13

2.10. Order Form :

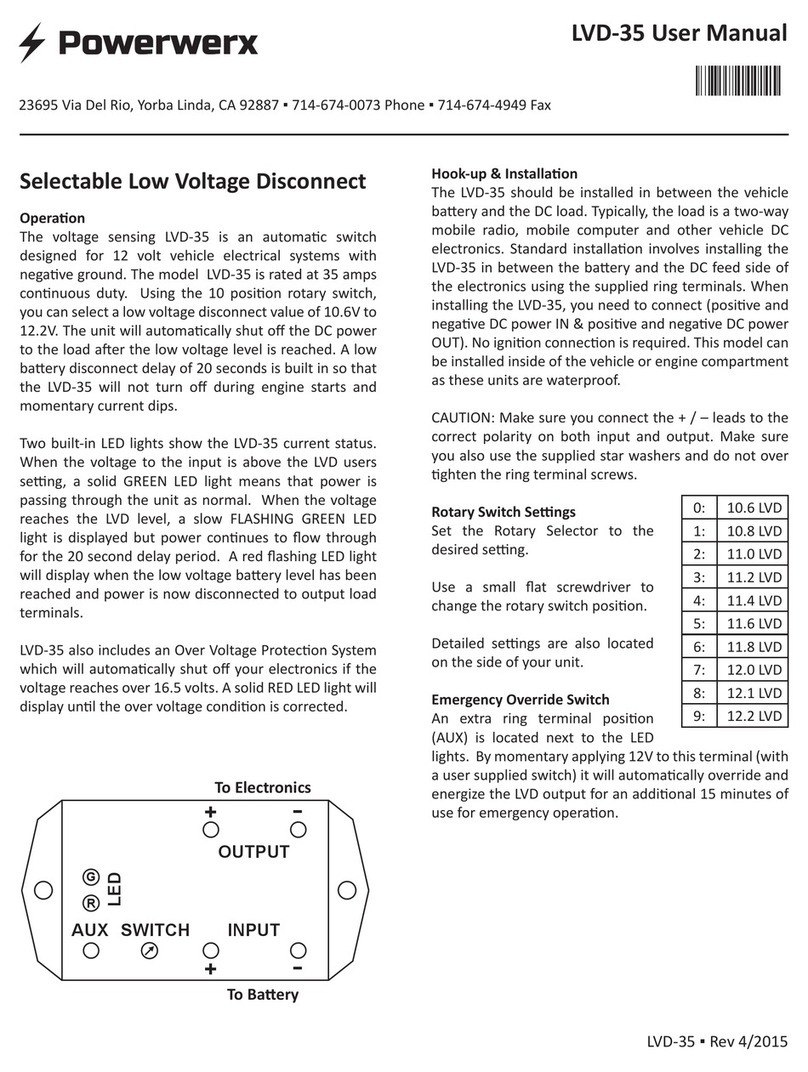

OUTPUT

7

ECAS 101 - Ø 10 - 300 mm - 0 - 0006 - 11 - 050 - 066 - 002 - 00 / 0

For conductive liquids , L= 300 mm, 1 BSP , Relay Output, Aluminium Housing , Ø 10 Probe

SAMPLE

Relay Output NA/NK (5A)......................................11

8

Special...........................................................................x

9

INSULATION MATERIAL

10

PBT........................................................................065

PTFE.....................................................................066

PFA........................................................................067

PEEK.....................................................................068

11

13

12

PROCESS TEMPERATURE

6

STEM LENGHT

5

MODEL ECAS

...............................................................................mm

Order Form :

Please consider sample models when coding.

OPTIONAL

None...................................................................../ 0

With By - Pass Tube............................................... / T

Shetter (For the outside of the tank) 304 St. St.../ K6

Seperable Electronic Unit................................................../ S

Wall Apparatus................................................................../ W

Special................................................................................/ x

CONNECTION MATERIAL

304 Stainless Steel ...............................................001

316 Stainless Steel ...............................................002

Brass......................................................................041

PVC........................................................................061

Polypropylene........................................................062

HOUSING

Aluminium

Housing , B20x .............................................603

Aluminium

Housing , B22x .............................................750

Stainless Steel

Housing , B101x.....................................800

Special..................................................................................x

Plastic Housing , B10p .........................................050

Plastic Housing , B11p .....................................053

Plastic Housing , B20p .........................................103

Aluminium

Housing , B10x ...................................503

Conductive Liquids....................................................1

Non-Conductive Liquids ...........................................2

Solids Particulate Materials..................................................3

Adhesive and Acid / Basic Materials...............................4

CERTIFICATE

None...........................................................................0 (EN10204-3-1)Material Certification..................................1

PROBE TYPE (MAX. LENGHT)

Single Probe - Insulated (Max. 4 m.) ..................... 1

Single Probe - Coaxial (Max. 4 m.) Ø 38 ............... 2

Single Probe - Thin Coaxial (Max. 1 m.), Ø 21 ...... 3

Rope - Non-Insolated (Max. 32 m.) ........................ 4

Single Probe - Non-Insolated (Max. 6 m.) .............. 5

Single Probe - High Temperature (Max. 4 m.) ........6

Rope - Insulated (0 ... 32 m.)................................... 7

Double Probe - Single Insulated (Max. 4 m.) ............................. 8A

Double Probe - Non-Isolated (Max. 6 m.) .................................. 8B

Double Probe - Double Insulated (Max. 4 m.) ........................... 8T

Double Probe - Double Insulated, PVC Coaxial (Max. 4 m.) .. 8Tp

Double Probe Thin - Double Insulated (Max. 1 m.) ................. 8Tm

Ceramic Insulated Probe (Max. 4 m.) ...........................................S

Double Probe - Insulated (Max. 4 m.) ............................. D

Special............................................................................................ x

PROBE DIAMETER (Ø)

150 °C (Standard).....................................................0

200 °C with Cooling Apparatus ...............................1

(-) 196 °C For Cyrogenic Tank ..........................................2

230 °C with Peek Insulated .................................................3

400 °C with Seramic Insulated ............................................4

CONNECTION

ELECTRICAL CONNECTION

With Terminal...........................................................00 Special...................................................................................x

Polyamide........................................................................069

Seramic............................................................................070

Rubber..............................................................................081

FKM..................................................................................084

Steel Shielded Cable (Max. 350 °C)...............................048

Special..................................................................................x

Delrin.................................................................................063

PVDF.................................................................................064

PBT...................................................................................065

PTFE.................................................................................066

Special...................................................................................x

Thread (ISO 228-1) Clamp (ISO 2852) ISO Flange(1092-1) ASA Flanged (B16.5)

1/2 BSP..............0004

3/4 BSP ...............0005

1 BSP....................0006

1 1/2 BSP..............0010

2 BSP...................0012

1/2 NPT............0203

3/4 NPT............0204

DN 32 - PN 16...1501

DN 50 - PN 16...1502

DN 65 - PN 16...1503

DN 25 - PN 16...0502

DN 32 - PN 16...0503

DN 50 - PN 16...0505

DN 80 - PN 16...0507

DN 100 - PN 16...0508

DN 50 - 150lb ... 1005

DN 65 - 150lb ... 1006

DN 80 - 150lb ... 1007

DN 100 - 150lb ... 1008

ISO Flange (1092-1)

DN 25 - PN 40...0702

DN 32 - PN 40...0703

DN 50 - PN 40...0705

DN 80 - PN 40...0707

DN 100 - PN 40...0708

Ø 10 mm (Std.).........................................................10 Ø 8 mm ..............................................................................08

Ø 12 mm ............................................................................12