L-SOLUTION 100 Ex Fibre machine . 4 First contact

System operation.............................................................................. 51

How it works.................................................................................................................................51

The control panel...........................................................................................................................53

The engraving menu ......................................................................................................................58

Engraving menu description............................................................................................................60

Automaton function (user standard Inputs/Outputs)...........................................................................68

Running the machine step by step .................................................... 69

Powering on..................................................................................................................................69

Creating the graphic.......................................................................................................................69

Setting the drivers' properties .........................................................................................................69

Downloading the le.......................................................................................................................69

Positioning the plate.......................................................................................................................70

Focusing the LASER beam...............................................................................................................70

Starting the engraving process........................................................................................................71

Removing and reloading the material................................................................................................72

Problems and solutions...................................................................................................................73

Options and accessories.................................................................... 74

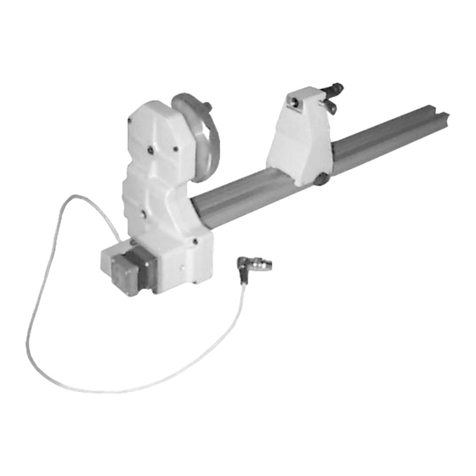

Cylinder attachment.......................................................................................................................74

L-SOLUTION 100 EX (Fibre) vacuum table.........................................................................................74

Compressor kit (air assist)..............................................................................................................75

Honeycomb cutting table ................................................................................................................75

Fiber lens kits................................................................................................................................75

Materials for Fiber LASER engraving ................................................. 76

Safety..........................................................................................................................................76

Printer driver setting tips ................................................................................................................77

List of materials for Fiber LASER engraving .......................................................................................77

General maintenance ........................................................................ 78

Suggested cleaning and maintenance supplies...................................................................................78

System cleaning............................................................................................................................79

Optics cleaning..............................................................................................................................80

Maintenance schedule ....................................................................................................................81

Autofocus adjustment.....................................................................................................................82

Technical characteristics................................................................... 85

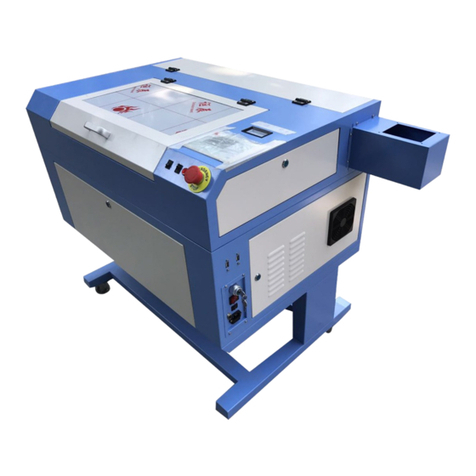

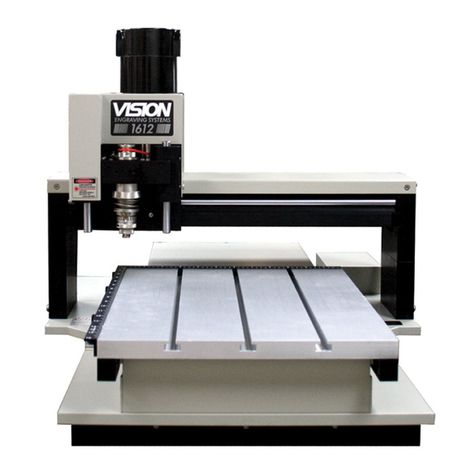

Physical characteristics...................................................................................................................85

Electrical characteristics..................................................................................................................86

Firmware and driver characteristics ..................................................................................................86

Optional accessories.......................................................................................................................87

Appendices........................................................................................ 88

Gravograph machines - Soft setup ...................................................................................................88