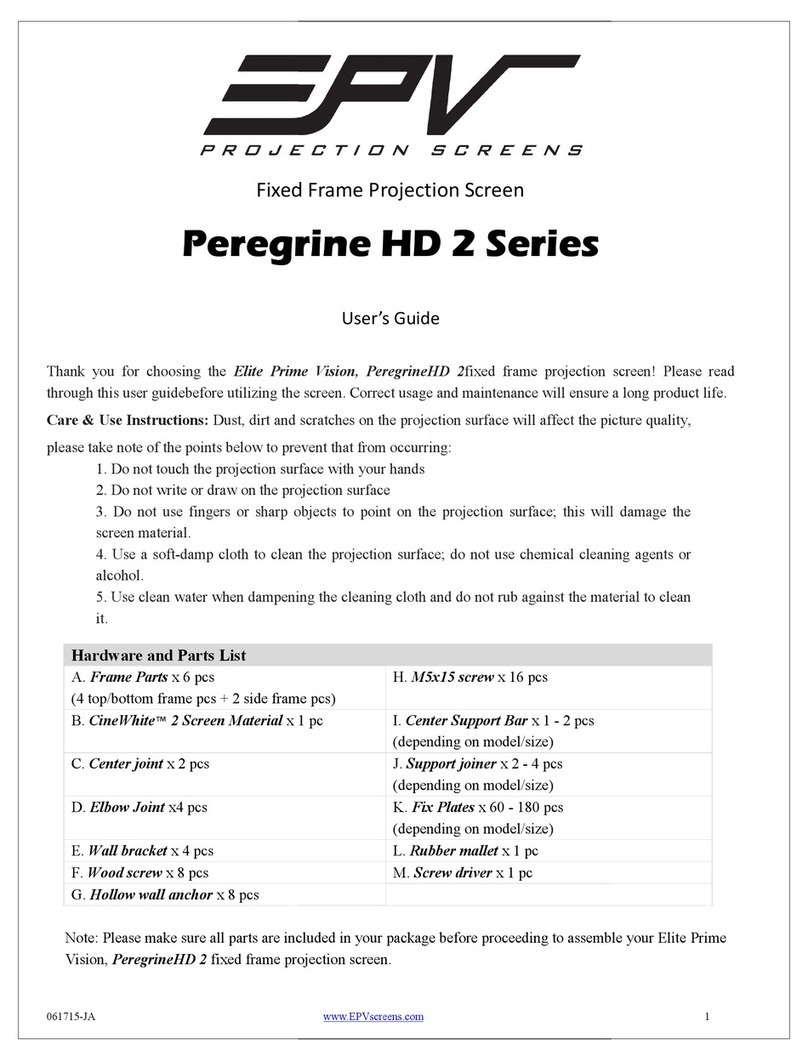

EPV EDGE FREE Sonic AT8 ISF eFinity Series User manual

Table of contents

Other EPV Projector Accessories manuals

Popular Projector Accessories manuals by other brands

Panasonic

Panasonic ET-SFD310 operating instructions

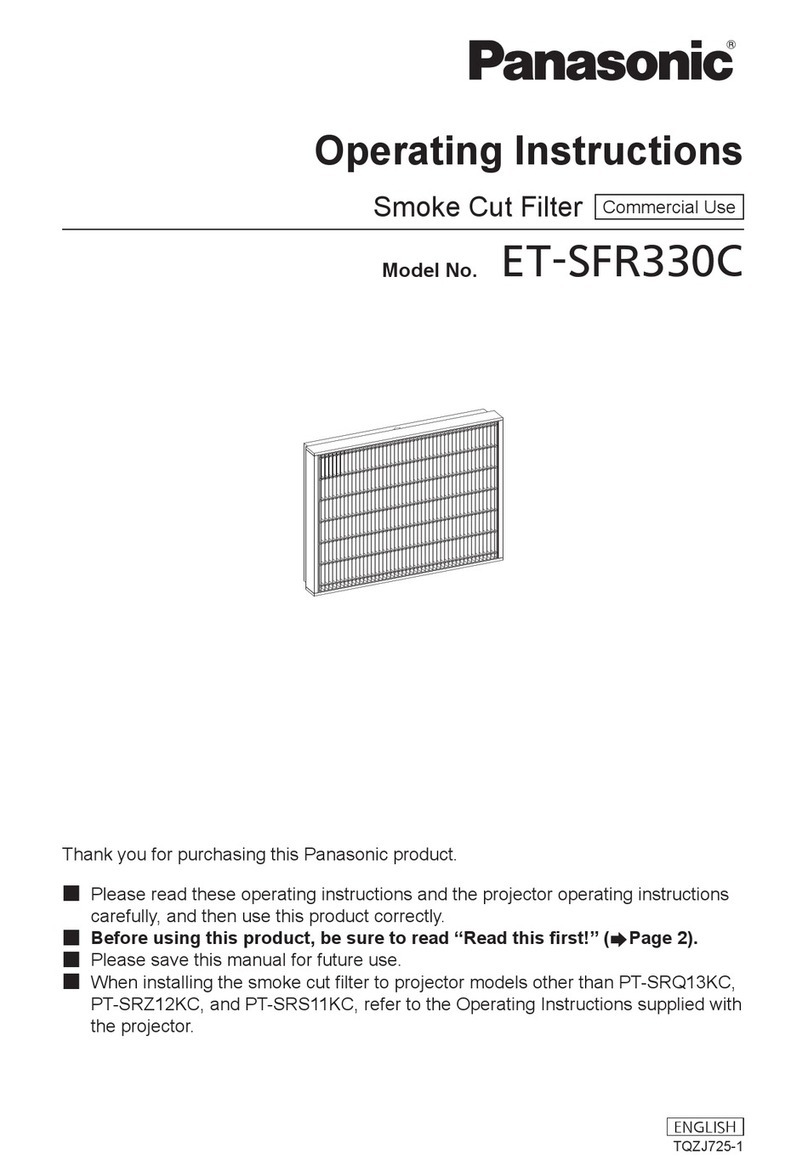

Panasonic

Panasonic ET-SFR330C operating instructions

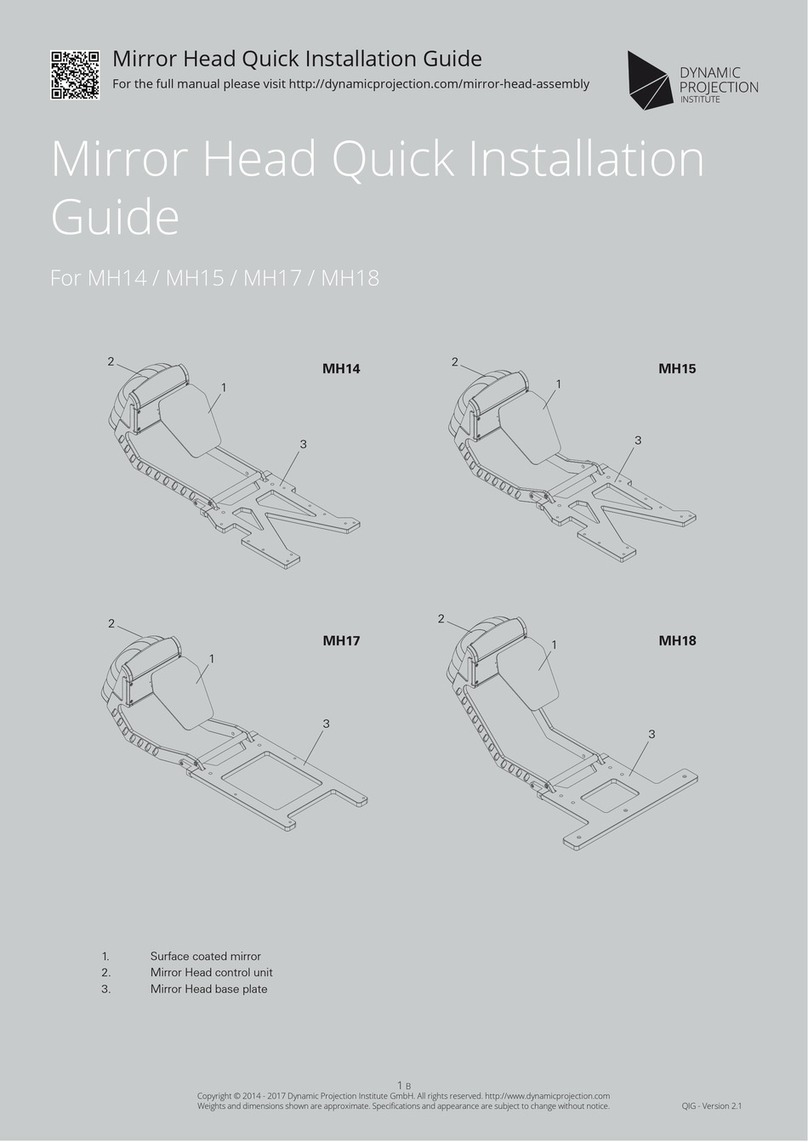

Dynamic Projection

Dynamic Projection Mirror Head MH14 Quick installation guide

vivtek

vivtek LauncherPlus quick start guide

Mitsubishi

Mitsubishi OL-XD2000FR specification

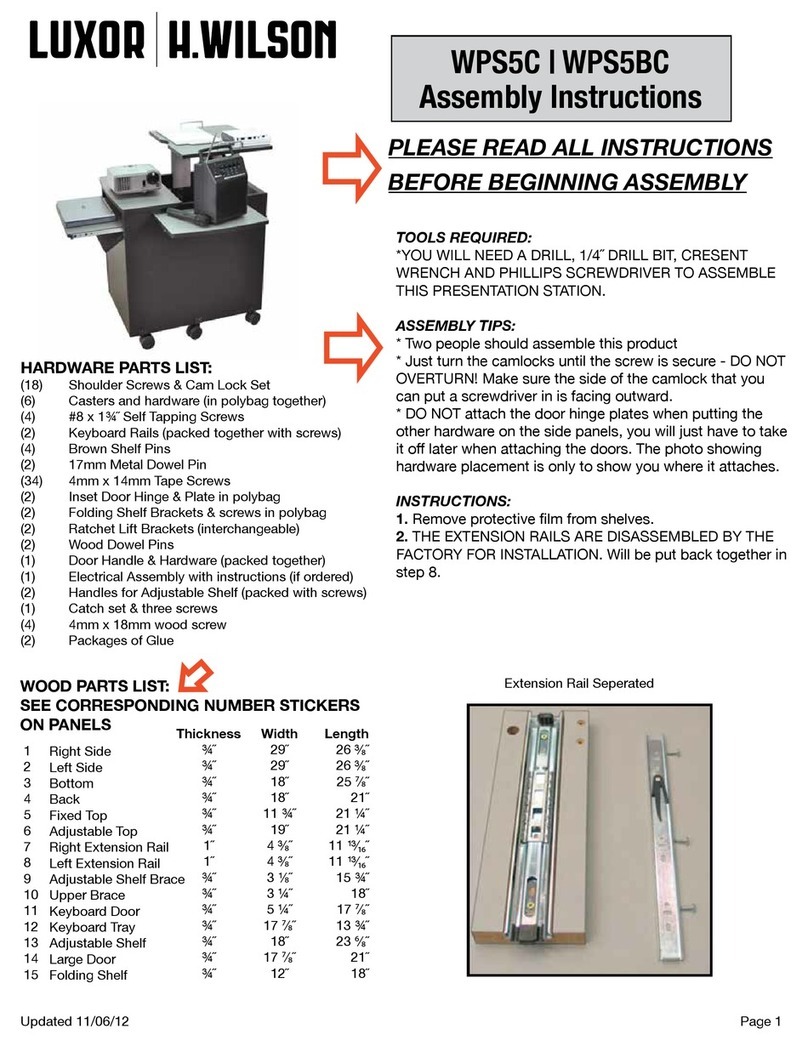

Luxor/H.Wilson

Luxor/H.Wilson WPS5C Assembly instructions

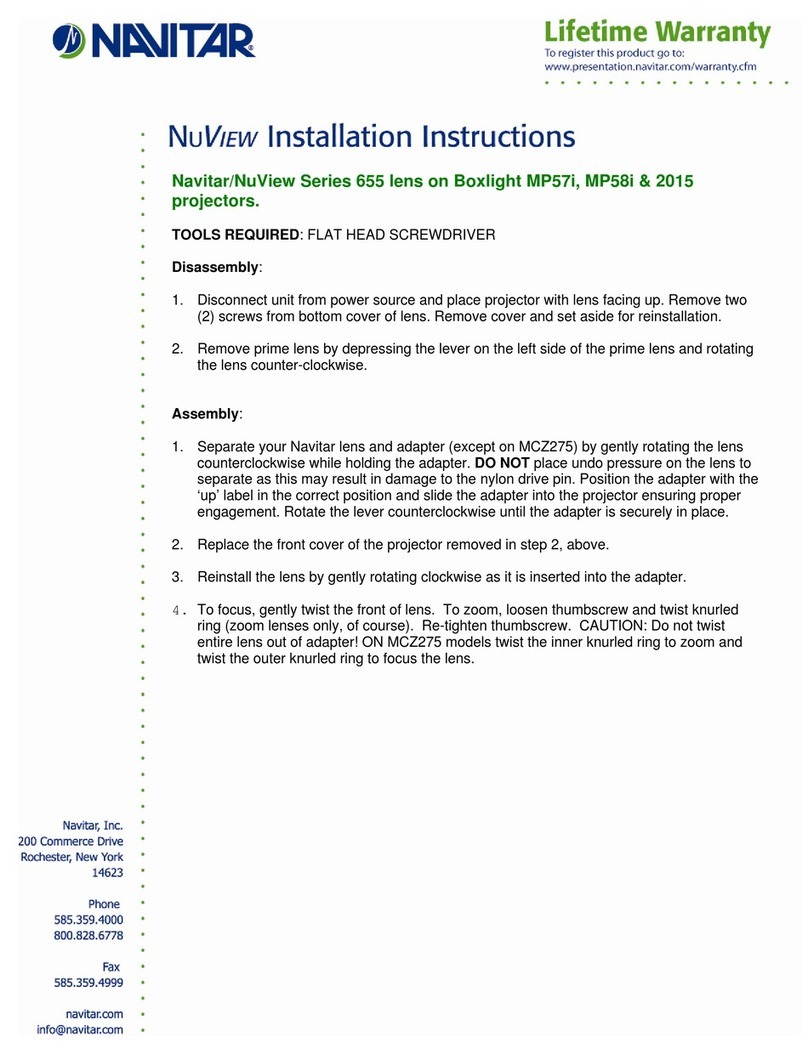

Navitar

Navitar 655MCL1028 installation instructions

Optoma

Optoma OWM3000 user manual

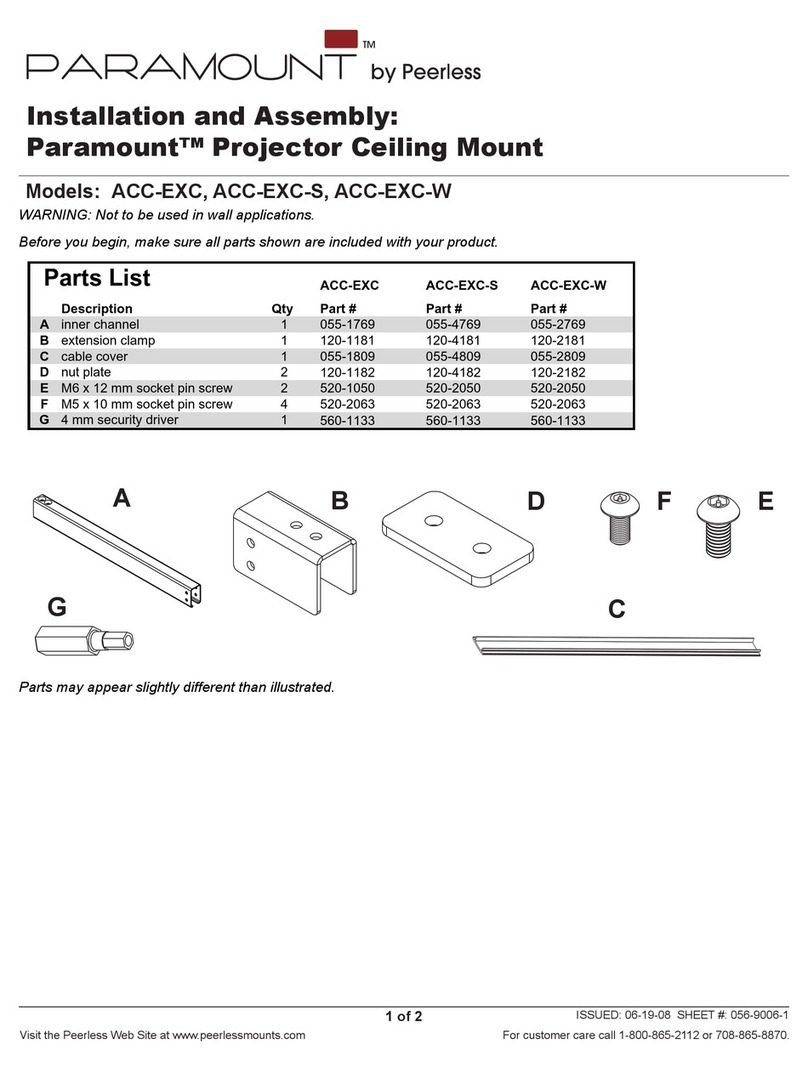

PEERLESS

PEERLESS PARAMOUNT ACC-EXC Installation and assembly

Barco

Barco ClickShare CSE-200 installation manual

Panasonic

Panasonic PressIT TY-WPSC1 operating instructions

Navitar

Navitar 585MCZ500 installation instructions

Epson

Epson EpiqVision Ultra LS500 quick start guide

Premier Mounts

Premier Mounts Universal Projector Mount PBL-UMS datasheet

Celexon

Celexon HomeCinema Electric Tension screen operating instructions

Prijector

Prijector PR-N101+ user guide

Navitar

Navitar 654MCL1028 installation instructions

Grandview

Grandview PE-L R3 Series Installation & user manual