Table of Contents

© 2019 Valeport Ltd Page 2

Table of Contents

..................................................................................................................................... 41. EU Declaration of Conformity - CE Marking

..................................................................................................................................... 72. Introduction

.................................................................................................................................... 72.1. rapidPro SVT

2.1.1 Sensor Specifications

.................................................................................................................................... 8

2.1.2 Dimensions

.................................................................................................................................... 9

.................................................................................................................................... 102.2. rapidPro CTD and rapidPro CTDplus

2.2.1 Sensor Specifications

.................................................................................................................................... 11

2.2.2 Fluorometers

.................................................................................................................................... 12

2.2.3 Linear Observation Range

.................................................................................................................................... 14

2.2.4 Quenching

.................................................................................................................................... 15

2.2.5 Turbidity

.................................................................................................................................... 16

2.2.6 Dimensions

.................................................................................................................................... 17

.................................................................................................................................... 182.3. ProLogger

2.3.1 Changing\Charging the ProLogger

.................................................................................................................................... 19

2.3.2 ProLogger Dimensions

.................................................................................................................................... 20

2.3.3 Rechargeable Battery

.................................................................................................................................... 20

..................................................................................................................................... 233. Communication | Memory | Software

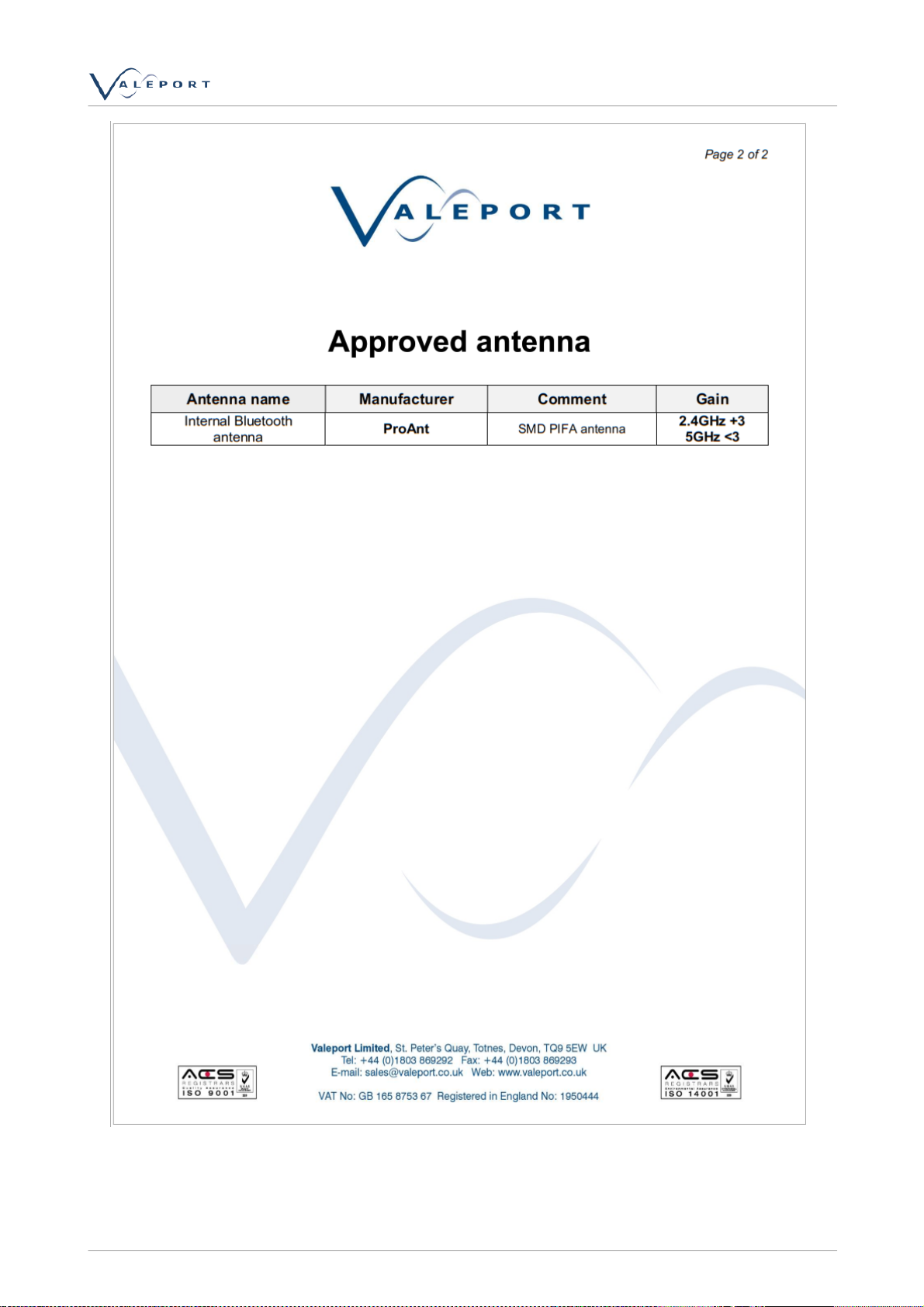

.................................................................................................................................... 233.1. Qualification and Approvals-Bluetooth Module

3.1.1 Compliance with RoHS Directive

.................................................................................................................................... 24

3.1.2 European Union Regulatory Compliance - Bluetooth Module

.................................................................................................................................... 25

3.1.3 Bluetooth Qualification Information

.................................................................................................................................... 26

..................................................................................................................................... 274. Operation

.................................................................................................................................... 274.1. Operating Modes

.................................................................................................................................... 284.2. Switching On/Off

.................................................................................................................................... 294.3. Deployment

.................................................................................................................................... 294.4. Pressure Tare

.................................................................................................................................... 304.5. Data Requests and Output Formats

4.5.1 Stop Command

.................................................................................................................................... 30

4.5.2 Run Commands

.................................................................................................................................... 30

4.5.3 Rapid Profile Settings

.................................................................................................................................... 31

4.5.4 Site information

.................................................................................................................................... 31

4.5.5 Instrument Information

.................................................................................................................................... 31