Environmental Express SimpleDist C6000 Administrator Guide

SimpleDist® System

Operation & Instruction Manual

©2021 Environmental Express. All rights reserved.

July 2021 1065EE3_M Rev 2

+1.800.343.5319 or +1.843.881.6560 envexp.com

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express

SimpleDist: Operation and Instruction Manual Contents

Contents

General Information

Limited Warranty and Repair Policies 1

Parts and Supplies 2-3

Safety Information 4

Getting Started

Setup and Assembly 5

About Your HotBlock®

HotBlock® Declaration of Conformity 6

HotBlock® Information and Markings 7

HotBlock® Unpacking and Installation 8

HotBlock® Temperature Information 9

HotBlock® Potential Hazards and Maintenance 10

Diagrams

Tubing Valve Assembly, Figure 1 11

Boiling Tube Assembly, Figure 2 12

Assembly Complete System, Figure 3 13

System Operation

Total Cyanide Distillation 14-15

Ammonia Distillation 15-17

Care and Maintenance of Your SimpleDist®

Circuitry Diagram 18

Troubleshooting SimpleDist® 19

Troubleshooting Your HotBlock® 20-22

HotBlock®Replacement Parts 23

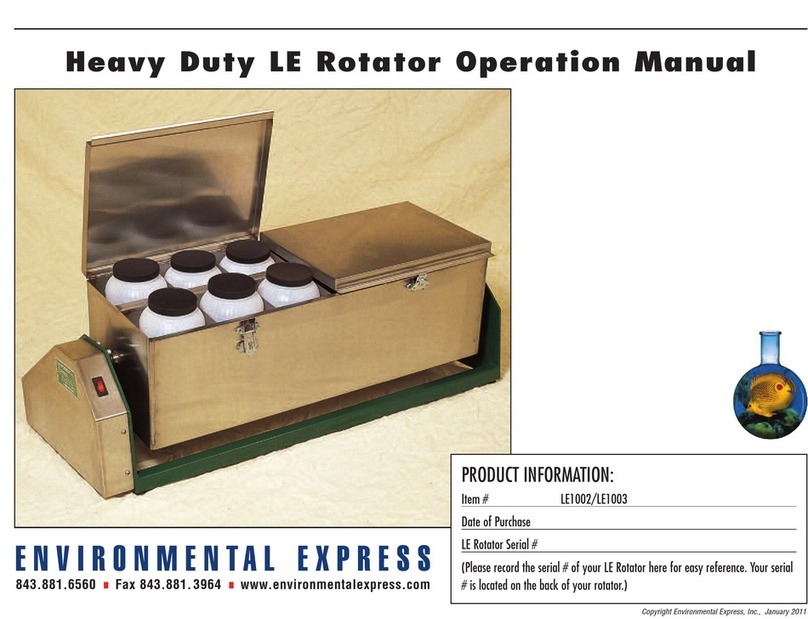

The C6000 SimpleDist®Complete System is

shown here. The 12-place Manifold Kit is also

sold separately, C6210, and ts the 36-well SC100

HotBlock®or the 12-place HotBlock®, C6002.

Pictured above, the 18-place SimpleDist®Manifold

Kit, C6200, ts the SC154 HotBlock®.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 1

SimpleDist: Operation and Instruction Manual General Information

Limited Warranty

The SimpleDist® System from Environmental Express is guaranteed to heat, hold temperature, and adequately perform

specied laboratory distillations for a period of one year from the date of shipment. This warranty extends to parts, labor, and

any approved transportation charges. This warranty applies only to damage or failure caused by normal laboratory use.

Environmental Express makes no other warranty, expressed or implied for this product with respect to merchantability, tness

for a particular use or any other matter. Environmental Express is not liable for any consequential or compensatory damages

arising from use of, or in conjunction with, this product. The maximum liability shall be the invoice price of this product.

Product Information:

Item # Date of Purchase

HotBlock® Serial # (if applicable)

If you ordered the C6000 please record the serial # of your HotBlock® here for easy reference. Your serial # is located on the back of your HotBlock®.

Under Warranty Repair:

If the SimpleDist® should fail to operate within the warranty period (one year from date of shipment) Environmental

Express will repair it and ship it back to the customer at our expense. The remainder of the warranty period will be

honored from the original ship date. Environmental Express will bear the cost of ground transportation both to and from

the customer’s location, and bear the cost of any parts, labor and cleanup required.

However, if it is determined that the damage to the SimpleDist® System was caused by negligence or improper use, this

warranty will not apply. The warranty is also void if the system is used beyond its intended purpose or in the event of any

unauthorized repair. In such cases, reasonable and customary repair charges will apply. Repair charges will be quoted prior

to work being done.

Out of Warranty Repair:

If the SimpleDist® System fails after the warranty period has lapsed, the repair procedure is as follows:

First, notify an Environmental Express service representative of product’s failure and place an order for repair. Whenever

possible, our customer service technician will walk you through possible troubleshooting scenarios which may enable you

to repair your block on site.

If on-site repair is not possible, the customer may return the non-working unit to Environmental Express using appropriate

shipping containers and insurance. Repair charges will be assessed and estimated prior to work being done. Repair charges

will include all freight costs as well as reasonable and customary charges for parts and labor.

Repair Policies

Note: This warranty does not apply to any glassware associated with the SimpleDist® System.

Call +1.800.343.5319 or +1.843.881.6560 envexp.com

2345 A Charleston Regional Pkwy • Charleston, SC 29492

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 2

SimpleDist: Operation and Instruction Manual General Information

Parts and Supplies

SimpleDist® Complete System C6000

Parts and Supplies Included:

Description Item #

12-well HotBlock® C6002

12-valve Manifold Kit C6210

SimpleDist® Manual

Includes operation Instructions with wiring diagram and temperature controller operation instructions.

12-well HotBlock® C6002

Parts and Supplies Included:

The 12-place HotBlock® is a compact block for laboratories digesting small batches of 50mL samples. Each block comes with a specially

designed 12-place polycarbonate tube rack (C6050) and has the same sturdy construction and features of our other HotBlock® Systems.

Description Item #

Tube Rack C6050

For handling 12 boiling tubes simultaneously, polycarbonate

Power Cord SC958

12-valve Manifold Kit C6210

Parts and Supplies Included:

Description Item #

12-valve PVC Vacuum Manifold C6003B

Base Supports, 2 piece set C6007B

12 Flow Control Valves C6005 each

Push lock design, accepts 3/8" diameter tubing

1 PVC Hose Barb for SCS, 1/4" C6160

12 Boiling Tubes C6010 each

30mm x 200mm threaded boiling tubes marked at 50mL, borosilicate glass

1 pack Collection Traps

Disposable polystyrene C6100 100pk

1 pack Polypropylene Reagent Addition Tubes C6110 100pk

2 packs Caps C6120 6pk

38mm open top closures

2 packs Black Neoprene Washers C6120A 6pk

2 packs 2-Port Cap Inserts C6130 6pk

1 12-Piece Tubing Kit C6142

Tubing kits come with 12 lengths of tubing (3/8" OD X 1/4" ID). Six pieces of tubing are 8" and the other 6 are 10.25".

The longer pieces extend from the manifold valves to the front row of sample collection asks while the shorter

lengths go to the back row of collection asks. Each length of tubing comes with a tubing adaptor and a barbed

tting adaptor already inserted.

Tubing Adaptors C6140 12pk

Barbed Tubing Adaptor C6006 6pk

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 3

SimpleDist: Operation and Instruction Manual General Information

18-valve Manifold Kit C6200

Parts and Supplies Included:

Description Item #

18-valve PVC Vacuum Manifold C6007A

Base Supports, 2 pieces C6007B

18 Flow Control Valves C6005 each

Push lock design, accepts 3/8" diameter tubing

1 PVC Hose Barb for SCS, 1/4" C6160

18 Boiling Tubes C6010 each

30 mm. x 200 mm. threaded boiling tubes marked at 50mL, borosilicate glass

1 pack Collection Traps C6100 100pk

Disposable polystyrene

1 pack Polypropylene Reagent Addition Tubes C6110 100pk

3 packs Caps C6120 6pk

38 mm. open top closures

3 packs Black Neoprene Washers C6120A 6pk

3 packs 2-Port Cap Inserts C6130 6pk

2 12-Piece Tubing Kits C6142

Tubing kits come with 12 lengths of tubing (3/8" OD X 1/4" ID). Six pieces of tubing are 8" and the other 6 are 10.25".

The longer pieces extend from the manifold valves to the front row of sample collection asks while the shorter lengths

go to the back row of collection asks. Each length of tubing comes with a tubing adaptor and a barbed tting adaptor

already inserted.

Tubing Adaptors C6140

Barbed Tubing Adaptors C6006 6pk

Snip & Pour, 0.2N H2SO4C7005 50x5mL

Snip & Pour, 1.25N NaOH C71155 50x5mL

Snip & Pour, 20g/L Boric Acid C7125 50x5mL

SimpleDist Manual

Includes operation Instructions with wiring diagram and temperature controller operation instructions.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 4

SimpleDist: Operation and Instruction Manual General Information

Safety Information

1. The Environmental Express SimpleDist® System should be set up and operated in a chemical fume hood with a face

velocity of not less than 100 CFM.

2. Wear appropriate Personal Protective Equipment (PPE) suitable for use with caustic and corrosive materials.

3. Do not operate the SimpleDist® System in the vicinity of combustible material.

4. Consult your in-house electrician to be certain the SimpleDist System power cord is properly grounded.

5. During operation the surfaces around the heater assembly will get HOT. Do not touch the outer surface.

6. Do not move the SimpleDist® System while hot.

7. Do not attempt to operate the SimpleDist® System block over 180°C.

8. Review Safety Data Sheets for all materials used or generated during the operation of the SimpleDist® System.

Avoid breathing any vapors that may come off of the SimpleDist® System; they may be harmful or fatal.

9. Vacuum should be continued until the SimpleDist® System has cooled down and the collection trap is removed from

the assembly.

10. The power should be kept plugged into its outlet until the unit has cooled down.

11. If boil over does occur during operation of the SimpleDist® System operation, immediately wipe the system down

with neutralizing solution, such as a mild solution of sodium bicarbonate.

12. Unplug the SimpleDist® System from the outlet prior to cleaning exterior surfaces. Wipe with damp sponge or

towel after each use, rst with mild sodium bicarbonate or similar solution followed by DI or distilled water. Avoid

solutions on or near the controls.

13. Install an excess gas trap in the vacuum line to remove excess vapors.

14. Use of micro-porous boiling chips in each distillation ask may help to prevent bumping.

Note: The above list contains some basic recommendations and safety precautions. By no measure should this list be considered

complete. More rigorous enhanced precautions may be necessary while operating this equipment. Please consult your Safety

Manager and Safety Data Sheets prior to operating this equipment.

Contact Environmental Express if there are any questions. User assumes all liability for damages arising from the operation of

this equipment.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 5

SimpleDist: Operation and Instruction Manual Getting Started

Setup and Assembly:

1. Unpack the heating unit and place it in a chemical fume hood with the temperature controller facing outward.

(If you are purchasing a manifold kit to use with a previously purchased HotBlock®, skip to step 2).

2. Unpack boiling asks. The boiling asks should be cleaned according to laboratory protocol and assembled in the

SimpleDist® block.

3. Unpack the bags of tubing which were packed with the heating unit.

4. Review the diagrams and familiarize yourself with parts, names, and locations of the parts for the chemistry you

are doing.

5. Save original packaging material in a dry area for use if unit needs to be returned for service. Refer to warranty

policy on page 1.

6. Assemble the vacuum manifold and base supports and then tighten 4" set screws using an 3/16" Allen

wrench.

7. Place vacuum manifold containing ow control valves behind the heating block. Slide the manifold forward until

base supports surround the heating block on both sides.

8. Connect vacuum tubing to the PVC barb located on the left leg of the vacuum manifold. An excess vapor trap

containing NaOH solution may be inserted between the manifold and the vacuum source.

9. Open the C6142 Tubing Kit to nd the lengths of silicone tubing with tubing on one end and barbed tting adaptors

into the other end. Depending on the manifold purchased, there are 6 or 9 long tubes for the front positions and

6 or 9 shorter tubes for the back positions. Insert the end with the barbed tting adaptors into the ow control valve.

Pull back on the orange locking collar of the valve and then push the adaptor rmly into the valve.

Note: See Tubing Valve Assembly, Figure 1, page 11.

10. The glassware/plasticware for the SimpleDist® System is assembled as follows:

a. Place a boiling tube into one of the left-most distillation block positions.

b. Place a washer (Item # 6120A) on top of a 2-port cap insert. Then, place a 2-port cap insert into one of the

closures (green cap).

Note: See Boiling Tube Assembly drawing, Figure 2, page 12.

c. Thread a closure/cap insert assembly onto the boiling tube.

d. Insert an assembled disposable reagent addition tube/tip into the smaller port on the cap insert.

e. Fit a collection trap into the larger top port of the cap insert.

f. Connect tubing/tubing adaptor onto the top of the collection trap.

g. Repeat steps A through F for the remaining glassware, working from left to right.

h. To remove the glassware, reverse the above procedure.

Note: See drawing #C6000, Figure 3, page 13, for complete assembly diagram.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 6

SimpleDist: Operation and Instruction Manual About Your HotBlock®

HotBlock® Declaration of Conformity

The manufacturer,

Environmental Express

2345A Charleston Regional Parkway

Charleston, SC 29492

declares that the following products,

HotBlock® Item #

SC196, SC154, SC150, SC151, SC100, and C6002,

are in conformity with:

Standard for Safety Electrical Equipment for Measurement, Control, and Laboratory Use; Part 1 General Requirements,

UL 61010-1, CAN/CSA-C22.2 No. 61010-1, 2nd Edition, Issued 12 July, 2004 with revisions through and including

28 October, 2008; Equipment for Measurement, Control, and Laboratory Use Part 2-010: Particular Requirements

for Laboratory Equipment for the Heating of Materials, IEY 61010-2-010, 2nd Edition, Issued 1 June, 2003, Safety

Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use - Part 2-010:Particular

Requirements for Laboratory Equipment for the Heating of Materials, CSA C22.2.61010.2.01.

4000040

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 7

SimpleDist: Operation and Instruction Manual About Your HotBlock®

HotBlock® Information and Markings

Environmental Express HotBlocksTM provide an efcient method of digesting and storing water, wastewater, soil and

sludge samples for metals analysis. These innovative digestion systems allow samples to be digested in a corrosion-free

environment. In addition, samples are handled in a small area with minimal radiant heat loss. Users should be aware of

potential dangers from heating certain types of compounds. Such hazards may include explosion or the release of toxic

or ammable gases.

Each HotBlock® displays certain markings and symbols. All personnel working with the HotBlocksTM should have an

understanding of the following symbols and denitions:

• V = voltage

• ~ = alternating current

• Hz = frequency

• A = amperes

This symbol means Caution

Hot Surface. The surface of the

HotBlock® may be too hot to

safely touch with bare hands.

This symbol means Read

and become familiar with

instructions before operation

of instrument.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 8

SimpleDist: Operation and Instruction Manual About Your HotBlock®

HotBlock® Unpacking and Installation

Unpacking Your HotBlock®:

1. Remove the HotBlock® from the shipping container by lifting from the bottom of the block. The lid should not be

used for lifting.

2. Your HotBlock® is shipped with metal screws securing the bottom panel. The metal screws must be removed before

operating your HotBlock®. Remove the metal screws and replace them with the PVC screws and rubber feet included

with your shipment. The corrosion-resistant PVC screws and rubber feet are designed to secure the bottom plate.

Important: Do not over tighten the PVC screws!

Installation Requirements

Locate the HotBlock® under a fume hood with a minimum face velocity of 100fpm, and allow a minimum of 2" of space on all

sides. The following environmental conditions should be observed:

• Ambient temperature range: 5-30°C

• Ambient relative humidity: 0-90%RH

• Altitude: sea level to 2500 meters

HotBlocksTM are rated as Pollution Degree 2 and Installation Category 2.

Electrical Requirements

Required Voltage: 120 volts, ~60Hz, 15A

(all HotBlocksTM are also available in 240V

with CE mark)

Power should not vary greater than ±10%. Use the supplied heat-resistant power cord or equivalent to connect to the power

supply.

For safety reasons, a separate power receptacle should be provided for each unit in the system. Do not use extension cords or

outlet adaptors. Make certain that power outlets are earth-grounded at the grounding pin.

See individual specications for each HotBlock® model.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 9

SimpleDist: Operation and Instruction Manual About Your HotBlock®

HotBlock® Temperature Information:

The pre-set factory “set point” temperature of your HotBlock® is 106°C. Factory tests have shown that this temperature is “sea

level safe.” Liquids in uncovered polypropylene tubes should not boil at this setting. Please note that the set point of the block

is not the same as the temperature of the liquids being digested. The block temperature should be optimized for the specic

digestion. The temperature of liquid contents of the digestion cup will vary according to:

• The material being digested

• The number of samples being digested

• The air movement of the digestion area

• The addition of a watch glass or reux cap

If watch glasses are being used, the control point temperature should be lowered approximately 10°C to avoid boiling.

Note: The maximum sample temperature tolerance for our polypropylene digestion vessels (SC475) is 130°C.

Remember that the temperature display (current block temperature) is not the temperature of the sample. Sample temperature

will usually be 5-15° less than the display temperature.

Adjusting the Temperature of Your HotBlock®:

1. Plug the HotBlock® into an approved receptacle. Turn the HotBlock® on by pressing the button on the back of the unit.

Wait until the display shows the current block temperature (in red) and the set point temperature (in green).

2. Press and hold or tap the or key. The display will show the set point temperature on the right in blue. The

adjustment is from ambient to 150°C in increments of 0.1°C. There is no need to press the green (advance) or ∞ button.

Safe-Sample™ Temperature Protection:

Your HotBlock® is protected from runaway temperatures by a fail-safe alarm system. In the unlikely event that the heating

system fails to respond to the controller, the Safe-Sample™ system will automatically shut the system off and sound an audible

alarm.

This alarm sequence occurs if the actual temperature of the block reaches a temperature that is fteen degrees higher than

the set point temperature. If this should occur, the HotBlock® will stop heating, preventing the loss of samples. The HotBlock®

must be turned off, then turned back on to reset the alarm.

If the alarm sounds, see the HotBlock® troubleshooting guide of your manual on pages 20-22.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 10

SimpleDist: Operation and Instruction Manual About Your HotBlock®

HotBlock® Potential Hazards and Maintenance

Potential Hazards:

The HotBlock® should only be operated by properly trained personnel using standard laboratory safety practices.

1. Use extreme caution when operating the HotBlock®. Plastic and graphite surfaces of the HotBlock® may be too hot to safely

touch with bare hands.

2. The HotBlock® contains electrical circuits and devices and compounds operating at dangerous voltages. Contact with these

circuits, devices and components can cause serious injury or painful electric shock.

3. Proper grounding is essential to avoid a potentially serious electric shock hazard. Ensure that there is an internal ground

connection between the metal base of the system and the 3-pin, earth-grounded receptacle.

4. For safety reasons a separate power outlet receptacle should be provided for each unit in the system. Do not use extension

cords or outlet adaptors. Make certain each power outlet is earth-grounded at the grounding pin.

5. See individual block specications for power requirements.

6. Application of the wrong supply voltage can create a re hazard and a potentially serious shock hazard, and could seriously

damage the HotBlock® system. See specications for individual HotBlocksTM.

7. Users should be aware of potential dangers from heating certain types of compounds. Such dangers may include explosion

or the release of toxic or ammable gases.

8. Always lift the HotBlock® from the bottom of the unit.

Maintenance:

1. Any service inquiries should be directed to Environmental Express Technical Service Department.

2. After each use, clean exterior surfaces with a damp sponge to remove acid residue.

3. For acid spills, sponge with a diluted solution of sodium bicarbonate followed by distilled water. Acid that is spilled directly

into the digestion wells should be neutralized and removed.

4. Before using any cleaning or decontamination methods except those recommended, check with Environmental Express to

conrm the proposed method will not damage your HotBlock®.

5. Avoid excessive spills, as liquid allowed to overow into the HotBlock® casing can severely damage electronic components.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 11

SimpleDist: Operation and Instruction Manual Diagrams

DETAIL A

SCALE 1 : 2

NOTE: BARBED FITTING ADAPTER

MUST BE FULLY SEATED IN THE

FLOW CONTROL VALVE TO

PREVENT LEAKING.

PULL THE ORANGE RELEASE

FITTING BACK AND PUSH

THE ADAPTER ALL THE WAY

IN UNTIL IT SEATS.

A

SIZE

WEIGHT:

2

ENVIRONMENTAL EXPRESS

JHO 5/21/10

DWG. NO.

A

REV.

ASSEMBLY DRAWING

PROPRIETARY AND CONFIDENTIAL FLOW CONTROL VALVE

BARBED FITTING ADAPTER/

SIMPLE DISTILLATION

MATERIAL

FINISH

DO NOT SCALE DRAWING

PROHIBITED.

COMMENTS:

SHEET 1 OF 1

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

DATE

NAME

ENVIRONMENTAL EXPRESS IS

WITHOUT THE WRITTEN PERMISSION OF

APPLICATION

REPRODUCTION IN PART OR AS A WHOLE

USED ON

ENVIRONMENTAL EXPRESS. ANY

NEXT ASSY

DRAWING IS THE SOLE PROPERTY OF

THE INFORMATION CONTAINED IN THIS

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH BEND

TWO PLACE DECIMAL

THREE PLACE DECIMAL

SCALE:1:20

Tubing Valve Assembly, Figure 1

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 12

SimpleDist: Operation and Instruction Manual Diagrams

Boiling Tube Assembly, Figure 2

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 13

SimpleDist: Operation and Instruction Manual Diagrams

SimpleDist

SimpleDist®

Assembly Complete System, Figure 3

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 14

SimpleDist: Operation and Instruction Manual System Operation

Total Cyanide Distillation with the SimpleDist®:

1.0 Scope and Application

1.1 This method follows US EPA method number 335.4 titled Determination of Total Cyanide by Semi-Automated

Colorimetry. It is applicable for the determination of total cyanide in drinking, ground, surface, and saline waters,

domestic and industrial wastes, and soils.

1.2 The standard range is typically 5 to 500µg/L. Lower detection limits can be achieved by using a longer path length

ow cell in the analysis step when using an automated continuous ow analyzer.

2.0 Summary of Method

2.1 The cyanide as HCN is released from metal-cyanide complexes by means of an acidic manual reux-distillation

whereby the HCN gas that is formed is separated from the sample matrix and absorbed in a dilute solution of

sodium hydroxide. The distillate can be analyzed for cyanide by semi-automated colorimetry, manual colorimetry,

titrimetric, or ion-selective electrode.

2.2 Reduced volume versions of this method that use the same reagents and molar ratios as in the original method are

acceptable provided they meet the quality control and performance requirements stated in the method.

3.0 Interferences

There are several known interferences with this method. A few of these are:

Aldehydes Thiocyanates

Nitrate-nitrite Thiosulfates

Chlorine Suldes

Some of these interferences are reduced or eliminated by the distillation process. For example, the nitrate-nitrite

interference is eliminated by addition of sulfamic acid during the distillation step. Further, the addition of magnesium

chloride, which acts as a catalyst, will promote the breakdown of refractory iron-cyanide complexes.

The reagent preparations for these two interferences will be summarized in the Reagent Preparation section. For all other

pretreatment procedures refer to the US EPA method number 335.4 and/or SW846 9010C.

4.0 Chemicals Required: Distillation Only

4.1 Sodium hydroxide

4.2 Sulfuric acid, 18N

4.3 Magnesium chloride, if refractory iron-cyanide complexes are present

4.4 Sulfamic acid – if nitrates and nitrites are present

4.5 Potassium cyanide

4.6 Potassium hydroxide

4.7 Reagent water ASTM Type II or equivalent

Note: The toxicity for each of the reagents used in this procedure are not fully documented. Treat each chemical as a potential

health hazard and limit exposure. Exercise good laboratory technique with an emphasis on safety.

5.0 Procedure

5.1 Pipette 50mL of sample or an aliquot diluted to 50mL with reagent water into the SimpleDist® System boiling tube.

For solid samples weigh 1.0g or less to the nearest 0.01g, dilute to 50mL.

5.2 Insert inlet port liner into the green screw cap and thread assembly onto top of glassware. Be sure that the “step” on

the inlet port liner is ush with the top opening of the green cap.

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 15

SimpleDist: Operation and Instruction Manual System Operation

5.3 Assemble inlet tube with funnel tip and insert into the smaller port on cap.

5.4 Pour the entire contents of the 1.25 N NaOH Snip & Pour tube into the collection trap. If Snip & Pour tubes are not

being utilized add a sufcient volume of NaOH solution that will result in a nal concentration of 0.25 N NaOH after

adding DI water to 25 mL. (Example: 10 mL of 0.625 N NaOH solution). For best results wait until the distillation is

complete to bring the trapping solution to nal volume. The trap may be attached to the glassware at this point or it

may be lled off-line and then placed onto the glassware. Attach tubing/adaptor to the collection trap.

5.5 Repeat 5.1 through 5.4 for all samples to be distilled.

5.6 Turn on the vacuum and slowly adjust each valve to provide an air ow bubble rate of 5-10 bubbles per second for

each position as viewed in collection trap. Vacuum should be sufcient to maintain slight negative pressure on the

assembly throughout the distillation.

5.7 If nitrate-nitrite is known to be present add 5.0mL of sulfamic acid reagent through the reagent inlet. Allow the air

ow to mix for several minutes.

5.8 If iron cyanide complexes are known to be present add 2.0mL of magnesium chloride reagent. If excess foaming

occurs, add an additional 2.0mL. Allow a few minutes to mix.

5.9 Slowly add 5.0mL of 18N sulfuric acid though the reagent inlet.

5.10 Turn the heat on and set the temperature of the heating block to 125°C. The block will achieve this temperature in

approximately 30 minutes. Heat for an additional 60 minutes after the block achieves this temperature.

5.11 Remove the collection trap from the assembly.

5.12 Turn air/vacuum valves to the off position. Repeat for each sample position.

5.13 Bring the volume of liquid in the collection trap up to the 25 mL line with DI water (a graduated cylinder, volumetric

ask, or other volumetric glassware may be used for volume measurements). The distilled cyanide in the trap is now

ready for analysis. Pour contents into an appropriate container. When pouring, position the vent tube of the trap up

to prevent trapping of air.

5.14 After use clean exterior surfaces with a damp sponge. For acid spills sponge with a diluted solution of sodium

bicarbonate followed by distilled water.

Total Cyanide Distillation with the SimpleDist® Continued:

1.0 Scope and Application

1.1 This method follows both Standard Methods 4500-NH3 titled Nitrogen (Ammonia) and US EPA Method 350.1

titled Determination of Ammonia Nitrogen by Semi-Automated Colorimetry. These methods are applicable to the

determination of ammonia nitrogen in drinking, ground, surface, and saline waters, domestic and industrial wastes,

and soils.

1.2 The standard applicable range is 0.01 – 2.0mg/L NH3 as N. Higher concentrations can be determined by sample

dilution.

2.0 Summary of Method

2.1 A sample is buffered at pH 9.5 with borate buffer to decrease hydrolysis of cyanates and organic nitrogen compounds.

It is then distilled into one of two catch solutions. Boric acid is used when nesslerization or titration are used for

analysis or into sulfuric acid when the phenate method or ion selective electrode method are used for analysis. The

distillate is then analyzed by one of the methods listed above.

2.2 Reduced volume versions of this method that use the same reagents and molar ratios are acceptable provided they

meet the quality control and performance requirements stated in the method.

2.3 Limited performance-based method modications may be acceptable provided they are fully documented and meet

or exceed method requirements.

Ammonia Nitrogen Distillation with the SimpleDist®:

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 16

SimpleDist: Operation and Instruction Manual System Operation

3.0 Interferences

3.1 Cyanate, which may be encountered in certain industrial efuents, will hydrolyze to some extent even at the pH of 9.5 at

which distillation is carried out.

3.2 Residual chlorine must be removed by pre-treatment of the sample with sodium thiosulfate or other reagents before

distillation.

4.0 Chemicals Required: Distillation Only

4.1 Ammonia-free water

4.2 Borate buffer solution

4.3 Sodium hydroxide, 1N

4.4 Boric acid catch solution (20g/L) – for use with the nesslerization and titration methods

4.5 Sulfuric acid catch solution, 0.04N – for use with the phenate and ion selective electrode methods

4.6 Sodium thiosulfate (for dechlorinating)

Note: The toxicity for each of the reagents used in this procedure is not fully documented. Treat each chemical as a potential health

hazard and limit exposure. Exercise good laboratory technique with an emphasis on safety.

5.0 Procedure

5.1 Adjust an aliquot of at least 25mL of sample to a pH of 9.5 using 1N sodium hydroxide and remove any residual

chlorine.

5.2 Pipette 25mL of pH-adjusted sample or an aliquot diluted to 25mL with reagent water into the SimpleDist® System

boiling tube. For solids weigh 1.0g +/- 0.01g and dilute to 25mL. Add boiling chips to the boiling tube.

5.3 Insert the inlet part liner into the green screw cap and thread assembly onto the top of the boiling tube.

5.4 Assemble inlet tube with funnel tip and insert into the smaller port on cap.

5.5 Pour the entire contents of the appropriate Snip & Pour trapping solution into the collection trap. The nal

analytical method will determine which trapping solution you use. Generally, titration methods use boric acid

while other methods use sulfuric acid. If Snip & Pour tubes are not being utilized add a sufcient volume of the

appropriate trapping solution that will result in the proper nal concentration after adding DI water to 25 mL.

(Example: 10 mL of 0.1 N H2SO4solution) For best results wait until the distillation is complete to bring the trapping

solution to nal volume. The trap may be attached to the glassware at this point or it may be lled off-line and then

placed onto the glassware. Attach tubing/adaptor to the collection trap.

5.6 Repeat steps 5.1 through 5.5 for all samples to be distilled.

5.7 Turn on the vacuum and adjust each valve to provide an air ow bubble rate of 10-15 bubbles per second for each

position as viewed in the collection trap. Vacuum should be sufcient to maintain slight negative pressure on the

assembly throughout the distillation.

Important: Monitor the vacuum to insure a back pressure does not build up in the boiling tube!

5.8 Add 1.25mL of borate buffer to the sample through the reagent inlet tube.

5.9 Turn the heat on and set the temperature of the HotBlock® to 135ºC. The block will achieve this temperature in

approximately 30 minutes. Heat for an additional 60 minutes after the block achieves this temperature.

5.10 Remove the collection trap from the assembly.

Important: Vacuum must remain on!

Ammonia Nitrogen Distillation with the SimpleDist® Continued:

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 17

SimpleDist: Operation and Instruction Manual System Operation

Ammonia Nitrogen Distillation with the SimpleDist® Continued:

5.11 Turn air/vacuum valves to the off position.

5.12 Bring the volume in the collection trap up to the 25 mL line with DI water (a graduated cylinder, volumetric ask, or

other volumetric glassware may be used for volume measurements).

5.13 The distillate in the collection trap is now ready for analysis. Pour contents into an appropriate container. When

pouring, position the vent tube of the collection trap up to prevent trapping of air.

5.14 Bring the volume in the collection trap up to the 25 mL line with DI water (a graduated cylinder, volumetric ask, or

other volumetric glassware may be used for volume measurements).

+1.800.343.5319 or +1.843.881.6560 envexp.com Environmental Express • 18

SimpleDist: Operation and Instruction Manual Care and Maintenance of Your SimpleDist®

Circuitry Diagram:

Table of contents

Other Environmental Express Laboratory Equipment manuals

Environmental Express

Environmental Express 35419-47 User manual

Environmental Express

Environmental Express LE1003 User manual

Environmental Express

Environmental Express HotBlock TKN System Administrator Guide

Environmental Express

Environmental Express SimpleDist Administrator Guide

Environmental Express

Environmental Express 35419-52 User manual