CONTENTS

I

.About

Safety····························...···········...···········... ···········..···········...···········..

·······2

I.

Main Use of Forklift Trucks· ·····························"···········"·············2

2.

Working environment and Areas of Forklift Trucks·······························.············2

3.

Safety Problem Before Use··· ············..············. ············ 5

4.

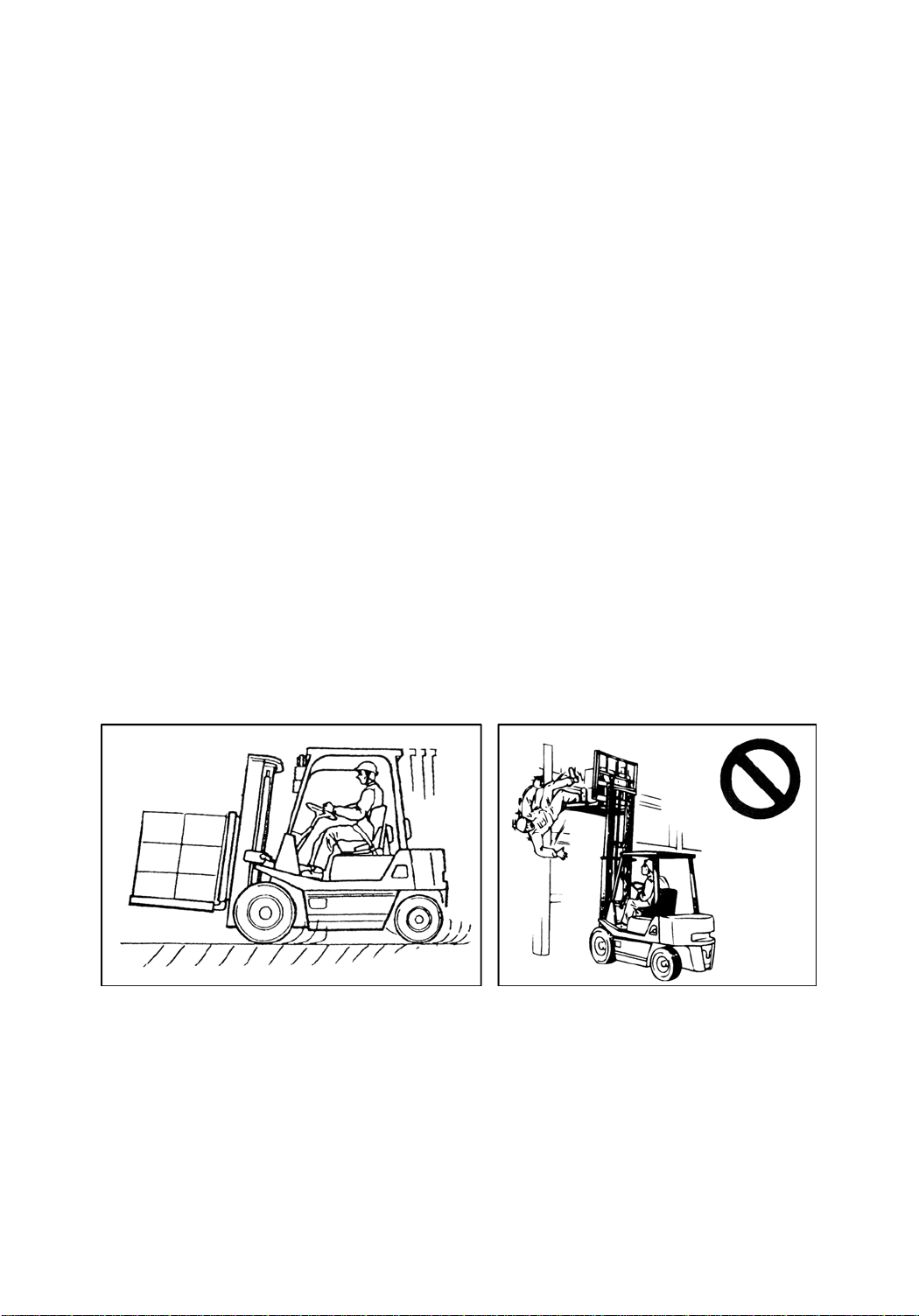

Safety Problem During Operation········..···········....··········..············..············. ····· 8

5.

Safety Problem During Service···············...··········....··········....··········... ··········... ·····19

6.

Safety

Problem

of

Battery

Using

•

•······•······•·········•······•······•·········•······•············.

·····22

7.

Safety problems during attachments installation, adjustment and using

...................

25

8.

Safety problem during LPG truck

...................................................................................

26

9.

Decal ............................................

II

. Operation Device & Use Method

I.Liquid Crystal Displayer················

........ 29

..... 39

.

...........................................42

2.

Switches············· ·················...... ·······..................................·······...... ······· ....... ..·· 44

3.

Controls

············· ....................... ········.............................................. ········ .............45

4.

Body

&

Others

···

·

····

···

······

·

··

·

·

...

··

·

······

·

·

...

··

·

··

·

····

··..

·····

·

····

···

··

·

······

·

·

...

··

·

······

·

·

...

•

•••• •••

50

5.

Cab (optional)

···········....·········....··········....··········....··········....·········....··········... ·

57

6.

Safety

devices

60

III

.Driving and Operation·

....................................................................................................

62

I.Notes on New Truck Usage

...............................................................................................

62

2.

Relationship Between Load and Stability of Truck····....·.·······....··········...············62

3.

Load Center and Rated Load

.............................................................................................

62

4.

Stability of Forklift Truck·····························............................................................. 63

5.

Transporting and Loading the Truck

•

•

63

6.

Before starting Engine & After Engine Has Started ········....··········..···········...

··

64

7.

Traveling··················

··················

·······································.. ···········.. ············..·

...

65

8.

Pick up

·········..············..············..···········..············..············..···········

...69

9.

Stacking Operation

10.

Picking Operation ············

11.

Notes when the truck isequipped with solid tire

12.

Storing ...

N .Periodic Inspection & Servicing··

I .General Rules On Inspection

2.Inspection Contents ··

3.Maintenance ·················

4.

Preventive Maintenance Service Schedule··

V

.Others·················

·············

·············

..... 70

.

.....................................................

71

72

.

72

73

_74

. 74

83

85

99

I. Lubrication

chart ·

·············

····························..···

········..···

·······.

···············99

2.Fuel

and

lubricants

used

for

forklift

truck

···

·..··

·

··

··

··

·

··..··

·

··

·

·····....····

·

··

·

··..

•

•••• • • ••

•

·

·

•

•

1OO