EP Equipment EPT20-15ET User manual

Original Instruction

Operation Manual

EPT18-EHJ

EPT20-18EA

EPT20-ET

EPT20-15ET

EPT20-15ET2

EPT20-15EHJEPT20-15ETL

Part No.508000004646

V4 07/2020

EP EQUIPMENT CO.,LTD. is one of the world’s

leading companies manufacture, design

material handling equipment and provide related

service. With over 100,000 square metres plant

it produces over 100,000 trucks per year, and

provides professional, eective and optimized

material handling solutions worldwide, until now

it has developed three major kinds of business:

Material handling equipment: Focus

on electric forklift and warehouse

equipment

OEM parts: Global parts supply

Imow industry,online: One-stop

industrial products supply

Guided by our customer-oriented concept, EP

has developed service centers in more than

30 countries around the world, from which

customers are able to receive timely local

service. Moreover, 95% of warranty parts can be

shipped out within 24 hours after been ordered.

Through our online after-sales service system,

customers can process their warranty claims,

order spare parts and consult the operation

manuals, maintenance materials and spare

parts catalogs.

With business all over the world, EP has

thousands of employees and hundreds

of agents worldwide to provide our global

customers with prompt local service.

Based on the concept of sharing economy ,

EP also oer rental service for various logistics

equipment. Adhering to the idea “Making the

leasing of logistic equipment more simple”,

EP is devoted to providing customized one-

stop leasing solutions for our customers with

our high quality, reasonable price and prompt

rental service.

EP’s mission&vision is “ Let more people apply

the electrical material handling equipment to

relieve the intensity of labour” and “Let’s grow

together”.

•

•

•

Fig0000-00011OM

EP EQUIPMENT CO., LTD

Address: No.1 Xiaquan Village,

Lingfeng Street, Anji, Huzhou,

Zhejiang

Tel: + 86-0571-28023920

Website: www.ep-ep.com

Email: [email protected]

Thank you for buying our products.

The manual will show you the way of correctly using the truck as well as relevant preventive

maintenance and safety operation. The truck should be operated only by well-trained professionals

and by no means by non-working personnel. Operators are supposed to read through the manual

before actually operating the truck.

With the continuous upgradation and improvement of our company’s products, you may nd a

slight dierence existing between your carrier and some introductions in the manual.

All the information, specications and illustrations in the manual are eective in times of printing

and our company maintains the right to modify the specication (s) or design (s) of our products at

any time without any beforehand notication.

Means that failure to comply can cause risk to life and/or major damage to property.

Please strictly adhere to these safety instructions to avoid personal injury or major damage to

equipment.

Please pay attention to the important safety instructions.

Pay attention to Instruction.

DANGER

i

CAUTION

NOTE

WARNING

Explanations on the manual

Safety signs and corresponding esplations

Preface

Internet address and QR code of

Parts manual

By entering the address http://www.ep-

care.com in a web browser or by

scanning the QR code, Login after

registration, Select “Parts purchase"

function and input part number or model

name to nd the truck.

Note: After registration, please send email

to info@ ep-care.com to activate your

account

The lift truck is designed for transporting and stacking the loads stated in the nameplate.

In particular we refer to:

• the safety rules of your trade association.

• In accordance with the special provisions for driving on public roads specied by national

specications.

• Other local regulations.

The rules for the intended and approved use of industrial trucks must be followed under all

circumstances by the responsible persons, especially by the operator and service personnel.

The user, and not EP, is responsible for any danger arising from applications not authorised by the

manufacturer.

If you want to use the truck for applications not mentioned in this manual, please rst contact your

authorised dealer.

No changes, particularly no modications and additions, may be made to the truck without the

approval of the manufacturer.

• These trucks are electrical low-lift pallet trucks pallet trucks for EPT20-15ET2 / EPT20-ET/

EPT20-15ET / EPT20-18EA.

• EPT15-EHJ and EPT18-EHJ are semi-electrical hand pallect truck with electrically powered drive

wheels.

• These trucks consists of robust steel chassis and is driving on a traction wheel and 2 load

wheels. Caster wheels(for EPT20-18EA,EPT20-ET) provide for good stability even with high

loads.

• These trucks will be stopped by a regenerative service brake and hold by an automatic

electromagnetic parking brake in it’s parking position.

• The load is lifted by a hydraulic cylinder that activates a lifting shaft that transmits the lifting

movement by a push-rod to the load wheels.

• The control handle is used for smooth steering and control of drive speed, lifting and lowering,

braking and the horn without changing the position of the hand. The long tiller shaft allows

eortless steering and a safe distance to the truck. A gas spring returns the control handle

always into a vertical position that activates the brake automatically.

• An emergency reverse switch on the control head protects the operator from being squeezed by

the truck in conned spaces.

• An electronic controller operates all electric functions and guaranties safety.

• A key switch secures the truck from unauthorized use.

• The ergonomic design of the truck guaranties safe and easy operation.

Intended use

Technical description

In the manual, “equipment user” refers to any natural person or legal person directly using or

appointing or authorizing others to use the carrier. In such special situations as renting or sales,

the “equipment user” represents the interested parties supposed to bear operation obligations

as specied by the contractual terms concluded between equipment owner and corresponding

users. Equipment users must ensure the use of the carrier only for purposes specied and timely

eliminate all the dangers that may threaten the life and health of the users themselves or any other

third party, in addition to which they must also strictly abide by accident prevention provisions,

other safety technology provisions and equipment operation, maintenance and repair guidelines,

and ensure that all the operators seriously read and completely understand the contents of the

operation instruction.

Should any violation of the operation instruction occur, the quality guarantee of our company will be

invalid automatically, and our company will assume none of the responsibilities for losses resulting

from any nonstandard operation of the equipment implemented by any client, equipment user or

any third party without the authorization of the client service department of our company.

Obligations and responsibilities of equipment user

Modication

Unauthorized modication to the truck can result in injury or death.

Can not remove, disable or modify any safeguards or other safety devices.

Exception:Only in the event that the truck manufacturer is no longer in business and there is no

successor in the interest to the business, may the user arrange for a modication or alteration to a

powered industrial truck, provided, however, that the user

a) arranges for the modication or alteration to be designed, tested and

implemented by an engineer(s) expert in industrial trucks and their safety.

b)maintains a permanent record of the design, test(s) and implementation of the modication or

alteration.

c) approves and makes appropriate changes to the capacity plate(s), decals, tags and operation

manual.

d) axes a permanent and readily visible label to the truck stating the manner in which the truck

has been modied or altered, together with the date of the modication or alteration and the name

and address of the organization that accomplished those tasks.

Wind forces can aect the stability of a truck when lfting, lowering and transporting loads with large

surface areas .

Light loads must be especially secured when they are subjected to wind forces. This will prevent

the load from sliding or falling.

Stop the truck in both cases.

Wind loads

Declaration

EP EQUIPMENT CO., LTD.

Address: No.1 Xiaquan Village, Lingfeng Street, Anji, Huzhou, Zhejiang

We declare that the machine

Industrial truck: according to this operation manual

Type: according to this operation manual

complies with the most recent version of Machinery Directive 2006/42/EC.

Personnel authorised to compile the technical documents:

See EC/EU Declaration of Conformity

EP EQUIPMENT CO., LTD.

EC/EU Declaration of Conformity

The manufacturer declares that this industrial truck complies with the EC Machinery Directive

and the provisions of other applicable EC/EU directives eective at the time of sale. This can be

veried by means of the EC/EU Declaration of Conformity and the relevant certication label on the

nameplate.

The industrial truck is supplied with the EC/EU Declaration of Conformity document. This

declaration proves that this truck complies with the requirements of the EC Machinery Directive.

Unauthorised modication or additional installation of equipment to the structure of the industrial

truck may aect its safety, and will therefore invalidate the EC/EU Declaration of Conformity.

The EC/EU Declaration of Conformity must be carefully stored and made available to be presented

to the relevant authorities when necessary. If this industrial truck is sold, this declaration document

must be handed over to the new owner.

Legal requirements for marketing

Table of contents

Pg.

A Identication points and data plates...................................................................................... A1

B Operation .............................................................................................................................. B1

2.1Utilization safety specication.............................................................................................. B1

2.1.1 EN standards ........................................................................................................................B2

2.1.2 Conditions for application .....................................................................................................B3

2.1.3 Stability..................................................................................................................................B3

2.2 Display and manipulation ................................................................................................... B4

2.2.1 Control handle......................................................................................................................B4

2.2.2 Key switch............................................................................................................................B5

2.2.3 Display instrument ...............................................................................................................B5

2.3 Truck use and operation .......................................................................................................B7

2.3.1 Preparation for use ...............................................................................................................B7

2.3.2 Comissioning ........................................................................................................................B8

2.3.3 Truck starting.........................................................................................................................B9.5

2.3.4 Runing, swerving and braking ..............................................................................................B11.

2.3.5 Good picking .........................................................................................................................B15.

2.3.6 Parking the truck securely ....................................................................................................B17

2.3.7 Drive directions .....................................................................................................................B18.10

2.3.8 Loading .................................................................................................................................B18

2.3.9 Using the truck on a slope ....................................................................................................B18

2.3.10 Operating the truck without its own drive system ..............................................................B21

2.3.11 Transporting the truck.........................................................................................................B22

2.3.12 Control handle installation ..................................................................................................B23

C Battery use and maintenance ............................................................................................... C1

3.1 Safety and warning............................................................................................................. C1

3.1.1 Safety regulations for handling acid batteries ................................................................. C12.1

3.2 Battery charging ................................................................................................................. C2

3.2.1 Precautions...................................................................................................................... C2

3.2.2 Charging the battery ............................................................................................................C2

3.2.3 Battery charging LED light ..................................................................................................C2

3.2.4 Battery type & dimensions&Charging time...................................................................... C4

3.3 Battery removal and installation ......................................................................................... C5

D Maintenance ......................................................................................................................... D2

4.1 Truck maintenance ............................................................................................................. D2

4.2 Maintenance table .............................................................................................................. D2

E Technical data ....................................................................................................................... E1

REV. 07/2020

1A

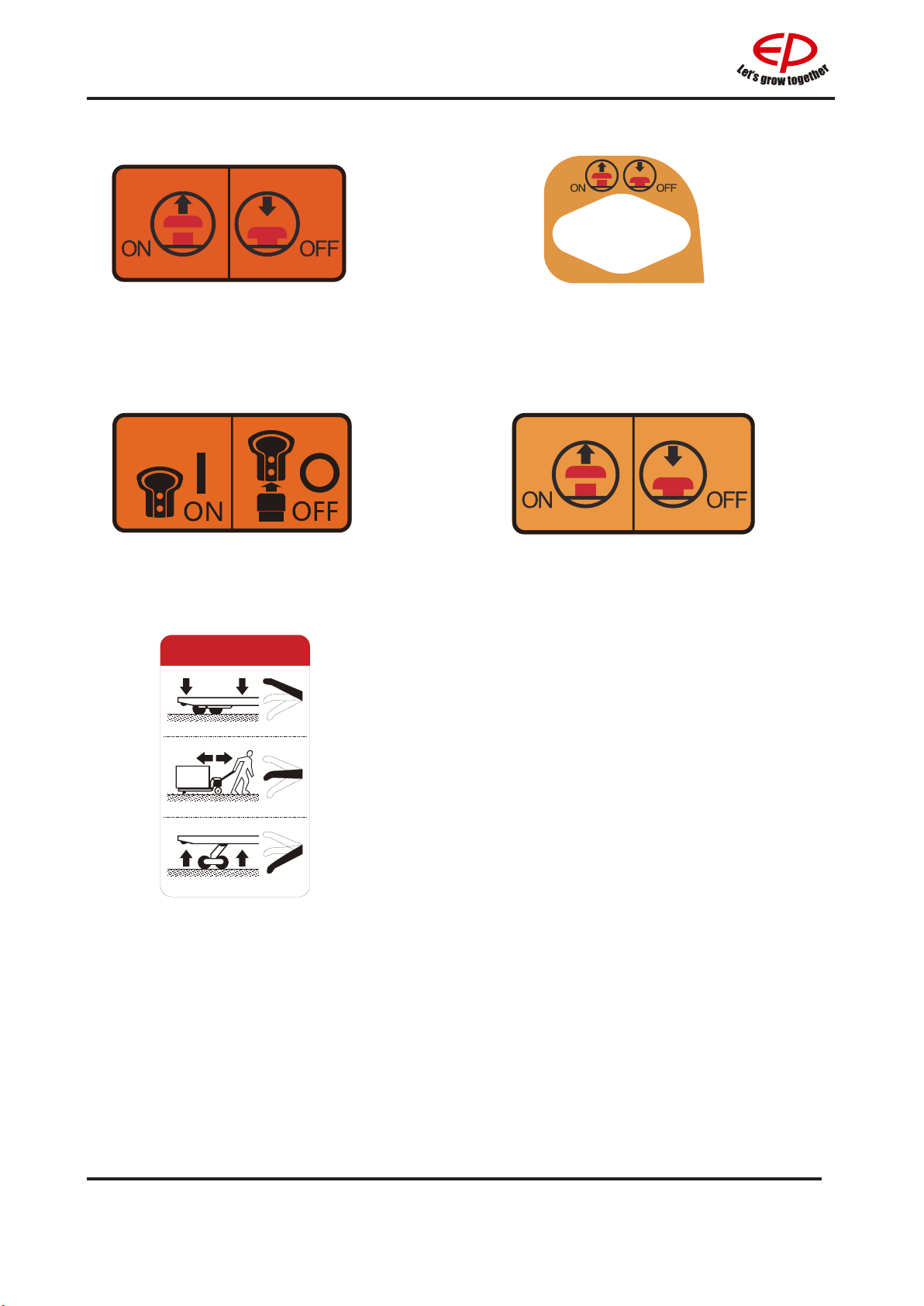

Identication points and data plates

A

Have the nameplates of a truck xed its main body and alarming and funciton labels pasted on

its outer cover or frame.

Should any nameplate or labels lose or be damaged, please conduct replacement immediately

or contact with the sales department or corresponding agent of our company when necessary.

Such truck-related information as product model, serial number, manufacturing date, rated

load lifting capacity, lifting height, load centre distance and dead weight are all shown in the

nameplates.

Nameplate

Instructions label

Anti-pinch label Do not rest on the pallet label

Charging Light indicator Key switch

REV. 07/2020 2A

Emergency stop switch Emergency stop switch

Emergency stop switch

EPT20-15ET2EPT20-15ET

EPT15-EHJ EPT18-EHJ

Operator notice:“lift/lower”

Operator notice:“on/o”

EPT15-EHJ/EPT18-EHJ

REV. 07/2020

3A

Nameplate

Item Description

1 PRODUCT NAME

2MODEL TYPE

3 SERIAL NO.

4 MANUFACTURE DATE

5 LIFT HEIGHT

6 UNLADEN MASS

7UNLADEN MASS WITHOUT

BATTERY

8 BATTERY VOLTAGE

9 RATED DRIVE POWER

10 MAX BATTERY WEIGHT

11 MIN BATTERY WEIGHT

12 RATED CAPACITY

13 LOAD CENTER

Fig0000-00015OM

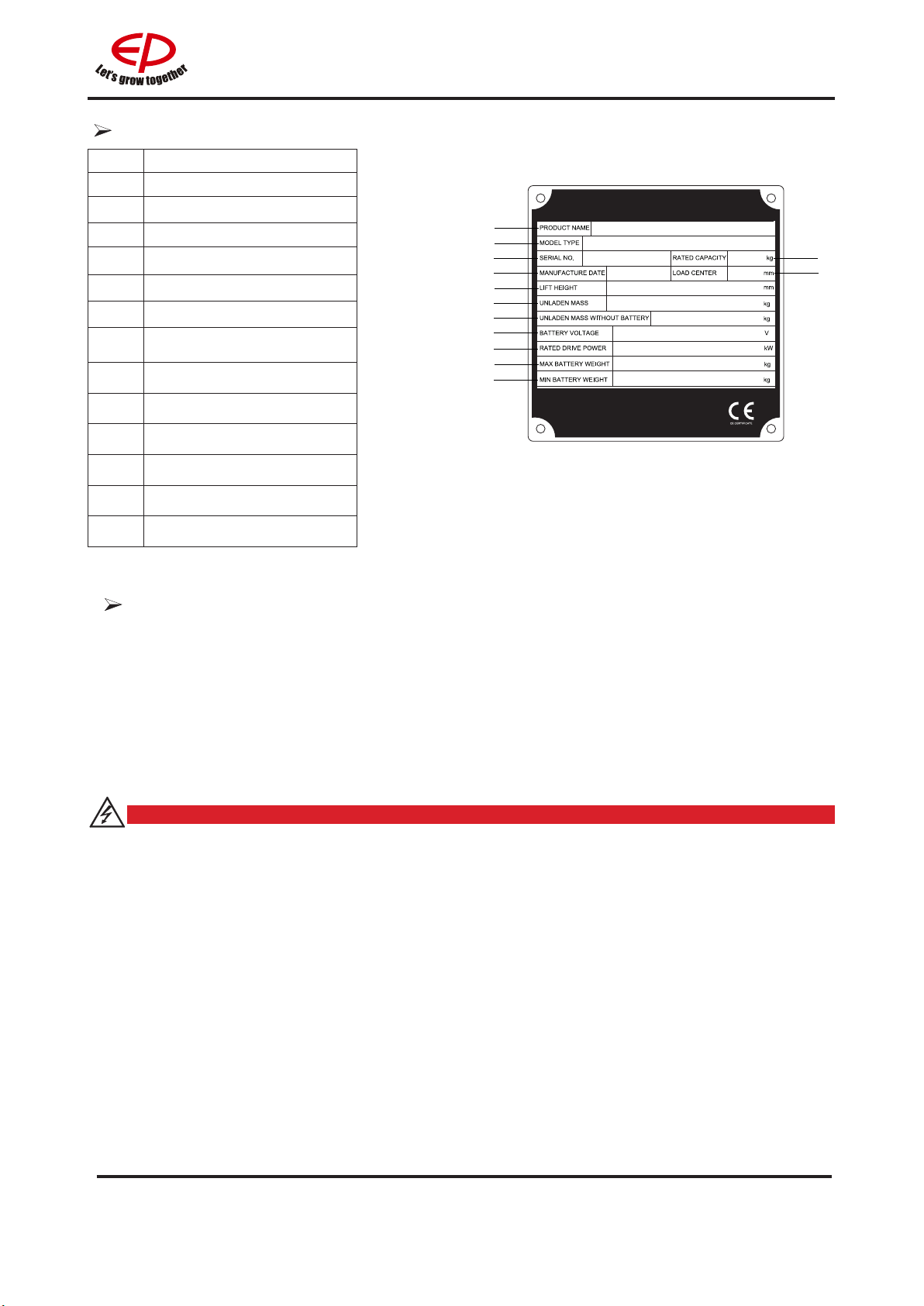

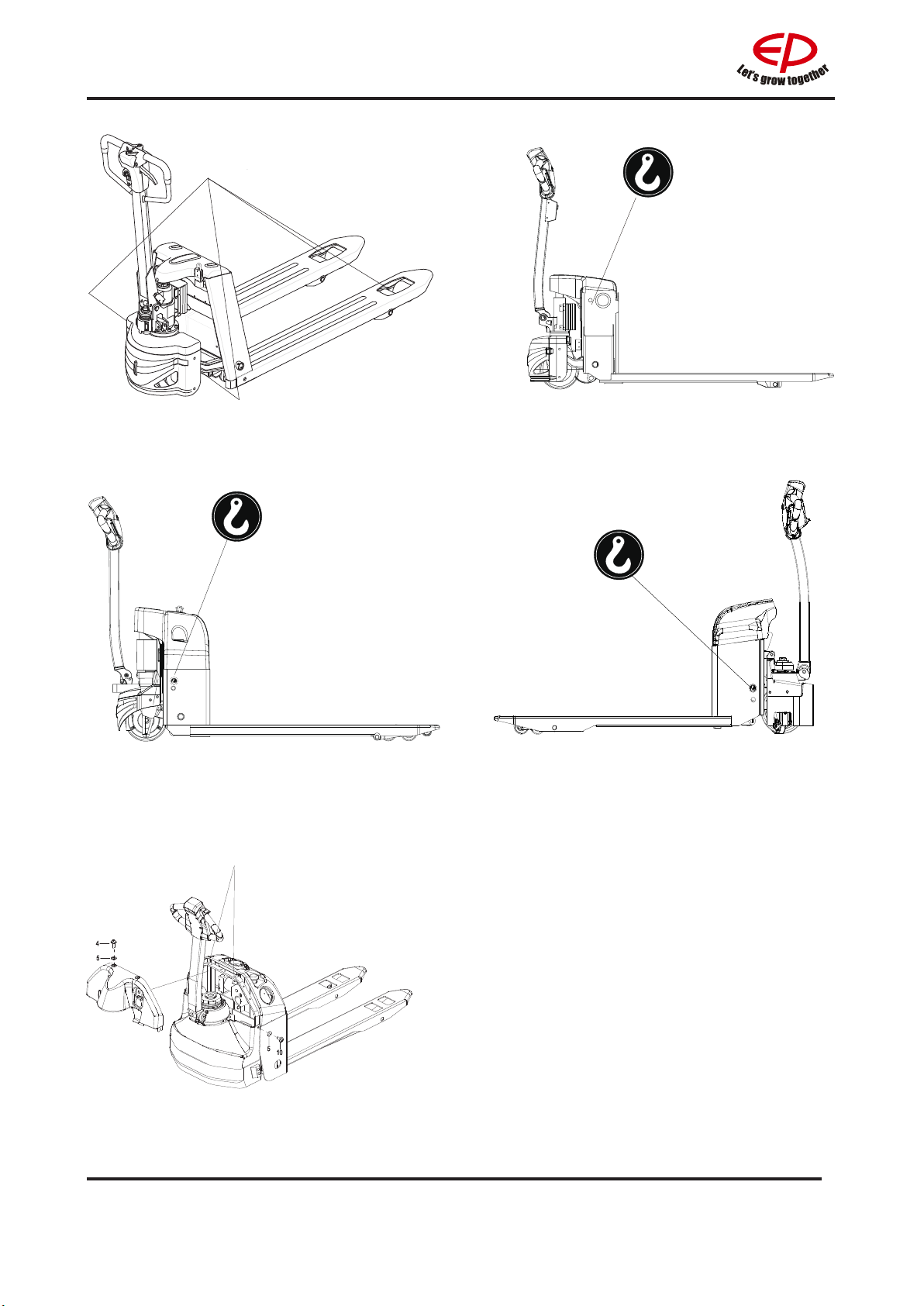

Hoisting

Remove the load before hoisting the pallet truck.

Disconnect the power supply.

Attach slings in the positions identied by the hook symbol.

Ax the crane lifting gear at the attachment points(1).(for EPT15-EHJ/EPT18-EHJ)

Personnel must not stand below or near the truck when the pallet truck is being lifted.

DANGER

Unscrew two screws (4) and two screws (10), then remove the upper cover(see the below

draft). Ax the crane lifting gear at the attachment points(1).(for EPT20-18EA)

1

2

3

4

5

6

7

8

9

10

11

12

13

REV. 07/2020 4A

1

EPT15-EHJ/EPT18-EHJ EPT20-15ET2

EPT20-15ET EPT20-ET

Fig1116-00044OM

Fig1115-00045OM

Fig1114-00046OMFig1122-00047OM

EPT20-18EA Fig1118-00043OM

1

REV. 07/2020

1

B

2.1Utilization safety specication

Operation

B

Applicable environment

temperature: 5 °C - 40 °C

Don’t use the truck in

rainwater.

Don’t use the truck in non-

position.

Avoid the use of the truck by non-

working personnel.

Don’t ride on the truck.

Don’t carry or lift people by the

truck.

Don’t use the truck on slippery

road surfaces.

(such as road surfaces with oil

stain or residual snow or those

frozen ones )

Don’t carry goods on steep

slope to prevent goods

from sliding o.

Conditions of operation road surface: the truck should run on solid, at, level and paved road

surfaces (including both running and lifting)

i

NOTE

i

NOTE

Fig0000-00120OM

Fig0000-00121OM

Improper use

Industrial trucks must be specially equipped and approved for continuous use in environments

with temperatures below 5 °C or in cold stores respectively with extreme temperatures or

humidity changes.

REV. 07/2020 2B

Don’t place any part of

your body in any moving

part of the truck to avoid

being clamped.

Don’t leave the truck before

it is parked as regulated.

Don’t use the truck when any

non-working personnel is in the

dangerous area.

Don’t be distracted when using the

truck.

Don’t be distracted when using the

truck.

2.1.1 EN standards

Continuous sound level: 74 dB(A)

according to EN 12053 as stipulated in ISO 4871

The continuous sound level is a value averaged according to standard regulations, taking the

sound pressure level into account when driving, lifting and idling. The sound pressure level is

measured at the ear.

Vibrations to which the hands and arms are exposed

The following value is valid for all truck models:

• āw< 2.5 m/s2

It is mandatory to specify the hand-arm vibrations, even where the values do not

indicate any danger, as in this case.

The value expressed above can be used to compare forklift trucks of the same category. It cannot

be used to determine the operator's daily exposure to vibrations during real operation of the

truck; these vibrations depend on the conditions of use (oor conditions, method of use etc.) and

therefore daily exposure must be calculated using data from

the place of use.

Electromagnetic compatibility (EMC)

The manufacturer conrms compliance with the limit values for electromagnetic emission and

interference immunity as well as testing of static electricity discharge according to EN 12895 and

the references to other standards contained therein.

Electrical or electronic components and their arrangement may only be modied after written

approval by the manufacturer has been obtained.

Fig1115-00122OM

REV. 07/2020

3

B

2.1.2 Conditions for application

Working condition requirements:

• The truck's maximum operation altitude is up to 2000m.

• Trucks can only be operated in adequately illuminated working areas to avoid injuries. In case

of insucient light, an additional lighting equipment is needed to ensure that the driver can see

properly.

• If you must travel on an incline, the gradients should be below A% at full load, or below

B%without a load.(For the value of A and B, refer to the Gradability in technical data)

2.1.3 Stability

Stability is guaranteed if your truck is used properly in accordance with its intended

purpose. Common reasons for a loss of truck stability include:

• Emergency stops or sharp turns

• Driving with a raised load or a load handling device

• Turning the vehicle around on or driving across a slope

• Driving up or down a slope with the load pointing downhill

• Driving with a wide load

• Carrying a swinging load

• Driving near the edge of a ramp or up steps

• Tilting the mast forward while carrying araised load

• Driving on uneven surfaces

• Overloading the truck

• Carrying bulky loads in strong winds

• When carrying liquid, its centre of mass inside the container may shift due to inertial force (such

as when pulling away, braking or turning)

Wind loads

Wind forces can aect the stability of a truck when lfting, lowering and transporting loads with large

surface areas .

Light loads must be especially secured when they are subjected to wind forces. This will prevent

the load from sliding or falling. Stop the truck in both cases.

REV. 07/2020 4B

2.2.1 Control handle

2.2 Display and manipulation

EPT20-15ET2 / EPT20-ET/

EPT20-15ET / EPT20-18EA EPT20-15EHJ / EPT18-EHJ

15 Drive forward button travel forward direction (see page B11)

16 Drive backward button travel backward direction (see page B11)

17 Lowering button Lower forks

18 Ling button Lift forks

19 Drive switch Controls travel direction and speed (see page B11)

20 Horn button Send out sound warning signals

21 Emergency reverse button Through touching the button, truck drives away from

operator.

Fig1115-00005OM Fig1122-00006OM

REV. 07/2020

5

B

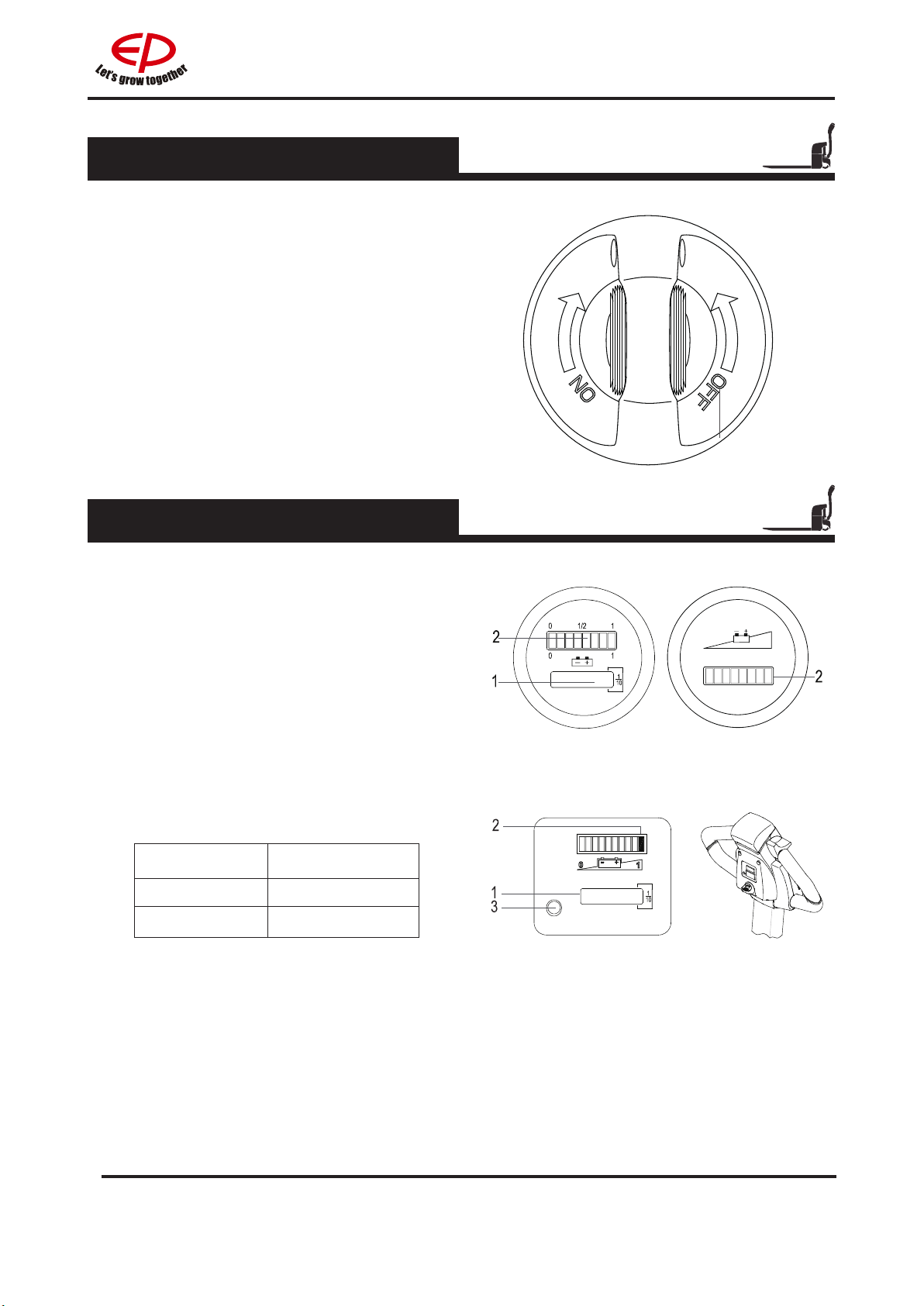

2.2.2 Key switch

1.Key switch A

Connect and interrupt control current.

• When the key rotates to gear “OFF”,

the control current of the truck will be

interrupted;

• When the key rotates to gear “ON”,

the control current of the truck will be

connected.

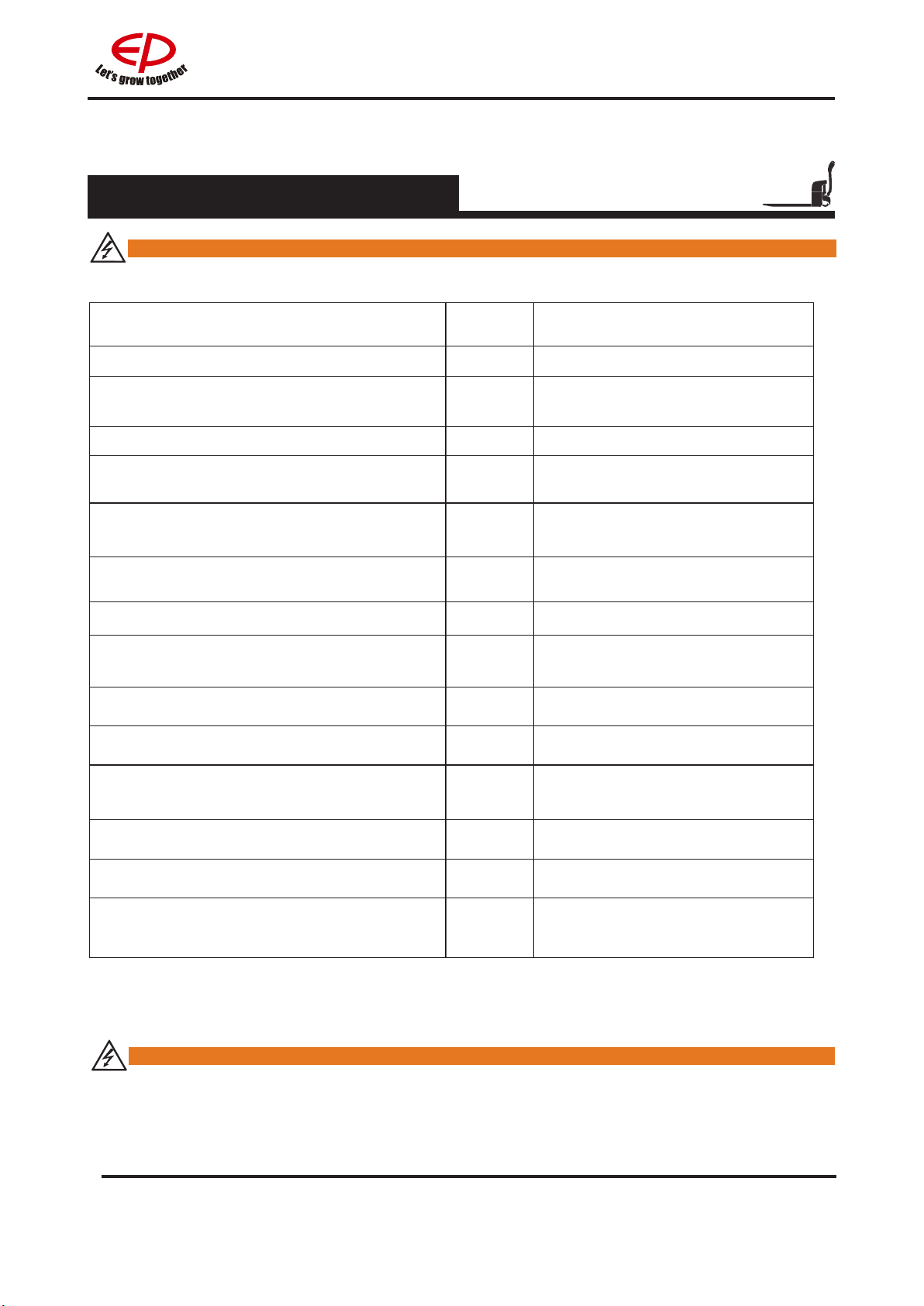

2.2.3 Display instrument

(EPT20-15ET /EPT20-18EA)

1

with hour meter Without hour meter

with hour meter without hour meter

Battery discharge indicator

The LCD display (1) show the

operating hours.

LCD (2) displays the residual electric

charge of the battery;

1.2.3

(EPT20-15ET2/ EPT20-ET)

LCD (1) displays the residual electric

charge of the battery;

LCD (2) displays the total operation time

of the truck;

LCD (3) is a fault indicating light.

DISPLAY DESCRIPTION

Continuous red Normal

Flashing Truck failure.

Refer to relevant descriptions in

“discharge indicator and hour meter” for

the display functions of LCD (1).

Fig0000-00070OM

Fig1115-00006OM

Fig1116-00006OM

REV. 07/2020 6B

The LCD display (2) show battery residual capacity.

When the truck has been released via the key switch, the battery charge status is displayed.

The colour of the LCD (2) represent the following conditions:

Component LCD colour residual capacity

Standard battery residual capacity

Green 70-100%

Orange 30-60%

Flashing Red 0-20%

If residual battery capacity is below 30%, One ashing Red segments.

If residual battery capacity is below 20%, Two ashing Red segments. The battery must be

charged.

EPT20-15EHJ / EPT18-EHJ

• When the truck starts up, the battery

discharge status is shown via the the

battery discharge indicator.

• If the battery is fully charged, each LCD on

the battery discharge indicator is lit red.

• If the last three LCDS are lit, this indicates

that 70% of the battery capacity has been

used and the reserves are being utilised.

• If the last two LCDs are lit,this indicates that

80% ofthe battery capacity has been used.

The battery must be charged.

Fig1122-00011OM

Operating hours display(1)

Display range between 0.0 and 99,999.0 hours. Travel and lifting are logged. This is a backlit

display.

Power up test on power up the display shows:

• the operating hours.

• the charge status.

REV. 07/2020

7

B

2.3 Truck use and operation

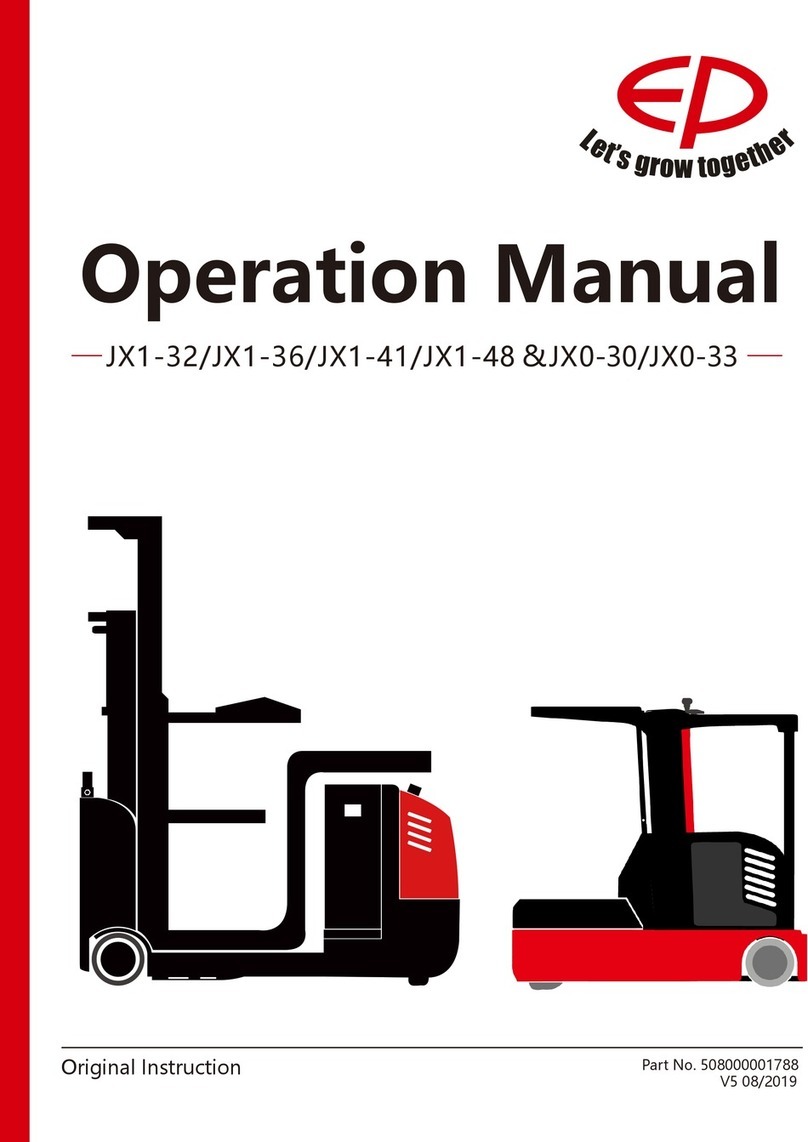

2.3.1 Preparation for use

The following are inspection and preparation operations that must be implemented before the

truck is put into daily use.

Daily Check Items O.K.(√) Remark

Check for Fluid Leakage

Check operation switch, display equipment

and component functions.

Check horn.

Check forward and reverse driving control

functions.

Check the function of the service braking,

reverse braking, regenerative braking.

Check lifting and lowering control functions.

Check emergency safety reverser function.

Check the battery installation, making

sure not to damage the battery cables.

Check the function of the steering system

Check the battery charging connector.

Check the drive wheels and rollers for wear

and damage.

Check the hydraulic functions.

Check brake function of electromagnetic

brakes.

Check whether optional functions are

operating normally.

WARNING

Table 1: Table of Daily Inspections by Operators is only a sample table for the daily inspections of

operators, and it can be adjusted according to specic requirements.

The truck should be regularly maintained by qualied maintenance engineers or technicians

that have passed the training of and also been authorized by the manufacturer.

WARNING

REV. 07/2020 8B

The truck must only be operated on battery current!

To prepare the truck for operation after delivery or transportation, the following operations must be

performed:

• Check the equipment for completeness.

• If necessary, install the battery. Make sure that the battery cable is not damaged.

• Fully charge the battery.

• Check for Fluid Leakage.

• Check the brake function.

• Check the lifting and lowering function.

• Check the driving function.

• Check the steering function.

The truck can now be started, see 2.3.3

2.3.2 Comissioning

WARNING

Wheel attening

If the truck has been parked for a long period, the wheel surfaces may tend to atten.

This attening has a negative eect on the safety and stability of the truck.

Once the truck has covered a certain distance, the attening will disappear.

If the truck is delivered in multiple parts, setup and commissioning must only be performed by

trained, authorised personnel.

i

NOTE

These trucks must only be operated with a lead-Acid batteries.

REV. 07/2020

9

B

2.3.3 Truck starting

1. Release the emergency stop switch. (Insert the emergency disconnect for EPT15-EHJ)

EPT-18EA

EPT20-15ET2

EPT20-15ET

EPT-15EHJ

EPT20-ET

EPT-18EHJ

Fig1115-00007OM Fig1118-00008OM

Fig1114-00009OM

Fig1122-00010OM

Fig1116-00011OM

Other manuals for EPT20-15ET

2

This manual suits for next models

6

Table of contents

Other EP Equipment Forklift manuals

EP Equipment

EP Equipment JX1-32 User manual

EP Equipment

EP Equipment IMOW ICE251 User manual

EP Equipment

EP Equipment CPD15/18/20FVD8(-C) User manual

EP Equipment

EP Equipment EPT20-15ET User manual

EP Equipment

EP Equipment EPL151 User manual

EP Equipment

EP Equipment EPT20-20RA User manual

EP Equipment

EP Equipment JX0-30 User manual

EP Equipment

EP Equipment EPL1531 User manual

EP Equipment

EP Equipment EPL153 User manual

EP Equipment

EP Equipment EPE151 User manual