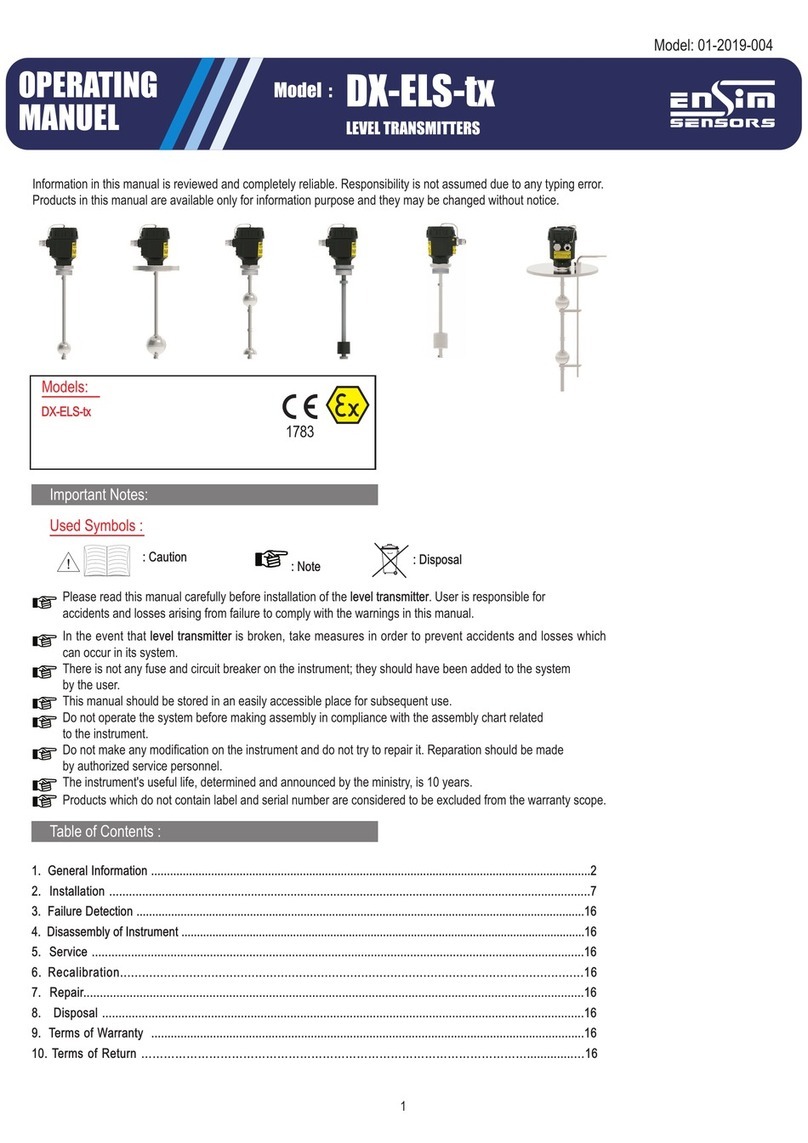

ENSIM SENSORS DX-ELS-tx User manual

OPERATING

MANUEL

LEVEL TRANSMITTERS

DX-ELS-tx

Model :

Model: 01-2023-009

Information in this manual is reviewed and completely reliable. Responsibility is not assumed due to any typing error.

Products in this manual are available only for information purpose and they may be changed without notice.

1

Models:

DX-ELS-tx

Important Notes:

Used Symbols :

Table of Contents :

: Caution : Note : Disposal

Please read this manual carefully before installation of the level transmitter. User is responsible for accidents and losses arising

from failure to comply with the warnings in this manual.

In the event that level transmitter is broken, take measures in order to prevent accidents and losses which can occur in its system.

There is not any fuse and circuit breaker on the instrument; they should have been added to the system by the user.

This manual should be stored in an easily accessible place for subsequent use.

The manufacturer's liability cannot exceed the purchase price of the device according to the law.

Do not make any modification on the instrument and do not try to repair it. Reparation should be made by authorized service staff.

Do not operate the system before making assembly in compliance with the assembly chart related to the instrument.

Products which do not contain label and serial number are considered to be excluded from the warranty scope.

The instrument's useful life, determined and announced by the ministry, is 10 years.

General Information...........................................................................................................................................................................2

Installation .........................................................................................................................................................................................7

Failure Detection..............................................................................................................................................................................18

Disassembly of Instrument ............................................................................................................................................................18

Service .............................................................................................................................................................................................18

Recalibration....................................................................................................................................................................................18

Repair................................................................................................................................................................................................18

Disposal ...........................................................................................................................................................................................18

Terms of Warranty ..........................................................................................................................................................................18

Terms of Return ................................................18

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

2

1. General Information :

1.1. Material Acceptance

Check that there is no damage on the packages during the transportation immediately after the material acceptance. If packages are

damaged, open the packages immediately and check whether products are affected or not, if there is any damage, send your

complaint report to the transporter company and its photocopy to the address of our company.

1.2. Information about Areas of Use

Level Transmitter is designed for industrial plants. It should never be used in mines.

Otherwise, the responsibility of the manufacturer is eliminated.

Tank level measurement and control,boiler kontrol,store room control..

Ambient Conditions: Relative Humidity: 0-98 % RH Ambient temperature: 60 °C (It is not used under -20 °C)

1.3. Working Principle

DX-ELS-tx level transmitter are used for tank levels and for controls. In the float when the magnet magnetic area moves according to the

liquid in the tube, then the reed swicthes the electrical circuit on or off when it reaches the level of the sensor.Reed swicthes in and out.

The changes of the reed sensors with alarm or a level information can be assessable with a relay circuit or a control device.Sensitivity increases

according to reed sensor lowering range.The advantages of providing the analog output in the enclosure are preferred by the users.

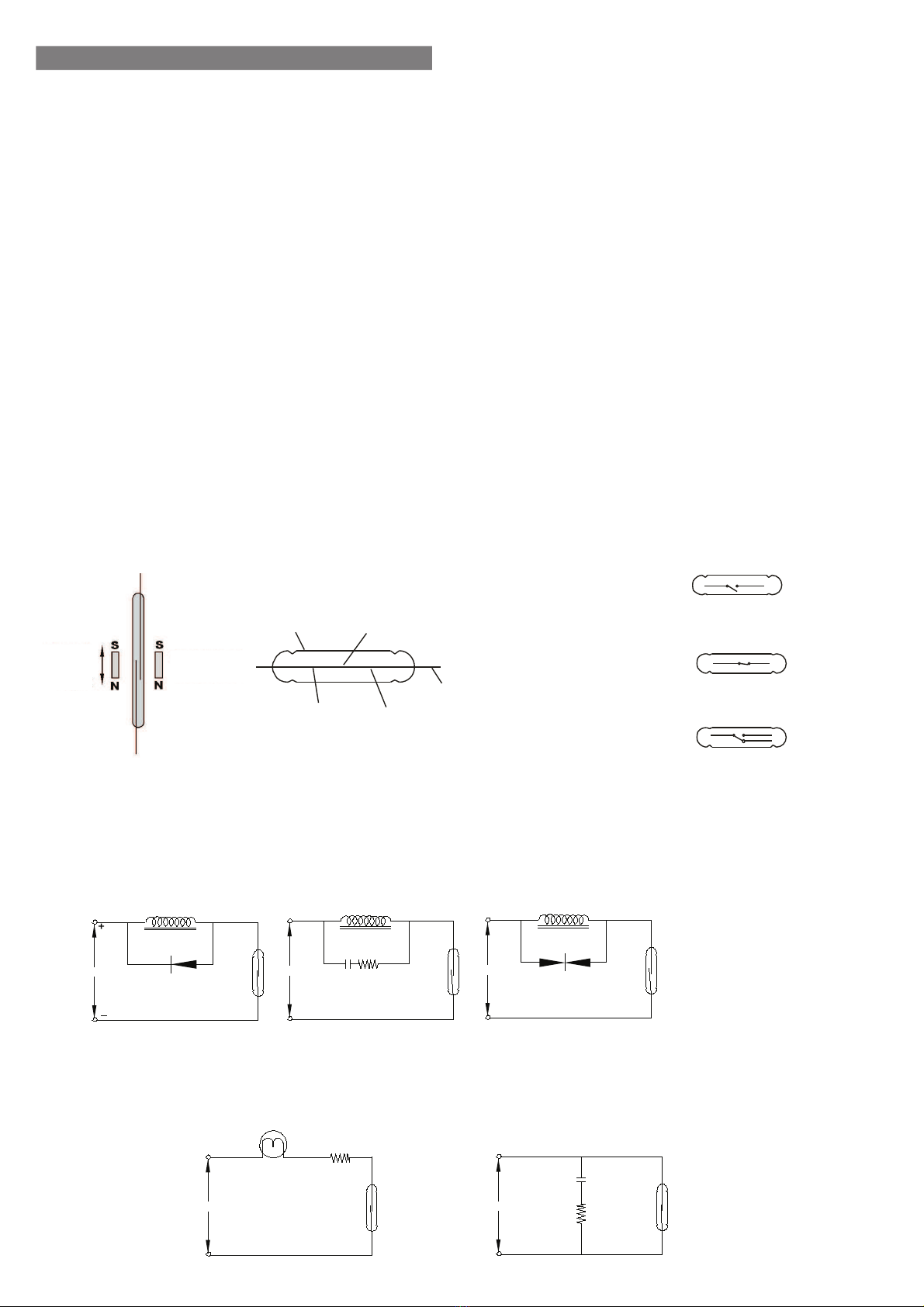

1.4. Reed Relay and Operation Conditions

Advantages:

*A variety of materials according to the flow

*Different choices of ignition

*Quick delivery

*Different types of technics

Glass Tube Contact

Inert Gas Magnetic Reed

Wire

Magnet

Closed

Open

SPST-NO

Single Pole-Single Throw

Normally Open

SPST-NC

Single Pole-Single Throw

Normally Closed

SPDT-NO/NC

Single Pole-Double Throw

Open / Closed Contact

Inductive Load

Capacitive Load

When reed switch is used for loads such as electromagnetic relay ,contactor or solenoid, reed switch may be exposed to very high

voltage depending on value of inductive load. This causes either failure of switch or shortening its service life. Therefore, it is

recommended to be used as follows depending on used voltage, for the purpose of protection of switch.

When reed switch is used with capacitive load, it may cause that high current passes over reed switch, depending on value of

capacity during Charge '96 Discharge of capacity. So this may cause failure of switch. It is recommended to be used as follows

depending on used voltage, for the purpose of protection of switch.

Inductive Load Inductive Load Inductive Load

Diod

DC AC AC

C R Varistor

Neon Lamp

AC

R

AC

C

R

3

1.5. Technical Specifications

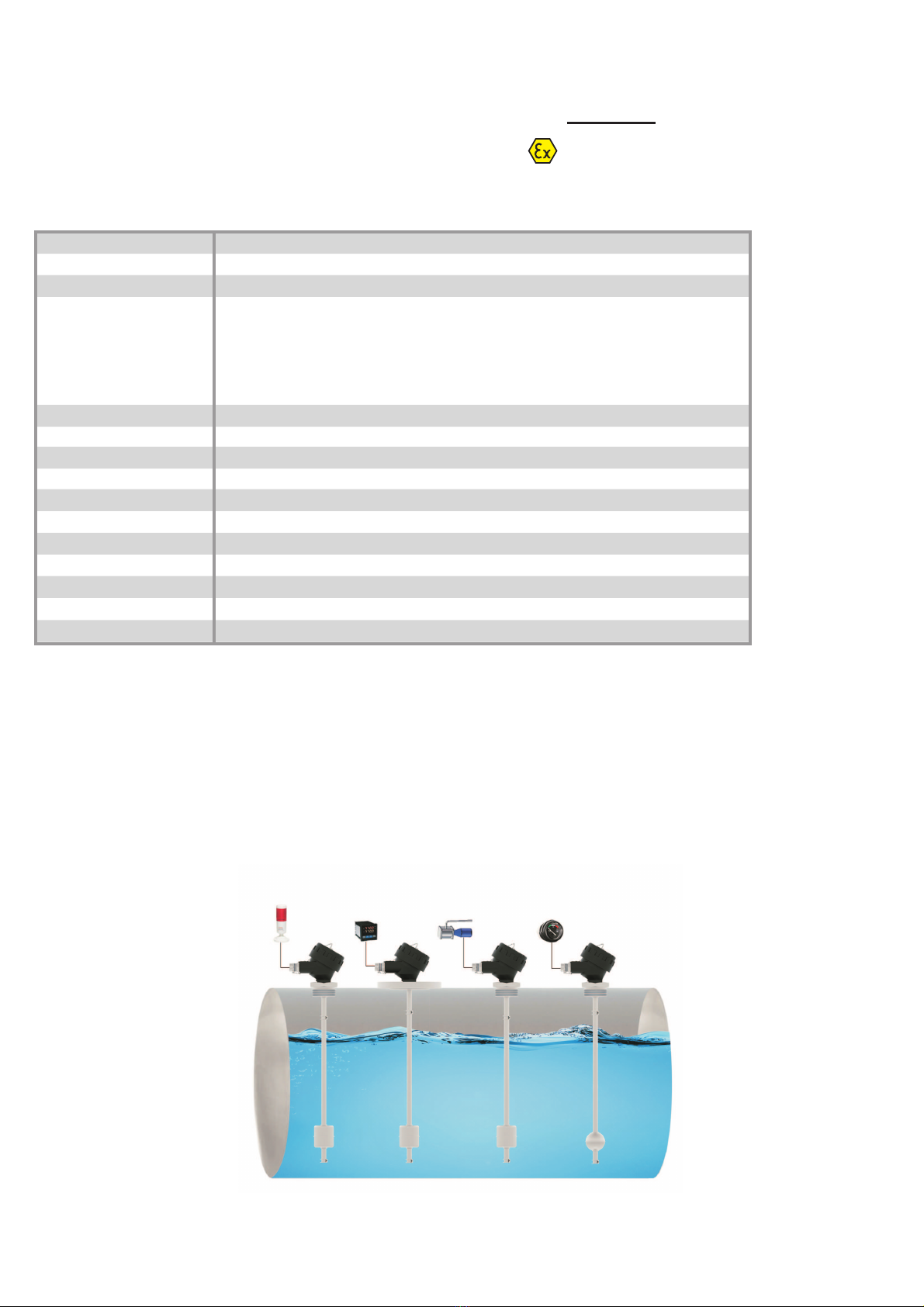

Example of application :

Certification

*

DigitalDisplay PLC Analogue IndicatorLight

DX-ELS-tx

Max. 125 °C

0-98 % Rh (Non-condensing)

(-) 20 °C ... (+) 60 °C

304 St.st. (Std.) Opt. 316 St.st. , Aluminum

Aluminium Injection Molding- AlSi12Fe (Std)

Black (RAL 9005)

316 St.st. (Std.) Opt. PU , PP

304 St.st. (Std.) Opt. 316 St.St. , Brass

2" BSP (Std.) Opt.Selectable from Table.

S40A (Std.) , Selectable from Table.

1 ( Std.) A large number of available.

Max. 2500 mm (Thread Included)

Terminals

M20 x 1,5 (Std)

4-20 mA Std. Two Wire Opt. 4-20mA , 0-20mA , 0-10V Three Wire, Ohm

Std. 15 mm / 10 mm / 5 mm / 1 mm

12...32 VDC

IP 66 / 68 (EN60529)

CE Declaration , EMC , LVD , ATEX

Working Temperature

(Tp)

Ambient Humidity

Ambient Temperature (Ta)

Material Connection

Housing

Float

Pipe

Connection

Float Type

Number of Float

Stem Length

Electrical Connection

Cable and Plug Entry

Output

Fequency of Detection

Supply Voltage

Protection Class

Certifications and Approvals

ll 1/2G Ex db ia llC T6...T2 Ga/Gb For Gas

ll 1/2D Ex tb ia lllC T85°C...T300°C Da/Db For Dust

Have a look at the temperature class chart.

4

1.6. Label Information :

1.7. Package and package contents :

Please check whether you have taken delivery

of below listed content completely or not and check

its conformity with criterions in your order:

*Float Level Transmitters

*This operating manual

Box

Label

Type

Level

Transmitteri

S.N.

Quantity

DX-ELS-tx 025-00-009-02-12-02-500-113-19-10/0

IE18030050-0008

:

:

1 pc.:

Serial Number

Model

Piece Barcode

Kullaným Kýlavuzu Montajdan Önce Okunmalýdýr.

Supply 24VDC ±%10:

IE18030050-0008

Supply Voltage

Explosive ProtectionAreaProduct Name

Std. Package

Product

Label

LEVEL SWITCH

MADE IN TURKIYE

www.ensim.com.tr

Serial Number

Notified

Date Sign

Explosive ProtectionArea

Product Name

Producer Website

Warning Symbols

Working Conditions

Manufacturer Brand

Type : DX-ELS-tx 025-00-009-02-12-02-500-113-19-10/0

Power Supply

Output

Process Temp. / Press.

T (Ambient)

Serial Number

24VDC +/- %10

4-20mA Two Wire

: Max. 125°C / Max. 30 bar

-20...+60°C

IE18030050-0008

DO NOT OPEN WHEN ENERGIZED

KEEP TIGHT WHEN CIRCUIT ALIVE

Product

Label

Ground

Label

Cable Plug

(Suitable Cable Diameter : Ø 6-12 mm)

Aluminium Housing

Grounding Terminal

(Max.1,5 mm²)

Recommended Cable

(5x1,5 mm²)

Bund

Stops

Metal

Label

IE 18 03 0095 - 0014

If the ATEX certificate metal label is damaged, you can contact

the manufacturer with the serial number.

Note :

Metal

Label

LONCA A.Þ. Ferhatpaþa Mah.Gazipaþa Cad. No:104A

34888 Ataþehir - ÝSTANBUL / TÜRKÝYE

IEP23ATEX1210X

ll 1/2G Ex db ia llC T6...T2 Ga/Gb

ll 1/2D Ex tb ia lllC T85°C...T300°C Da/Db

Type B22x

www.ensim.com.tr

16A 240 VAC 50 / 60 Hz IE18030095-0014

S.No:

Manufacturer Name ManufacturerAddress

Model Housing

Serial

Number

Housing Features

Explosive Protection

Area ATEX Classes

Product

Number

System

Number

Month

Year

Work

Order

1.10. Safety Ýnstructions (ATEX)

Safety instructions should be read and applied to the end.

-The following notes must be taken into attention to protect the operator and the enviroment from possible hazards.

-The device setup and maintenance of this device must be done by knowledgeable persons who has read the instructions and is familiar with

the safety at work.

-Ýt should be checked by the users that the products are fitted suitable to the zone maps.

-Work safety,must be observe by accident prevention regulations and national installation standards.

-The product should be used within the specification presented guideline.

-You can only mount the device when there is no presure.

-These safety instructions are protected in terms of 1 / 2 D and 1 / 1 G category for DX-ELS-tx coded series and is compatible with

IEP23ATEX1210X and CE certificate.

-The Label should be used in appropriate environments.

-Because the enviroment is max. 60 °C you should choose a suitable cable for use.

-Do not over tighten the cable gland in order not to affect the IP protection class.

-Make sure the cable entry and plug is tightened right.

-Ground connection must be done properly and checked without energizing.

-Before starting use make sure the lid is fully closed and the set screw is tightened.

-DX-ELS-tx models are metal protected.Ýt is Compatible with different supply voltages specified in the catalog.

- The metal enclosure must be in the 2D or 2G zone. The pipe and float section must be located in the 1D and 1G zone.

-Max. working temperature,max. Surface temperature can change depending on the model, Please read the document carefully before using.

-During the mounting it should be checked that there is no mechanical stress or deformation in the tank wall.When this happens, the sensor should

not be energized without the necessary correction measures.

-Check that the presure in the tank hasnt exceed the presure shown in the catalog.

-The mounting sensor must be mount properly in the tank filling system.In case it is not suitable, the sensor must be protected and the in-tank

apparatus must be protected.

- Flange surface smoothness must be maintained in flanged connection.

- Flange seating surface should not be scratched, and suitable liquid gasket should be used instead of sealing with gasket in counter flange mounting.

- Flanged connections are welded with the sensor part.

-The sensor is designed to withstand the chemical effects of the materials.Check the suitability of different materials.

-The Sensors are in suitable storage conditions and protected from dust and damp.

-Device repairs should only be done at the manufacturer Lonca Inc.

-Protect the device from friction and cleaning should be done without water.

-In case of improper circuit conditions, the main energy must be completely disconnected and safety measures should be taken without replacing

the temperature circuit breaker with its backup.Changes should be made in a safe area.

5

1.8. Target Group

This operating manual has been prepared for qualified technical personnel.

1.9. Certifications and Approvals

:It shows that, product meets required conditions of EU with CE stamp

and stipulate that product passed quality assessment stages

All the features and tests on this decument has manufactured with DX-ELS-tx models at LONCA Inc.

Note:

TS EN 61326 - 1 : 2021EMC (2014 / 108 / AT) :

TS EN IEC 60079 - 0 : 2018

TS EN 60079 - 1 : 2014

TS EN 60079 - 11 : 2012

TS EN 60079 - 31 : 2014

ATEX (2014 / 34 / AB) :

LVD (2014 / 35 / AB) : TS EN 60204 -1 : 2018

TS 3033 EN 60529 : 2014

Other manuals for DX-ELS-tx

1

Other ENSIM SENSORS Transmitter manuals

Popular Transmitter manuals by other brands

Geo

Geo Web Pack quick start guide

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual