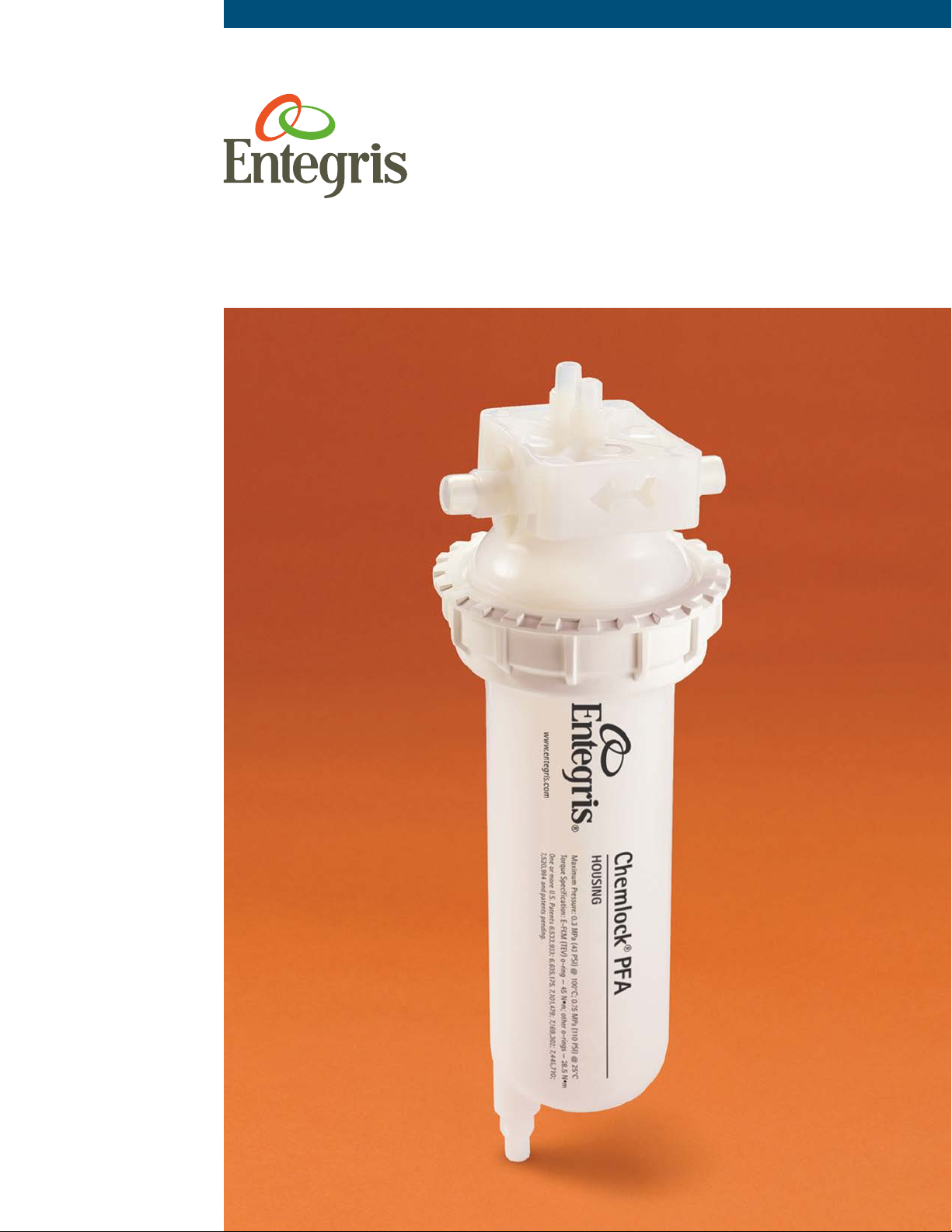

entegris Chemlock PFA Guide

CONTAMINATION CONTROL SOLUTIONS

CHEMLOCK® PFA AND PP

FILTER HOUSINGS

Installation and use manual

ENTEGRIS, INC. CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL 1

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

Introduction ....................................... 2

Safety ............................................... 2

Specifications ..................................... 2

PFA ..................................................... 2

PP ...................................................... 2

Dimensions ........................................ 3

Minimum Space Requirements ................... 3

Installation ........................................ 4

Facility Requirements .............................. 4

Mounting ............................................. 4

PFA .................................................. 4

PP .................................................... 5

O-ring Installation and Removal ................. 6

Filter Installation ................................... 7

Housing Integrity Testing ......................... 8

Cartridge Removal .................................. 9

Ordering Information ........................... 10

Accessories ....................................... 10

Product Warranties ............................. 11

Terms and Conditions ........................... 11

For More Information .......................... 11

Table of Contents

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

2 CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL ENTEGRIS, INC.

Introduction

Entegris’ Chemlock®PFA and PP housings offer a

space-saving solution like no other cartridge filter

housing available today. These revolutionary hous-

ings lock the cartridge into the bowl, allowing the

bowl and cartridge to be removed as a single unit.

Safety

Special considerations and precautions are

included in the manual, as described below.

Contact Entegris with any questions regarding

the safe and proper use of your equipment.

DANGER! Indicates a hazardous situation

that, if not avoided, could result in death

or serious injury.

WARNING: Indicates a potential hazardous

situation that, if not avoided, could result in

death or serious injury as well as irreparable

damage to the equipment.

CAUTION: Indicates a potential hazardous

situation that, if not avoided, could result in

minor to moderate injury as well as minor to

moderate damage to the equipment.

WARNING: Only technically qualified personnel

should install the housing.

WARNING:CHEMICAL HAZARDS

DOUBLE-CONTAINMENT is required

when used with toxic and hazardous

chemicals. All filter housings, filters

and other pressurized vessels must be double-

contained to prevent serious personal injury.

SAFETY CLOTHING, eye protection and safety

apparatus appropriate for the liquids in use

must be worn during component changeout

and startup. Perform all operations with stan-

dard liquid handling procedures in accordance

with all local codes for safety and ventilation.

!

!

!

!

!

Specifications

PFA Housing

Materials: Head, molded-on fittings, bowl, plugs PFA 440 HP or equivalent

O-ring E-FKM

Locking ring (nonwetted part) PVDF or GFPP (glass-filled polypropylene)

Mounting hardware – nuts and bolts

(nonwetted parts)

PVDF

Fluid connections: See data sheet

Cartridge connections: Code 0 (dual 2-222 o-rings)

Operating conditions: Maximum inlet pressure 0.3 MPa (3.0 bar, 43 psi) @ 100°C (212°F)

0.75 MPa (7.5 bar, 110 psi) @ 25°C (77°F)

Maximum operating temperature 100°C (212°F)

PP Housing

Materials: Head and bowl Polypropylene (PP)

O-ring 2-345 EPR

Locking ring PVDF (nonwetted part)

Fluid connections: FNPT, Flaretek®, union, Rc, or see data sheet

Cartridge connections: Code 0, 2-222 o-ring and Chemlock cartridges with key

Operating conditions: Maximum inlet pressure 0.14 MPa (1.4 bar, 20 psi) @ 90°C

0.69 MPa (6.9 bar, 100 psi) @ 25°C

Maximum operating temperature 90°C (194°F)

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

ENTEGRIS, INC. CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL 3

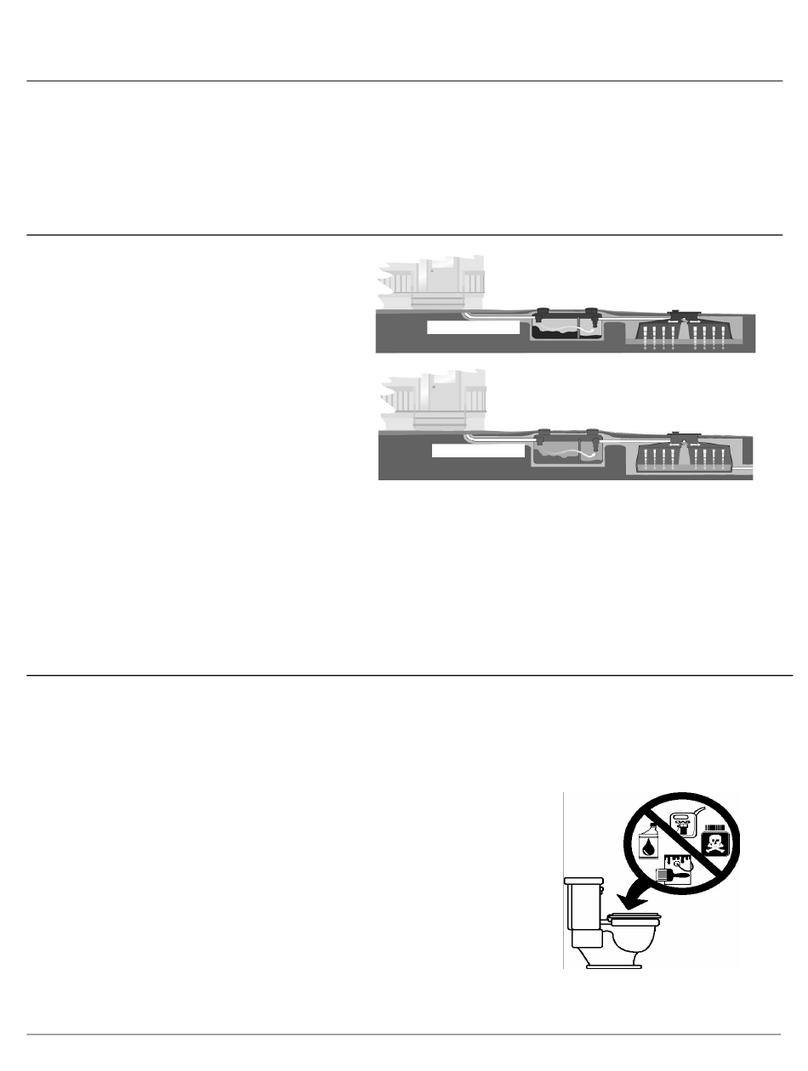

Downstream/

outlet/vent

Upstream/

inlet/vent

A

B

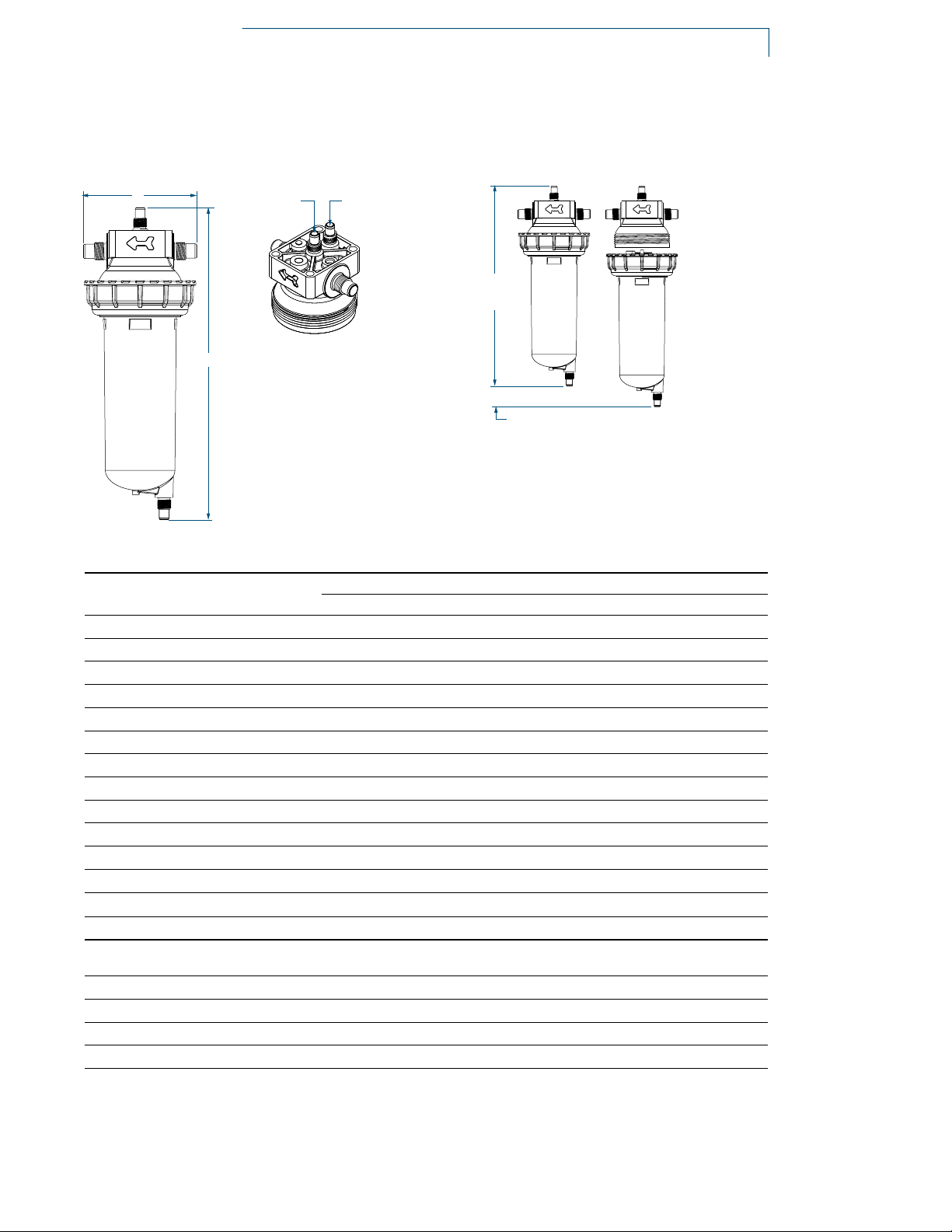

Dimensions

PFA Housing

Inlet/Outlet Vent/Drain

Dimensions

BA (11” Housing) A (20” Housing)

3⁄4”Flaretek 1⁄4”Flaretek 156 mm (6.2”) 450 mm (17.7”) 696 mm (27.4”)

3⁄4”Flaretek 1⁄2”Flaretek 156 mm (6.2”) 434 mm (17.1”) 681 mm (26.8”)

1” Flaretek 1⁄2”Flaretek 168 mm (6.6”) 434 mm (17.1”) 681 mm (26.8”)

3⁄4”pipe 1⁄4”pipe 201 mm (7.9”) 416 mm (16.4”) 663 mm (26.1”)

3⁄4”pipe —201 mm (7.9”) 398 mm (15.7”) 644 mm (25.4”)

3⁄4”NPT 1⁄4”NPT 134 mm (5.3”) 378 mm (15.0”) 622 mm (24.5”)

3⁄4”Super* 1⁄2”Super* 178 mm (7.0”) 431 mm (17.0”) 683 mm (26.9”)

1” Super* 1⁄2”Super* 156 mm (6.1”) 431 mm (17.0”) 683 mm (26.9”)

3⁄4”S300** 1⁄2”S300** 170 mm (6.7”) 431 mm (17.0”) 678 mm (26.7”)

1” S300** 1⁄2”S300** 152 mm (6.0”) 431 mm (17.0”) 678 mm (26.7”)

1” S300** 1⁄4”S300** 170 mm (6.7”) 438 mm (17.2”) 686 mm (27.0”)

3⁄4”S300** 1⁄4”S300** 152 mm (6.0”) 438 mm (17.2”) 686 mm (27.0”)

1” PrimeLock®1⁄4”PrimeLock 222 mm (8.7") 444 mm (17.5") 694 mm (27.3")

3⁄4”PrimeLock 1⁄4”PrimeLock 212 mm (8.4") 444 mm (17.5") 694 mm (27.3")

PP Housing

3⁄4”FNPT 1/4” NPT 137 mm (5.4”) 396 mm (15.6”) 646 mm (25.4”)

3⁄4”flare 1/2” Flare 163 mm (6.4”) 450 mm (17.7”) 700 mm (27.5”)

3⁄4”Rc 1/4” Rc 137 mm (5.4”) 396 mm (15.6”) 646 mm (25.4”)

1” union 1/4” NPT 203 mm (8.0”) 396 mm (15.6”) 646 mm (25.4”)

* Super Type Pillar® fitting

** Super 300 Type Pillar fitting

See Chemlock

drawing

dimension “A”

50.8 mm (2”)

Minimum Space Requirements

A minimum installation clearance

of dimension “A” plus an additional

50.8 mm (2.0”) is required for removal

and installation of Chemlock cartridges.

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

4 CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL ENTEGRIS, INC.

Installation

Facility Requirements

Housing should be plumbed with ability to isolate

both upstream and downstream flows as required

for filter changeout.

Mounting

PFA Housing

Components are double-wrapped for cleanroom

use. Handle components according to your

cleanroom procedures.

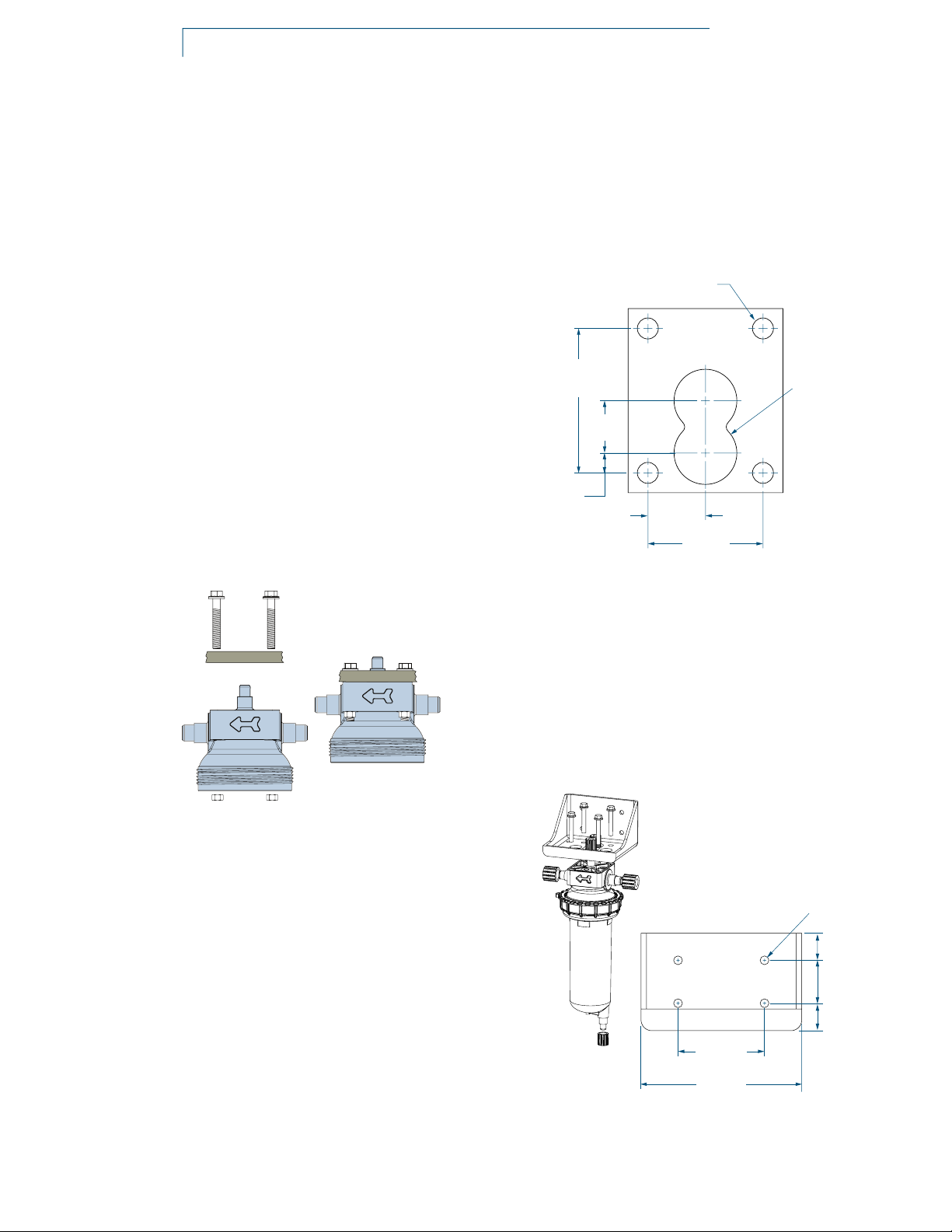

Suggested Mounting Method #1:

Customer-supplied Mounting Plate

1. Use screws and nuts (part no. YY5600010) to

secure the housing head to your equipment

or facility mounting bracket (Figure 1).

2. The Chemlock PFA housing can be installed

either bowl UP or bowl DOWN.

Figure 1.

MOUNTING BRACKET TEMPLATE

Use Figure 2 as a guide for drilling holes into

a customer-supplied mounting plate, when

mounting the Chemlock PFA head.

Figure 2. Chemlock PFA mounting template

Suggested Mounting Method #2:

L-bracket Mounting

1. Use screws and nuts (part no. YY5600010)

to secure the housing head to the L-bracket

(part no. YY4610190,) available from Entegris

(Figure 3). The Chemlock PFA housing can

be installed either bowl UP or bowl DOWN.

Figure 3.

Shown assembled with customer-

supplied mounting plate. If the

mounting bracket is >12.7 mm (0.5”)

thick, longer screws must be used.

Mounting plate

(NOT supplied)

<12.7 mm [0.5”]

thick for use with

supplied screws

34.93 mm

(1.38”)

4 × clearance holes

for 3⁄8” screws

Ø12.70 mm (0.50”)

87.63 mm

(3.45”)

2 places

31.75 mm

(1.25”)

69.85 mm

(2.75”)

2 places

Ø 38.10 mm

(1.50”)

thru 2 places

12.07 mm

(0.48”)

Mounting template detail for reference only.

Not shown to scale

PFA Mounting Template

Mounting template detail for reference only.

Not shown to scale

L-bracket

Mounting Template 4 × Ø10.36 mm

(0.41")

31.75 mm

(1.25”)

31.75 mm

(1.25”)

50.80 mm

(2.00”)

188.72 mm

(7.43")

101.60 mm

(4.00")

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

ENTEGRIS, INC. CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL 5

PP Housing

Components are double-wrapped for cleanroom use.

Handle components according to your cleanroom

procedures.

Suggested Mounting Method #1:

Customer-supplied Mounting Plate

1. The Chemlock PP housing head has four M12 × 1.75

threaded holes for mounting (Figure 4). Determine

the length and type of bolts to secure the housing

head to your equipment or facility mounting bracket.

Bolts are not provided.

2. The Chemlock housing can be installed either bowl

UP or bowl DOWN.

Figure 4.

MOUNTING BRACKET TEMPLATE

Use Figure 5 as a guide for drilling necessary

holes into a customer-supplied mounting plate,

when mounting the Chemlock PP head.

Figure 5. Chemlock PP mounting template

Suggested Mounting Method #2:

L-bracket Mounting

1. Use screws and nuts to secure the housing head

to the L-bracket (part no. YY66BRACK) (Figure 6).

The Chemlock PP housing can be installed either

bowl UP or bowl DOWN.

Figure 6.

Shown assembled with customer-

supplied mounting plate and bolts

Mounting

plate

Threaded depth:

17.8 mm (0.7”)

36.2 mm

(1.43”)

4 × clearance holes

for M12 hardware

Ø15.06 mm (0.59”)

90.7 mm

(3.57”)

31.75 mm

(1.25”)

72.39 mm

(2.85”)

2 places

Ø 38.10 mm

(1.50”)

6.35 mm

(0.25”)

13.2 mm

(0.52”)

Mounting template detail for reference only.

Not shown to scale

PP Mounting Template

Mounting template detail for reference only.

Not shown to scale

L-bracket

Mounting Template 4 × Ø10.36 mm

(0.41")

31.75 mm

(1.25”)

31.75 mm

(1.25”)

50.80 mm

(2.00”)

188.72 mm

(7.43")

101.60 mm

(4.00")

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

6 CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL ENTEGRIS, INC.

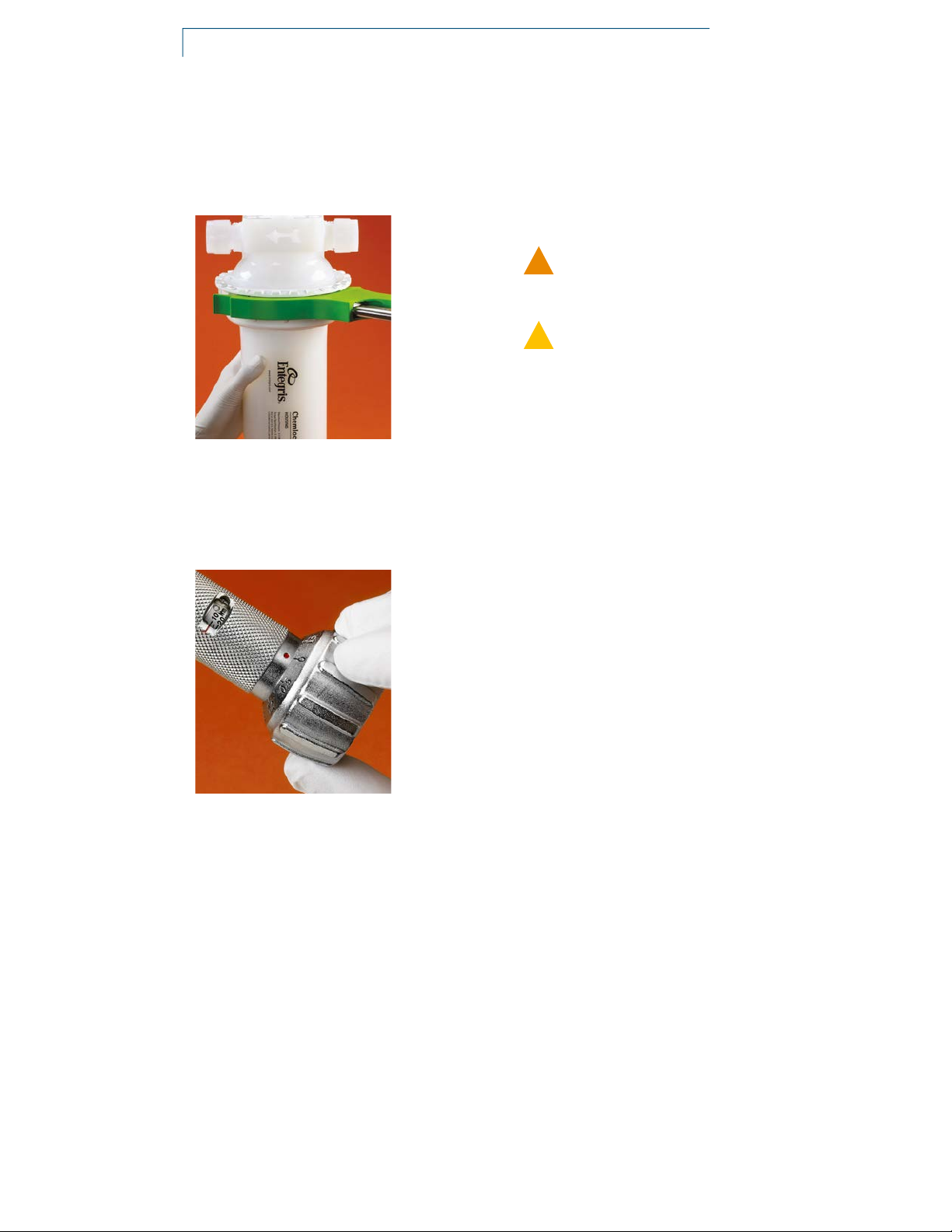

O-ring Installation and Removal

CAUTION: Replace the o-ring every time the

housing is opened.

1. Verify that the o-ring is installed in the housing.

If not, properly seat an o-ring into the housing

bowl, as described below.

2. Prewet the housing o-ring with a fluid compatible

with your process chemical (such as DI water,

IPA, etc.) to aid in installation and ensure a

proper seal.

3. For best results when using E-FKM o-rings,

heat the o-ring to 60°C prior to installation.

Heat the o-ring by immersing in hot water for

2 minutes, or by placing the o-ring 25 mm (1”)

below a 250-watt heat lamp for 1 minute.

Install the o-ring while it is still warm.

4. For all housings, handle the o-ring with care.

Insert the o-ring into the groove and push the

o-ring securely and evenly in place. DO NOT

roll or twist the o-ring.

5. To remove the old o-ring, slide the hook end of

the housing wrench tool under the o-ring, then

slide the tool around the bowl.

CAUTION: Use caution when removing the

o-ring. Contacting the o-ring seal areas

with the removal tool can damage the

sealing surface.

To view a video showing correct procedures for

o-ring replacement and housing installation,

go to www.entegris.com in the Chemlock

Housing section.

!

!

Removal of o-ring from Chemlock housing

using the hook on the housing wrench.

Installation of the o-ring onto the Chemlock housing using

clean gloves to minimize possibility of contamination.

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

ENTEGRIS, INC. CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL 7

Install the Filter

Install a filter in the housing bowl and tighten

the bowl to the housing head:

1. Cut open the bottom of the bag only.

2. To ensure cleanliness, hold the cartridge by

the bag, and insert it into the housing bowl.

3. Using the end of the bag, the two finger tabs on

the key can be used to turn the cartridge 1/4turn;

then lock the cartridge in place.

NOTE: Lock the cartridge in place by turning

it clockwise.

4. Attach and tighten the bowl to the housing head.

The housing can be mounted in either a bowl Up

or bowl Down position.

5. Adjust the torque setting to 45 N•m if using an

E-FKM o-ring. For other o-ring types, 28.5 N•m.

Once set, twist the lever at the end of the wrench

clockwise to LOCK the setting in place.

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

8 CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL ENTEGRIS, INC.

6. Tighten the housing ring until the torque

wrench clicks. Stop and retighten until

another click is heard.

7. Wait 5 minutes before continuing. After waiting

5 minutes, retighten the locking ring according to

the previous step (#6.) You may see the locking

ring move again. This is normal.

8. Reset the torque setting to 10 N•m for storage.

Housing Integrity Testing

Prior to usage, the piping system should be

tested to check for leaks. Follow your facility

leak checking protocols.

WARNING: IF SYSTEM IS SHUT DOWN,

IT IS NECESSARY TO RETIGHTEN THE

HOUSING (see previous steps) IN ORDER

TO PREVENT LEAKS.

CAUTION: DO NOT tighten or adjust the

plumbing at elevated temperatures (>100°C)

as you may overtighten the fittings and

create excessive stress and leakage either

at elevated temperatures or during changes

in system temperature.

NOTE: Yearly calibration of the wrench is

recommended.

Include periodic seal integrity testing in your

system’s preventative maintenance schedule.

!

!

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

ENTEGRIS, INC. CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL 9

Cartridge Removal

WARNING: Wear chemically-resistant garments

and eye protection during cartridge changeout

and startup.

1. Isolate and drain the housing. If necessary, allow

the housing to cool to a workable temperature.

2. Use the housing wrench to loosen the housing ring.

3. Remove the bowl from the head.

4. Turn the cartridge key to unlock the cartridge

from the bowl.

5. Lift the cartridge out of the bowl or tip the bowl to

gently slide the cartridge out of the bowl.

To view a video showing correct procedures for

o-ring replacement and housing installation, go to

www.entegris.com in the Chemlock Housing section.

!

ChemloCk PFA And PP Filter housings instAllAtion And use mAnuAl

10 CHEMLOCK PFA AND PP FILTER HOUSINGS MANUAL ENTEGRIS, INC.

Accessories

Part Number Description

YY4600005 Chemlock integrated housing wrench

YY4600006 Chemlock housing wrench head

YY5600010 Mounting hardware kit:

(4) PVDF 3⁄8” — 16 × 2.5" (63.5 mm)

hex head cap screw

(4) PVDF nuts 3⁄8” — 16

Y Y461019 0 PVDF L-mounting bracket (use for both

Chemlock and Chemgard PFA housings)

YY66BRACK PP L-mounting bracket (use for both

Chemlock PP and Chemgard PFA housings)

Ordering Information

Chemlock cartridges are compatible with the

Chemlock PFA and Chemlock PP housings.

Cartridges can be ordered by adding either a

“K” or a “Y” to the end of a standard cartridge

catalog number, depending on the product family.

Standard cartridges (without the key) are still

available under their usual catalog number.

Any standard 10" Code 0 cartridge can be used

with the universal Chemlock housing. Only

Entegris’ Chemlock cartridges can utilize the

cartridge locking mechanism. Use of a Chemlock

key or any other key with a third party cartridge

shall void the warranty of the housing and may

infringe one or more of Entegris’ pending or issued

U.S. and foreign patents. Such patents and warranty

do not apply to use of third party cartridge without

any key.

Refer to www.entegris.com for ordering information.

Chemlock bowls are easily retrofitted to

ChemgardTM housings.

PFA Chemlock bowls are designed to fit with

Entegris T-line PFA Chemgard heads. Also,

Chemlock PP bowls are designed to fit with

Entegris T-line PP Chemgard heads. An

installed Chemgard housing may be retrofitted

with a Chemlock bowl and cartridge. However,

the Chemlock PFA and Chemlock PP are not

interchangeable with each other.

Chemgard

housing head

Chemlock

bowl

ENTEGRIS, INC.

Corporate Headquarters | 129 Concord Road | Billerica, MA 01821 USA

Customer Service Tel. +1 952 556 4181 | Customer Service Fax +1 952 556 8022

In North America 800 394 4083 | www.entegris.com

©2001–2013 Entegris, Inc. All rights reserved Printed in USA 4411-7281ENT-0213

Entegris®, the Entegris Rings Design®, Chemlock®, Chemgard™

, Flaretek®, and PrimeLock® are trademarks of Entegris, Inc.

Pillar®is a registered trademark of Nippon Pillar Packing Company, Inc.

For More Information

Please call your Regional Customer Service

Center today to learn what Entegris can do

for you. Visit www.entegris.com and select the

Customer Service link for the center nearest you.

Terms and Conditions of Sale

All purchases are subject to Entegris’ Terms

and Conditions of Sale. To view and print

this information, visit www.entegris.com and

select the Legal Notices link from the footer.

Product Warranties

For Product Warranties, visit www.entegris.com

and select the Legal Notices link from the footer.

Other manuals for Chemlock PFA

1

This manual suits for next models

1

Table of contents

Other entegris Water Filtration System manuals