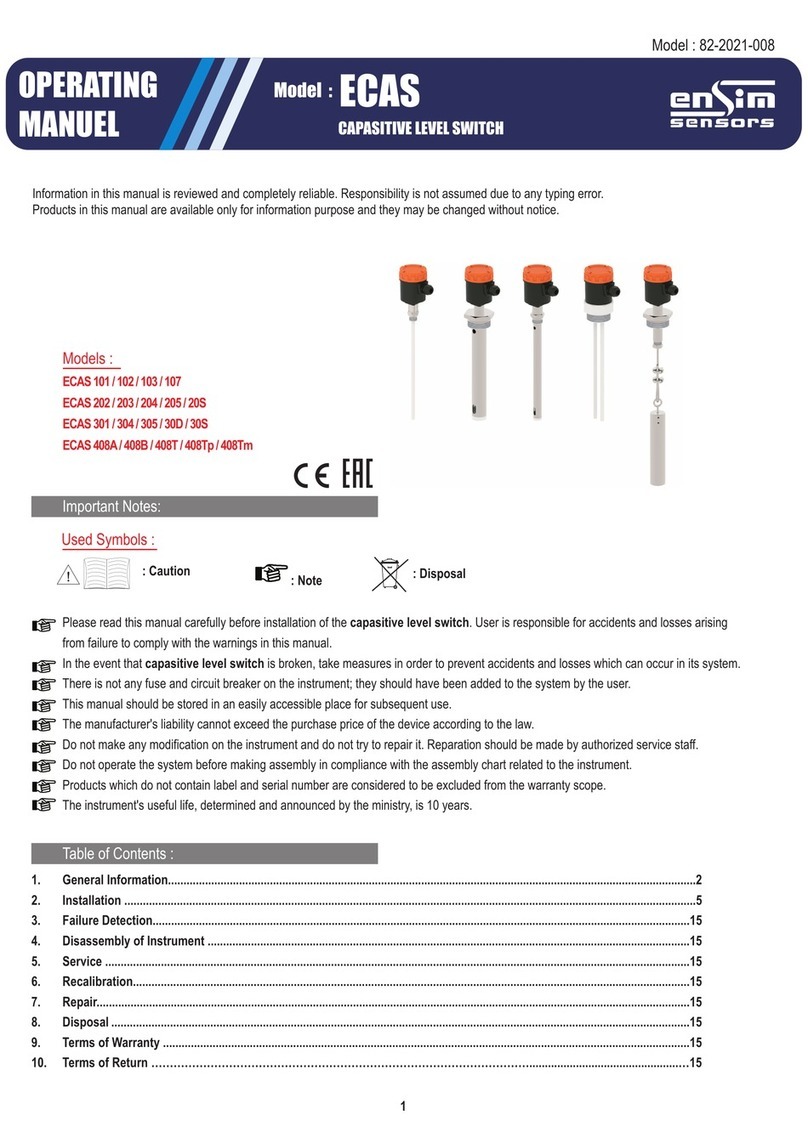

ENSIM SENSORS ELT User manual

OPERATING

MANUEL

VIBRATING TYPE LEVEL SWITCH

ELT

Model :

Model : 51-2021-003

Important Notes:

Used Symbols :

Please read this manual carefully before installation of the level switch. User is responsible for

accidents and losses arising from failure to comply with the warnings in this manual.

In the event that level switch is broken, take measures in order to prevent accidents and losses which

can occur in its system.

There is not any fuse and circuit breaker on the instrument; they should have been added to the system

by the user.

This manual should be stored in an easily accessible place for subsequent use.

Do not operate the system before making assembly in compliance with the assembly chart related

to the instrument.

Do not make any modification on the instrument and do not try to repair it. Reparation should be made

by authorized service personnel.

The instrument's useful life, determined and announced by the ministry, is 10 years.

Products which do not contain label and serial number are considered to be excluded from the warranty scope.

: Caution : Note

Table of Contents :

1. General Information...........................................................................................................................................2

2. Installation ..................................................................................................................................................3

3. Failure Detection..............................................................................................................................................6

4. Disassembly of Instrument ..................................................................................................................................6

5. Service ......................................................................................................................................................6

6. Recalibration...............................................................................................................................6

7. Repair....................................................................................................................................................................6

8. Disposal................................................................................................................................................6

9. Terms of Warranty .....................................................................................................................................6

10.Terms of Return ..............6

1

: Disposal

Modeller :

Information in this manual is reviewed and completely reliable. Responsibility is not assumed due to any typing error.

Products in this manual are available only for information purpose and they may be changed without notice.

ELT 101 , ELT 102 , ELT 103 , ELT 104

ELT 201 , ELT 202 , ELT 204

2

1. General Information :

1.1. Material Acceptance

Check that there is no damage on the packages during the transportation immediately after the material acceptance. If packages are

damaged, open the packages immediately and check whether products are affected or not, if there is any damage, send your

complaint report to the transporter company and its photocopy to the address of our company.

1.2. Information about Areas of Use

ELT series single vibrating material level switch is one of the tuning fork material level switches. It is not afraid of hanging materials, not afraid

of impact, without clamping problems, and has higher sensitivity.Its cylindrical single measuring rod structure determines its wider

adaptability to industrial field.

Areas of Application :

Sugar, Hazelnut, Clay, Sunflower Seed, Coffee, Various Granules, Wheat, Bauxite, Ceramic, Legumes, Cereal, Fish Feed, Sand, Pebble,

Isolation Materials, Corn, Rice ...

Ambient Conditions: Relative Humidity: 5-95 %RH Ambient temperature: 60 °C (It is not used under -5 C)

1.3. Working Principle

Single rod vibrating level switch uses the "resonance" principle of tuning fork to generate vibration

under the driving of piezoelectric elements.

Only when all around the probe rod are surrounded by materials, the vibration amplitude will be

sharply reduced, resulting in switch action.

1.4. Technical Specifications :

(((

(((

Fluid

Wet Parts

Fork Material

Housing Material

Max. Solid Particle Size

Max. Liquid Viscosity

Measurement Density

Vibration Frequency

Delay

Time

Exit

Supply

Power consumption

Connection

Working Pressure

Working Temperature

Ambient Temperature

Ambient Humidity

Protection Class (EN60529)

(For ELT101, 201)

(For ELT103)

(For ELT102,104, 202, 204)

Liquid, Solid, Powder

316 Stainless Steel

316 Stainless Steel

Aluminuim, Stainless Steel (For ELT103)

<10 mm

<1000 mm² / sec

For Solid> 0,1 g / cm³

For Liquid> 0.7 g / cm³

280 KHz (For ELT102,104, 202, 204)

300 ± 50KHz (For ELT101, 201)

0.5 sec (Vibration Stop)

1-2 sec (Vibration Start)

It can be adjusted between 1-60 seconds.

1 x 3A NO / NC Relay 30 VDC / 220 VAC

1 x 5A NO / NC Relay 30 VDC / 220 VAC

2 x 8A NO / NC Relay 24 VDC / 220 VAC

15-80 VDC, 15-260 VAC

2.5 W, 1 W (For ELT103)

1 BSP (Std.) Male Thread

Opt. Flanged

Max. 20 bar (For ELT101, 201)

Max. 40 bar (For ELT102,104, 202, 204)

Max. 30 bar (For ELT103)

(-) 20 °C ... (+) 150 °C (Std.)

Opt. 200 °C

(-) 20 °C ... (+) 80 °C

% 95 RH

IP 66, IP 67 (For ELT103)

3

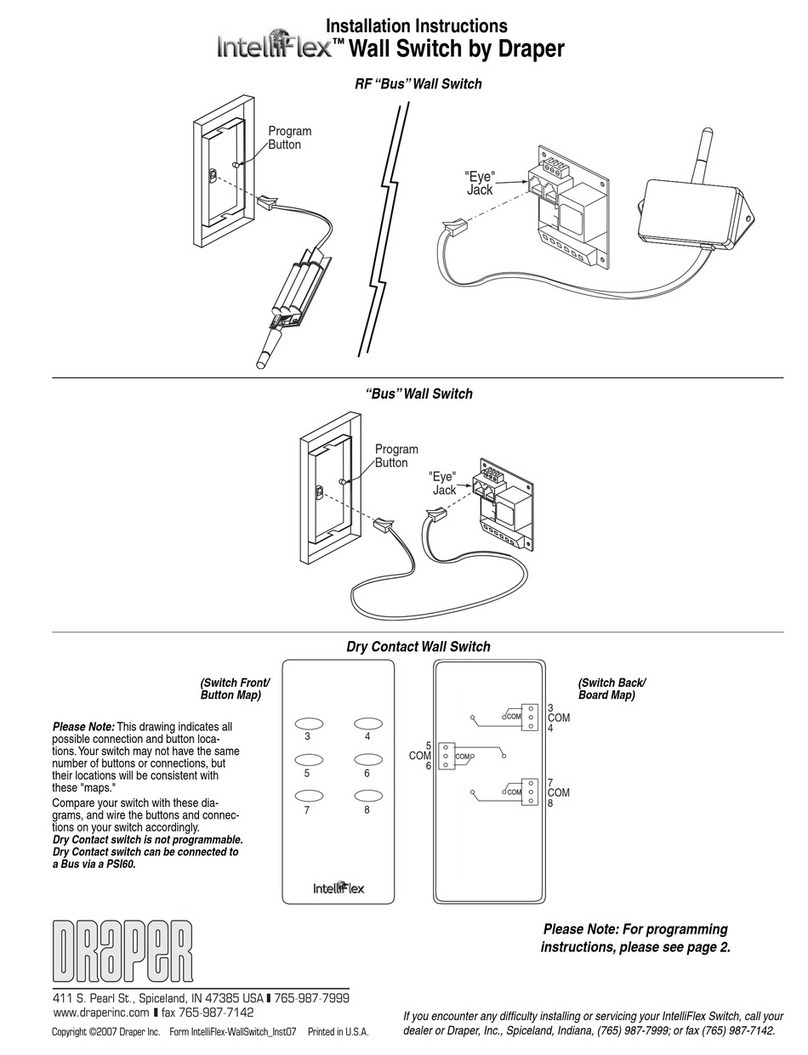

1.5. Electrical Installation

Make the electrical connection of the instrum ent according to details on its label, table and cable figures in this manual.

For ELT 103

Material : 304 Stainless Steel

Welded manufacturing

Opens - Closes Hinged

To Protect Against external conditions.

Protection Case:

For ELT 101 / 201 For ELT 102 / 104 / 202 / 204

Aluminium

Housing :

B20x

a

b

MATERIAL PROTECTION

CLASS

TEMPERATURE

(oC)

TYPE

B20x Aluminium IP 66 -40...+200

ORDER

CODE

5240

SIZE

a x b (mm)

132 x 104

DO NOT OPEN WHEN ENERGIZED

KEEP TIGHT WHEN CIRCUIT ALIVE

M3

Bund

Stops

Grounding Terminal

(Max.1,5 mm2)

Recommended Cable (5x1,5 mm2)

Cable Plug

(Suitable Cable Diameter : Ø 6-12mm)

Aluminium Housing

NO

A

B

C

D

E

(-)

(+)

NC

COM

E

A

B

C

D

24 VDC

Frequency

L/ + NCCOM NO

Power LED

_N

+

L

220 VAC

Sensitive

N/ -

Location

selection

HL

12-36

VDC

Vibration

Sensitive

Frequency

H

L

AC 220V

LN

DC 24V H

L

H

L

+

1 2 3 4 5 6 7 8 9 10 11

Location

selection Sensitive Delay Reset

HL

State Power 1

0

928

37 46 5

1

0

60

50 5

40 10

30 15

20

1 2 3 4 5 6 7 8 9 10 11

L N +_NC NO NC NO

Location Selection

(Min. or Max.)

COM

COM

H (Max. Location)

220 VAC

24 VDC

Delay

Factory Settings

Sensitive

Power L ED

State L ED

NO NC NO NC

COM

COM

(Min. Location)L

State L ED

NC

NO

COM

4

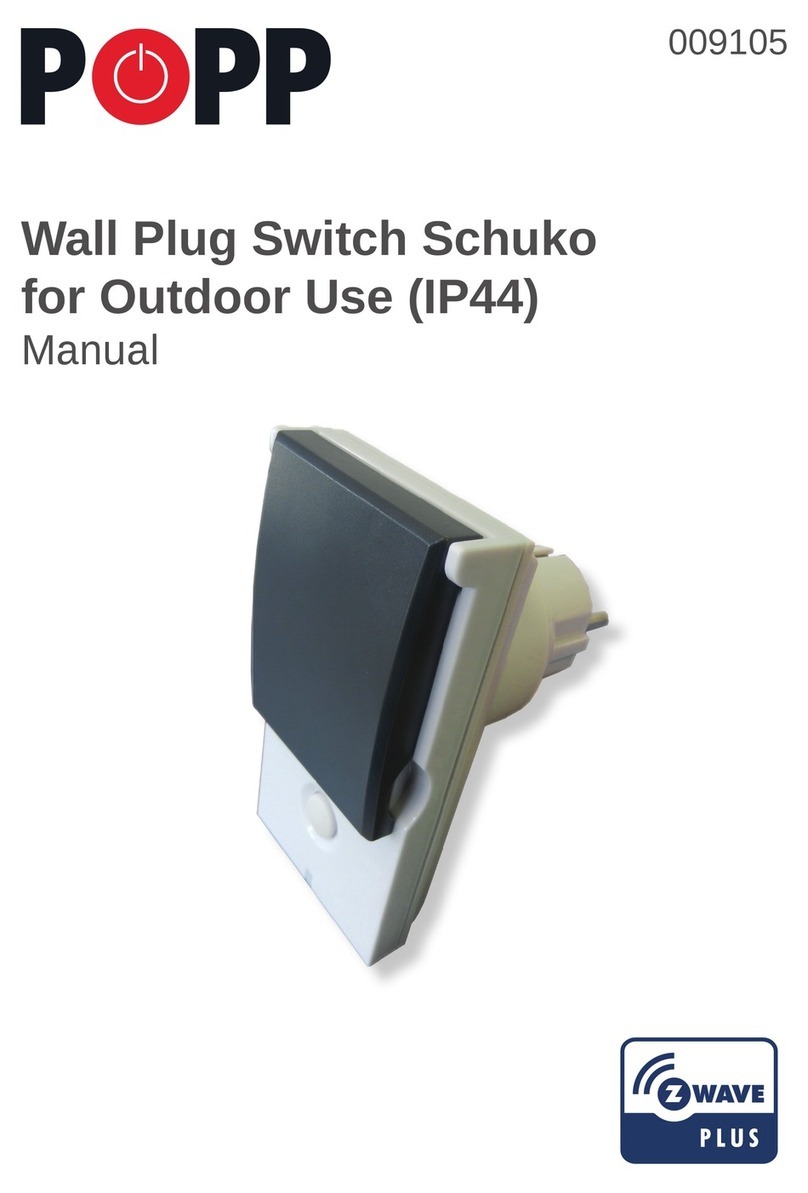

1.6. Label Information :

1.6.1. Content of Package

Please check whether you have taken delivery of below listed content completely

or not and check its conformity with

criterions in your order:

*Level switch

*This operating manual

Quality

Label

Box

Label

QC

VIBRATING ROD LEVEL SWITCH

MADE IN TURKIYE

www.ensim.com.tr

Type :

Power Supply

Contact Output

Process Temp./ Press

T (Ambient)

S.N.

:

:

:

:

:

ELT101-200-006-02-11-1-378/0

24 VDC / 220 VAC

1 x 3 A NA / NK

-20...+150 °C / 10 bar

-20...+80 °C

IE20070006-0001

!

Ürün

Etiketi

LEVEL SWITCH

www.ensim.com.tr

MADE IN TURKIYE

Model

Type :

Power Supply

Contact Output

Process Temp./ Press

T (Ambient)

S.N.

:

:

:

:

:

ELT101-200-006-02-11-1-378/0

24 VDC / 220 VAC

1 x 3 A NA / NK

-20...+150 °C / 10 bar

-20...+80 °C

IE20070006-0001

Serial Number

Kutu

Etiketi

Model

Serial

Number

Contact

Output

Manufacturer

Website

Product

Name

Manufacturer

Brand Warning

Symbols Approval

Sign

Approval Sign

Warning Symbols

Warning Symbols

Product

Name

Contact

Output

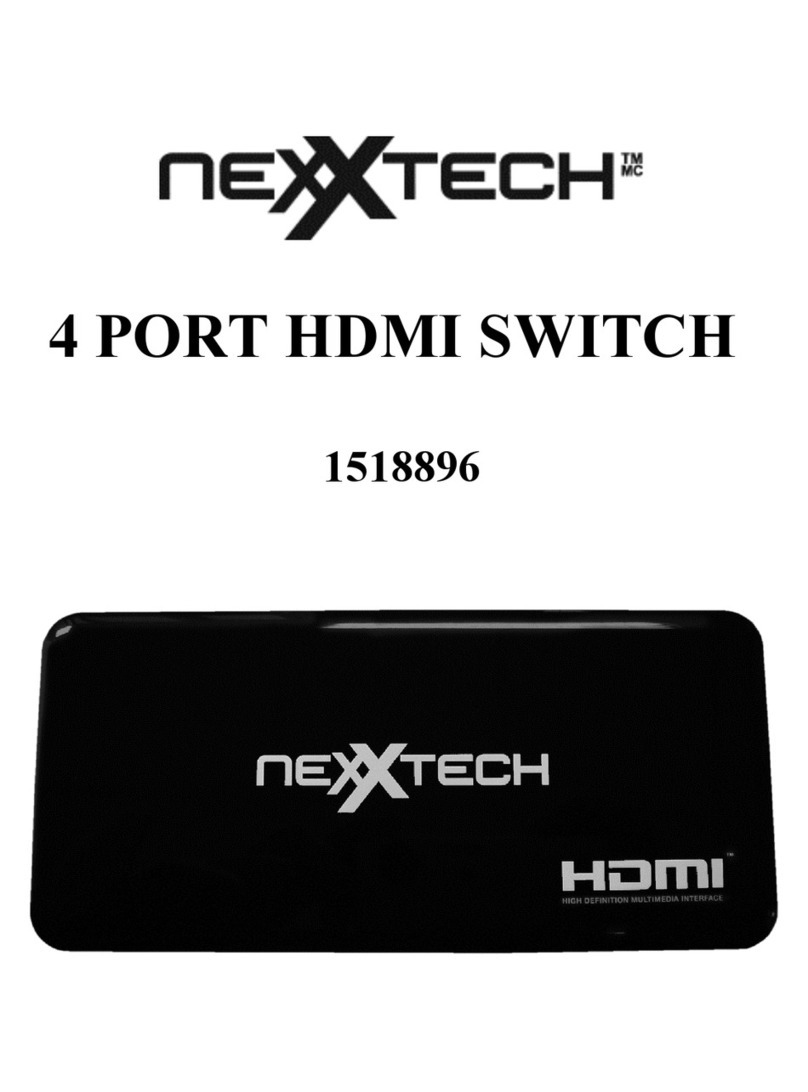

1.7. Dimensions :

ELT 201

R

Ø19

L1L

200

ELT 101

L1L

R

HEX

200

Ø19

ELT 102

L1L

R

19

100

ELT 202

L1L

R

19

100

HEX HEX HEX

Manufacturer

Website

5

1.8. Target Group

This operating manual has been prepared for

qualified technical personnel.

1.9. Security Notes

Following notes should be taken into consideration in order to avoid dangers which can occur on the operator and around

the ambient:

Installation, operation and maintenance of this instrument should be made only by people who have read the operating manual and

who are knowledgeable about work safety!

It should be complied with work safety, accident prevention regulations and national installation standards.

Product should be used only within the scope of stated specifications!

You can assemble the instrument only when pressure is not available!

2. Installation :

2.1. General Notes

Installation of the instrument should be made only by authorized personnel.

Do not apply force to the instrument during the installation!

Do not use the level indicator with a greater pressure than recommended pressure.

Do not forget that instrument is precise, carry it carefully and prevent to be damaged.

It should be guaranteed that there are not any magnetic particles.

2.2. General Installation Stages

*Remove level indicator from the box carefully

*Check whether gasket is appropriate for fluid or not. If is not appropriate, contact with the producer.

*Then, apply below mentioned explanations according to structure of the design.

2.3. Special Notes

*Please ensure that there is no mechanical stress on the shaft following installation.

Such case will cause slipping in thecharacteristic curve.

*Level switch should be mounted vertical on tank's plate

*Allocate valve certainly in the process connection while instrument is used.

*Allocate blowdown valve under bottom flange for blowdown.

*If instrument is mounted outside and if there is any danger of lightning or

excessive pressure, take preventive measures by taking necessary measures.

2.4. Installation For Mechanical Connections

*Use appropriate O-Ring or gasket for tightness.

*Ensure that its surface is clean and smooth.

*Assemble the instrument manually.

Detachable

Housing

ELT 103

LL1

R

19

100

HEX

ELT 104

L1L

19

100

R

HEX

ELT 101

ELT 201

ELT 102

ELT 202

ELT 103

ELT 104

ELT 204

Connection

R (mm) L

(mm) L1

(mm)

1 BSP

1 BSP

1 BSP

1 BSP

1 BSP

1 BSP

1 BSP

220

220

125

125

125

Max.

1500

134

217

134

217

115

134

217

HEX

(mm)

40

40

38

38

38

38

38

Dimensions:

6

Order Form: Please consider sample models when coding!..

2.5.

Order Form :

EXAMPLE

ELT 101 - 200 - 0006 - 002 - 43 - 1 - 5240 / 0

1MODEL

Std. Type....................,................................................1

ELT

4STEM LENGHT (mm) L

6WETTED PART MATERIAL

9HOUSING

8WORKING TEMPERATURE

5CONNECTION

10 OPTIONAL

Std. ..................................................................100

Std. ........................................................................200

316 Stainless Steel.................................................002

(-) 20 °C...(+) 150 °C...................................................1

Aluminium Housing , B20x IP 66..........................

5240

None........................................................................./ 0

Protection Case - for Outside Tank. 304 St. St. ..../ K2

Detachable Housing................................................./ S

Special...................................................................../ x

Special........................................................................x

Special........................................................................x

1 BSP (Std.)........................................................0006

3CONNECTION TYPE

Thread Type................................................................1 Thread Fork Type.......................................................2

Mini Fork Type............................................................3

Long Fork Type...........................................................4

Special........................................................................x

DN 50 - PN 16 (Std.).............................................0505

DN 80 - PN 16.......................................................0507

DN 100 - PN 16.....................................................0508

Special........................................................................x

(-) 20 °C...(+) 200 °C...................................................2

Special........................................................................x

Vibrating Type Level Switch, Model ELT101 , L=250 mm , 1 BSP Male Thread , 1 Contact

7OUTPUT

1 x 5A NO / NC Relay (For ELT103) ....................... 11

2 x 8A NO / NC Relay (For ELT102, 202) .............. 12

1 x 3A NO / NC Relay (For ELT101, 201) ............... 43

Special........................................................................x

High Temperature Type..............................................2

Std. .......................................................................1000

Special........................................................................x

2CERTIFICATE

None.................................................................................0 (EN10204-3-1) Material Certification............................1

7

2.6.

Please do not dip cables

potting into liquids,otherwise

instulation problem may cause.

Do not fasten switch reversely ,

otherwise its characteristics

might be changed.

Please do not drop ,

otherwise the characteristics

might be changed.

Vibration might be

caused instability. In case vapour splash cable

potting points,insulation

problem may cause.

Excess current , to be drawn as

a result of direct connection to motor,

may burn relay of switch

Please avoid using with liquids which

damage materials of parts ,otherwise

quality can not be maintained accurately.

Do not remove the plastic parts

of the bottom of the switch body ,

do not loosen.

Do not remove the float from

connection part. Because its pin

might be damaged.

WARNING !!!

Please pay attention to following matters in order to operate your flow switch properly.

Do not pull the cable strongly,

otherwise the characteristics

might be changed.

8

3. Failure Delection

If you find an error, try to eliminate it by using this table or send the instrument to our service address for repair.

The instrument should be repaired only by authorized service!

4. Disassembly of Instrument

Instrument should be disassembled while feeding and pressure is not available!

5. Service

6. Recalibration

Calibration is not required during long period useful life of a level switch.

7. Repair Manufacturer Address

If irreparable breakdowns occur, the instrument should be sent to us for repair purpose. Before this, the instrument should be

cleaned carefully and packaged so as not to be broken. Furthermore, you should also add a detailed explanation which

describes the breakdown while instrument is sent. If your instrument contacts with harmful substances, decontamination

report should be also sent additionally. In the event that instrument does not have any decontamination report or our service

department has doubts about instrument, repair process will not start until an acceptable report is sent.

If the instrument contacts with hazardous substances, necessary measures should be taken for decontamination!

Service -Manufacturer Company Name and Address:

LONCA MAK. SAN. TÝC. A.Þ.Ferhatpaþa Mahallesi Gazipaþa Caddesi No:104 A 34888 Ataþehir / ÝSTANBUL - TÜRKÝYE

8. Disposal

The instrument should be disposed according to 2002/96/EC and 2003/108/EC European Directives (waste electrical and

electronic instruments). Waste electrical and electronic equipment should not be mixed with domestic wastes!

If the instrument has contacted with harmful substances, special attention should be paid for its disposal!

9. Terms of Warranty

The instrument has warranty legally for 24 months after delivery date. Warranty demands are not accepted in case of

inappropriate operation, damage on the instrument or any modification on the instrument.

10. Terms of Return

In the return of materials, user should send an open list related to damage or problem, malfunction of the material

to be returned or its operation in the different modification, with the instrument. If it is required to return the

material, used in the dangerous, corrosive or toxic fluid, in this case, used part should be cleaned very carefully.

Security of personnel should be ensured. All products to be returned should be sent to our company address, which

we have stated.

The instrument does not require maintenance. If it is desired, residue accumulated inside should be blown according to kind

of fluid and instrument can be cleaned with soft cleaning solutions. Measures should be taken during the disassembly.

No relay output

/ Continous relay output

Probable cause Failure detection\correction

Unstable Switch

Breakdown

-Notify the authorized service.

-Check the swich setting.

-It should be prevented from vibration affecting the product

or it must connected to a place where vibration will not occur.

-Notify the authorized service.

-Adjust the connection angle to the proper position.

-Notify the authorized service.

-Check the swich setting.

Fork broken or bent -The size of the particles are larger than

measurable size

Broken or dissolved housing -Physical damage is received from working

environment.

-Housing damaged from chemical effect.

-Outer physical effects must be prevented.

Change of equipment position is advised.

-Housing type can be changed for more protection against

outer effects, please contact with manufacturer with

determined environment conditions.

-The contact may be burnt out.

-Connection angle is not properly connected.

-Applied values higher than the application

current or voltage.

-Swich setting is not correct.

-Product was dropped or hit from outside

-Swich setting is not correct.

-The product is exposed to excessive vibration

Appropriate products should be used

Please contact the manufacturer for another model selection.

This manual suits for next models

7

Table of contents

Other ENSIM SENSORS Switch manuals

ENSIM SENSORS

ENSIM SENSORS DX-ELF 101 User manual

ENSIM SENSORS

ENSIM SENSORS DX-ELS Series User manual

ENSIM SENSORS

ENSIM SENSORS ECAS 101 User manual

ENSIM SENSORS

ENSIM SENSORS DX-ELB 11 User manual

ENSIM SENSORS

ENSIM SENSORS DX-ECAS Series User manual

ENSIM SENSORS

ENSIM SENSORS ELP Series User manual

ENSIM SENSORS

ENSIM SENSORS ELP User manual

ENSIM SENSORS

ENSIM SENSORS ELC 21d User manual

ENSIM SENSORS

ENSIM SENSORS ELS User manual

ENSIM SENSORS

ENSIM SENSORS DX-ELS User manual