EpiSensor ZPC-10 User manual

User Guide

Wireless Pulse Counter

Applies to: ZPC-10, ZPC-12, ZPC-20, ZPC-22

EPI-058-00

© EpiSensor

Table of Contents

Safety Information 4

Electrical Installation 4

Intended Use 6

Related Documents 6

Introduction 6

Pulse Output Installation 7

Configuring the Jumpers 7

Pulse Types 8

Dry Pulse 9

Open Collector Pulse 9

Active Pulse 9

Pulse Rate 10

Pulse Width 10

User Interface 10

Status LED 11

Alt LED 11

Mode Button 12

Install Mode 12

Electrical Installation 13

Mechanical 13

Enclosure & Label Material 13

Mounting Instructions 13

Opening the Enclosure 14

Tamper Evident Seals 14

Compliance 15

Battery Life 16

Page 2of 21

Safety Information

Please read these instructions carefully before trying to install, operate, service or maintain the ZPC. The

following special notes may appear throughout the user guide (or on the equipment labels) to warn of potential

hazards or to call attention information that clarifies or simplifies a procedure for users.

Symbol

Description

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an

electrical hazard exists which will result in personal injury if the instructions are not

followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Electrical Installation

Electrical equipment should be installed, operated, serviced and maintained only by qualified personnel. No

responsibility is assumed by EpiSensor for any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction, installation, and operation of

electrical equipment and has received safety training to recognize and avoid the hazards involved.

Installation, wiring, testing and service must be performed in accordance with all local and national electrical

codes.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only

after reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the

equipment may be impaired.

Page 4of 21

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources

of electric power. Assume that all circuits are live until they have been completely de-energized,

tested, and tagged. Pay particular attention to the design of the power system. Consider all sources of

power, including the possibility of backfeeding.

➔Turn off all power supplying the ZPC and the area in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been

left inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into an energised

bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter

is installed, disconnect all input and output wires to the ZPC.

➔High voltage testing may damage electronic components contained in the ZPC.

➔Failure to follow these instructions will result in death or serious injury.

Installation & Safety Notes

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified

personnel. EpiSensor does not assume any responsibility for any consequences arising out of the use

of this equipment.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

Page 5of 21

Intended Use

Do not use this device for critical control or protection applications where human or equipment safety relies on

the operation of the control circuit. Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Related Documents

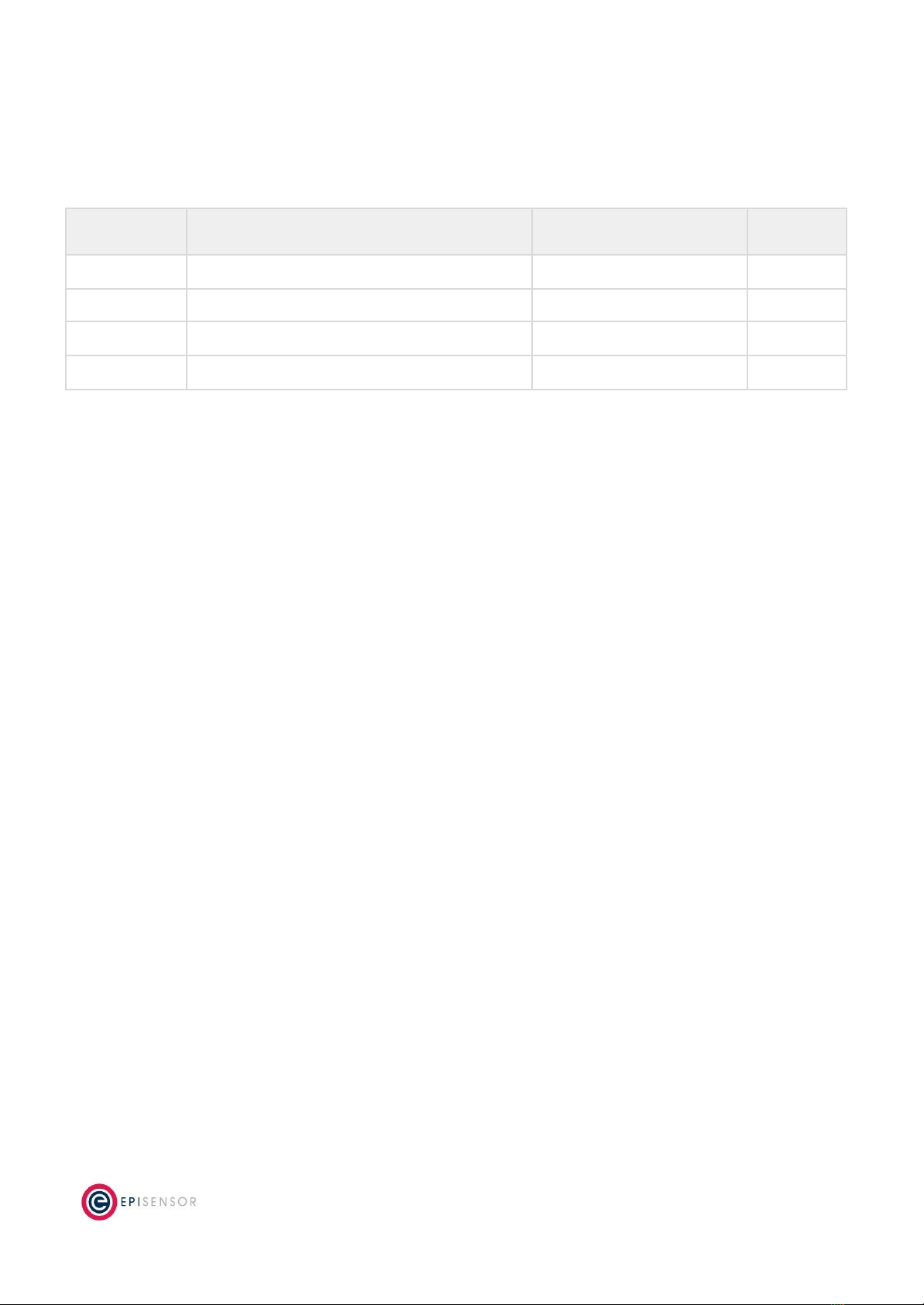

Related installation and configuration documents are listed in the following table:

Document

Reference No.

EpiSensor ZPC Datasheet

EPI-072-00

Install Sheet for ZPC-1X

EPI-073-00

Install Sheet for ZPC-2X

EPI-074-00

Gateway API User Guide

ESE-009-08

Introduction

EpiSensor’s ZPC Pulse Counter is intended to interface with sensor products which produce either a dry contact

(relay), open collector, or an active voltage pulse output. The ZPC reports the data through the wireless sensor

network to the Gateway.

The ZPC Pulse Counter interfaces with existing meters that provide a pulsed output (gas or water flow, power

consumption, etc.). The ZPC reports data in terms of the ‘number of pulses counted’ and users of 3rd party

software systems can interpret these values and convert to the appropriate Units of Measure for the sensor. The

ZPC-10/12 product variants are battery powered, and the ZPC-20/22 are mains powered versions. The available

product variants are as follows:

SKU

Description

ZPC-10

Single Channel, Battery Powered Pulse Counter

ZPC-12

Dual Channel, Battery Powered Pulse Counter

ZPC-20

Single Channel Mains Powered Pulse Counter

ZPC-22

Dual Channel Mains Powered Pulse Counter

Page 6of 21

Pulse Output Installation

The pulse wires should be fed through the enclosure’s M10 waterproof glands and connected to the terminal

block, taking note of the positive and negative terminals. There will be 2 terminals used per channel, so the

dual-channel pulse counter would use 4 terminals. The pulse input wires are connected to IN1 for single channel

models, and IN1 and IN2 for dual-channel models.

Diagram of a pulse output connected to Input 1 of the single-channel ZPC-10

Note: the single-channel pulse counter may use the same hardware as the dual channel version and so would

also have a 4-pin terminal block. However, only the first channel (IN1) will be enabled on the ZPC-10/12 variants.

Dry pulses are not polarity sensitive, but Open Collector and Active pulses are polarity sensitive. Take note of the

positive and negative terminals for both inputs.

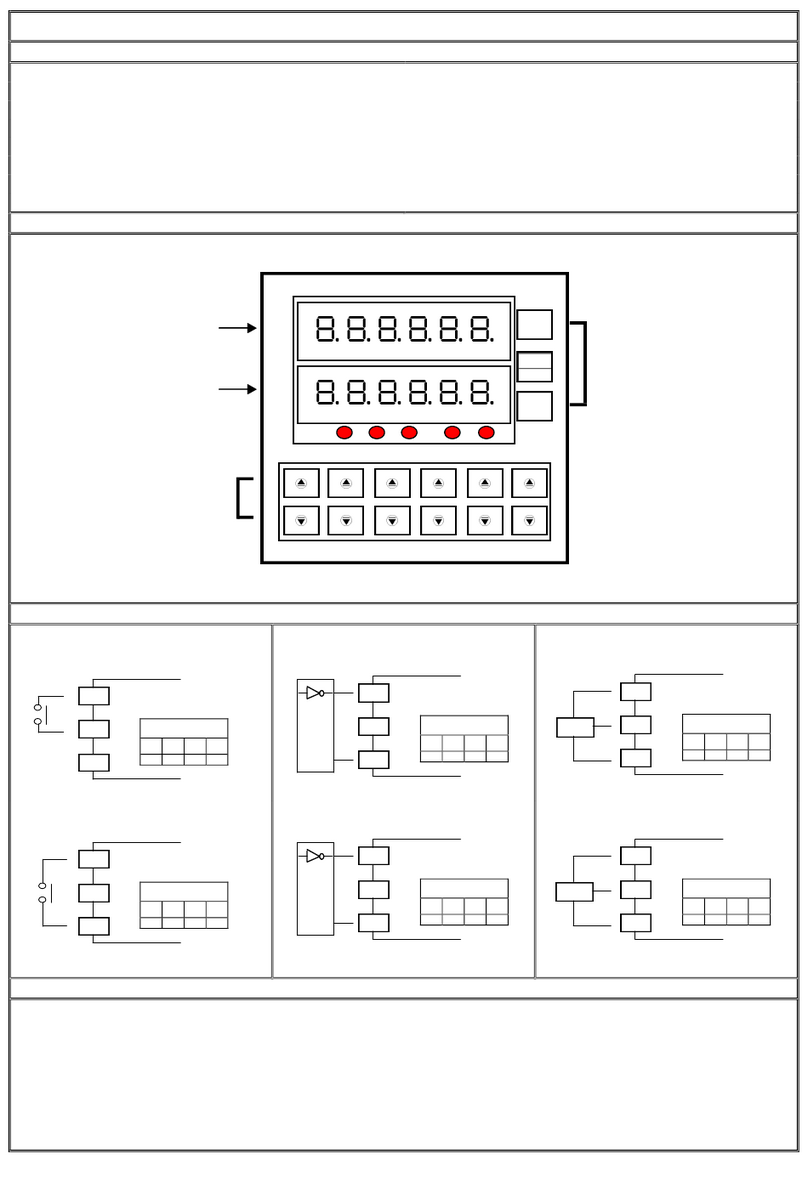

Configuring the Jumpers

To the right of the terminal block there is a selector grid that is used to configure the ZPC for different types of

pulse inputs. There are two rows of jumpers in the grid, the top row for IN1 and the bottom for IN2. The columns

of the grid are used to configure the pulse type. For Battery Powered Pulse Counters the selector options are:

●T for Temperature Sensors (Not used on the ZPC product range)

●AP for Active Pulse Inputs

●DP for Dry Pulse Inputs, or Open Collector Inputs

The image below shows a single-channel battery powered pulse counter (ZPC-10) configured for a Dry Pulse

Input. Note that because this is a single channel device, the location of the jumper for Input 2 is not important.

Page 7of 21

Diagram showing a ZPC-10 with Input 1 configured for a dry pulse (DP)

For Mains Powered Pulse Counters the selector options are:

●AP for Active Pulse Inputs

●DP for Dry Pulse Inputs, or Open Collector Inputs

●0-10 for 0-10 Volt Sensors (not used on the ZPC product range)

●4-20 for 4-20 Milliamp Sensors (not used on the ZPC product range)

The image below shows a dual channel mains powered pulse counter where IN1 is configured for a Dry Pulse

and IN2 is configured for an Active Pulse:

Diagram showing ZPC-22 with IN1 configured for an Active Pulse, and IN2 configured for a Dry Pulse

Pulse Types

This section describes the operation of the 3 different pulse types.

Page 8of 21

Dry Pulse

A dry pulse can be thought of as a simple switch. Window alarm contacts or reed switches would be examples of

such a connection. In this configuration, a small voltage is applied to the + terminal of the IN connector. A pulse

is detected when this signal is connected to the negative (–) terminal of the IN connector.

The selector grid for Dry Pulse should be on the “DP” setting.

Open Collector Pulse

An Open Collector pulse is generally used by electronic meters. The diagram below is an example of such a Pulse.

Schematic diagram of an open collector pulse output

When the Integrated Circuit (IC) Output is pulsed, the signal on the “Open Collector” gets connected to the IC’s

Ground. This system is polarity sensitive. The Open Collector connection must be connected to the positive (+)

terminal of the IN connector and IC Ground must be connected to the negative (–) terminal of the IN connector.

As the Open Collector is simply an electronic switch, the selector grid for the Open Collector Pulse should be on

the “DP” setting.

Active Pulse

An active pulse occurs when the system generating the pulse applies a positive DC voltage for a short period of

time. This system is polarity sensitive. The Pulse Generator and ZPC units share a common Ground on the

negative (–) terminal of the IN connector. The positive DC voltage representing the pulse must be connected to

the positive (+) terminal of the IN connector.

Note: The Active Pulse Voltage on the ZPC-20/22 should not exceed 40 Volts!

The jumper should be in the “AP” position on the selector grid for monitoring Active Pulse outputs.

Page 9of 21

Pulse Rate

Depending on the version of ZPC you have, the maximum pulse rate that the ZPC can handle will vary. For mains

powered versions (ZPC-20, ZPC-22) the maximum pulse rate is 40 pulses per second, or 40Hz. For battery

powered versions, the limit is 4Hz.

Pulse Width

The pulse width is the length of time the pulse needs to remain in a changed state to ensure the pulse is

registered on the ZPC.

The minimum pulse width is 10 milliseconds, but this should be configured to a higher value where possible in

the meter or other device that’s generating the pulse. There is no maximum pulse width.

For battery powered pulse counters, the “active state” (closed for dry contacts, or logic high for an active pulse)

should be kept as short as possible. The ZPC will consume battery power while the pulse is in the active state.

Sensors & Settings

Node level settings, sensor level settings and a list of sensors (data feeds) available on the ZPC are listed below.

Data reporting can be enabled or disabled as required for each of the sensors listed.

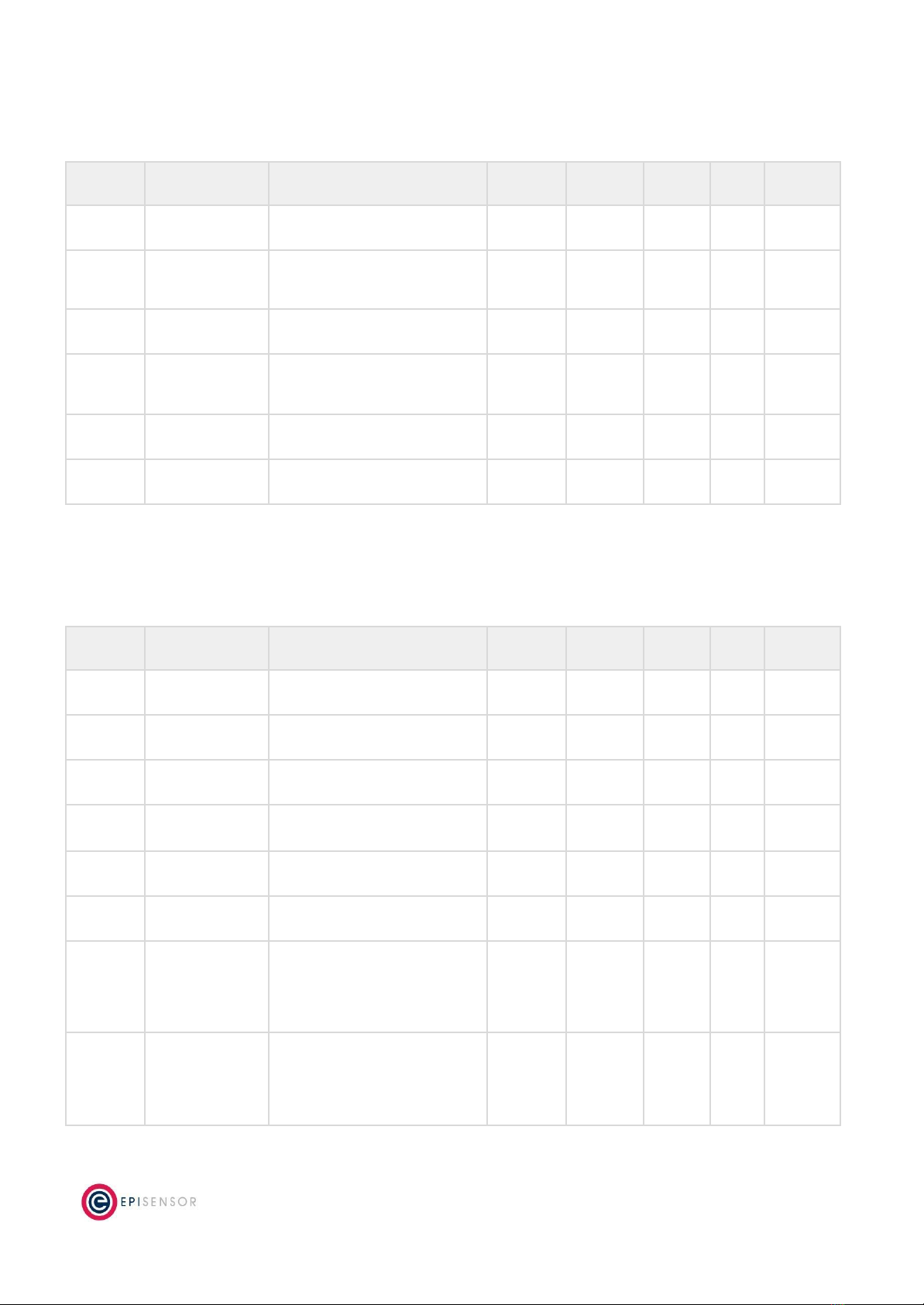

Node Level Settings

The following table lists the settings available at the node level on the ZPC.

Property ID

Setting

Description

Unit

Resolution

Reporting

Default

Read/Write

7012

Radio Power

The power the unit will set for RF

communications. These must be

valid values from the Radio

Manufacturers settings or the radio

will use the next lower valid setting.

If a Power Amp is used, this power

level is amplified further. Care must

be taken not to exceed the regional

variances for max radio power. Both

the Radio Power, and Amplifier

Power must be taken into

consideration when setting this

power level.

dBm

1

8

Read Only

for non

“engineer”

logins.

Read/Wrive

for

“engineer”

Page 10 of 21

Sensors

These data feeds show the number of pulses counted by the ZPC, wireless performance and battery health:

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Write

450

Pulse Count

The total Pulse Count on Channel 1

of the Pulse Input

pulses

1

Off

-

Read/Write

462

Interval Pulse

Count

The total number of Pulses on

channel 1 during the previous

reporting interval

pulses

1

On

15

Read Only

463

Pulse Count 2

The total Pulse Count on Channel 2

of the Pulse Input

pulses

1

Off

-

Read/Write

464

Interval Pulse

Count 2

The total number of Pulses on

channel 2 during the previous

reporting interval

pulses

1

On

15

Read Only

4097

Link Quality

A gauge on radio performance based

on incoming and outgoing packets.

%

1

Off

-

Read Only

4099

RSSI

A measure of received signal at the

radio on the current channel

dBm

1

Off

-

Read Only

Note: The maximum value for Pulse Count sensors (450 and 463) is 4294967295. If this value is reached, the count will reset

back to zero.

Mains Powered ZPC versions (ZPC-20, ZPC-22 and ZPC-23) have the following additional sensors:

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Write

444

Pulse Rate 1

The instantaneous Pulse Rate on

Channel 1

Hz

0.001

Off

-

Read Only

445

Min Pulse Rate 1

The minimum Pulse Rate during the

last time interval

Hz

0.001

Off

-

Read Only

446

Max Pulse Rate 1

The Maximum Pulse Rate during the

last time interval

Hz

0.001

Off

-

Read Only

447

Pulse Rate 2

The instantaneous Pulse Rate on

Channel 2

Hz

0.001

Off

-

Read Only

448

Min Pulse Rate 2

The minimum Pulse Rate during the

last time interval

Hz

0.001

Off

-

Read Only

449

Max Pulse Rate 2

The Maximum Pulse Rate during the

last time interval

Hz

0.001

Off

-

Read Only

4101

Neighbour Count

The number of radio devices within

radio range that would route radio

messages back to the Gateway

1

Interval

and Delta

3600

change

d to

360 in

3.71

Read Only

4102

Child Count

The number of battery powered

devices that are using this node as a

routing parent

1

Interval

and Delta

3600

change

d to

360 in

3.71

Read Only

Page 11 of 21

Battery powered ZPC versions have the following additional sensors:

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Write

4096

Battery Level

The voltage measured on the battery

mV

1

Snap to

Clock

1440

Read Only

Sensor Level Settings

The following table lists the settings available at the sensor-level on the ZPC:

Property

ID

SensorID

SensorID

Setting

Description

Unit

Resolution

6202

ALL

ALL

Reporting Mode

Defines the style of reporting for the sensor

-

-

6203

ALL

ALL

Reporting Interval

Sets the interval for timed sensors reports

seconds

1

6204

ALL

ALL

Logging

When logging is on, the sensor will store

values on the node when communication

with the gateway is not available

boolean

-

6205

ALL

ALL

Reporting Delta

For Delta style reporting, this is the value for

the “difference” from the last reported value

Sensor

units

Sensor

Resolution

6280

462, 464

Interval Pulse

Count 1 & 2

Delta No Input

Timeout

When the Reporting Mode is any of the

Delta settings, this defines the number of

seconds after the last pulse when the value

is reported. For example, if the Delta value is

1, then every pulse could potentially

generate a radio message. So when a

number of pulses arrive together, it may be

better to report that number once the pulse

line goes quiet rather than a stream of 1’s.

seconds

1

6280

444, 447

Pulse Rate 1 & 2

Delta No Input

Timeout

When the Reporting Mode is any of the

Delta settings, this defines the number of

seconds after the last pulse when the pulse

rate is deemed to have returned to zero

seconds

1

User Interface

There are two LED’s and one button on the front panel of the ZPC product range that are used to show the status

of the product and to issue commands. This section describes how to interact with user interface and what each

state means.

Page 12 of 21

A node must be in “command mode” before users can interact with the product. To put the node in Command

Mode, press and hold the “MODE” button for 2 seconds, then release. At this point, a battery powered node will

switch the LED On Solid, while a mains powered node will flicker the LED and then switch the LED On Solid.

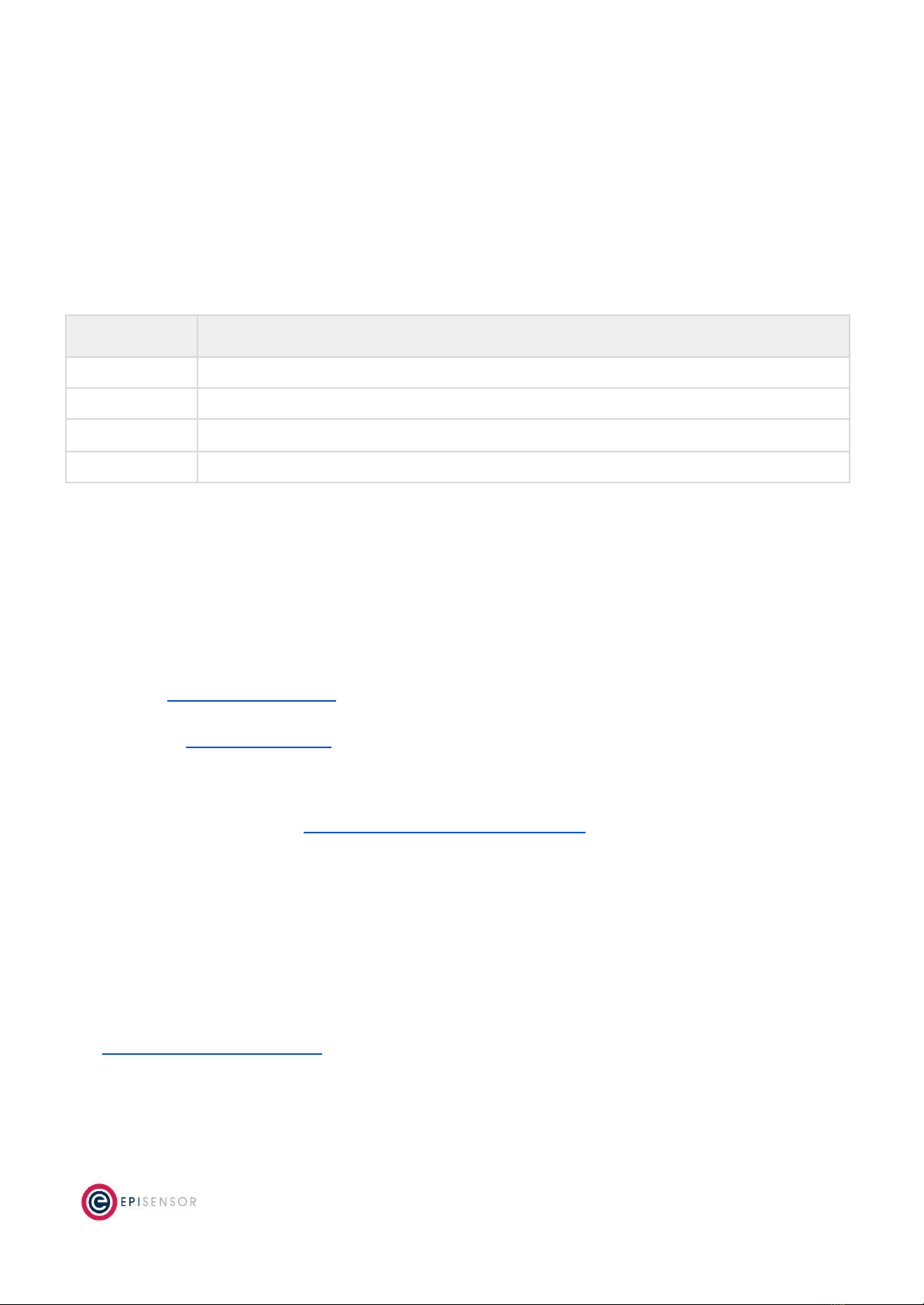

Status LED

The red status LED will flash in different sequences depending on the current state of the ZPC. This table below

lists all possible LED flash sequences and their meaning.

Flash Sequence

Description

Diagram

Heartbeat

The node is operating correctly and has

successfully joined a wireless network.

Inverse Heartbeat

The node has received valid security keys, but is

not connected to a Gateway.

Page 13 of 21

Square Wave

The node is operating correctly but has lost

contact with the Gateway.

On Solid, or Off

If the LED is On Solid, the node is searching for a

Gateway to join. If it is Off, the node may not be

powered, or there is a problem with the node.

Check the power supply, and if the problem

persists, contact EpiSensor support.

Alt LED

The Alt LED will flash when data is transmitted or received on the ZigBee wireless network. For mains powered

nodes, it will always be active - but for battery powered nodes, it will only be active when in Command Mode.

Mode Button

The following options are available with Command Mode. The button should be pressed and then released to

register a valid button press. If no further button presses are made, the device will terminate “command mode”

4 seconds after the last button press.

Press

Description

0

Send a PING message disable any active Install Mode or Range Test Mode. If the node is not joined,

try and join a network.

1

Send a DATA message to the Gateway for any enabled sensors that are not reporting in

‘snap-to-clock’ mode.

2

Leave the current network. Mains powered Nodes will automatically try and join a new network

once they have left and will periodically retry the join. Battery powered nodes will go to sleep.

4

Start “Install Mode”. Node sends a PING message every 15 seconds, with the LED pulse speed

indicating the wireless signal strength of the reply. Automatically expires after 5 minutes.

6

Reboot the node. Security keys for the wireless network the node is joined to will not be erased, and

all other settings will remain the same.

8

Factory-reset the node and perform a reboot. All settings and security keys will be lost. The node will

be returned to its factory default state.

12

Start “Range Test” mode. Node will send a PING message every 5 seconds. The LED pulse speed

indicates the wireless signal strength of the reply. Automatically expires after 5 minutes.

Page 14 of 21

Install Mode

Issuing a press sequence on the Mode button of a powered node can enable either “Install Mode” or “Site

Survey Mode” on that node. In this mode, the LED will flash at a rate that indicates the wireless signal strength

(Link Quality Indicator) of that node, based on the following table:

Flash Rate

Flashes per Second

Wireless Signal Strength

LQI

Very Fast

10 flashes / second (Light on 50ms, off 50ms)

Very good Signal

> 200

Fast

2 flashes / second (LED on 250ms, off 250ms)

Good Signal

> 150

Slow

1 flash / 2 seconds (LED on 1 sec, off 1 sec)

OK Signal

> 100

Very Slow

1 flash / 6 seconds (LED on 3 sec, off 3 sec)

Poor Signal

< 100

Note: This mode expires after 15 minutes for Install Mode and 5 minutes for Site Survey Mode.

Electrical Installation

The ZPC-20/22 is a mains powered device – the mains cable on the ZPC-20/22 is colour coded to conform to

European CENELEC standards. The CENELEC standard insulation colours are as follows:

Live – Brown

N – Blue

Important Note: The ZPC-20/22 should be connected via a switched junction box and breaker to protect the

cable. Also, please ensure that the live connection is made on the same circuit as the neutral connection where

residual-current devices (RCD’s) are used.

Installation should only be carried out only by personnel qualified in the installation of electrical equipment. All

parts of the circuit within the enclosure must be considered to be at dangerously high mains voltage when the

unit is connected to a mains voltage source.

Mechanical

This section describes how to wall-mount the ZPC enclosure, the enclosure materials and important safety

considerations when connecting the ZPC to external systems.

Page 15 of 21

Enclosure & Label Material

The ZPC is housed in an IP67 water and dust proof enclosure to provide maximum safety, flexibility and

reliability. The enclosure material is polycarbonate plastic, which is resistant to a variety of chemicals, oils and

detergents.

The front label is made from polycarbonate. There will be two or more labels on the back of the enclosure,

depending on the model selected. The compliance label is made from PVC and the serial number label is made

from polyethylene film.

Mounting Instructions

The ZPC-10/12 product range will have one or two cable glands at the bottom for the pulse inputs depending on

the model. The ZPC-20/22 is housed in the same enclosure, but includes an additional gland and mains voltage

input cable.

The ZPC product requires 2 screws for mounting. These screws can be preinstalled on a vertical surface spaced

122mm vertically apart. The head of the screw should be less than 8.5mm in diameter and the screw thickness

should be less than 4.5mm. The screws should be left unscrewed by more than 5 mm before installing the

enclosure.

Important Safety Note

The enclosure of the ZPC must not be drilled, cut or modified in any way for mounting or

connecting to external systems.

All parts of the circuit within the enclosure must be considered to be at dangerously high

mains voltage when the unit is connected to a mains voltage source. Modifying the

enclosure could expose parts of the system to users, or cause an internal fault or short

circuit.

There are no user-serviceable parts inside the ZPC enclosure, and it should always be

isolated from mains voltages before opening the enclosure lid.

Opening the Enclosure

To make connections to the ZPC, it is necessary to open the lid of the enclosure. This is fastened with four screws

that are accessible from the back of the enclosure. This should only be done by qualified personnel, and for the

mains powered version, only when the ZPC-2X has been isolated from any high voltage supplies. Please consult

the safety notes at the start of this user guide for more information.

Page 16 of 21

Important Safety Note

EpiSensor equipment should be installed, operated, serviced and maintained only by

qualified personnel.

There are no user-serviceable parts inside the ZPC-2X enclosure, and it should always be

isolated from mains voltages before opening the enclosure lid.

When closing the lid, take care to ensure that no wires or cable ties are obstructing the gasket of the enclosure,

as this could interfere with the waterproof seal. When tightening the screws on the lid, apply pressure to the

enclosure so the gasket is compressed, and tighten each screw gradually and in sequence.

Tamper Evident Seals

Some applications (particularly applications where data is used for billing purposes) will require a tamper evident

seals to be attached to the ZPC enclosure. These seals can be attached to two or more of the corners of the ZPC

enclosure, as shown on the diagram below.

Compliance

There is a compliance label on the back of the ZPC enclosure that has important regulatory and node

identification information.

The label material is gloss white PVC foil with permanent adhesive and gloss overlaminate. The following table

lists the certification and safety symbols that appear on the certification labels of EpiSensor products. Please

refer to it for a definition of each symbol.

Symbol

Name

Description

CE Mark

This marking certifies that a product has met EU consumer safety,

health or environmental requirements.

Page 17 of 21

WEEE Symbol

The directive imposes the responsibility for the disposal of waste

electrical and electronic equipment on the manufacturers of such

equipment.

Class II IEC

Protection

This certifies that this product has been designed in such a way that it

does not require a safety connection to electrical earth/ground.

IP / NEMA Rating

Water and dust ingress protection standard. IP67 / NEMA 4 means

complete protection against contact with dust, and protected from

ingress of water when immersed in up to 1 metre depth for up to 30

minutes. For more information, see IEC 60529.

RoHS Directive

Restriction of Hazardous Substances Directive restricts (with

exceptions) the use of six hazardous materials in the manufacture of

various types of electronic and electrical equipment.

Safety Alert

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

Danger / Warning

The addition of either symbol to a “Danger” or “Warning” safety label

indicates that an electrical hazard exists which will result in personal

injury if the instructions are not followed.

EpiSensor products are not suitable or specifically designed, manufactured or licensed for use in military,

aviation, powerplant, medical or in other inherently dangerous or safety critical applications.

Battery Life

The following table estimates battery life for the ZPC-10/12 range. There are other environmental factors that

this table does not take into account, and the calculations are made assuming the wireless node is not logging

data for long periods of time, that the pulse frequency is low, and that the pulse duration is quite short.

Reporting Interval

Estimated Battery Life

1 minute

3 months

15 minutes

6 years

30 minutes

8 years

60 minutes

10 years

Page 18 of 21

Wireless Communications

All EpiSensor products use IEEE 802.15.4 ZigBee Pro for wireless communications operating at 2.4GHz. This is a

secure, scalable mesh networking communications protocol designed for transmitting small amounts of data

reliably, and at low power levels.

There are two types of nodes in the EpiSensor wireless mesh network: powered nodes and battery nodes.

Powered nodes on the wireless sensor network are capable of routing data from any other type of wireless

nodes.

Range extenders are powered nodes where the main function is to route data. Any node with a mains power

supply will act as a routing node in the network. Battery nodes do not route data – they spend most of the time

in a low power mode.

Each powered node can have up to 32 ‘neighbours’ which are nodes with a mains power supply and can Route

data back to the Gateway. They can also have up to 32 ‘children’ which are nodes that are battery powered and

cannot participate in any routing in the network.

The range that can be achieved with ZigBee will depend mainly on two factors: the power level of the ZigBee

radio module and the environment that the device is installed in. There are two types of ZigBee radio module

used across the EpiSensor product range, a power amplified version, and non-power amplified version.

The power output of nodes with a power-amplified module can be configured with an output power level of +20

dBm depending on the region they are deployed in. Non-power amplified nodes have a maximum output power

of +8 dBm.

Module Type

Tx Power

Rx Sensitivity

LoS Range

Region(s)

Normal

+8 dBm

-101dBm

up to 300m (985ft)

Worldwide

Power-amplified

+20 dBm

-106dBm

up to 1600m (5250ft)

North America (FCC / IC)

Page 19 of 21

All communications over the ZigBee wireless network is AES 128-bit encrypted. For more detailed information on

ZigBee security features, contact EpiSensor support.

Ordering Information

EpiSensor products are available to order directly or via EpiSensor’s distribution partners. The following table

lists the available ZPC options.

SKU

Description

ZPC-10

Wireless Digital Signal Sensor (pulse counter) single channel, 4Hz max, battery powered

ZPC-12

Wireless Digital Signal Sensor (pulse counter) dual channel, 4Hz max, battery powered

ZPC-20

Wireless Digital Signal Sensor (pulse counter) single channel, 40Hz max, mains powered

ZPC-22

Wireless Digital Signal Sensor (pulse counter) dual channel, 40Hz max, mains powered

Troubleshooting & Support

If you are experiencing problems with your ZPC or any other part of your EpiSensor system, or you notice

something unusual - please contact EpiSensor support at the following email address, phone number or via live

chat on our website.

●Email: support@episensor.com

●Tel: +353 61 512 500

●Website: http://episensor.com

For customers and partners who are deploying systems in business-critical environments, there are a number of

support packages available that offer a higher level of service and response time. For more information on

EpiSensor Premium Support, visit: http://episensor.com/premium-support/

Warranty

All EpiSensor products and provided with a 365 day limited warranty effective from the shipping/invoice date of

an order. During the warranty period, under the conditions of normal use, EpiSensor will repair or replace any

product that has a manufacturing defect.

Warranty can be extended by up to 4 years within 30 days of a purchase. For more information on warranty,

visit: http://episensor.com/warranty/

Page 20 of 21

This manual suits for next models

3

Table of contents