Table of Contents iii

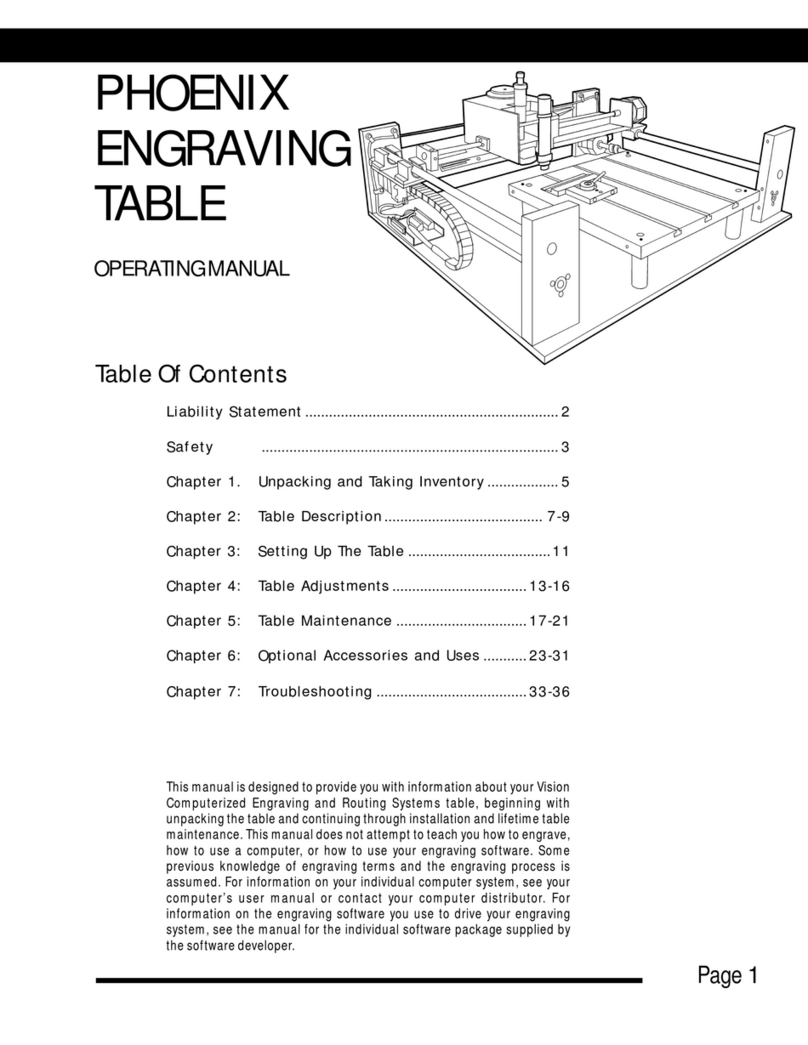

Table of Contents

CHAPTER 1 - BEFORE YOU BEGIN 5

About This Manual ........................................................................................................................................5

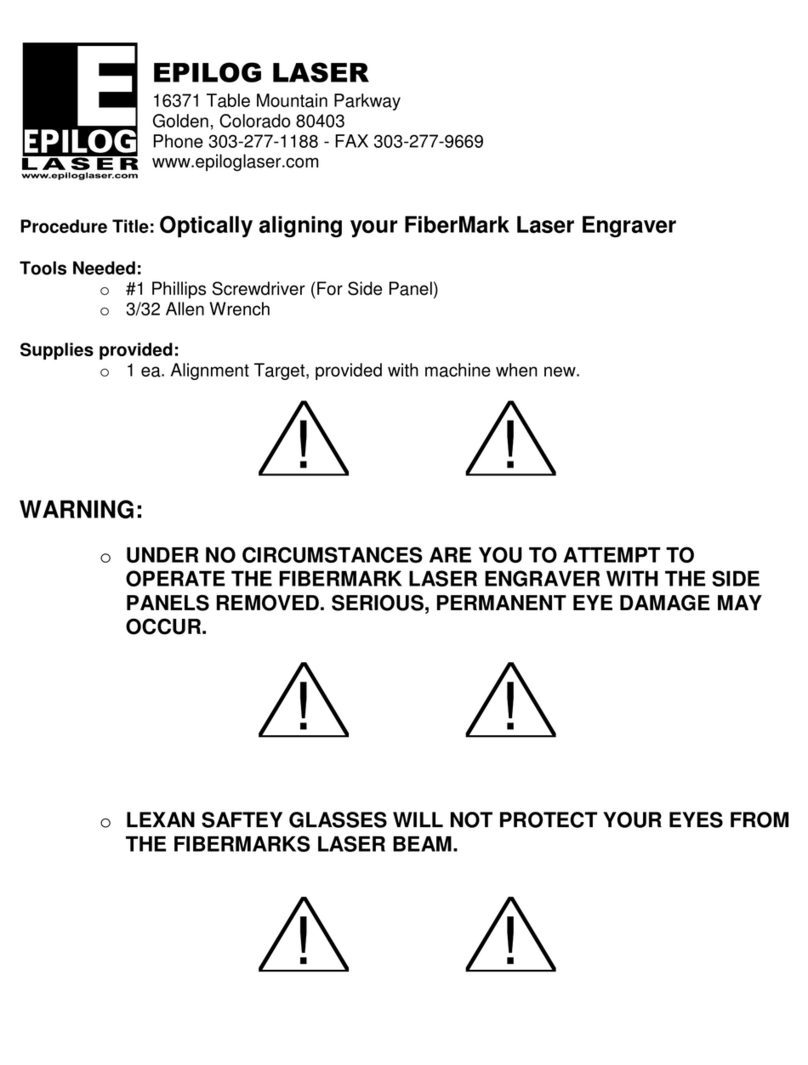

Safety ...............................................................................................................................................................5

Unpacking and Taking Inventory.................................................................................................................6

Specifications ..................................................................................................................................................6

CHAPTER 2 - INSTALLATION 7

Hooking up the table......................................................................................................................................7

CHAPTER 3 - OPERATIONS 11

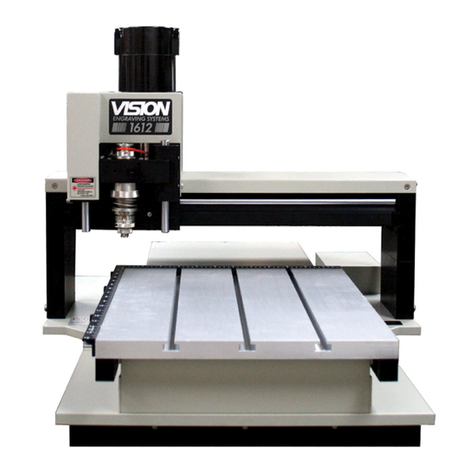

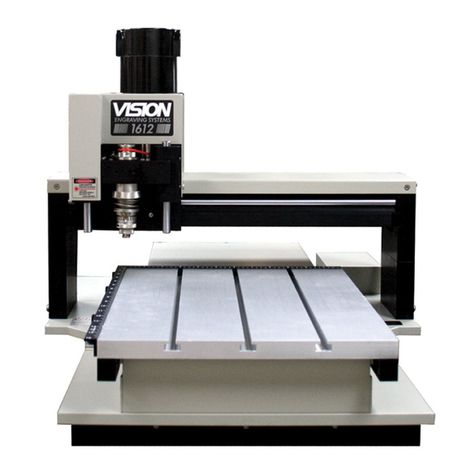

Machine Description & Terminology.........................................................................................................11

DEFINITION OF TERMS 11

Flat Engraving..............................................................................................................................................14

Flat Objects - Initial Setup..........................................................................................................................................14

Plates...........................................................................................................................................................................17

Pens.............................................................................................................................................................................17

Special Shapes ............................................................................................................................................................18

Rotary Engraving.........................................................................................................................................18

Round Objects - Initial Setup...................................................................................................................................... 18

Level Surface Engraving............................................................................................................................................. 20

Angled Engraving .......................................................................................................................................................21

Adjusting the Spindle...................................................................................................................................23

Diamond Drag Engraving ...........................................................................................................................................23

Rotary Engraving........................................................................................................................................................24

Burnish Engraving ......................................................................................................................................................26

Non Nose Riding Rotary Engraving ...........................................................................................................................28

CHAPTER 4 - OPTIONAL ACCESSORIES 31

Clamping Devices .........................................................................................................................................31

Vacuum Chip Removal System...................................................................................................................33