Environics 6202-1 Manual

Model 6202-1

Reduced Oxygen Breathing

Device 2

Operator’s Guide

Revision 8

September 2nd 2016

Software Rev. 6202-2.00-XX

Environics Inc.

69 Industrial Park Road East

Tolland, CT 06084-2805 USA

Phone (860) 872-1111 Fax (860) 870-9333

E-mail: [email protected] Web: HTTP://WWW.ENVIRONICS.COM

II

COPYRIGHT

© 2016 Environics Inc. All Rights Reserved. This manual and the software contained

within the product(s) described are copyrighted with all rights reserved.

TRADEMARKS

Environics is a registered trademark of Environics Inc. All other brand names,

company names and product names mentioned are the property of their respective

owners.

PATENTS

This product is licensed from the U.S. Navy under U.S. Patent Application No.

10/959.764

WARRANTY

Environics Inc. warrants this product to be free from defects in material and

workmanship for a period of one year from the date of shipment. Environics warrants

the following expendable items for 30 days from the date of shipment: fuses, lamps,

batteries. During the warranty period, Environics will, at our option, either repair or

replace any product that proves to be defective.

To exercise this warranty, contact Environics at the address below for assistance and

instructions for returning the products. Repaired or replaced products are warranted

for the balance of the original warranty period or at least 30 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification made

without Environics’ express written consent, or misuse of any product or part. This

warranty also does not apply to software, damage from battery leakage or problems

arising from normal wear or failure to follow instructions.

This warranty is in lieu of all other warranties, expressed or implied, including any

implied warranty of merchantability or fitness for a particular use. The remedies

provided herein are the buyer’s sole and exclusive remedies.

Neither Environics nor any of its employees shall be liable for any direct, indirect,

special, incidental or consequential damages arising out of the use of its instruments

and software even if Environics has been advised in advance of the possibility of

such damages. Such excluded damages shall include, but are not limited to: costs of

removal and installation, losses sustained as the result of injury to any person or

damage to property.

WARNING

READ THIS MANUAL CAREFULLY BEFORE USING THIS INSTRUMENT.

FAILURE TO DO SO MAY VOID THE WARRANTY,

DAMAGE THE INSTRUMENT OR CAUSE SERIOUS INJURY.

III

ROBD2 Operator’s Guide changes

Manual

Revision

#

Software

Revision

#

Manual

Release

Date

Enhancements

1 0.93-XX 11/1/2004 Initial release

2 0.96-XX 10/26/2005

Added MFC safety feature, changed fitting color codes, reduced

maximum altitude to 34K feet, modified self-tests, added purge to pilot

test menu, added purge after test altitudes (self calibration)

3 0.96-XX 02/09/2006

Fixed erroneous information and typographical errors

Added statement (bottom page 1) Added Breathing loop pressure port

(Bottom page 6), Added safety feature (Top page 31)

4 0.96-XX 04/26/2006 Modified O2 dump screen (page 29).

5 0.96-XX 9/27/2006 Added restrictions to connecting pulse oximeter probe (pages 3, 10 & 12)

Added note about powering on the pulse oximeter in Quick start (page 10)

6 0.97-xx 5/5/2010 Added O2 DUMP PRESSURE setting to OPTION menu

Modified O2 Dump and O2 Pressure safety feature section

Corrected Patent information

7 2.00-XX 7/30/2016 Updated manual to include modifications made for new model 6202-1

8 2.00-XX 9/2/2016 Added information about the vent plug in the vent port

I

V

TABLE OF CONTENTS

LIST OF FIGURES v

LIST OF ABBREVIATIONS / ACRONYMS vi

OVERVIEW 1

SYSTEM LAYOUT 2

Front Panel Layout 2

Rear Panel Layout 4

UNPACKING AND INSTALLATION 7

Standard packaging and unpacking 7

Transport case option and unpacking 7

Installation 7

POWER AND GAS CONNECTIONS 8

Power Connection 8

Gas Connection 9

QUICK START PROCEDURE 10

POWER UP AND SELF-TESTS 11

Power up 11

Warmup 11

Self-test/calibration 11

Self-test Operations 12

Self Calibration Operations 13

SYSTEM OPERATION 15

Entering data 15

Main Screen - Ready mode 16

START – Pilot Test mode 17

Option menu 21

SAFETY FEATURES 26

PULSE OXIMETER 28

SpO2 and Pulse Rate Displays 28

SpO2 and Pulse Rate Alarms 29

V

LIST OF FIGURES

FIGURE 1 - FRONT PANEL LAYOUT .................................................................. 2

FIGURE 2 - REAR PANEL LAYOUT .................................................................... 4

FIGURE 3 - P&ID ................................................................................................ 34

VI

LIST OF ABBREVIATIONS / ACRONYMS

AC Alternating Current

EMI Electromagnetic Interference

HZ Hertz

LCD Liquid Crystal Display

LPM Liters Per Minute

MFC Mass Flow Controller

NAG Nitrogen and Air Generator

P&ID Piping and Instrument Diagram

PSIG Pounds Per Square Inch Gauge

RFI Radio Frequency Interference

SUT Subject Under Test

VAC Volts, Alternating Current

VDC Volts, Direct Current

OVERVIEW

ROBD2 USER’S GUIDE SEPTEMBER 2016

1

OVERVIEW

The second generation Reduced Oxygen Breathing Device (ROBD2) is a

computerized gas-blending instrument. The system uses Thermal Mass Flow

Controllers (MFC) to mix breathing air and nitrogen to produce the sea level

equivalent atmospheric oxygen contents for altitudes up to 40,000 feet. The

MFCs are calibrated on primary flow standards traceable to the National Institute

of Standards and Technology (NIST). NIST is a federal agency whose mission is

to develop and promote measurement, standards, and technology to enhance

productivity, facilitate trade, and improve the quality of life. Several safety

features are built into the ROBD2 to prevent over-pressurization of the Pilot’s

mask and to prevent reduced oxygen contents below those being requested for a

particular altitude. The software is Menu driven. The main operator’s menu

consists of three selections, simplifying the use of the system for the field

operator. Built in self-tests verify all system component functionality before the

operation of the system can begin. If any self-tests fail, the system will not

operate.

This manual contains information and guidance for setting up and operating the

ROBD2.

Step by step instructions are provided for connecting power and gas sources,

running self-tests, running the self-calibration routines and running a pre-

programmed sequence of altitudes on the subject under test (SUT).

Descriptions of alarms and safety features are provided along with actions to be

taken in the event of an alarm condition.

A piping and instrument diagram (P&ID) is provided on the last page of the

manual for an overview of the electrical, pneumatic and electro-pneumatic

components contained within the instrument.

IMPORTANT: The ROBD2 operator should be certified in first-aid and CPR and

have access to communication in the event of an emergency.

Prior to participation in ROBD2 training or research, the subject under test should

have the equivalent to a FAA physical of any class or military flight physical and

be screened for current health status prior to the run.

SYSTEM LAYOUT

ROBD2 USER’S GUIDE SEPTEMBER 2016

2

SYSTEM LAYOUT

Front Panel Layout

Figure 1 - Front panel layout

SYSTEM LAYOUT

ROBD2 USER’S GUIDE SEPTEMBER 2016

3

LCD Display

The liquid crystal display (LCD) is a four line, 20 characters display, protected by a

clear lens. The display is illuminated when the system is in operation.

Function Keys

Three function keys (F1, F2 and F3), located below the display, and are used to

make various selections from the menu displayed on the bottom line of the screen.

The current function of each key is displayed above each function key The function of

each key will change, depending on the current operating mode.

Advance and Stop keys (program)

The ADVANCE and STOP keys are used while running a program in the Pilot Test

Mode (START mode). The STOP key aborts the program immediately upon pressing

the key. The ADVANCE key immediately advances the program to the next step.

Numeric Keypad

The numeric keypad is used for data entry of numbers 0 through 9 and a decimal

point. Pressing the ENTER key completes the entry of the numeric data selected.

Arrow Keys

The arrow keys are used to move the cursor on the display screen to and from

different fields located on the different entry screens or to scroll up or down a menu or

list of information. Pressing and holding the arrow keys will cause them to repeat.

Menu Key

The MENU key has no function while the system is in the Operator’s mode. This key

is used to move between multiple menus while the system is in the Administrator

(ADMIN) mode. The ADMIN mode is restricted to those who program the ROBD2.

Oxygen dump switch

This emergency stop switch causes the supply of 100% 02 to the subject under test.

Breathing mask connector

This female connection port (MS 22058-1), with spring-loaded cover, is for the pilot’s

breathing mask connection.

Pulse oximeter

The new 6202-1 pulse oximeter has a color touch screen. The details of the pulse

oximeter are covered in the pulse oximeter section of this manual

SYSTEM LAYOUT

ROBD2 USER’S GUIDE SEPTEMBER 2016

4

Rear Panel Layout

Figure 2 - Rear panel layout

SYSTEM LAYOUT

ROBD2 USER’S GUIDE SEPTEMBER 2016

5

Power Input

The power entry module supplies AC power to the internal power supplies. The

internal power supplies convert and regulate the AC signal to the five DC voltages

required by the system electronics. The power entry module has integrated EMI/RFI

filtration and switch one or both hot lines dependent upon 110 or 220 VAC operation.

The power entry module also has two replaceable fuses.

Gas Inputs

These gas inputs supply source gas to the system components. The optional quick

connect fittings for these ports are colored and keyed. The Nitrogen input is black,

the Air input is yellow and the oxygen input is green. The Nitrogen and air inputs

should be pressurized to a dynamic pressure of 40 PSIG and the oxygen input

should be adjusted to a dynamic pressure of 20 PSIG.

RS-232 Port

One 9-pin RS-232 serial port is connected to the embedded controller of the ROBD

system. This port is used for remote control of the ROBD2 using a host computer

and communications software. Communication protocol is provided in the

programming and technical guide. This protocol can be used to develop control and

data collection programs using programs such as National Instruments’ LabVIEW.

Cooling fan

The cooling fan moves approximately 36 cu/ft per minute of filtered air through the

ROBD chassis and out the cooling vents on the top cover of the chassis. The cooling

fan should not be obstructed.

Service port

The service port is used for factory calibration of the thermal mass flow

controllers.

Important: The silver plug must not be removed during normal operation.

Pulse oximeter probe connector

Plug the pulse oximeter probe into this port. Once connected the probe is

latched. The probe is removed, by pressing the side tabs on the probe connector

and pulling it out.

SYSTEM LAYOUT

ROBD2 USER’S GUIDE SEPTEMBER 2016

6

Vent port

This port vents the excess flow of gas not used during inhalation and exhalation and

also limits the pilot mask pressure.

Important: A filtered vent plug has been installed into the vent port. This vent

plug will provide a slight positive pressure to the breathing mask. If the absence

of positive pressure is desired, remove the threaded plug. When the instrument is

not being used, reinstall the plug. This vent plug should only be hand tightened.

Do not install any other type of fitting into this port, as the breathing loop may

become over-pressurize and cause damage to the instrument.

Note: Removing the vent plug does not diminish the amount of gas, that the

subject under test receives, when inhaling.

UNPACKING AND INSTALLATION

ROBD2 USER’S GUIDE SEPTEMBER 2016

7

UNPACKING AND INSTALLATION

Standard packaging and unpacking

1. Remove the system from the cardboard box in which it was delivered from the

factory.

2. Remove and read any important instructions or notes found within the box.

3. Save and store the box and foam inserts in the event the system needs to be

returned to the factory or delivered to another site for operation.

4. If the optional pressure regulators were purchased with the system, they are

delivered in a separate box.

Transport case option and unpacking

1. The transport case is provided with the ability to be locked. If a lock has been

added, remove the lock and undo the rotary latches.

2. Remove the cover and pull the system out by the side handles.

3. If the optional pressure regulators were purchased with the system, they are

stored under the area taken up by the ROBD2.

Installation

1. Install the system on a table or cart

2. Remove caps on the N2, air and 02 in ports. Do not remove the plug in the

Service port or the vented plug in the Vent port. See the rear panel layout

section, on page 6 for instructions for the vent plug in the vent port.

3. Proceed to the section titled Power and gas connections.

POWER AND GAS CONNECTIONS

ROBD2 USER’S GUIDE SEPTEMBER 2016

8

POWER AND GAS CONNECTIONS

After the RODB2 is unpacked, the system should be connected to power and the

appropriate gas sources to the gas inlet ports on the rear panel. Environics

recommends the use of a power conditioner, as recommended for computers, to

eliminate power problems from affecting system operation.

Power Connection

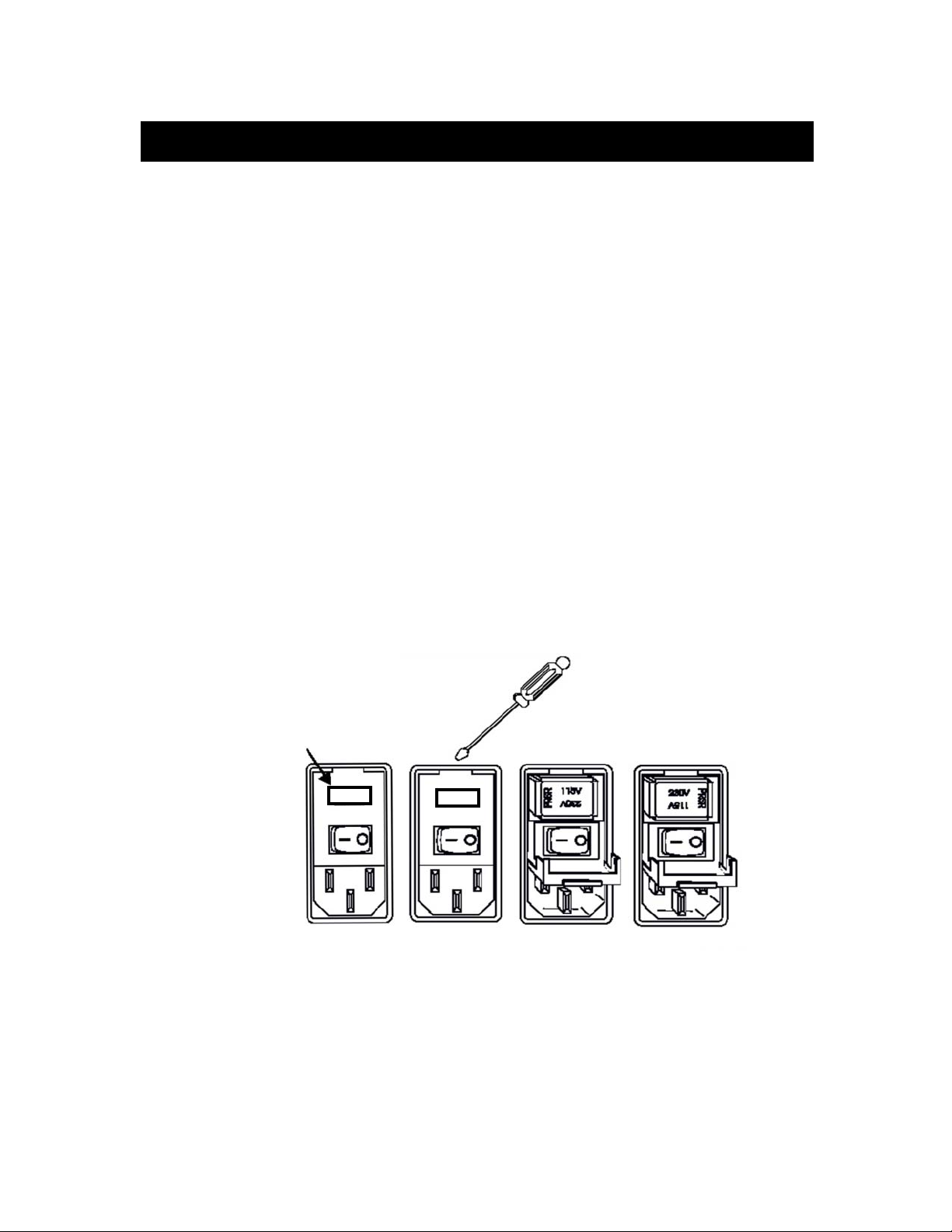

1. The indicating insert of the power entry module should read either 115V or

230V dependent upon the actual voltage being used. If it is not set for the

voltage being connected, remove the insert, rotate it to the correct setting and

reinstall; see below. Set for 115V for 100-120 VAC 50/60 HZ and 230 V for

200-240 VAC 50/60 HZ operation.

2. Insert the standard power cord supplied with the system into the power

connector on the rear panel and insert the plug into a properly grounded

outlet. The standard unit allows for 110 – 240 VAC (50/60 Hz).

3. Do not turn the power on at this point, proceed to the section titled

Gas connection.

Voltage indicator

115V

115V

POWER AND GAS CONNECTIONS

ROBD2 USER’S GUIDE SEPTEMBER 2016

9

Gas Connection

Input Gas Connections

Input Gas connections are keyed and colored quick connect fittings.

1. On the rear of the ROBD2, connect the air (yellow) and nitrogen (black), at a

pressure of 40 to 50 PSIG, to the respective ports. Connect the 100% oxygen (green)

source at a pressure of 20 PSIG. These pressures may need to be adjusted

while the system is flowing. The above listed pressures are dynamic.

It is important that the gas pressures stay within the ranges specified for each

gas port. Otherwise, the system may produce gas blends that fall outside the

accuracy specifications of the system.

2. Connect the pilot mask to the Breathing mask connector on the front panel of the

system.

3. Proceed to the Section titled Power-up and self-tests. As an option the following

Quick start procedure can be used. This is a less detailed step by step guide on

how to operate the instrument.

QUICK START PROCEDURE

ROBD2 USER’S GUIDE SEPTEMBER 2016

1

0

QUICK START PROCEDURE

1. Before Powering on the system make sure to perform the steps outlined in

the section titled Power and gas connection.

2. Connect the pulse oximeter probe any time before or after powering on the

instrument.

3. Power on the system.

4. Allow the warm-up time to elapse (10 minutes)

5. Once warm up time has elapsed, press the SELFTST function key. Follow the

self-test prompts carefully as errors in following the prompts will cause

failures in the self-test. After the self-tests have run, the system will perform a

self-calibration. The 02 sensor will calibrate and test altitudes will be

performed.

DANGER: During self-tests, gas will be delivered to the mask

and vent port. Do not breathe through the mask during the

self-test or self-calibration process, since oxygen will not be

present at all times.

6. The pilot’s mask can now be connected.

7. Press the START key to enter the PILOT TEST MENU.

8. Enter RUNPRG to run a pre-programmed sequence. Select one of twenty pre-

saved programs.

9. Either allow program to complete or select MENU to run a manual altitude.

Manual altitude will interrupt the program. Select EXIT to return to the

program.

10. Select ADVANCE or STOP keys to perform the respective function. ADVANCE

will automatically skip to the next step in the program, STOP will abort the

program.

11. If the subject is at risk of becoming hypoxic, press the 02 DUMP emergency

switch. Once the switch is turned off (turn clockwise) the flow of 100% 02 will

stop.

POWER UP AND SELF-TESTS

ROBD2 USER’S GUIDE SEPTEMBER 2016

11

POWER UP AND SELF-TESTS

Power up

The system power switch is on the rear panel power entry module. It is important

that all gas connections are made before self-tests. Refer to the section titled

Gas connection.

Warmup

The system requires a 10 minute warmup period after it is powered up. During

the warmup period, the screen will display WARMUP and show a 600 second (10

minute) countdown. During the warmup period, the system cannot be run and no

self-tests can be performed. The only available function is the OPTION key.

After the warmup period, the system will show TEST ERR, indicating that the

system self-tests have not been run. The SELFTST function key is now

available, allowing the system self-test to be run.

Self-test/calibration

Pressing the SELFTST key will automatically run all self-test and calibration

steps sequentially. Some tests require user interface while others do not.

At any time after the system has been powered up and self-tests have run for the

first time, these self-tests can be run again, either individually or all together, from

the OPTION menu. This is useful for troubleshooting purposes to detect a failure

that has occurred after the initial power up self-test routine.

Select SELF-TEST from the options menu to run the system self-tests.

Select SELF-CALIBRATE to run the system calibration functions, including O2

sensor calibration.

DANGER: During self-tests, gas will be delivered to the mask,

breathing bag and vent port. Do not breathe through the mask

during the self-test or self-calibration process, since oxygen

will not be present at all times.

POWER UP AND SELF-TESTS

ROBD2 USER’S GUIDE SEPTEMBER 2016

12

Self-test Operations

Oxygen sensor test

The oxygen sensor test will check the on-board oxygen sensor accuracy. The

system will provide air to the sensor for 20 seconds and report the 02 content as

read by the un-calibrated 02 sensor. If the 02 content falls outside the limits set

by the test, the test will fail. Click OK to acknowledge the failure.

Oxygen dump test (tests the O2 switch, O2 valve and alarm)

This test checks the operation of the emergency oxygen dump switch and the

valve that provides the flow of 100% oxygen. The operator will be prompted in

this test to activate and de-activate the dump switch. Pay close attention to the

prompts. After the switch is tested, the system will verify the operation of the

DUMP valve by verifying that the O2 sensor reads 100% O2. Finally, the test will

sound the audible oxygen alarm. The operator will be prompted to press OK if the

alarm is audible and FAIL if it is not.

Oxygen pressure switch test

This test will verify that the oxygen pressure switch works properly. The operator

will be prompted to remove pressure from the oxygen port. This can be done by

disconnecting the hose at the O2 cylinder. The quick connect fitting on the gas

regulator has a check valve. When the hose is removed, the gas regulator is

isolated. Be sure to follow the prompts carefully.

Pulse Oximeter test

This test verifies that the embedded micro controller, of the ROBD2, can

communicate with the integrated pulse oximeter and that the pulse oximeter has

passed its own internal self-test. The pulse oximeter has its own built in self-test

which runs upon power up.

Air MFC shutdown test

This test confirms the operation of a safety feature to shut the system down in

the event of low input air pressure. The air MFC has an alarm signal that

activates if the internal MFC valve opens to maximum capacity. This generally

indicates that there is not enough pressure on the MFC to satisfy the required

flow rate. This would lead to elevated N2 levels in the breathing loop during

normal operation. This feature uses the MFC alarm signal to stop flow and

provide 100% oxygen to the breathing loop. The operator must follow the

prompts to disconnect and reconnect the air source to confirm the passage of

test.

POWER UP AND SELF-TESTS

ROBD2 USER’S GUIDE SEPTEMBER 2016

1

3

Self-Calibration Operations

Before running programs, the system must run through its self-calibration routine at

the start of each operating day, and every time the system is powered on. These

tests will run automatically after the system has warmed up for 10 minutes. If this

process is not run, the system will not allow the operator to enter the START mode.

At any time after the system has run the automatic self-test function, individual self-

tests or self-calibration routines can be run individually from the OPTION menu. To

run the self-calibration sequence, select the self-calibration menu item from the

OPTION menu. Depending upon the gas source being used, the self-calibration

process will vary. Either way, no operator interface is required during each self-

calibration routine.

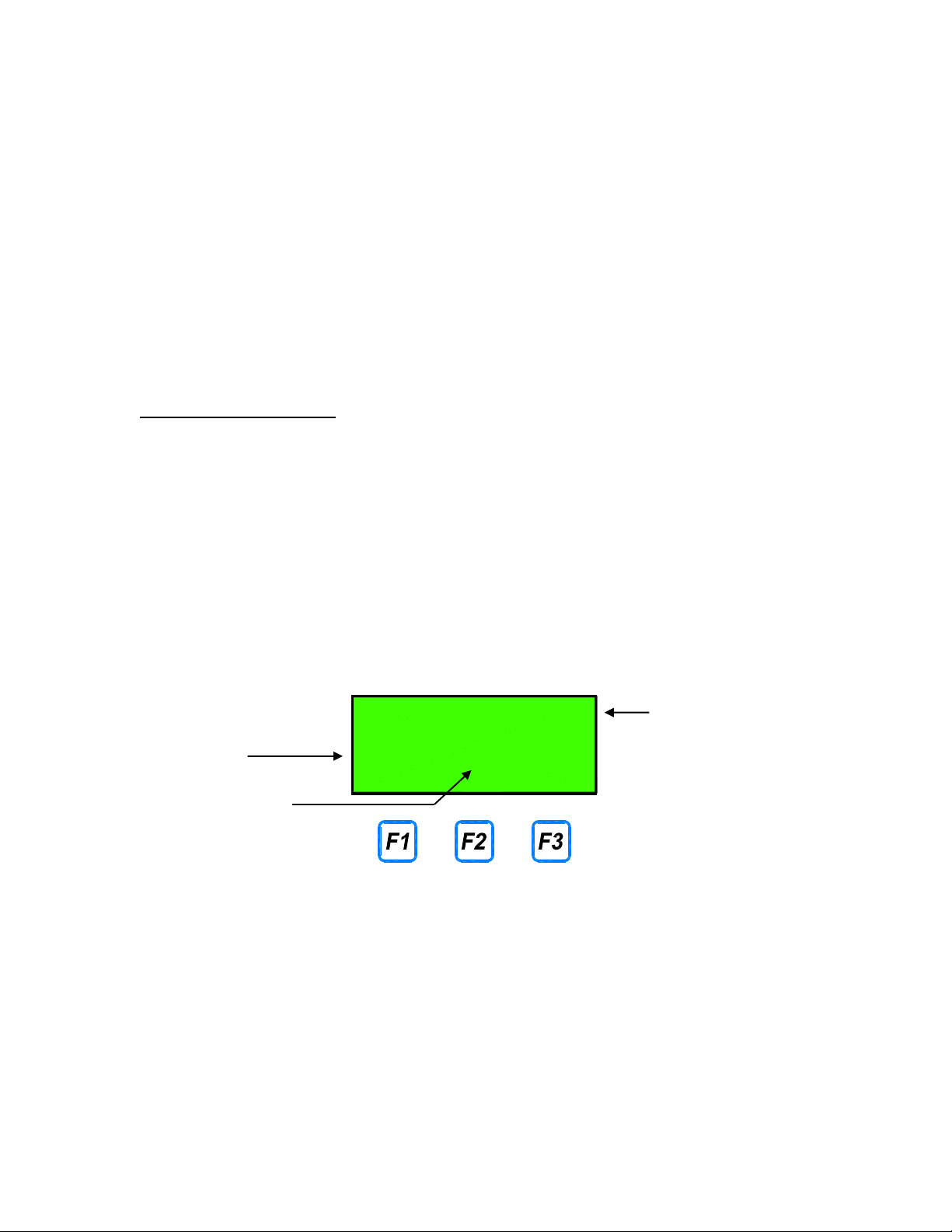

Oxygen sensor calibration

The oxygen sensor calibration is run automatically from the SELFTST key, or can be

run separately by selecting CAL O2 SENSOR from the OPTION – SELF

CALIBRATE menu.

To calibrate the oxygen sensor, first air is delivered to the oxygen sensor. The 02

content of air is known to be 20.947. The following will be displayed:

02 SENSOR CAL 10

MEASURING 02 AIR

02= 20.9% V=.830

C

ANCEL

ANALYZING AIR 02

REMAINING TIME

ACTUAL 02 PERCENT

AS READ BY 02

SENSOR

DC VOLTAGE

PRODUCED

BY 02 SENSOR

POWER UP AND SELF-TESTS

ROBD2 USER’S GUIDE SEPTEMBER 2016

1

4

ALTITUDE BEING

TESTED

TESTING ALTITUDES

ALT:20000 02: 9.09

MEASURING 02….

EXPECTED 02

VALUE

ALTITUDE BEING

TESTED

TESTING ALTITUDES

ALT:20000 02: 9.09

PASSED 02=9.10

EXPECTED 02

VALUE

MEASURED 02

VALUE

RESULT

Once the system has calibrated the sensor for air, it will proceed to supplying

100% 02 to the sensor. The following will be displayed:

Once the sensor has calibrated to 100% 02, the calibration will display complete and

automatically move on to the next calibration routine. If any failures occur during this

test, refer to the troubleshooting section in the Programming and Technical Guide.

Pressing CANCEL during the process will terminate the calibration process and the

new calibration data will not be stored.

Test altitudes

This routine checks the accuracy of the blending system and the oxygen sensor by

running air and nitrogen blends that span the full range of the MFCs. Three altitudes

are tested; 5000 feet, 20000 feet and 34000 feet. From the OPTION menu, select

TEST ALTITUDES. The following information will be displayed during the testing of

each altitude:

The following information will be displayed after each altitude is tested:

ACTUAL 02 PERCENT

AS READ BY 02

SENSOR

02 SENSOR CAL 10

MEASURING 02 100%

02= 99.5% V= 3.803

CANCEL

ANALYZING 100% 02

REMAINING TIME

DC VOLTAGE

PRODUCED

BY 02 SENSOR

This manual suits for next models

1

Table of contents

Other Environics Respiratory Product manuals

Popular Respiratory Product manuals by other brands

Full Support

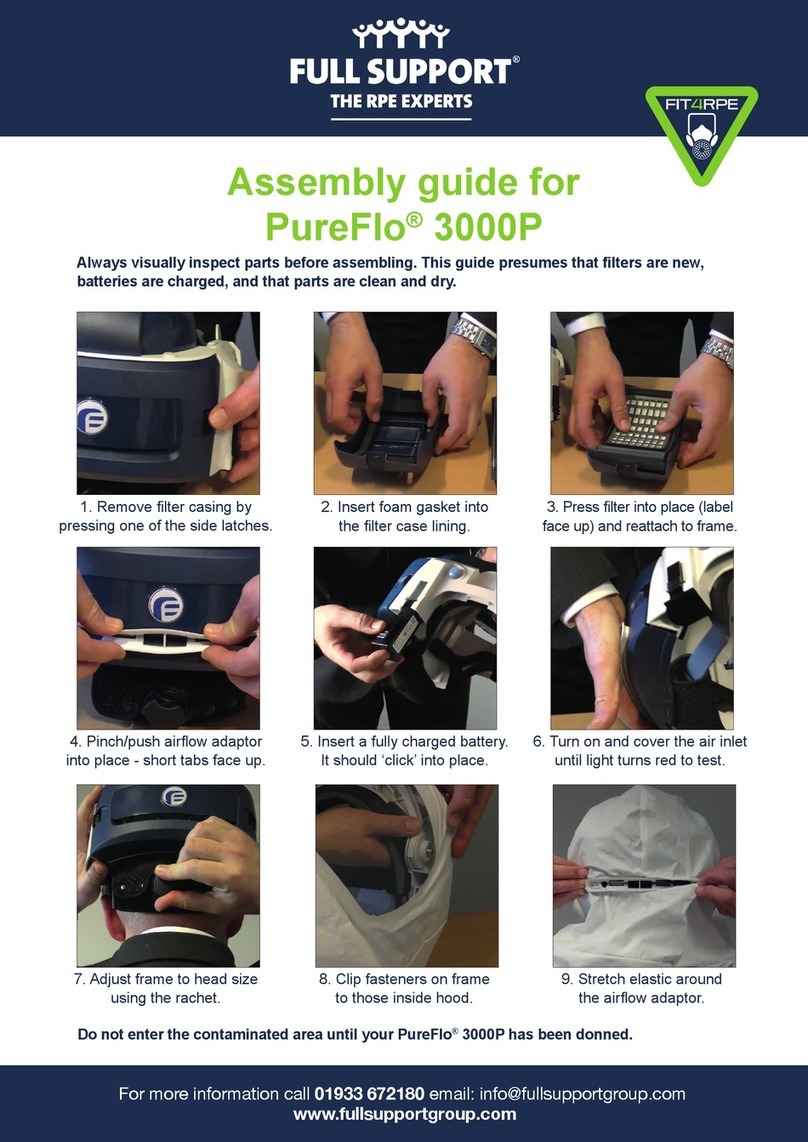

Full Support PureFlo 3000P Assembly guide

Sealey

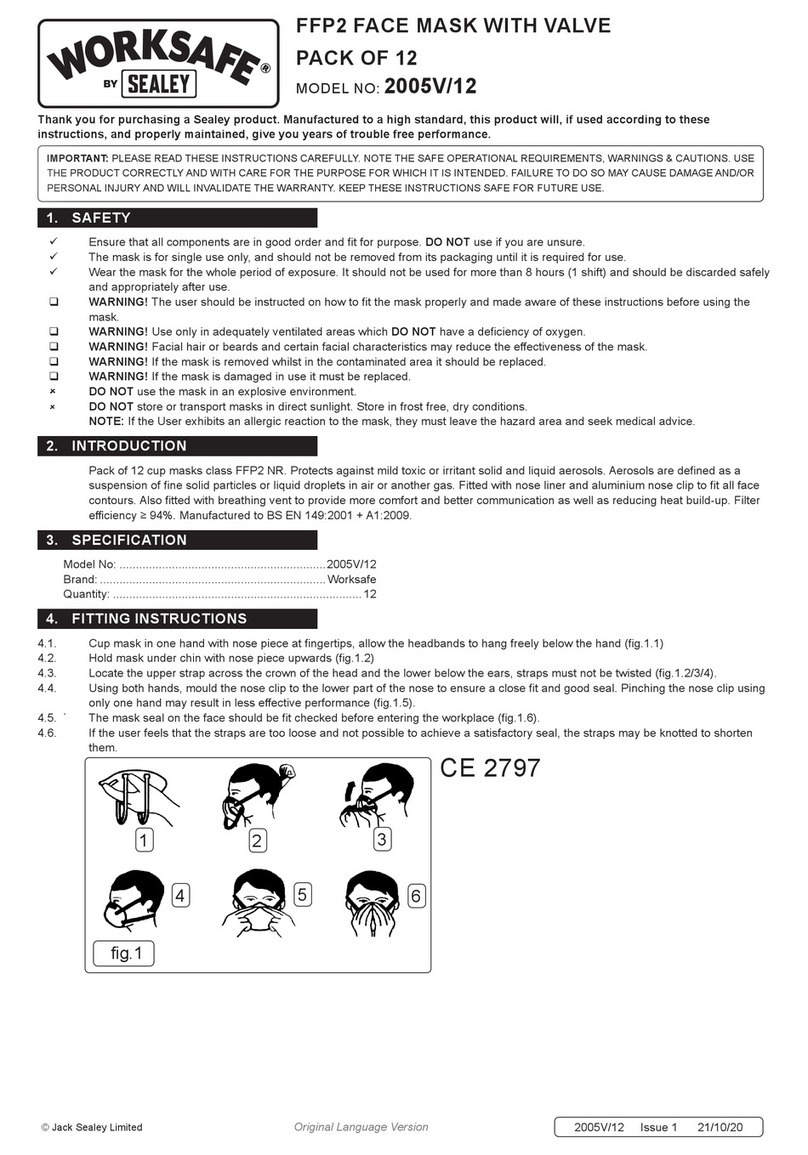

Sealey Worksafe 2005V/12 quick start guide

MSA

MSA 3S small quick start guide

Philips

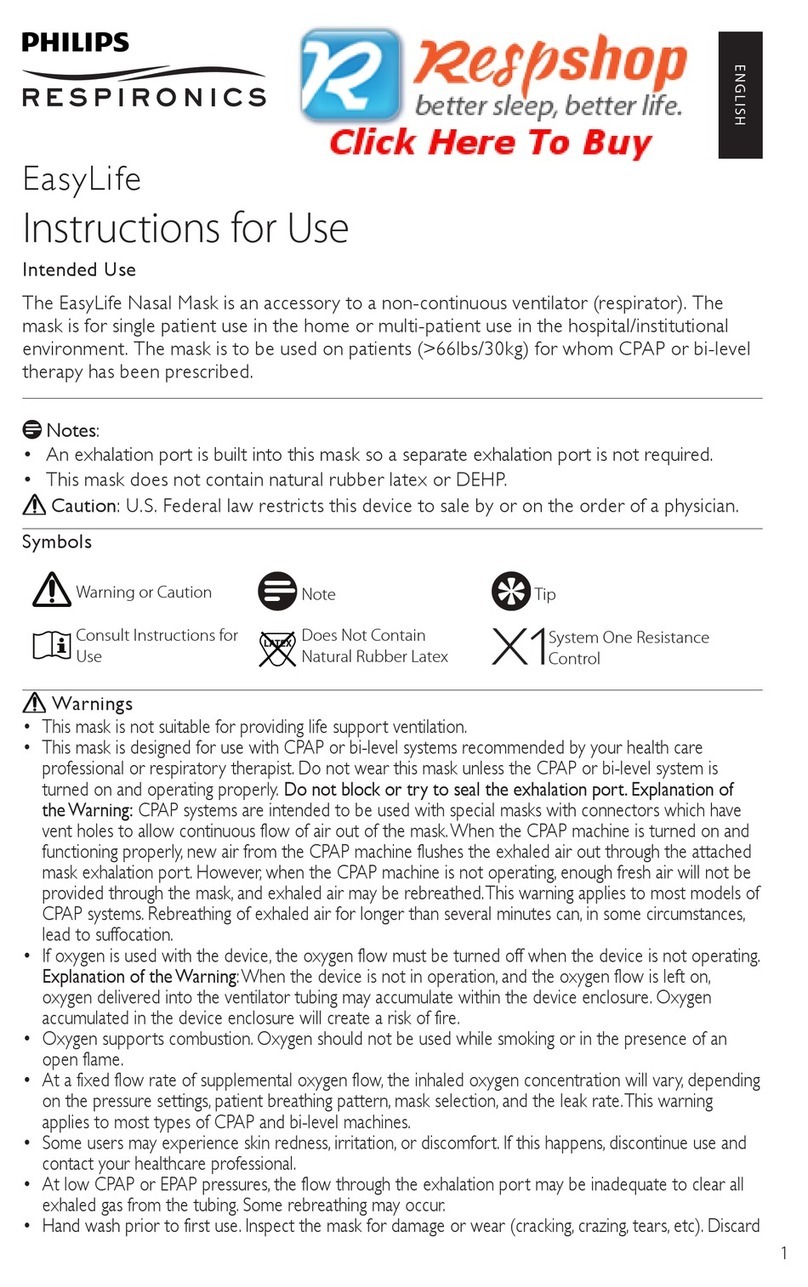

Philips Respironics EasyLife Instructions for use

e-breathe

e-breathe SMARTBLOWER 322002100 instruction manual

Philips

Philips Respironics CoughAssist T70 Patient guide