Contents

1.The General Introduction.............................................................................................1

2.Proper usage.....................................................................................................................2

3.Introduction of the product.........................................................................................3

3.1Overview of main components ........................................................................................ 3

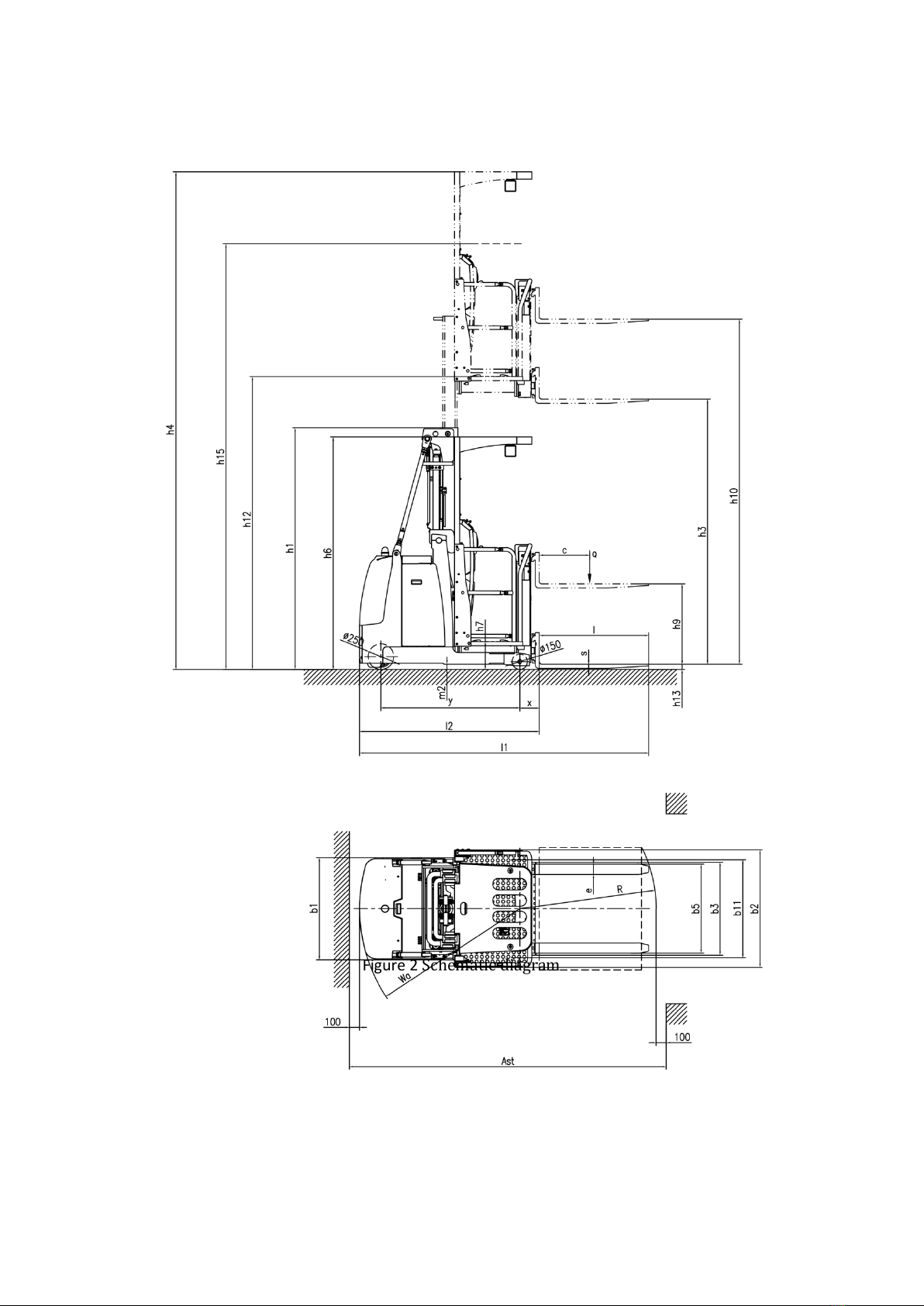

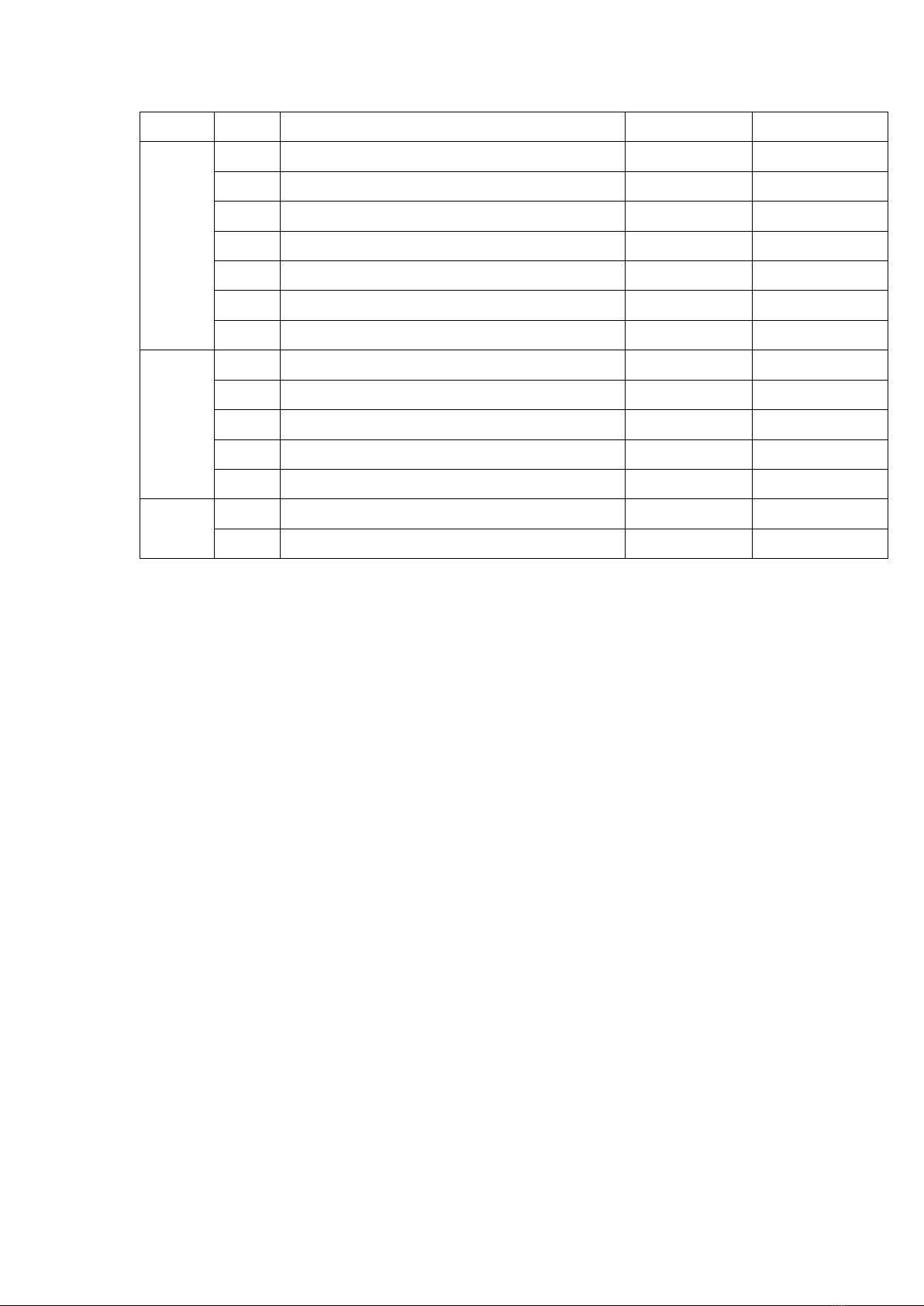

3.2Truck schematic diagram & Model parameters...................................................... 4

3.3Safe operation and warning labels ................................................................................. 7

3.4Name plate ............................................................................................................................. 8

4.Safety Caution...................................................................................................................8

5.Test run,Transportation,Outage............................................................................. 10

5.1Test run .................................................................................................................................10

5.2Lifting & Transportation...................................................................................................10

5.3Outage......................................................................................................................................11

6.Routine Inspection ...................................................................................................... 11

7.The Schematic diagram of Operating Mechanism............................................ 11

8Operating specification............................................................................................... 14

8.1Parking ....................................................................................................................................14

8.2Loading capacity graph.....................................................................................................14

8.3Lifting up/Lowering down ..............................................................................................15

8.4Traveling.................................................................................................................................16

8.5Steering .................................................................................................................................17

8.6Monitor .................................................................................................................................18

8.7Braking ....................................................................................................................................19

8.8Brake structure &Brake Schematic ..............................................................................20

8.9Trouble....................................................................................................................................20

8.10Emergency situations......................................................................................................20

9Changing and Replacement for battery................................................................. 21

9.1Replacement .......................................................................................................................22

9.2Charging ................................................................................................................................23

10.Maintain Introduction .......................................................................................................23