the electronic unit and are

comprised of:

Three LED indicators depicting active

status

reports for limit alarms, maintenance and

system faults

Graphic enabled, back-lit display

Four softkeys with varying layout

(softkeys)

Numeric number bloc

3.6 Status LEDs 3.7 Softkey Symbols

Alarm, - orange - is lit when an

alarm has been activated (e.g.

O

2

limit alarm)

Moves the selection one position

upwards

Moves the selection one position

down-wards

Maint. - Orange - a function

has been accessed which may

affect the measurement

Leave an area

Abort a function or entry

Error - red - is lit when a

system error has occurred

Select or confirm a function/value

3.8 System Code

Info

The system code on delivery is 0000. In this state, entry into the system is granted without having to enter the

system code. The system code protects the system from unauthorized use. Functions which may alter the

measurement of O

2

are therefore also protected.

Caution: If the system code has been altered, it must be kept in a safe place!

3.9 Adjustment of the Analyzer to the Dryer

The water vapor is not measured directly, but is calculated using the measured oxygen content. The water vapor

concentration is proportional to the quantity of the displaced oxygen. The water vapor is calculated using the

measurement of the O

2

concentration.

The O

2

reference value (dry), which is necessary for this evaluation, is different for each dryer and process.

Before commissioning, the system must be adjusted to the dryer, of which moisture content is to be measured. This

is carried out under:

SYS MENU -> System configuration -> H2O measuring range -> O2 reference value (dry).

Software Overview and Explanations Installation and Operation Manual – AQUATEC 1000

20 Doc.-ID: AQUA_16012020_EN

4 Software Overview and Explanations

4.1 Menu Overview - SYS-MENU

SYS-MENU

System Information

Actual measured values

O2measured value (% O2) {may be ppm}

O2-mA output 17A/B (mA)

O2sensor input (mV)

H2O measured value

H2O mA output 34A/B

Flow rate reference air (l/h)

O2probe temperature (°C / °F)

O2probe heater power (%)

Thermocouple input (mV)

Terminal temperature (°C / °F)

Internal temperature (°C / °F)

Process pressure (rel) (mbar/psi)

O2 sensor life (%)

Lambda

Calibration results

e.g. 2012-05-11 (Choose date/time)

Executed at

Calibration method

O2 sensor calibration

~~ Calibration results ~~

O2value at test air (20,95 % O2)

♦calibrated to (% O2)

O2value at test gas (% O2) } only if determined

♦calibrated to (% O2)

~~ Calibration data ~~

O2sensor offset (mV)

O2sensor slope (mV / dec) } only 2 point calibration

~~ Test gas data ~~

Test air (20,95 % O2)

Test gas (e.g. 2,1 % O2)

~~ Sensor raw data~~

O2voltage at test air (mV)

♦at pressure (mbar/psi)

O2voltage at test gas (mV) } only if determined

♦at pressure (mbar/psi)

O2response to test gas (s) } only if determined

O2response to process (s) } only if determined

O2sensor life

Table of contents

Other Enotec Analytical Instrument manuals